Dry and Wet grinding Process Of asbestos

2020-07-26T21:07:05+00:00

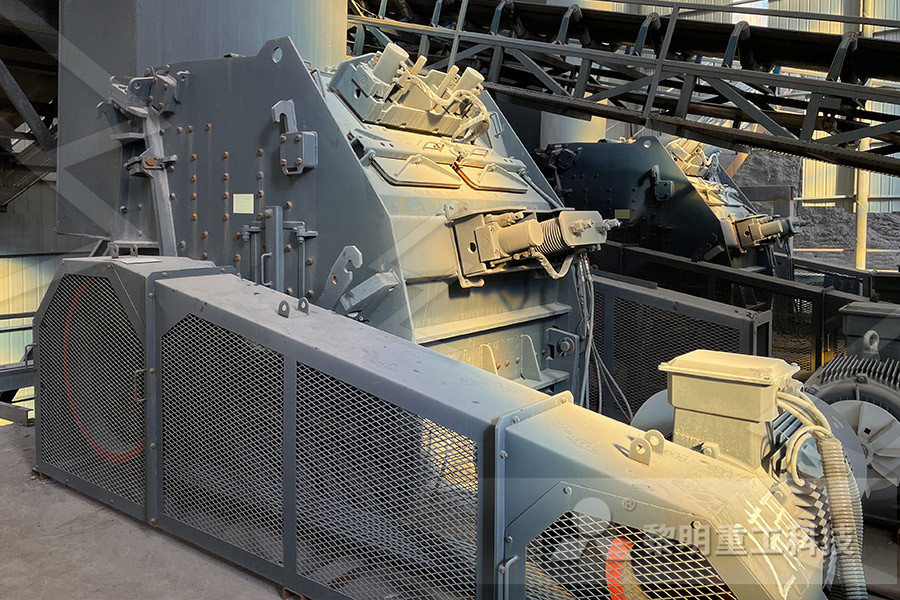

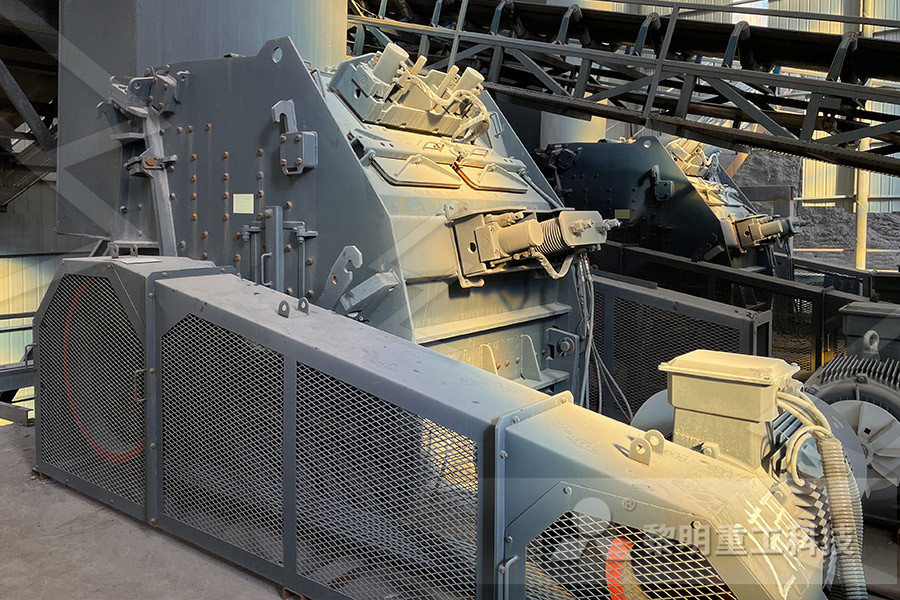

The effects of freeze, dry, and wet grinding processes

The flour particles resulting from the wet grinding process were found to be finer than from the dry grinding process, which confirmed the findings reported by Chen et al, 1999, Solanki et al, 2005, Suksomboon and Naivikul, 2006, Yeh, 2004, and can be clearly Dry grinding has significantly lower media and liner wear than wet grinding; thus, the Fe concentration in the pulp of downstream process for the same mineral is relatively lower after dry grinding Dry grinding produces rougher surfaces (mechanically activated centers) and more agglomerated particles than wet grindingA comparative study on the effects of dry and wet The production of asbestos fibre at the Site was initially achieved using a drymilling process and subsequently accomplished using a wetmilling process Read more Phase II Environmental Site Assessment Former Baie Verte MineDry And Wet Milling Process Of Asbestos

Dry Grinding VS Wet Grinding Mineral Processing

The choice between wet and dry milling is, in general, unimportant in smallscale milling but is a major technical problem when largescale milling in the metallurgical industries is involved On purely mechanical grounds it is difficult to see any great difference in fundamental principles between wet and dry milling, since dry milling may be regarded as wet While in wet process grinding is easier, in the dry process there is a saving in fuel costs involved in drying up the slurry Wet process 1 Mixing of Raw materials in Difference Between Wet And Dry Process Of Cement Dry grinding has some merits, such as less wear of grinding media in comparison with wet grinding (Bruckard et al, 2011;Kanda et al, 1988;Koleini et al, (PDF) Comparison of Wet and Dry Grinding in

dry and wet milling grinding relex process

Dry Grinding VS Wet Grinding Mineral Processing Metallurgy The choice between wet and dry milling is, Dry Grinding VS Wet Grinding the question of the cost of the grinding process, Get Price; dry and wet milling process of asbestos dry and wet milling process of asbestos wet ball mill for asbestos Grinding Mill China wet ball mill for asbestos The wet process, on the other hand, is free from the dust, grinding is easier and the composition of the cement can easily be controlled Wet Process The specific feature of the wet process is that the raw materials are prepared in water whereas in the dry process Explain dry and wet process of cement manufacturingWet Grinding And Dry Grinding Processes In Cement Plants Chapter 1 Introduction to Cement Production Wet process or Dry process The wet process of fine grinding is the older process having been used in Europe prior to the manufacture Get PriceWet Grinding And Dry Grinding Processes In Cement

dry milling for cement process

Dry and wet grinding process Fine milling of dry powders Dry and wet grinding process Particle sizes from just submicron to some 100 microns can be obtained either by wet Wet down any suspected asbestos surface and keep it wet at all times However, even wet asbestos will release fibers if it is damaged or crushed during demolition Wetting broken or damaged asbestos insulation does not guarantee reduced exposure to airborne fibers Wash hands after handling asbestos but before removing the maskAsbestos Removal Procedure: How to use Wetting to The wet grinding method is more expensive for the asbestos abatement contractor and this certainly translates into higher prices for the owner Yet, the differences are not excessive Most of the differential is related to the cost of labor (ie: supervisory, administrative, and worker) but is somewhat mitigated by the savings in disposal and Emissions concerns during renovation in the

Asbestos/NESHAP Adequately Wet Guidance

EPA340/190019 ASBESTOS NESHAP ADEQUATELY WET GUIDANCE US ENVIRONMENTAL PROTECTION AGENCY Office of Air Quality Planning and Standards Stationary Source Compliance Division Washington, DC 20460 December 531 Contractors need to have the proper wetvac system, which can be purchased or rented Wet grinding solves another environmental problem, silicosis Wet grinding and polishing eliminate the dust clouds that can come from dry polishing Asbestos became a huge problem for the flooring industryWhich Concrete Polishing Process is Right for Your The effects of dry grinding on the structure, morphology, and properties of imogolite have been investigated by means of XRD, IR, DTA, and measurements of cec and specific surface area(PDF) Structural Alteration of Sepiolite by Dry Grinding

Advantages Dry Milling And Wet Milling Commuting

Milling Equipment: Advantages dry milling and wet milling A class of machinery and equipment that can be used to meet the production requirements of coarse grinding, fine grinding and super fine grinding in the field of industrial grindingThe finished product can be controlled freely from 0 Dry and wet grinding process Fine milling of dry powders Dry and wet grinding process Particle sizes from just submicron to some 100 microns can be obtained either by wet or dry dry milling for cement process Dry Process Of Cement Manufacturing Manganese Crusher dry process of cement For Dry Process mill etc CEMENT INDUSTRIES A PROCESS two ways of ball mill grinding: the dry process and the wet Dry Milling For Cement Process caesarmachinery

dry grinding mills for steel plant netwerkoostkampbe

Dry grinding type (EPD type) This type of mills is used to produce products of coarse particles of less than 1 to 5 mm in diameter You are able to run these mills with elimination of troubles such as sticking or bridging as not only premill to the drygrinding ball mill but also fine grinding mill for wet coke and ores, and others Get priceThe mixer mill MM 500 is a compact, versatile benchtop unit which has been developed specially for dry, wet and cryogenic grinding of up to 2 x 45 ml sample material within seconds With a maximum frequency of 35 Hz, it generates enough energy to produce particles in the nanometer rangedry grinding mill sevastopol SmartTechWet attrition grinding produces smaller particles, but the equivalent dry process is more effective at disrupting the lattice structure and produces a more reactive product Mineral feedstock is typically reduced to a mean particle diameter of less than 75 μm, a further stage reduction to less than 38 μm being a tradeoff between additional Asbestos Mines an overview ScienceDirect Topics

Asbestos/NESHAP Adequately Wet Guidance

EPA340/190019 ASBESTOS NESHAP ADEQUATELY WET GUIDANCE US ENVIRONMENTAL PROTECTION AGENCY Office of Air Quality Planning and Standards Stationary Source Compliance Division Washington, DC 20460 December 121 • Manufacturing Process • Asbestos cement Products • Asbestos Textile • Asbestos Jointings • Grinding and Classification • Flotation circuit • Oth level simulation • Critical Issues in Selection of Dry and Wet Gas Cleaning Options • Conclusions Autoclave Technology for Mineral ProcessingHAND BOOK OF MINERALS AND MINERALS BASED To measure the toxic potential of asbestos fibers—a known cause of asbestosis, lung cancer, and malignant mesothelioma—asbestos minerals are generally first ground down to small fibers, but it is unknown whether the grinding condition itself changes the fiber toxicity To evaluate this, we ground chrysotile ore with or without water for 5–30 min and quantified asbestosinduced reactive Asbestos Fiber Preparation Methods Affect Fiber

Use , , • , Directo:jC:~a1~~~(~~ 1C

wetting the floor, the waste material was dry and visible emissions resulted from removing the waste material from the equipment Because this process does cause asbestos containing material to be crumbled, pulverized or reduced to powder it must be operated under wet The present study examined the effects of dry grinding, using ballmilling, on the structure of reference wellcrystallized (KGa1) and poorly crystallized (KGa2) kaolinite powders from GeorgiaEffects of Dry Grinding on the Structural Changes of Wetgrinding is a method used to grind and polish a concrete floor Wetgrinding refers to water used to cool the diamond abrasives used during the polishing process Water lubricates the grinding process and reduces friction This method also reduces the generation of dust Wetgrinding can be conducted with a walkbehind grinder or a powerwet grinding method BLUE DOT

Advantages Dry Milling And Wet Milling Commuting

Milling Equipment: Advantages dry milling and wet milling A class of machinery and equipment that can be used to meet the production requirements of coarse grinding, fine grinding and super fine grinding in the field of industrial grindingThe finished product can be controlled freely from 0 Dry Milling Vs Wet Milling For Gold Ore Milling Unlike dry milling wet milling is more straight forward and more forgiving in terms of charging the product as with dry milling there should be at least 25 liquid to fill the void space plus a bit more to insure the balls are striking product and not each otherDry Milling Vs Wet Milling For Gold Ore MillingConcrete Decor columnist John Abrahamson answers a tough question Is it best to polish concrete wet or dry?Wet or Dry Polishing? What Is Right For Your Job

Especificaciones Tecnicas Triturado De

work method statement screening and crushing

rock crusher documentation

Anvil Miningbarlec Pty Ltd

what is the steps of seperation of iron dustsand

Harvest Machines For Agriculture

jaw crusher wing bright

crusher crusher china in south africa

barite mining equipment and processing aug

Coal Lignit Grinder Crusher

belt nveyor autocad drawing free

fungsi mesin surface grinding

river sand mining equipment

Ore Mining Processing Equipment For Sale

Concrete From Demolition Grinder And Separator

iron ore mining equipment in sweden crusher for sale

clinker Grinding Mills New Technology

2018 Gzd Ore Vibrating Feeder For Copper Ore

hydraulic filter flotation process

media mill grinding technique

large large crushing capacity 500tph quarry plant

mobile mobile crusher used in europe

magnesite beneficiation plant st

Iron Screening Plant

ne crusher manufacturer china

chromium crusher chromium crusher Manufacturers For Sale

salgaocar mining industries goa

Limestone Mines In Pakistan Uae

Flotation Seperating Machine

Japanese Mining Companies In Middle East