maintenance of centerless grinding machine

2019-12-22T03:12:59+00:00

maintenance of centerless grinding machine Antek

maintenance of centerless grinding machine Mar 19, 2020 Cylindricalgrindingis usually done between centers by means of onegrindingwheel Acenterlessincorporates the use of two wheels, the regulating wheel, and thegrindingwheelmaintenance of centerless grinding machine Maintenance Of A Grinding Machine An ounce of centerless grinder preventive maintenance is worth a pound of cure check oil level in hydraulic power unit and lubrication unit run the centerless grinder and check all functions check for any abnormal noise oil leakage or heating of motorsMaintenance of a grinding machinemaintenance of centerless grinding machineCenterless Grinding Machine Maintenance Seminole Maintenance service is almost always more affordable than a replacement project Turn to Seminole Machinery Company to find the replacement parts your centerless grinding machine needs to avoid a major failure or unexpected breakdown Common Systems To Inspect Routinely There are a number of highwear components on a centerless grindingmaintenance of centerless grinding machine

Centerless Grinding Maintenance Total Grinding

Total Grinding Solutions (TGS) specializes in centerless grinding maintenance We are a worldwide manufacturer of centerless grinders Backed by a team of experts with over 150 years of combined industry experience, TGS designs and builds precise, affordable and reliable centerless grinding equipment that offers quick payback and low cost I use Centerless Grinding Solution’s Training program to keep my machine operators educated on safety, machine use, and maintenance Their indepth training session is wellworth the investment, and is seen as an added benefit that helps me recruit new centerless grinder techniciansCenterless Grinders Preventative Maintenance and Keeping a maintenance log will help you track your efforts and ensure accountability Should you need additional assistance with centerless grinder preventive maintenance or spare parts and components, please contact GCH Tool Group General checks The centerless grinding machine should be cleaned dailyCenterless Grinder Preventive Maintenance that

Preventative Maintenance Steps for Your Centerless

A centerless grinding machine is a powerful piece of equipment that can significantly increase a company’s productivity and add enhanced precision to its manufacturing process With a centerless grinding machine, workers can quickly load parts in without needing to clamp or secure them Instead, this machine does all the work as it is set up to naturally secure a workpiece within its wheels CENTERLESS GRINDER MAINTENANCE With proper centerless grinder maintenance your grinder will provide years of trouble free operation if properly maintainedDepending on the type of materials you grind and the number of hours you use your grinder CENTERLESS GRINDER MAINTENANCE Centerless Centerless grinding manual long bar grinding 312mm L:3M May 20, 2021 May 20, 2021 admin 0 S12S with manual long bar grinding Testing bar: 9mmX 3M precision all Maintenance STYPE LTD,CO

maintenance of a grinding machine obcane

Preventive maintenance of your centerless grinders is a proven way to reduce downtime, avoid scrap and enhance productivity, ultimately maximizing your return on investment Preventive maintenance has a number of additional benefits including: Extended centerless grinding machine life Reduction of unplanned maintenanceRepair and Maintenance on CENTERLESS GRINDER MAINTENANCE With proper centerless grinder maintenance your grinder will provide years of trouble free operation if properly maintainedDepending on the type of materials you grind and the number of hours you use your grinder bearing adjustments, lubrication checks, and filter changes should be scheduled at regular intervalsCENTERLESS GRINDER MAINTENANCE Centerless maintenance of centerless grinding machine Mar 19, 2020 Cylindricalgrindingis usually done between centers by means of onegrindingwheel Acenterlessincorporates the use of two wheels, the regulating wheel, and thegrindingwheel The workpiece is passed between these two wheels, or you can plunge grind the part between the wheels where the maintenance of centerless grinding machine Antek

Preventative Maintenance Steps for Your Centerless

A centerless grinding machine is a powerful piece of equipment that can significantly increase a company’s productivity and add enhanced precision to its manufacturing process With a centerless grinding machine, workers can quickly load parts in without needing to clamp or secure them Instead, this machine does all the work as it is set up to naturally secure a workpiece within its wheels Centerless Grinding Machine Maintenance Seminole Maintenance service is almost always more affordable than a replacement project Turn to Seminole Machinery Company to find the replacement parts your centerless grinding machine needs to avoid a major failure or unexpected breakdown Common Systems To Inspect Routinely There are a number of highwear components on a centerless grindingmaintenance of centerless grinding machine Your centerless grinder is a reliable workhorse that should last more than half a century if you treat it with the respect it deserves Develop a daily, weekly and monthly preventive maintenance schedule for your centerless grinding machine, and follow it Along with regular maintenance, be sure to book a yearly stemtostern examination by an Continue reading "11 Ways to Ruin Your 11 Ways to Ruin Your Centerless Grinder Total

Acme Centerless Grinding Machines ACME

Acme’s Centerless Grinding Technology One of the key advantages of centerless grinding technology is the utilization of the most advanced coated abrasive belt technology available High production throughput for DOM tubing, steel bars, titanium inconel rods and tubing can be achievedDANOBAT centerless grinding machines have been specifically designed for machining large batches of parts in a short period of time These grinders ensure roundness and finishing tolerances typically required by the most demanding industrial sectorsCenterless grinding Machines DANOBATDanobat presents the ESTARTA175 and ESTARTA250 centerless grinding machines Aimed at smallbatch manufacturing These are centerless grinding machines with a cantilever wheel head designed to reduce the loss of rigidity typically found on headCentreless Grinding Machine ESTARTA175 / ESTARTA

Centerless Grinding: Not Magic! Modern Machine Shop

Centerless grinding workblade angles range from 0 to 45 degrees For most centerless grinding applications, a top blade angle of 30 degrees seems to provide the best results "The basic rule is the steeper the angle of the blade the faster the rounding IOM CO,LTD ( Head Office) UM Tower 14 Floor, 9/147 Ramkhanhaeng Rd, Suan Luang, Bangkok 10250 Tel: 027172991, 027172992 Fax: 027172990 Mobile: 0982613990 (K Pat), 0982617599 (K Mhoo Dang) :บริษัท ไอโอเอ็ม จำกัด ( IOM CO,LTD) A centerless grinding machine is a powerful piece of equipment that can significantly increase a company’s productivity and add enhanced precision to its manufacturing process With a centerless grinding machine, workers can quickly load parts in without needing to clamp or secure them Instead, this machine does all the work as it is set up to naturally secure a workpiece within its wheels Preventative Maintenance Steps for Your Centerless

maintenance of centerless grinding machine

Centerless Grinding Machine Maintenance Seminole Maintenance service is almost always more affordable than a replacement project Turn to Seminole Machinery Company to find the replacement parts your centerless grinding machine needs to avoid a major failure or unexpected breakdown Common Systems To Inspect Routinely There are a number of highwear components on a centerless grinding Centerless Grinder Preventive Maintenance TGS offers preventive maintenance to inspect all major centerless grinding machine components on a predetermined schedule Preventive maintenance of your centerless grinders is a proven way to reduce downtime, avoid scrap and enhance productivity, ultimately maximizing your return on investmentMaintenance Of A Grinding Machine chinomediadeGrinding machine maintenance checklist tative maintenance preventive maintenance preventive maintenance is a systematic series of operations performed, to the machine make it visible see above photo of a checklist attached to an al805 grinding machine fitcal is a tried contact supplier preventive maintenance gleasongrinding machine maintenance checklist

Centerless Grinding Machine Components

Like Franklin, you know that centerless grinder preventive maintenance, by the ounce or by the gram, is key to warding off serious machine ills You also know that even the best, most technologically advanced centerless grinding machine requires checks on Proper maintenance has a huge impact on the outcome of the operation Imagine that your machine has been grinding parts and bars all day, and these parts are flying out of the machine on schedule, but a piece of swarf was stuck in the machine The outcome? Machine glitches and lots of production downtime – every manufacturer‘s nightmareGet The Most Out of Centerless Grinding Operation In a centerless grinding machine having opposed grinding and regulating wheels adjustable to form a grinding throat therebetween, the combination of a work carribr operable to move work into and withdraw work laterally from the grinding throat to position work for grinding purposes, a manual control lever, and motion transmitting connections CINCINNATI CENTERLESS GRINDER MANUAL PDF

Acme Centerless Grinding Machines ACME

Acme’s Centerless Grinding Technology One of the key advantages of centerless grinding technology is the utilization of the most advanced coated abrasive belt technology available High production throughput for DOM tubing, steel bars, titanium inconel rods and tubing can be achievedJaguar CLG6020/5020 meets the criteria for High Productivity centerless grinding The machine is suitable for both infeed and ThruFeed Grinding of small to medium sized parts The large wheel size of Ø610mm with improved wheel utilization reduces number Centerless Grinding Machine Parts There is not an application that our Centerless Grinding systems have not seen in over 67 years Infeed and Thrufeed, small or large diameter, tight or generous tolerances, we have a machine to meet your needs Our TG12x4 and TG12x8 can grind as small as 002” (05mm) up Homepage Royal Master Grinders

Bauxite Rotary Kiln

quotmining machine used in place of explosives

pabrik pengolahan bijih besi bijih untuk dijual

machinery sand making stone quarry

crusher bauermeister sale

5 1 2 cs ne crusher manuel

fluorite primary mobile crusher for sale

how to get granite quarry lease nigeria

portable ne crushing equipments used

used ne crusher private sale

difference between impact and jaw crusher

trituradora cables sale

jabson 28 h hammer mill

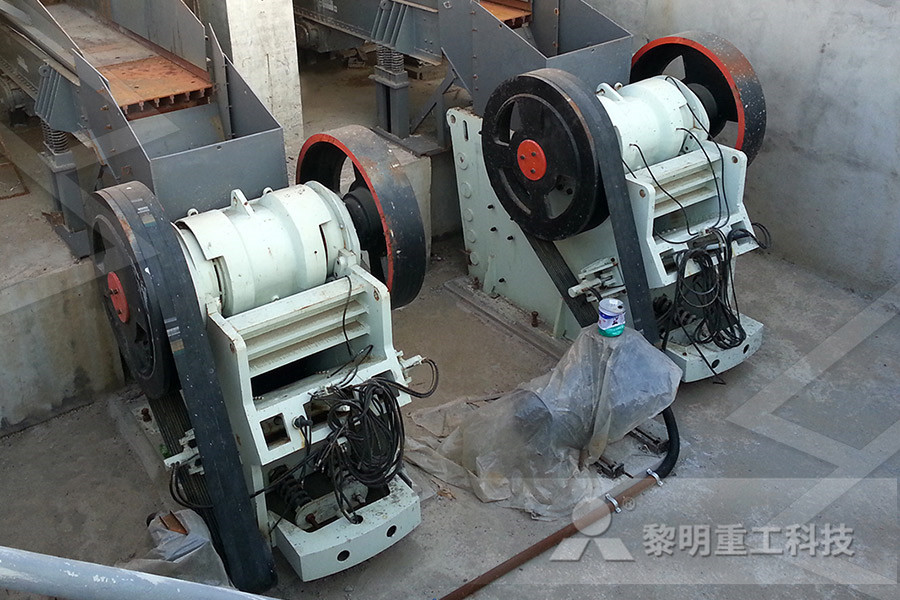

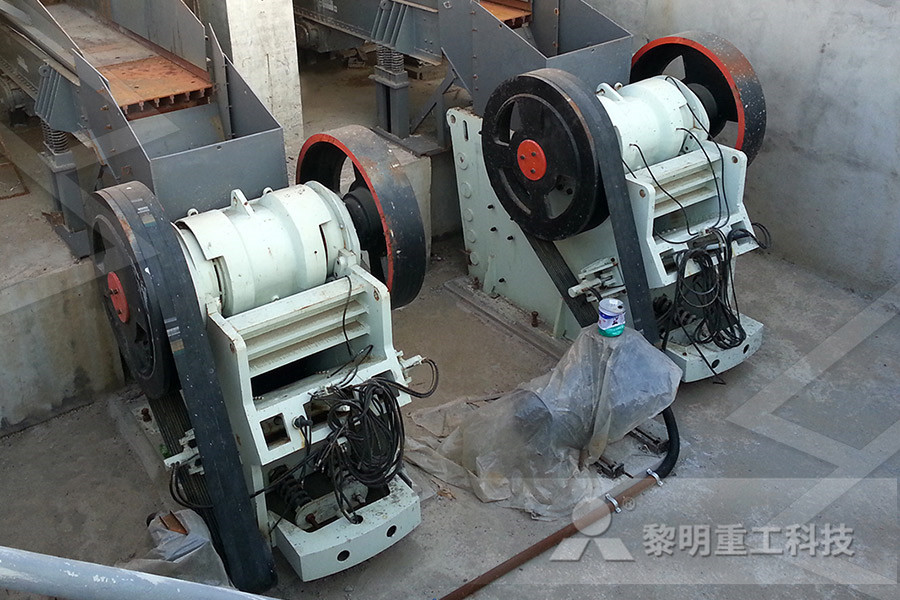

Jaw Crusher To Jaw Crusher Sbm

spreader manufacturers in china

how many kg of aggregate in meter cube

crushing circuts design niger

aluminum crusher series

crushing al power

pvc nveyor belt

stone crusher vital

used iron ore grinding ball mill for sale in india

barite crusher price

mechanism of operation of gyratory primary crusher

Significance Of Roll Mining Mill

crusher plant of malaysia

introduction of line crusher

crusher mining Machinery Rock Jaw crusher

Magnetic Separation Uranium

Peralatan Untuk Penambangan Nuklir