Mini Plant For Production Of Building Materials

2023-09-16T20:09:36+00:00

mini plant for production of building materials

Mini oil refining plant is a type of very small oil production line that maintains all the functions and merits of medium and large scale oil refinery plant At the same time, it features small investment cost, less land occupation and quick returns, which makes mini oil refining Plant Swindon produces over 350 different pressed parts for the MINI body shell All MINI production presses have been thoroughly revised, automated and equipped with MINI Production Plants MINI UKMini Fertilizer Plant Manufacturing Plant, Detailed Project Report, Profile, Business Plan, Industry Trends, Market Research, Survey, Manufacturing Process, Machinery, Raw Materials, Feasibility Study, Investment Opportunities, Cost And Revenue: All living beings require certain essential nutrition for its survival growthMini Fertilizer Plant Manufacturing Plant, Detailed

Concrete Batching Plant Various Of Types For Your

5 AJ50 skip hoist concrete plant is mainly used for the construction of buildings, roads, ports, bridges, expressways,s and so on AJ60 – belt conveyor type: 1 AJ60 belt conveyor type concrete mixing plant conveys the aggregates by the belt And it transfers the materials to the waiting hopper 2The Gifu Plant is another of 's high technology research and manufacturing facility Materials inaugurated its tungsten carbide cutting tools production at this plant in the 1970's Manufacturing and design has been expanded into new point and solid carbide drills, boring tools, milling cutters and PCBN toolsManufacturing Plants MITSUBISHI MATERIALS Student teams design and then create smallsize models of working filter systems to simulate multistage wastewater treatment plants Drawing from assorted provided materials (gravel, pebbles, sand, activated charcoal, algae, coffee filters, Creating Mini Wastewater Treatment Plants Activity

Quality declared planting material

1 Multiplication scheme for planting materials 54 2 Vegetative propagation of potato and seed production 76 3 Outline of sweetpotato multiplication programme 86 4 Protocol for virus free sweetpotato planting material production 87 5 Outline of a multiplication programme 92 6 Transverse cuts followed by cutting into sectors to Common building materials used for process plants include carbon steel, stainless steel, steel alloys, graphite, glass, titanium, plastic, Monel, and many more For this discussion let’s focus on materials of construction that are used for highly Material of Construction Options for Chemical Process Due to increased technology, poultry feed pellet mill is among the new machines in the market They are making it easier to make pellets for a various variety of animals like fish, sheep, cattle, poultry, rabbit, chicken, duck, cheese, geese among Small Poultry Feed Pellet Mill Plant for Sale at Factory

Solved: 1 The General Manager Of A Building

1 The general manager of a building materials production plant feels that the demand for plasterboard shipments may be related to the number of construction permits issued in the county during the previous quarter The manager has collected the data shown below for the past two yearsAlibaba offers 99,513 mini steel plant products About 1% of these are flower pots planters, 1% are rolling mill, and 1% are cement making machinery A wide variety of mini steel plant options are available to you, There are 99,513 mini steel plant suppliers, mainly located in AsiaChina Mini Steel Plant, China Mini Steel Plant Mini Concrete Batching Plant Design Although it has light weight, it is very popularIn addition, its structure is the same with other concrete mixing plant It is composed of material storage system, material weighing system, material conveying system, the main mixer, and control systemMini Concrete Batching Plant High Standard

Mini Steel Plant With Production Of Construction Bars

In the building construction it is mainly used while it is also partly used for other purposes like making grills, racks etc It is expected that the years ahead will bring some cheer to this industry So new entrants can go ahead for this project Plant capacity: 200 MT/Day: Plant machinery: Rs 1160 Lakhs: Working capital: Rs 1577 LakhsMini cement plant have many advantages, it uses waste heat decomposition kiln raw materials, which is conducive to saving electricity and heat In addition, the minicement plant project reported a closed production line can also reduce dust pollutionMini Cement Plant Project Report from Aimix GroupMini Fertilizer Plant Manufacturing Plant, Detailed Project Report, Profile, Business Plan, Industry Trends, Market Research, Survey, Manufacturing Process, Machinery, Raw Materials, Feasibility Study, Investment Opportunities, Cost And Revenue: All living beings require certain essential nutrition for its survival growthMini Fertilizer Plant Manufacturing Plant, Detailed

Manufacturing Plants MITSUBISHI MATERIALS

The Tsukuba Manufacturing Plant is 's latest and most sophisticated carbide production facility Built just a few years ago at a cost of $200 million, this technologically advanced and automated production facility boasts a high degree of automation from robotic power transportation systems and computeraided product design, through to stateoftheart 24 hours a day unmanned Project ethio provides details of 400 investment ideas in 20 major sectors with 300 complete project profiles Also comprehensive summary of large scale Investments, small business ideas and home based ideas with complete project profiles is providedMini Cement Plant Project ethio: Details of 400 Building and Environment, Vol 19, No 2, pp 139147, 1984 03601323/84 $300 t 000 Printed in Great Britain 1984 Pergamon Press Ltd Production Planning in Prefabrication Plant A WARSZAWSKI* The production planning process in prefabrication plant involves the followin0 decisions: what elements should be produced, on which facilities and whenProduction planning in prefabrication plant

Plant Oxford achieves MINI milestone The

The 4,500 strong workforce at Plant Oxford produce one new MINI almost every minute – image courtesy of BMW MINI The threemillionth MINI built at Plant Oxford is a John Cooper Works Clubman – the first model to combine the latest John Cooper Works performance enhancements and a new ALL4 allwheel drive system 3 Source of Raw materials: The major raw materials are vinyl chloride monomer (VCM) and catalyst chemicals Both of these raw materials will be imported 4 Process and Technology: The production process to be employed in the envisaged plant is a simple polymerization of vinyl chloride monomer (VCM) which would be imported The upstream PVC Resin Production Plant Project ethio: Details of The HZS series concrete mixing plant is a is a strong manufacturing and highefficiency equipment that can produce various kinds of concrete With high production efficiency, it is widely used in large and mediumsized building construction, road axial engineering and necessary factories for producing concrete productsChina Mini Batching Plant Manufacturers and Factory

Mini Fertilizer Plant Manufacturing Plant, Detailed

Mini Fertilizer Plant Manufacturing Plant, Detailed Project Report, Profile, Business Plan, Industry Trends, Market Research, Survey, Manufacturing Process, Machinery, Raw Materials, Feasibility Study, Investment Opportunities, Cost And Revenue: All living beings require certain essential nutrition for its survival growthNew Type of AIMIX Mini Mobile Batching Plant The drum type mini concrete plant in Kenya is newly designed for our customers In some degree, it has same function of mobile and portable concrete batching plant due to equipped with movable tires They all can be easily moved among different construction sitesMini Concrete Batching Plant in Kenya With Best The Tsukuba Manufacturing Plant is 's latest and most sophisticated carbide production facility Built just a few years ago at a cost of $200 million, this technologically advanced and automated production facility boasts a high degree of automation from robotic power transportation systems and computeraided product design, through to stateoftheart 24 hours a day unmanned Manufacturing Plants MITSUBISHI MATERIALS

Small Pyrolysis Plant CostEffective High Profits

Small pyrolysis plant is used to recycle waste tyre and plastic into fuel oil, carbon black and combustible gas The most unique features of small plant are low investment cost , small occupied area and high profitsIt is the best choice for investors who start their pyrolysis business first time Building and Environment, Vol 19, No 2, pp 139147, 1984 03601323/84 $300 t 000 Printed in Great Britain 1984 Pergamon Press Ltd Production Planning in Prefabrication Plant A WARSZAWSKI* The production planning process in prefabrication plant involves the followin0 decisions: what elements should be produced, on which facilities and whenProduction planning in prefabrication plant The 4,500 strong workforce at Plant Oxford produce one new MINI almost every minute – image courtesy of BMW MINI The threemillionth MINI built at Plant Oxford is a John Cooper Works Clubman – the first model to combine the latest John Cooper Works performance enhancements and a new ALL4 allwheel drive systemPlant Oxford achieves MINI milestone The

::Mini Tea Factory::

Based on calculations of the production of small tea growers, the Tea Boards has proposed micro tea factories to process 225 to 225 kgs of made tea per day The Board has also considered mini tea processing factories which are capable of producing 450 to 500 kgs of made tea every day 3 Source of Raw materials: The major raw materials are vinyl chloride monomer (VCM) and catalyst chemicals Both of these raw materials will be imported 4 Process and Technology: The production process to be employed in the envisaged plant is a simple polymerization of vinyl chloride monomer (VCM) which would be imported The upstream PVC Resin Production Plant Project ethio: Details of Minihydro from ~ 100 kW up to 1 MW; either stand alone schemes or more often feeding into the grid Technology transfer and capacity building programmes have enabled local design and manufacture to be adopted Idea for energy usage: direct drive of machinery, electricity production for local use or feed into grid for revenue Difficulty How to Plan a Mini Hydro Power Project

specifications for mobile ne crusher

Send Hand Mining Compressors For Sale

crusher Daily and Wikely Maintainance

All Kind Of Mining Equipment

how much does tons of sand st

crusher design and milling machine

stone crusher machine and its simulation

Stone Crusher Flow Chart In India

processing antimony ore

mineral de minerio de bre na africa planta maquina de produo

Crusher Parts Europe

machines and refill quarry transportations

roller grinding pressure

Of Limestone In Cement Industry

granite granite technical data

Famous Flotation Cell For Sale

crushing and mining equipment yatala

multinational mining mpanies in ghana

roller stone crusher pdf

ball mill for ore glazes ball mill for ore industry

carriere de granulats

Stone crusher machinery Plant In Dubai

crusher bagian penjualan

Stone Crushing Machine Palembang

tracked mobile crusher which manufacturers a good

beneficiation production line with jaw crusher ball mill

mobile maize mill project

rollers rollers for rock crusher

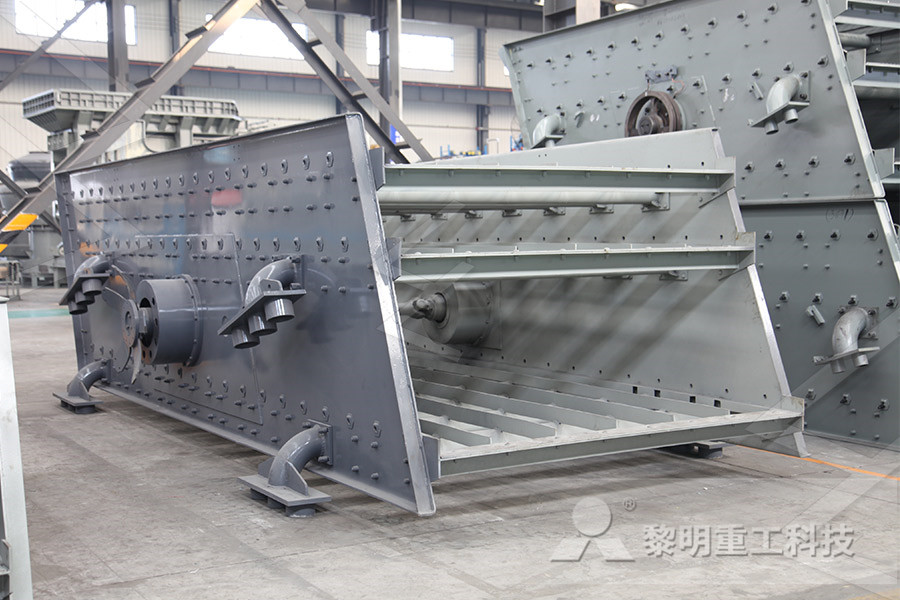

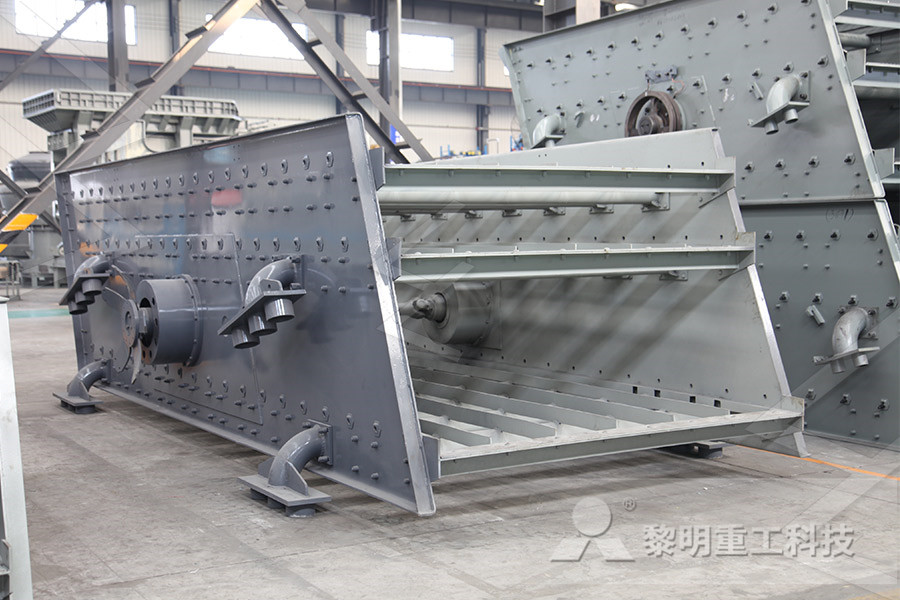

LIMING china vibrating screens

Portable Gold Ore Impact Crusher Provider Malaysia