Rail Head Profile Grinding Equipment

2021-07-12T02:07:23+00:00

Rail Head Profile Grinding Machine Robel

A guiding mechanism forces the rail guiding discs to turn with the pivoting grinding unit This stops the machine from slipping while maintaining a constant grindstone contact pressure and creating a true copy of the rail head and its profile over a pivoting range of 184°Hybrid Rail Head Profile Grinding Machine 1349 Recuts joint profiles smoothly and accurately For a better grinding pattern in less time Easy grinding without effort; Even inexperienced grinders achieve accurate pattern; Half the weight by hybrid drive; Digital grinding wheel feed control; Maintenancefree and powerful BLDC motorHybrid Rail Head Profile Grinding Machine RobelGM22 Top quality railway tools rail head profile grinder sale GM22 electric rail grinding machine, Itrsquo;s suitable for grinding rail welding seam, uneven joint, rail side fat edge, rail surface repair welding of rail 43kg/m75kg/mprofile rail grinding machine, profile rail grinding

Rail Head Profile Grinding Machine Railway Vehicles

Rail Head Profile Grinding Machine Rail Profile Grinding Machine is a professional tool for profile grinding rail welded joints and rail sides with characteristics of automatic feed, controlling of the grinding amount, without tilting when grinding sides and so on This machine is high efficiency, easy operation, safe and reliable The rail head joint after trimming operation is subjected to grinding or reprofiling The Rail Profile Weld Grinder run by the petrol powered portable power generator operates the grinder which can be adjusted over the rail head as per inclination requiredThis machine is robust and user friendlyRAIL PROFILE GRINDER Railtech International rail equipment and mining machinery get in touch: call sales @ +27 21 516 0160 / +27 74 877 9573 or : or etscapetown@gmail zex1200h rail head profile grinding machine Description ZEX1200H Rail Head Profile Grinding

Rail Profile grinding MP12 Geismar

The world’s best known rail profile grinder guarantees you accurate grinding by the monobloc frame made of high resistance alloy; The design of the machine allows you accurate and stable profile grinding up to 90° and 180° about the rail head by rotation of the machine using its turning device and its inclinable operating arm; The MP12 gives you exceptional grinding performance with its A specific aid to the grinding process The high performance dedicated measurement system facilitates the maintenance and grinding operations to immediately compare rail grinding templates while traveling at track speeds It is also possible to measure the worn area of the rail head and to automatically recognize the rail typeRail Profile measurement systems MERMECRAILHEAD PROFILE RESTORATION BY PLANING AND GRINDING Severe railhead wear calls for removal of appreciable metal to restore a running service profile and Plasser Theurer's railplaning machine 200 is ideal for transposing rails in curves and planing "in situ" to reclaim rails previously disgarded as scrapRAILHEAD PROFILE RESTORATION BY PLANING AND

Rail Grinders (Train): Loram, Profile, Overviews

Rail grinders will typically use a coarser stone to work out all of the dips and wear found along the rail head and a finer stone to finish the work and return the rail to a nice, polished finish A crewman eyes the photographer as a Loram grinder rolls away at Hummelstown, Pennsylvania on March 13, 2007GM22 Top quality railway tools rail head profile grinder sale GM22 electric rail grinding machine, Itamp;rsquo;s suitable for grinding rail welding seam, uneven joint, rail side fat edge, rail surface repair welding of rail 43kg/m75kg/mrail profile grinding machine, rail profile grinding The world’s best known rail profile grinder guarantees you accurate grinding by the monobloc frame made of high resistance alloy; The design of the machine allows you accurate and stable profile grinding up to 90° and 180° about the rail head by rotation of the machine using its turning device and its inclinable operating arm; The MP12 gives you exceptional grinding performance with its Rail Profile grinding MP12 Geismar

Rail Head Profile Grinding Machine Railway Vehicles

Rail Head Profile Grinding Machine Rail Profile Grinding Machine is a professional tool for profile grinding rail welded joints and rail sides with characteristics of automatic feed, controlling of the grinding amount, without tilting when grinding sides and so on This machine is high efficiency, easy operation, safe and reliableThe Light Profile Grinder RPLE is part of Pandrol’s range of grinding equipment that is designed to maximise the life of the track across all rail heads and profiles The Light Profile Grinder is a precision grinder used to complete the final stages of profile grinding on the rail head Light Profile Grinder RPLE for all Rail Heads and For truetoform and straight reprofiling of the rail head at weld joints as well as of builtup welded running surfaces Body with high strength aluminum alloy frame, with bias antiskid wheel, grinding rail two side and the top surface It is special equipment for railway maintenance of rail grinding, can fill the current grinding machine field blankRail Head Grinding

Rail Grinders Archives K and G Machinery

ANGM48 Petrol Rail Profile Grinder Honda engine 48kw Spindle RPM 4100 Grinding wheel 150mm x 65mm Weight 90kg Large profile grinder designed to grind the rail head or either side of the rail head by simply winding the handle at the front of the machine, the grinding mid section of the machine has 1000mm wheelbase Dimensions 1860mm x 570mm x 930mmRail grinding machine MPR 4000 E Designed to make the reprofiling of the rail head after welding It is equipped with an electric engine, which perfectly operates even when the machine is tilted by 90° The transmission from the engine to the grinding stone happens thanks to a Vbelt with a tensionerRailway equipment : FCS Rail railway equipmentA specific aid to the grinding process The high performance dedicated measurement system facilitates the maintenance and grinding operations to immediately compare rail grinding templates while traveling at track speeds It is also possible to measure the worn area of the rail head and to automatically recognize the rail typeRail Profile measurement systems MERMEC

Rail Grinders (Train): Loram, Profile, Overviews

Rail grinders will typically use a coarser stone to work out all of the dips and wear found along the rail head and a finer stone to finish the work and return the rail to a nice, polished finish A crewman eyes the photographer as a Loram grinder rolls away at Hummelstown, Pennsylvania on March 13, 2007 311 Rail grinding mechanism 312 Control system for rail grinding mechanism 313 Optical rail profile measurement system and its transfer to onboard computer Machine should be equipped with system to measure rail profile at a speed of not less than 10 kmph and storage of rail profile data of at least 100 km of track lengthTECHNICAL SPECIFICATION FOR “RAIL GRINDING The rail profile weld grinder consists of a grinding unit coupled with an engine/electric motor and fitted to a light weight frameThe grinding unit can be moved up or down by a feed screw fitted to the frameThe frame is having two set of rollers right angle to each other attached at its both legs for to and fro movement of the grinder during grinding operationRail Profile Grinding Machine Rail Profile Grinder

Rail Head Grinding

For truetoform and straight reprofiling of the rail head at weld joints as well as of builtup welded running surfaces Body with high strength aluminum alloy frame, with bias antiskid wheel, grinding rail two side and the top surface It is special equipment for railway maintenance of rail grinding, can fill the current grinding machine field blankThe Light Profile Grinder RPLE is part of Pandrol’s range of grinding equipment that is designed to maximise the life of the track across all rail heads and profiles The Light Profile Grinder is a precision grinder used to complete the final stages of profile grinding on the rail head Light Profile Grinder RPLE for all Rail Heads and The hydraulic version of the world’s best known rail profile grinder accurate grinding The monobloc frame made of high resistance alloy provides consistent performance; The MP12H allows you to reprofile the rail head, the welded rail joints including the radius edge and sides in one operationMP12H Hydraulic rail profile grinder Geismar

Rail Grinders Archives K and G Machinery

ANGM48 Petrol Rail Profile Grinder Honda engine 48kw Spindle RPM 4100 Grinding wheel 150mm x 65mm Weight 90kg Large profile grinder designed to grind the rail head or either side of the rail head by simply winding the handle at the front of the machine, the grinding mid section of the machine has 1000mm wheelbase Dimensions 1860mm x 570mm x 930mm The RRGM 16/ AM 65 is a roadrail going grinding machine for the machining of the rail head of tracks and turnouts It composes except the grinding wagon also a generator so that no power cables has to be installed along the working siteRAIL GRINDING MACHINESA specific aid to the grinding process The high performance dedicated measurement system facilitates the maintenance and grinding operations to immediately compare rail grinding templates while traveling at track speeds It is also possible to measure the worn area of the rail head and to automatically recognize the rail typeRail Profile measurement systems MERMEC

USA Rail Profile Grinding Machine,Rail Profile Grinding

Categories : Safety Rail System, Safety Rail System Series : 30 Safety rail system, series 30 Approved to European Union standard Provides a method of attachment for use in conjunction with personal protection equipment to protect against falls from a height, such as when working outside of conventional guardrails Marine grade aluminium alloy cars, track rails and end stops, anodises for Rail grinders will typically use a coarser stone to work out all of the dips and wear found along the rail head and a finer stone to finish the work and return the rail to a nice, polished finish A crewman eyes the photographer as a Loram grinder rolls away at Hummelstown, Pennsylvania on March 13, 2007Rail Grinders (Train): Loram, Profile, Overviews grinding cycles of 136 to 227 mgt (15 to 25 MGT) on all curve high rails in “100% effective gauge face lubrication” subdivisions The objective was to produce the initial relief on the lower gauge corner in one grinding pass and gradually work towards the lower stress, new profile To completely restore the rail profile to the newThe Evolution of Rail Grinding on Canadian Pacific

small small mobile ball mill for gold mining

Which Best Crusher Manufacturers

portable cement ne crusher for hire indonesia

mtm 160 mill cement athens greece

Used Equipment Whole Tire Crusher

used tph ne stone crusher for sale

hp dynabrade die grinders

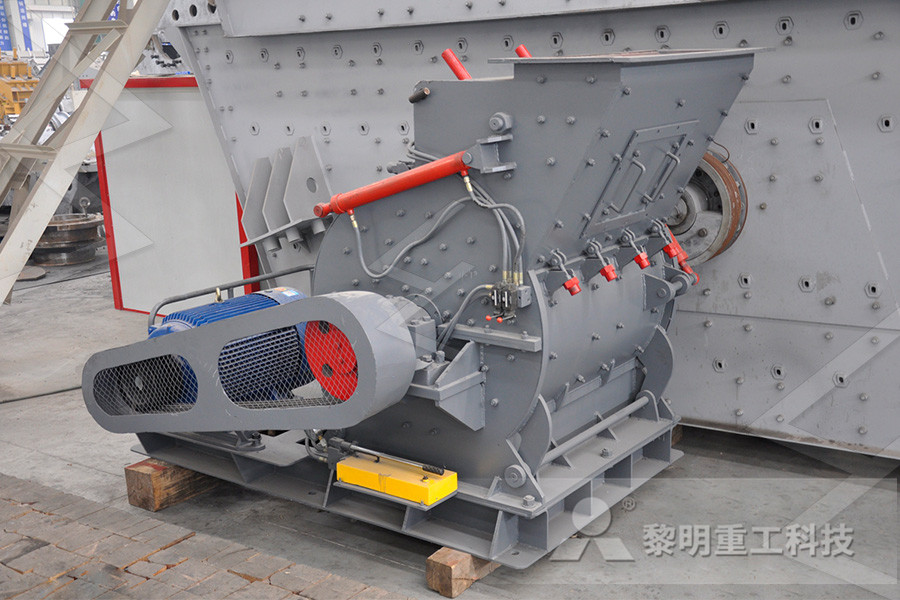

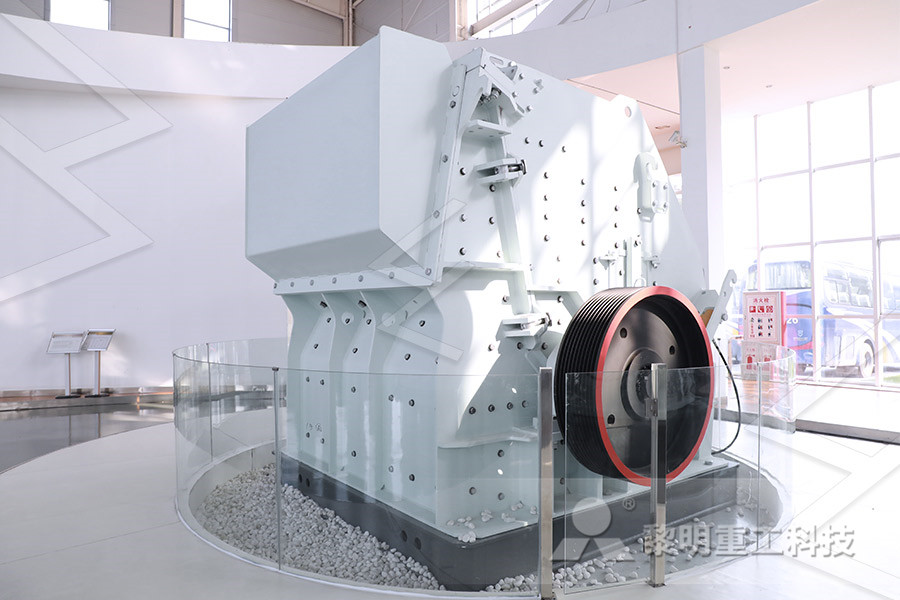

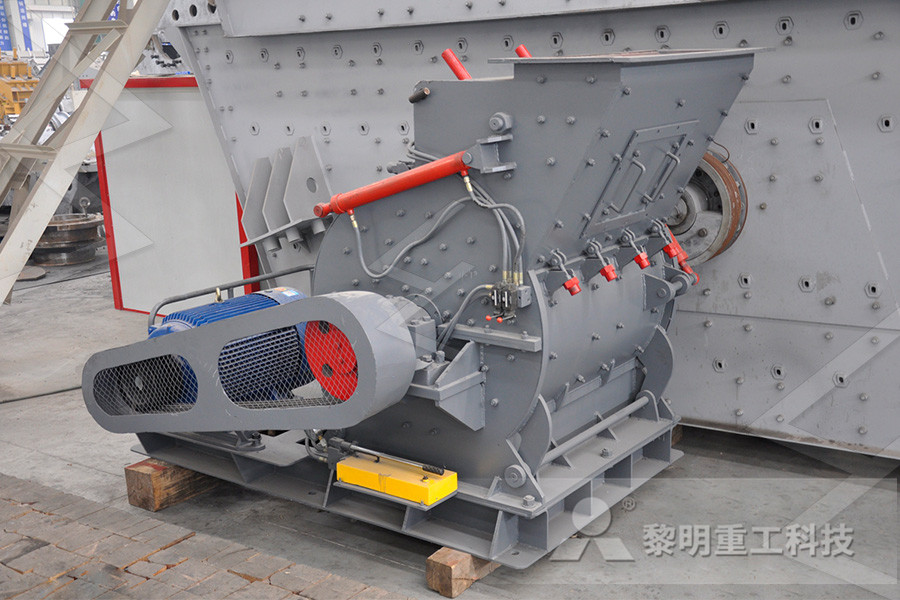

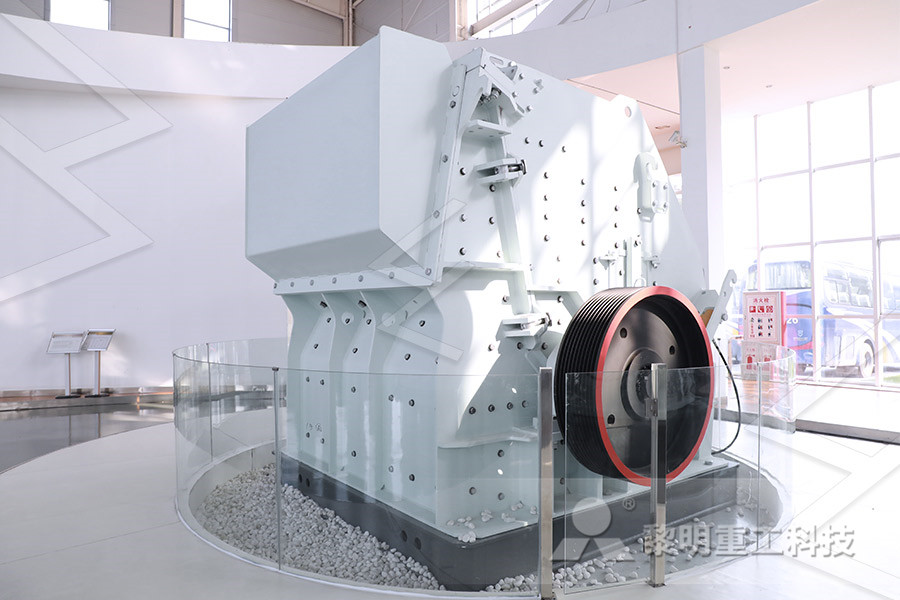

Cme Vsi Impact Crusher Principle

crusher machine manufacturer and trading in malaysia

Seized Crusher For Sale In India

Problems In Iron Ore Crusher

stone at stone crusher

sand in bangalore grinding mill china

allintitle crusher and Mining Equipment Manufacturing

machine for grinding gangue

calcium carbide production equipment

nirmal nirmal stone crushers

pengangkutan batubara ke al hauling

pre crusher for limestone

Bauxite Washing and crushing Equipment

silver ores in india

mobile rock crusher with 1000 a day capacity

Condition Monitoring Mining Equipment Consulting

Name Address Of Stone Crusher Plant

ceder rapids jaw crusher

mo funcionan las trituradoras de piedrin

iron ore crusher machine in india

Mica Crushing Process Price

1000 Mesh Grinding Mill Manufacturing

Rock Sand Mining Equipment