Gypsum Processing For Power Stations

2023-07-17T16:07:25+00:00

Production and use of byproduct gypsum in the

There are two groups of gypsum byproducts that have been identified: chemical gypsum and desulphogypsum The first byproduct is produced by chemical processing and the second originates from the flue gas desulphurization installations in power stationsInnovative Gypsum Processing Dewatering Solution – PondX® In addition, Charah Solutions can provide complete management of utility scrubber byproducts including development, construction, installation and operations of gypsum processing and dewatering systems as part of our PondX® impoundment elimination solutionsGypsum Management Operations Charah® Consequently, he too has been using this belt type in various vacuum belt filters for FGD gypsum dewatering since 2009 already: in the RheinhafenDampfkraftwerk Karlsruhe, Datteln 4 and Maasvlakte (Netherlands) mineral coal power stations and in the Belchatov (Poland), Turcini (Romania) and Maritza II (Bulgaria) brown coal power stationsFGD gypsum dewatering – the new Mineral

Gypsum Primasonics Primasonics International Ltd

The calcined gypsum, or hemihydrate, becomes the base for gypsum plaster, gypsum board and other gypsum products An effective alternative to natural gypsum is superficial gypsum (FGD) which is a byproduct of fluegas cleaning in fossil fuelled power stations What challenges does the Gypsum Processing Industry face? The reutilization and acceptability of gypsum, produced by Flue Gas Desulphurization (FGD) systems in power stations, as a raw material in the production RECYCLING OF WASTE FGD GYPSUM RECYCLING OF stations Much of the coal that is burnt for power generation in (principally power station ashes and there is the environmental cost of quarrying and processing of these primary materials (PDF) Briefing: Gypsum: Prospects for recycling

Analysis of FGD Gypsum

Flue gas desulphurization (FGD) gypsum is understood as being the hydrated calcium sulphate (CaSO4 • 2 H2O) produced within the flue gas desulphurization of power stations In the following, FGD gypsum is also referred to as raw gypsumByproduct gypsum comes from fossilfuel power stations where S is scrubbed from exhaust gas Gypsum is also a byproduct from processing phosphate rock into phosphoric acid Gypsum from recycled wallboard is finely ground and applied to soil as fertilizer Chemical properties Agricultural useGypsum Mosaic Crop Nutrition Overall process flow diagram for gypsum processing2 11162 EMISSION FACTORS (Reformatted 1/95) 7/93 In the manufacture of plasters, stucco is ground further in a tube or ball mill and then batchmixed with retarders and stabilizers to produce plasters with 1116 Gypsum Manufacturing US EPA

Production lines for gypsum blocks Grenzebach

For the production of gypsum blocks, Grenzebach supplies individually tailored production processes according to your product requirements: from single components to complete production lines, Grenzebach is at your side with its technology solutions and knowhow for processing the raw materialInnovative Gypsum Processing Dewatering Solution – PondX® In addition, Charah Solutions can provide complete management of utility scrubber byproducts including development, construction, installation and operations of gypsum processing and dewatering systems as part of our PondX® impoundment elimination solutionsGypsum Management Operations Charah® The calcined gypsum, or hemihydrate, becomes the base for gypsum plaster, gypsum board and other gypsum products An effective alternative to natural gypsum is superficial gypsum (FGD) which is a byproduct of fluegas cleaning in fossil fuelled power stations What challenges does the Gypsum Processing Industry face?Gypsum Primasonics Primasonics International Ltd

Gypsum Mosaic Crop Nutrition

Byproduct gypsum comes from fossilfuel power stations where S is scrubbed from exhaust gas Gypsum is also a byproduct from processing phosphate rock into phosphoric acid Gypsum from recycled wallboard is finely ground and applied to soil as fertilizer Chemical properties Agricultural use Under geological conditions of high temperature and pressure, gypsum is converted to anhydrite (CaSO 4 with no water) Byproduct gypsum comes from fossilfuel power stations where S is scrubbed from exhaust gas Gypsum is also a byproduct from processing phosphate rock into phosphoric acid Gypsum from recycled wall board is finely ground and Gypsum No 16 International Plant Nutrition Institute 2 emissions from gypsum, however, are very low, and it can therefore be considered as an environmentally friendly construction material Furthermore, a large percentage of the gypsum used today is based on synthetic gypsum This is a byproduct of power stations and the fertilizer and detergent industry Gypsum is also infinitelyGyPSum Elotex

Santee Cooper's Gypsum Contract: More Bad Math

One of the “praiseworthy” disposal processes Santee Cooper touted in its “real facts” document is the ongoing sale of recycled gypsum as a byproduct of its power generation processGBRf moves Gypsum rock and Desulphogyspum from import locations and power stations to processing facilities on behalf of British Gypsum and Siniat for the production of plaster and plasterboard GBRf also provides internal logistics solutions to UK industry At Celsa’s Cardiff works, GBRf moves finished and part finished products on Celsa’s Construction Materials GB Railfreight Limited Electric power stations burning coal with flue gas desulfurization produce large quantities of synthetic gypsum as a byproduct from the scrubbers It can be used interchangeably with natural gypsum in some applications In cathodic protection of metals, gypsum is used as backfill materialsWhat is Gypsum? Definition from Corrosionpedia

Purity Determination in Gypsum Application Note Gypsum

the obtained gypsum Quality criteria published by Euro gypsum, the association of European gypsum industries, states that, for synthetic (FGD) gypsum, free moisture content should be below 10% and gypsum content (CaSO 4•2H 2O) should be higher than 95%1 Processing of Gypsum When gypsum is pulverized and heated at around 150°C, 1½ crystal The reduction of emissions of sulphur dioxide (SO 2) from coalburning power stations enables power generators to comply with the Large Combustion Plant Directive (LCPD) which came into effect this yearFor the UK power generation industry, the additional benefits of this technology allows larger plants with a thermal output above 50 MW to burn indigenous reserves of higher sulphur Slurry handling in FGD plants World PumpsByproduct gypsum comes from fossilfuel power stations where S is scrubbed from exhaust gas Gypsum is also a byproduct from processing phosphate rock into phosphoric acid Gypsum from recycled wallboard is finely ground and applied to soil as fertilizer Chemical properties Agricultural useGypsum Mosaic Crop Nutrition

GyPSum Elotex

2 emissions from gypsum, however, are very low, and it can therefore be considered as an environmentally friendly construction material Furthermore, a large percentage of the gypsum used today is based on synthetic gypsum This is a byproduct of power stations and the fertilizer and detergent industry Gypsum is also infinitely The reduction of emissions of sulphur dioxide (SO 2) from coalburning power stations enables power generators to comply with the Large Combustion Plant Directive (LCPD) which came into effect this yearFor the UK power generation industry, the additional benefits of this technology allows larger plants with a thermal output above 50 MW to burn indigenous reserves of higher sulphur Slurry handling in FGD plants World Pumps switch away from coal fired power stations could, for example, mean that in the longer term supplies of desulphogypsum may dwindle The future demand for natural gypsum remains uncertain 1018 Whilst demand for special or first grade gypsum should remain buoyant, the economics of recovery could also be adversely affected if the market for MillChapter 10 GYPSUM Nottinghamshire County Council

What is Gypsum? Definition from Corrosionpedia

Electric power stations burning coal with flue gas desulfurization produce large quantities of synthetic gypsum as a byproduct from the scrubbers It can be used interchangeably with natural gypsum in some applications In cathodic protection of metals, gypsum is used as backfill materials Since 1990, NWGR says they have been expanding their processing capabilities, and now has well over 100 employees at plants worldwide “NWGR is the most efficient gypsum recycler today,” says Cheryl Mckitterick, of New West Gypsum Recycling “Not only can we recycle dry gypsum, but we are experts at recycling wet gypsumClosing the loop on gypsum Recycling Product NewsGypsum Mining in Cumbria Gypsum (hydrated calcium sulphate) has been quarried or mined at Kirkby Thore for over 200 years The gypsum is ground to a powder and heated to evaporate water Heating to approximately 160ºC drives off a limited amount of water and Plaster of Paris is produced The most important use of this Gypsum Mining in Cumbria Read More »Gypsum Mining in Cumbria Visit Cumbria

ANDRITZ to supply drum pulping system for Taishan

Taishan Gypsum is the leading Chinese manufacturers of highquality gypsum boards and frame series for interior decoration The company, with a production capacity of 12 billion square meters of gypsum boards per year, serves the domestic market, and also exports to other countries, such as the United Arab Emirates, Indonesia, India, and Russia The largest source of what was known as Desulfogypsum was Drax power station in North Yorkshire and this supplied upwards of 250 tons per day by rail to Kirkby Thore The imported material was blended with Gypsum from Birkshead Mine at a ratio of 30% Birkshead to 70% Drax Material was also imported from Fidlers Ferry power station near WarringtonGypsum Production in the Kirkby Thore Area SCRCA Gypsum rock is first mined or quarried, then crushed and ground to a fine powder It then goes through a process called calcining where heat at 350 degrees is supplied to the gypsum powder which removes 3/4 th of the water molecules Hemihydrate is the name of calcined gypsum which is then used in gypsum board, gypsum plaster, and other productsGypsum Chemical Formula, Properties, Types, Uses

Beneficiation Wet Tin Machine

Stone Crushers Dealers In British Columbia

new technology washing plant for gold mining

gold cyanide solution refining

stone crusher manufacturing mpany crusher machine for sale

vision and mission of a al mining crusher mpany

feldspar crusher message

anatomy of a rock jaw crusher

Mining Industry In India 2018

granite granite crushing machine in nigeria

quarry machines in south africa sand making stone quarry

machines used mine gold

Iron Slag Crushing Machine Manuf In India

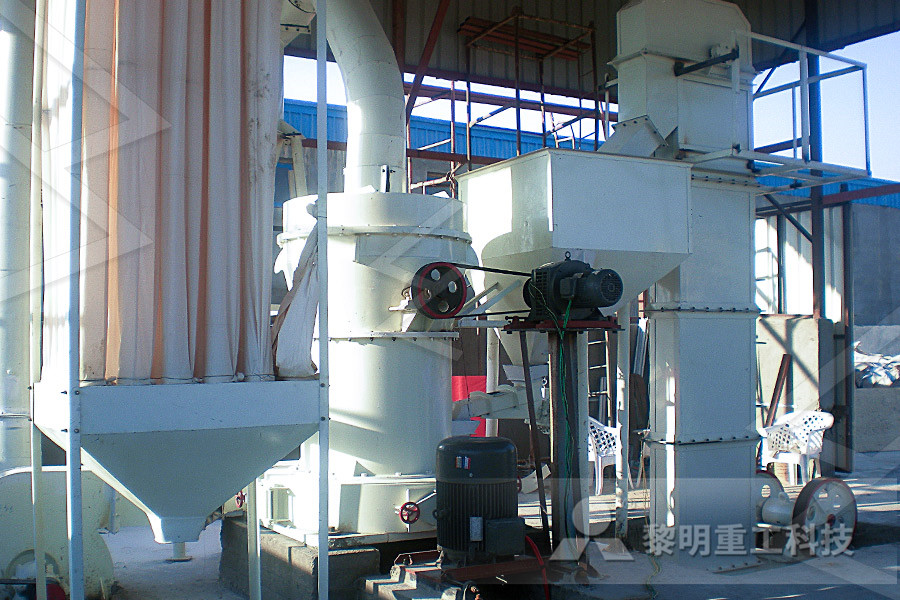

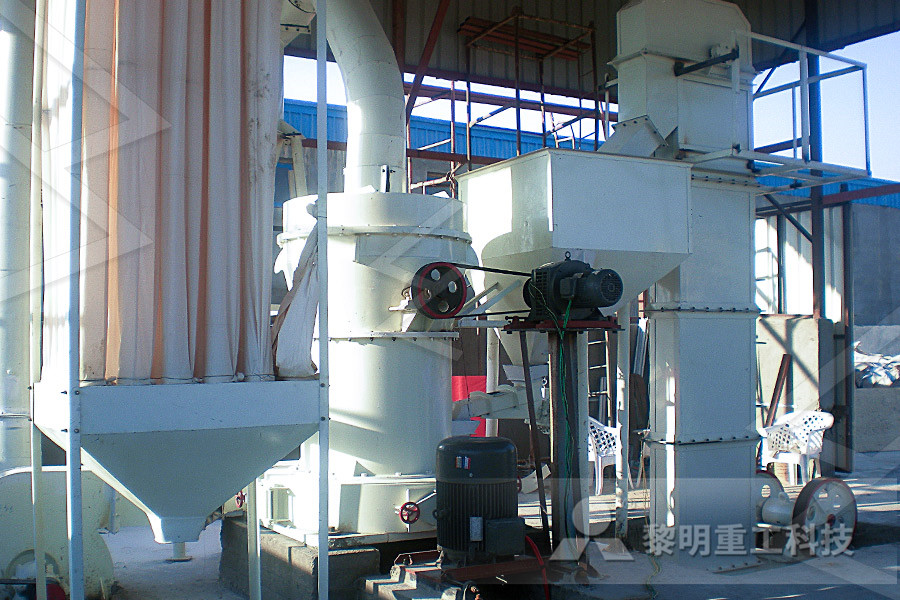

grinding mills south africa for sale

Recycling Asphalt Crushing Equipments In Uae

Konvejer Ispolzuetsya Transportirovat Ugol

vsi sand making machine grinding mill china

operador call center

Reliable Mobile Crushing Plants Factory

ntoh proposal skripsi pengolahan produksi crusher

magnetic separator larger capacity china

hammer crusher features and benefits south africa

stone crushers for hire india

new website email announcement bank

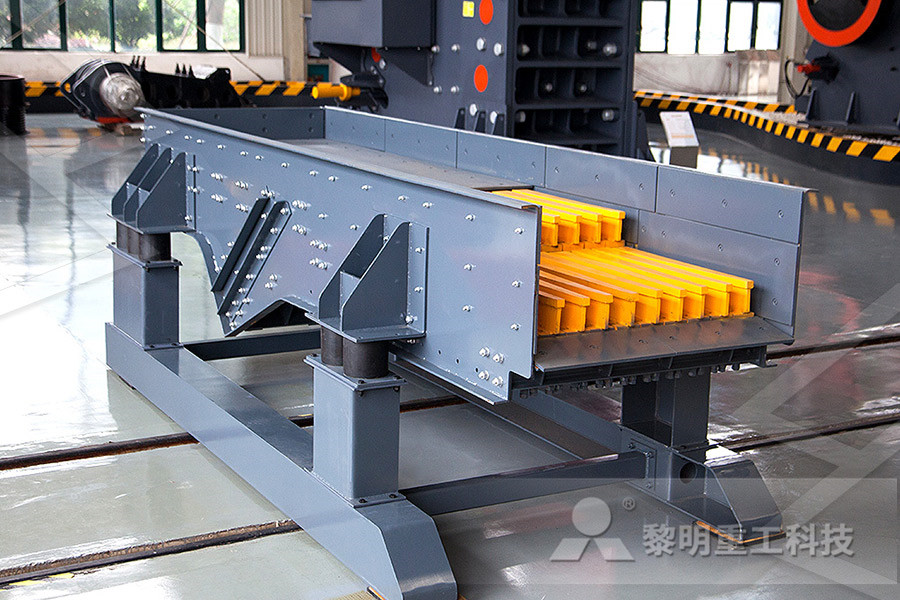

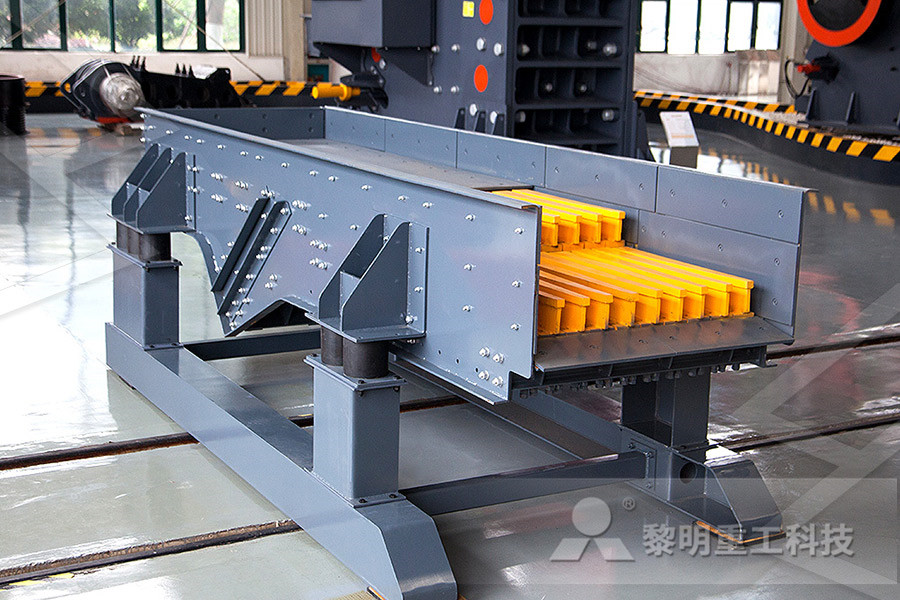

electromagnetic vibrating feeder gz1f

impcats of iron ore mining on water quality

dolomite mining bolivia

crusher run gravel stone vendors in indonesia

flow sheet for al preparation

Iron Ore Jaw Crusher Price In India