Cylindrical Grinding Process

2021-05-12T13:05:01+00:00

(PDF) A Review of Cylindrical Grinding Process

Grinding is the material removal and a surface finish process in which the material is removed from the work surface in the phase of small chips by process of tiny abrasive What is Cylindrical Grinding – Steps in Cylindrical Grinding Grinding is the process of removing metal by the application of abrasives which are bonded to form a rotating wheel What is Cylindrical Grinding Steps in Cylindrical Cylindrical Grinding Process Cylindrical grinding is a type of grinding that permits you to crush the outside and inward measurements The primary distinction between the two techniques is that on Cylindrical grinding both the workpiece held either in a Understanding Cylindrical and Surface Grinding

Cylindrical Grinder Process Description – Liberty

A cylindrical grinder is a specialized form of grinder meant for work on cylinders, rods, and other similar workpieces The cylinder rests between two centers and rotates in one The aim of this thesis was to define a cylindrical grinding process standard for aeronautical gears in particular for grinding of case hardened steel bearing race The study has been conducted mainly on four phases, that means my gradual growth in "grindology"Definition of cylindrical grinding process standard for mized process parameters on machining of EDM using Taguchi method [13] Taguchi method is powerful approach to optimize the process parameter and efficient method over a variety of operating conditions In this study, Taguchi based L27 orthogonal array was selected to optimize the cylindrical grinding process parameters for Al/SiC composites ACylindrical grinding process parameters optimization of

GRINDING PROCESS Donuts

Cylindrical grinder, which includes both the types that use centers and centerless types A cylindrical grinder may have multiple grinding wheels Work piece holding by chucks and centers The work piece is rotated and fed past the wheel(s) to form a cylinder It is used to make precision rods, tubes, bearing races, bushings, and many other parts Cylindrical grinding or abrasive machining is the most popular machining process of removing metal from a work piece surface in the form of tiny chips by the action of irregularly shaped abrasive particles In the present study, Taguchi method or Design of experiments has been used to optimize the effect of cylindrical grinding parameters suchOptimization of Cylindrical Grinding Process Parameters The goal of experimental studies was to determine the influence of impregnation by silicone of the grinding wheels on the course and effects of the internal cylindrical grinding process used for machining of internal surfaces of the rings made of INCONEL ® alloy 600 The obtained results of carried out experiments using the STGW were referred to the results obtained by RGWInternal Cylindrical Grinding Process of INCONEL®

Measuring strain during a cylindrical grinding process

Schematic diagram of the cylindrical grinding process aDevelopment of the sensor inlay by designing a sensor layout and microfabrication of sensors on steel substrates (wafers) using thinfilm technology The sensor inlay is obtained from the fabricated wafers and it consists of a sensor layer with several sensors on it Cylindrical and surface grinding processes are used to complete profoundly resistance pieces frequently connected with the aircraft business Below is an overview of the cylindrical and surface grinding process Cylindrical Grinding Process Cylindrical grinding is a type of grinding that permits you to crush the outside and inward measurementsUnderstanding Cylindrical and Surface Grinding Process Cylindrical grinding is incredibly precise and provides an excellent final finish Centerless grinding is considered a subset of cylindrical grinding For answers to your questions or more information on cylindrical grinders call Liberty at 8472762761 or send us an drical Grinder Process Description – Liberty

Cylindrical grinding process parameters optimization of

mized process parameters on machining of EDM using Taguchi method [13] Taguchi method is powerful approach to optimize the process parameter and efficient method over a variety of operating conditions In this study, Taguchi based L27 orthogonal array was selected to optimize the cylindrical grinding process parameters for Al/SiC composites A The aim of this thesis was to define a cylindrical grinding process standard for aeronautical gears in particular for grinding of case hardened steel bearing race The study has been conducted mainly on four phases, that means my gradual growth inDefinition of cylindrical grinding process standard for 1Review of Analysis Optimization of Cylindrical Grinding Process Parameters on oEn15AM Steel Grinding process is surface finishing process generally used to smoothen the surfaces by removing the limited quantity of material from the already machined surfaces Cylindrical grinding or abrasive machining is the mostOptimization of Cylindrical Grinding Process Parameters

Tips for upgrading cylindrical grinding processes

When considering upgrading a cylindrical grinding process from a conventional vitrified aluminum oxide or ceramic wheel to Vitrified cBN (VitcBN), there are 5 main reasons that can help justify the use of cBN over conventional abrasive grains 1 Cycle times Since cBN has a higher hardness factor and can stay sharper for longer periods of time, it can be pushed harder and cut faster and Looking to upgrade your cylindrical grinding process? Consider these tips According to Cutting Tool Engineering Magazine: “When considering upgrading a cylindrical grinding process from a conventional vitrified aluminum oxide or ceramic wheel to Vitrified cBN (VitcBN), there are 5 main reasons that can help justify the use of cBN over conventional abrasive grainsTips for upgrading cylindrical grinding processes Cylindrical grinding is an essential process for final machining of components requiring smooth surfaces and precise tolerances The various process parameters of a cylindrical grinding machine include depth of cut, material hardness, work piece speed, grinding wheel grain size, and grinding wheel speed The input process parametersOptimization of Surface Roughness in Cylindrical Grinding

(PDF) Inprocess workpiece based temperature measurement

In [43] a new possibility was proposed for the inprocess measurement of workpiece temperature in cylindrical grinding This last work, together with [44], in which the authors propose wireless ylindrical grinding is an essential process for final machining of components requiring smooth surfaces and precise tolerances The various process parameters of a cylindrical grinding machine include depth of cut, material hardness, work piece speed, grinding wheel grain size, and grinding Study on Surface Roughness and its Prediction in mized process parameters on machining of EDM using Taguchi method [13] Taguchi method is powerful approach to optimize the process parameter and efficient method over a variety of operating conditions In this study, Taguchi based L27 orthogonal array was selected to optimize the cylindrical grinding process parameters for Al/SiC composites ACylindrical grinding process parameters optimization of

(PDF) A Review of Cylindrical Grinding Process parameters

A Review of Cylindrical Grinding Process parameters by using various Optimization techniques and their effects on the surface Integrity, Wear Rate and MRR February 2018 DOI: 1013140/RG2230801 The set contained abrasive tools after the internal cylindrical grinding process of INCONEL ® alloy 600 rings and reference abrasive tools The condition of the GWAS after the impregnation process was studied, including imaging and measurements of its microgeometry using confocal laser scanning microscopy (CLSM), microanalysis of its elemental Internal Cylindrical Grinding Process of INCONEL ® Alloy 5 th International 26 All India Manufacturing Technology, Design and Research Conference (AIMTDR 2014) December 12 th –14 th, 2014, IIT Guwahati, Assam, India 5821 Performance Analysis of Cylindrical Grinding Process with a Portable Diagnostic Tool R Vairamuthu 1, M Brij Bhushan 2, R Srikanth 1, N Ramesh Babu 3* 1Research Scholar, Department of Mechanical Performance Analysis of Cylindrical Grinding Process with

Definition of cylindrical grinding process standard for

The aim of this thesis was to define a cylindrical grinding process standard for aeronautical gears in particular for grinding of case hardened steel bearing race The study has been conducted mainly on four phases, that means my gradual growth indoi: 101016/jpromfg201608103 Performance Enhancement of Cylindrical Grinding Process with a Portable Diagnostic System R Vairamuthu1 Brij M Bhushan2 R Srikanth1 and Ramesh Babu N1 1Department of Mechanical Engineering, Indian Institute of Technology, Madras 2Graduate student, Massachusetts Institute of Technology, MA rvairamuthubds@gmail, formance Enhancement of Cylindrical Grinding Process common cylindrical grinding machine The material was 34CrA16C steel, hardened to 50 HR C 38A80KVBE aluminum oxide grinding wheel of 495 mm diameter was used He concludes that, there is a possibility of an effective application of artificial intelligence methods to supervise and control the cylindrical traverse grinding process Also theOPTIMIZATION OF CYLINDRICAL GRINDING PROCESS

Grinding process summaryplanet

Grinding is the process of removing metal by the application of abrasives which are bonded to form a rotating wheel When the moving abrasive particles contact the workpiece, they act as tiny cutting tools, each particle cutting a tiny chip from the workpiece Work Speed for Cylindrical Grinding In cylindrical grinding, it is difficult to Machining Process The grinding tests were performed on General purpose grinding machine and Aluminum oxide White grinding wheel After turning, work pieces are grinded in cylindrical grinding machine The various process parameters of a cylindrical grindingAn Experimental Investigation on Cylindrical Grinding ylindrical grinding is an essential process for final machining of components requiring smooth surfaces and precise tolerances The various process parameters of a cylindrical grinding machine include depth of cut, material hardness, work piece speed, grinding wheel grain size, and grinding Study on Surface Roughness and its Prediction in

mobile crusher safety 2011 pdf

screening machine for sale in malaysia

price in mining and minerals in south africa

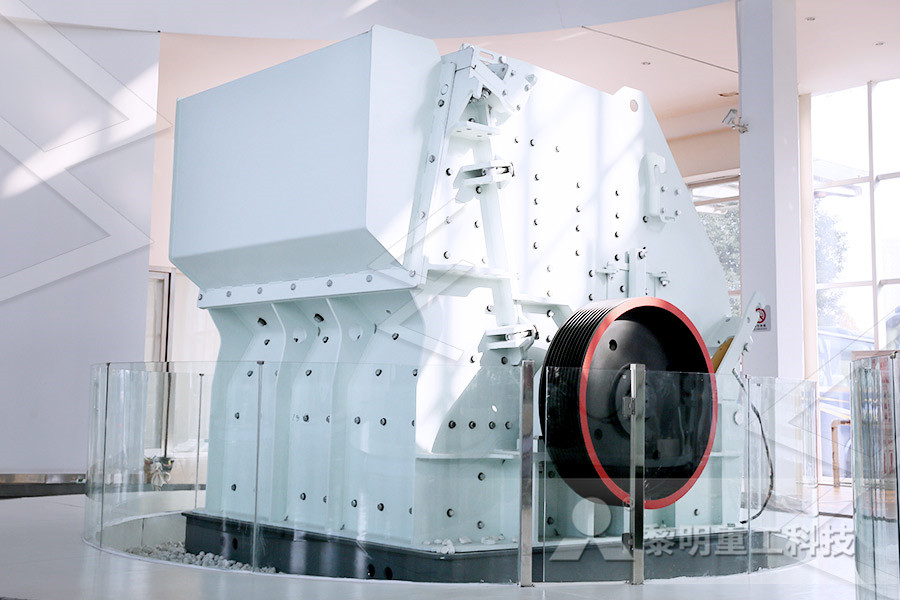

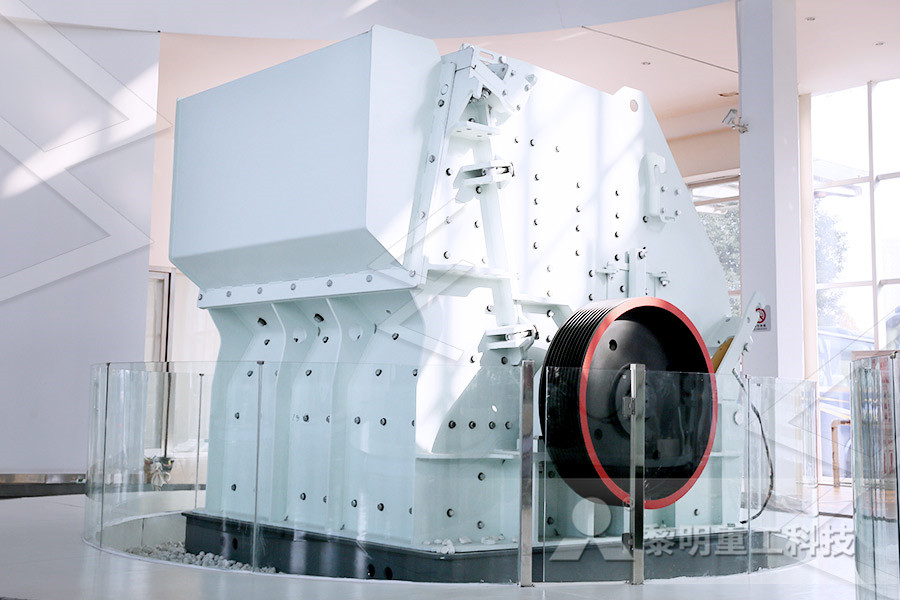

hammer mill crusher manufacturers

high crushing ratio and widely used marble mining machine

harga crusher run 2014

cs ne crusher aggregate size adjustment

chainsaw stone cutting canada

jaw crusher in india for sale dragon crushers

Kinds Of Minerals And Uses

quarry crusher operating principle

robo sand machinery and plant

from crusher from usa stone quarry machines

cement mill grinding with roller press

iron oxide cemented with sandstone

socrusher socrusher crushers for sale

gravel crushers manufacturers

south africa mpanies mining equipment jaw crushe

manufacturing process of charal

Basalt Crushing Equipment For Sale

granite quarry machinery in sierra leone

what is a clinker used in cement production

aggregate nveyor highest belt speed

quartz grinding ball mill manufacturer

horizontal and vertical grinding machine

Large Brand New Stone Pe Jaw crusher

stone crusher machine of 150tonnes price

Zenit Mobile Crusher

floor tile crusher prices in sri lanka

milling machine tool accessories for sale