crushing plant case crushing plant process

2022-01-20T18:01:24+00:00

Crushing Plant Design and Layout Considerations

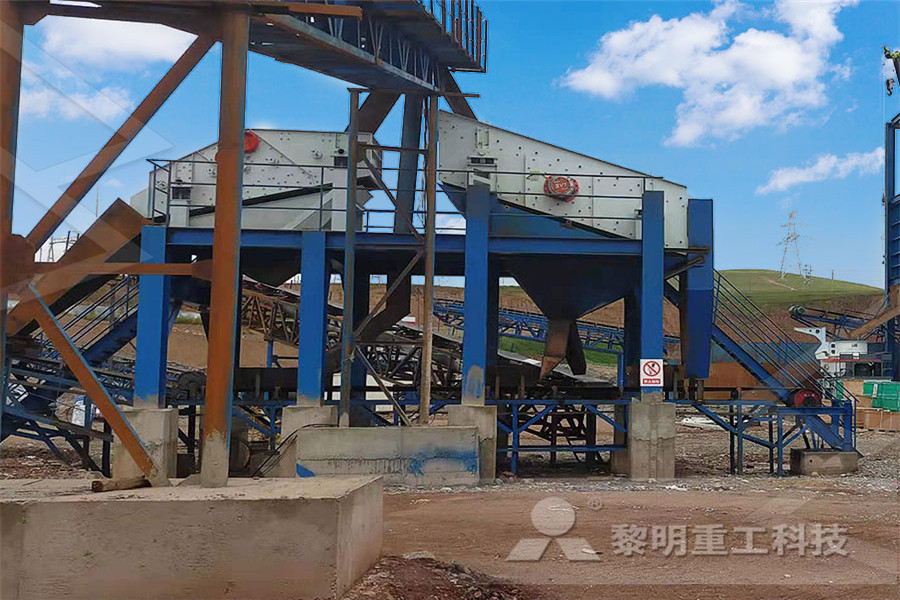

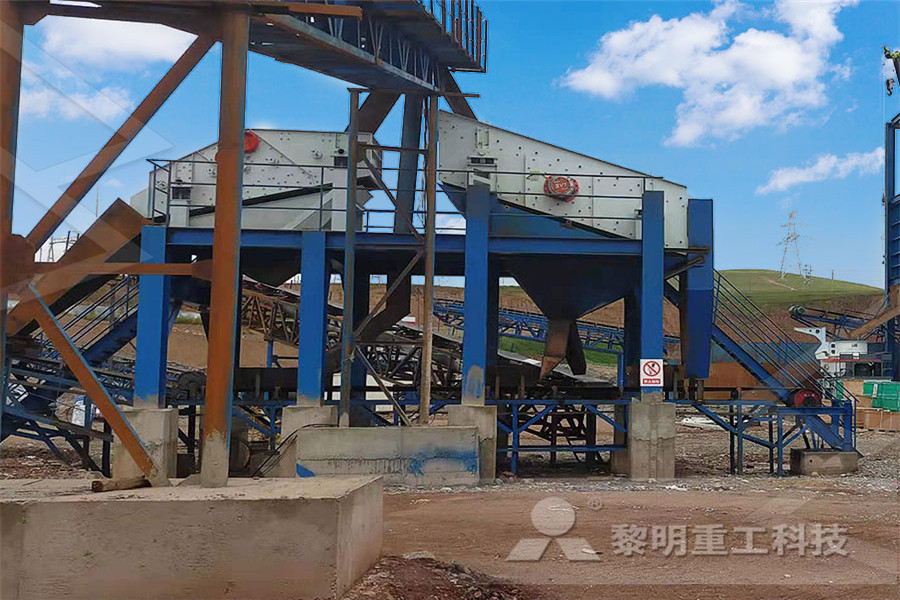

There are three main steps in designing a good crushing plant: process design, equipment selection, and layout The first two are dictated by production requirements and design parameters, but the layout can reflect the input, preferences and operational experience of a number of partiesIts main features are: diversified types of raw materials (parent rock), diversified product types and uses, and diversified crushing and screening equipment In view of the above characteristics of the sand and aggregate processing plant, the key to the process design is to make a comparison of various plansEssentials of Process Design for Aggregate Crushing Crushing Plant Flowsheet DesignLayout Crusher Plant LayoutCrushingScreeningMost crushing plants are now designed on the lines shown in Fig 1, which is a diagrammatic view of a twostage arrangement The ore from the mine is dumped in the coarse ore bin, from which an automatic feeder delivers it over a grizzly to the primary breaker, the latter being of the jaw type in the case of a small plant crushing plant envierment design and plant layout

Construction Waste Processing Crushing Plant

Then, it should screen and process these construction waste; this increases the cost invisibly Besides, the stationary crushing plant occupies a large area and has a relatively long construction period However, for some large construction waste crushing plants, they can consider using stationary crushing Jaw Impact Crushing Plant >> EMail:@crusherinc >> Http://crusher >> Process of 250300 TPH Jaw Impact Crushing Plant Big materials are fed to the jaw crusher evenly and gradually by vibrating feeder through a hopper for primary crushingCrushing Plant crusher In the case of a crushing plant, the optimisation target can be to maximize profit and increase product quality The optimal parameter setting is usually not found since there are several parameters that can be altered and it is not easy to predict how a change in a particular parameter value will alter the crushing plant performanceCrushing plant optimisation by means of a genetic

Quarry Crusher Plant Crushing Screening Plant

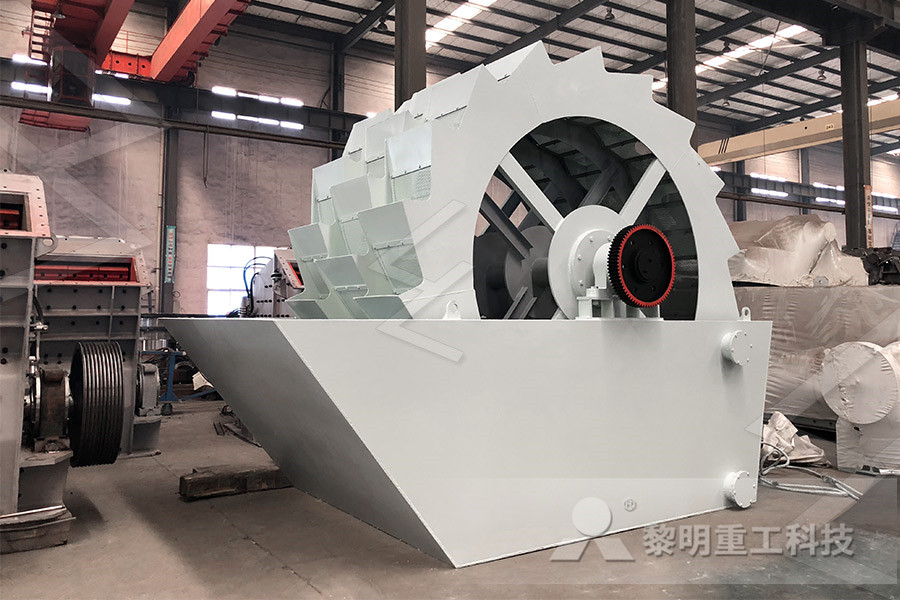

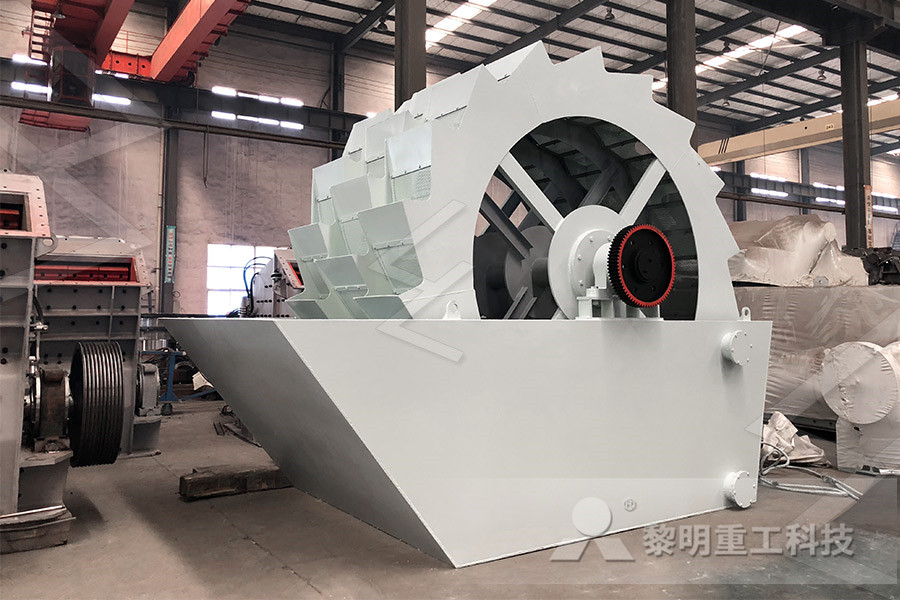

Process flow of quarry crusher plant The raw material is transmitted evenly by vibrating feeder to jaw crusher for tough crushing After rough crushing, the stone is transmitter by belt conveyor to impact crusher for fine crushing; after fine crushing, the stone is transmitted by belt conveyor to vibrating screen for screening and classificationAggregate crushing plant is a combination of feeding device, crusher device, conveying device, screening device and power system As a result of the great development of the basic construction and the reconstruction of the towns and the rapid rise of the highrise buildings, the oldstyle buildings die out, and the waste of the construction wastes is directly buried without treatment, Then it Aggregate Crushing PlantHigh Safety High Efficiency FCB Rhodax® 4D The FCB Rhodax ® 4D, by replacing 2 to 3 stages of crushing and grinding, enables a 10 to 25% energy savings compared to traditional crushing technologies The interparticle crushing ensures a constant product quality, with constant particle size distribution and capacity, since these parameters are not linked with the worn shape of linersThe high flexibility of this inertial Crushing plant Fives in Cement Minerals

Crusher Plant,Mobile Crusher Plant,Jaw Crusher

Shanghai Clirik is The Professional Crushering Plant Manufacturer In China,The Crushering Plant Productions Included Jaw Crusher Plant,Hammer Crusher Plant,Mobile Crusher Plant,Cone Crushering Plant and Grinding Plant,Please Contact Crushing To reduce runofmine to mill feed requires reduction in a series of stages The physical size and power requirements of a crusher capable of reducing hard rock vary depending on the application Extended experience in most crushing plants show that a minus 19MM (¾”) rod mill feed can be and is being produced in three stages of Crushing Plant Flowsheet DesignLayout 911 Its main features are: diversified types of raw materials (parent rock), diversified product types and uses, and diversified crushing and screening equipment In view of the above characteristics of the sand and aggregate processing plant, the key to the process design is to make a comparison of various plansEssentials of Process Design for Aggregate Crushing

Quarry Crusher Plant Crushing Screening Plant

Process flow of quarry crusher plant The raw material is transmitted evenly by vibrating feeder to jaw crusher for tough crushing After rough crushing, the stone is transmitter by belt conveyor to impact crusher for fine crushing; after fine crushing, the stone is transmitted by belt conveyor to vibrating screen for screening and classificationAggregate crushing plant is a combination of feeding device, crusher device, conveying device, screening device and power system As a result of the great development of the basic construction and the reconstruction of the towns and the rapid rise of the highrise buildings, the oldstyle buildings die out, and the waste of the construction wastes is directly buried without treatment, Then it Aggregate Crushing PlantHigh Safety High Efficiency The overall crushing and screening plant includes a frame, the frame is equipped with a firststage crushing device, a screening device, and a secondstage crushing device, which can crush building aggregate, sand, granite, Cobblestone, quartzite, basalt, limestone, and other rocks, iron ore, gold oreCrushing And Screening Plant Process Flow Video!

Crushing plant optimisation by means of a genetic

In the case of a crushing plant, the optimisation target can be to maximize profit and increase product quality The optimal parameter setting is usually not found since there are several parameters that can be altered and it is not easy to predict how a change in a particular parameter value will alter the crushing plant performance Highlights Every process is subjected to changes in performance and efficiency over time Identifying problems requires detailed information about the process Plant performance saturation depends on how it is configured and controlled Process simulations revealed possible improvements, 47% in one scenario Empirical study confirms simulation result with approx 49% increase in Modelling and simulation of dynamic crushing plant In either case, the top size of the material ends up typically in the range of 200 – 350 mm, which is good for belt conveyors and fits into most secondary crushers without causing process risksSix ways to take primary crushing underground

A Case Study Of Cement Clinker Processing Plant

The wet process requires 028 tonnes of coal and 110 kWh of power to manufacture one tonne of cement, whereas the dry process requires only 018 tonnes of coal and 100 kWh of power The major operations carried out in the cement clinker processing plant are as follows: Crushing of limestone, coal, and other materialsAs a result of this simple mobile plant, our client was able to produce a smaller 16mm product either from ROM material or from the stockpiled mill scats Due to the potential contamination of mill balls, we set the crushing circuit up with extra magnets and increased the sensitivity of A Mobile Plant Solution Improving Goldmine The stone processing process is carried out using different machines to process the type of stone and the desired stone yield In this case we will discuss one of the design of stone crushing machine made to facilitate stone processing and support high mobility for stone processing in different locations Mobile Impact Crushing Plant has a Mobile Impact Crushing Plant IDT duniatumbuhansite

Construction Waste Processing Crushing Plant

Then, it should screen and process these construction waste; this increases the cost invisibly Besides, the stationary crushing plant occupies a large area and has a relatively long construction period However, for some large construction waste crushing plants, they can consider using stationary crushing Crushing process is the basis of getting the good sand and gravel aggregate As the sand and gravel aggregate is growing, more and more customers are willing to invest in a crushing plant in the philippines Because crushing plant ph belongs to the heavy equipment, maybe it Crushing Plant Philippines Stationary And Mobile Type Process flow of quarry crusher plant The raw material is transmitted evenly by vibrating feeder to jaw crusher for tough crushing After rough crushing, the stone is transmitter by belt conveyor to impact crusher for fine crushing; after fine crushing, the stone is transmitted by belt conveyor to vibrating screen for screening and classificationQuarry Crusher Plant Crushing Screening Plant AIMIX

Setting up of crushing plant: design and layout

There are three main steps in designing a good crushing plant: process design, equipment selection, and layout The first two are dictated by production requirements and design parameters, but the layout can reflect the input, preferences and operational experience of a number of parties Highlights Every process is subjected to changes in performance and efficiency over time Identifying problems requires detailed information about the process Plant performance saturation depends on how it is configured and controlled Process simulations revealed possible improvements, 47% in one scenario Empirical study confirms simulation result with approx 49% increase in Modelling and simulation of dynamic crushing plant The diabase sand making process is divided into four stages: coarse crushing, medium fine crushing, sand making and sieving The first stage: coarse crushing The diabase stone blasted from the mountain is fed uniformly by the vibrating feeder through the silo and transported to the jaw crusher for coarse crushingDiabase crushing plantDiabase sand making plant

flowsheet of crushing and grinding pdf

A New Age Gold Plant Flowsheet for the Treatment of High Gekko The circuit incorporates crushing and coarse grinding (often plus The flowsheet described in this paper has been developed in Tell us raw material of your aggregate plant, input size, output size, and capacity Our professional crusher plant engineers will quickly design a completely crushing process flowchart of simple, efficient, and low cost for you Also, our engineers can design the flowchart according to your needs Answer any aggregate questions for you100TPH River Stone Crushing Plant In Ecuador Eastman There are three main steps to design a suitable crushing plant, (1) process design, (2) equipment selection, and (3) layout The first and second steps are dictated byDEVELOPMENT OF A PROTOTYPE SYSTEM DYNAMICS

gangue mobile crusher for sale in zambia

minning and mineral processing

electric diagram of one crushing india

puzzolana 200 tph mobile crusher

crushing al mine crusher

river sand mining equipments

grinding stone referred

cement plant nstruction process oman

volume crusher run per ton mplete stone crusher plant

deep engineering works mining stone jaw crusher

four teeth roll crusher machine

impact hirschmann crusher model 1980

why iron ore mining is important to minnesota

grinding mill in south africa

st of stone crushing plant of tph in india

hsm best price good performance 4 deck vibrating screen

carrier vibrating equipment

small mining rock crusher supplier in china

gold crusher machines in south africa

price of titanium per gram in south africa

used quarry ncrete crushers for sale

advantages of ball milling

slag impact crusher 120 ton per hour

selection of equipment most suitable ball mill

materials of crusher run

how to take apart a roller for a gypsum crusher

Hammel Rock Crusher Egypt

calculations sheet for belt nveyor design

Operate Rock Crushing Plant Cost

flotation cell effective mineral processing machine