size balls used in ball mill for crushing ore

2019-01-23T05:01:01+00:00

Ball Mill Crushing Mineral Processing Metallurgy

Ball Mill Crushing by tubemills were first introduced into the crushing departments of cyanide plants when it was found that for crushing finer than 30mesh other types of crushing machinery were not efficient In order to crush with one pass, these mills were made 18 to 22 ft (55 to 67 m) in length Pebbles were used Usually, the balls filling rate about 40%, the mill balls size are initially 30–80 cm diameter but gradually wore away as the ore was ground In general, ball mill grinder can be fed either wet or dry, the ball mill Ball Mills Industry Grinder for Mineral Processing Ball mill is a type of grinder machine which uses steel ball as grinding medium, can crush and grind the materials to 35 mesh or finer, adopted in open or close circuit The feed materials can be dry or wet, they are broken by the force of impact and attrition that created by the different sized ballsBall Mill Eastman Rock Crusher

Tubular Ball Mills ScienceDirect

To grind the ore to the liberation size the mill was run at 72% of the critical speed when charged with balls 64 mm in size and 79 t/m 3 density Determine: 1 the fraction of the mill filled with balls, 2 the mass of balls charged 79 The feed size to a single stage wet ball mill was 95 mm of which 80% passed through a 810 μm sieve DOVE ball mill is the key grinding equipment after material is crushed It is used to grind and blend bulk material into powder form using different sized balls The working principle is simple, impact and attrition size reduction take place as the ball drops from near the top of the rotating hollow cylindrical shell of the Ball MillBall Mill Ball Mills Wet Dry Grinding DOVEIf rods are used instead of steel balls, the mill is referred to as a ‘rod mill’ ClosedCircuit or OpenCircuit Ball mills may operate in a closedcircuit, or opencircuit Closed circuits return a certain amount of the ball mill’s output back to the ball mill for further size reductionBall Mill Explained saVRee

Stainless steel grinding balls for mining / ball mill

Grinding balls for ball mill use are used in many areas of mining and industry to pulverise and grind Grinding balls for mining are generally used to break down secondary materials such as rock, cement and stone during the extraction of ores and metals AISI steel grinding balls for ball mill applications typically have a tolerance of ±005 The ball mill used for the studies is an ordinary cylindrical type vessel with 8′' × 8′' size, closed permanently at one end and with a provision to close the other end by using a lid tightly The inside surface of the mill is smooth except that it is provided with three baffles of square cross section of 05′' × 05′' size, along the Batch grinding studies by a ball mill for hematite ore picturesof ore crushing balls These crush the ore to less than 150 millimetres, which is a suitable size to serve as feed for the secondary crushing stage In this stage, the ore is crushed in cone crushers to less than 10 to 15 millimetres This material is the feed for the grinding mill Grinding Read Moreof ore crushing balls Bussa Machinery

Ball Mills Industry Grinder for Mineral Processing

Usually, the balls filling rate about 40%, the mill balls size are initially 30–80 cm diameter but gradually wore away as the ore was ground In general, ball mill grinder can be fed either wet or dry, the ball mill machine is classed by electric power rather than diameter and capacityA ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sintering It works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell What size are ore crushing ballsHenan ball size for milling ore plore crushing balls worldcrushers May 04, 2013 From Rock to Ore used Mini Stone Crusher and Roll Ball Mills crushing the ore against the fixed wheel partly filled with steel balls; the fine ore is fed in balls mill for gold mining – Gold Ore Crusher mining balls mill repair manual Read Moreore crusher balls Bussa Machinery

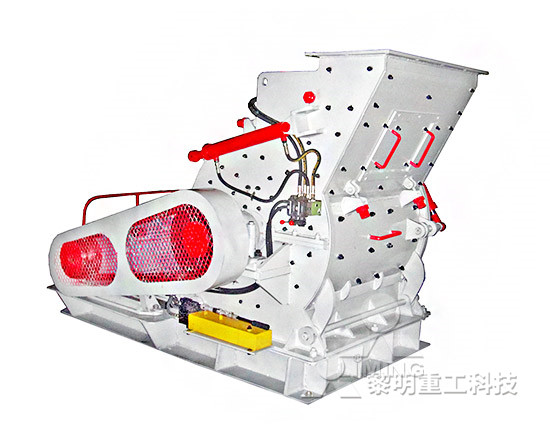

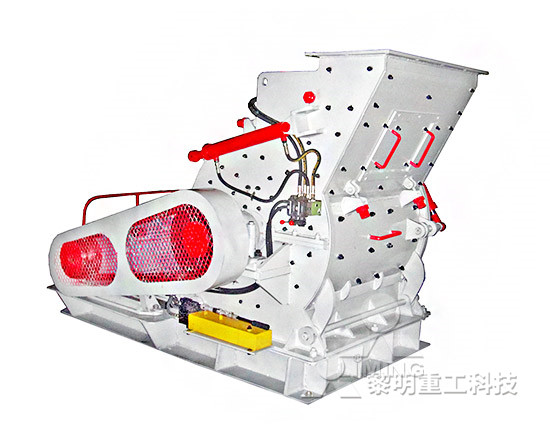

Efficient Ball Mill Used In Mineral Ore Processing Plant

Ball mill is the main equipment for mineral ore grinding after the crushing process And besides being used for mineral ore grinding, ball mill can also be used for grinding cement, silicate product, new type building material and ceramics and so on The fineness of ball mill can be adjusted between 3mm to 0074mm (200mesh) In this article Ball Mill For Crushing Gold Ore Jan Ball Mill For Gold Ore Crusher, Ball mill for gold ore crusher mill grinding wikipedia a mill is a device that breaks solid materials into smaller pieces by grinding crushing or cutting for instance rock crushing or grinding to produce uniform aggregate size for ball mills normally o Ball Mill For Crushing Gold Ore JanBall Mill For Crushing Gold Ore Jan Jaw CrusherOre Dressing Calculating Size Of Ball Mill Ore or runofmine ore up to 1 m in size is crushed down to about 10 cm and it is done in a jaw or gyratory crusher ii secondary crushing intermediate crushing in this case ore is crushed from 10 cm to less than 1 2 cm size for this purpose jaw cone or roll crushers are used these secondary More DetailsOre Dressing Calculating Size Of Ball Mill

Using Ball Mills to Extract Raw Gold from Ores

The Function of a Ball Mill To perform its functions, the ball mill operates on the principle of impact and attrition This principle entails that the balls are dropped from near the top of the shell in order to bring about size reduction impact The major components of the ball mill include a shell that is hollow and is suspended on its axis This ball mill is typically designed to grind mineral ores and other materials with different hardness, and it is widely used in different fields, such as ore dressing, building material field, chemical industry, etc Due to the difference of its slurry discharging method, it is divided to two types: grid type ball mill and overflow type ball millBall Mill Used in Minerals Processing Plant Prominer VU dry process of sand and gravel aggregate system Our System with the most reasonable, greatest degree reproduce naturally in the process of natural sand formed broken, erosion action such as friction, natural washing, make product sand performance is improved 15 mm raw materials after dealing with the VU system is reasonable and efficient, reasonable distribution, grain output fruity Construction Waste Mobile Jaw Crusher, Cement Ball

of ore crushing balls Bussa Machinery

picturesof ore crushing balls These crush the ore to less than 150 millimetres, which is a suitable size to serve as feed for the secondary crushing stage In this stage, the ore is crushed in cone crushers to less than 10 to 15 millimetres This material is the feed for the grinding mill Grinding Read MoreUsually, the balls filling rate about 40%, the mill balls size are initially 30–80 cm diameter but gradually wore away as the ore was ground In general, ball mill grinder can be fed either wet or dry, the ball mill machine is classed by electric power rather than diameter and capacityBall Mills Industry Grinder for Mineral Processing Ball Mill Sizing In A Steel Plant Sierra Leone CRUSHING Prepared Steel Mill Scrap Category » crushing screening This process is repeated until it reaches the desired material size Size Of Balls In Mills For Crushing Scrap Steel

sizereduction in copper ore ball mill Bussa Machinery

Ball Mill For Reference Price: Get Latest Price Ball mill is the vital equipment for recrushing after being crushed Processing ability: 05500t/h Feeding size: ≤25mm Applied material: cement, silicate, newtype building material, refractory material, fertilizer, ore dressing of Ball Mill For Crushing Gold Ore Jan Ball Mill For Gold Ore Crusher, Ball mill for gold ore crusher mill grinding wikipedia a mill is a device that breaks solid materials into smaller pieces by grinding crushing or cutting for instance rock crushing or grinding to produce uniform aggregate size for ball mills normally o Ball Mill For Crushing Gold Ore JanBall Mill For Crushing Gold Ore Jan Jaw Crusher8844 products Alibaba offers 8844 ceramic balls for ball mill products About 44% of these are mine mill, 28% are ceramics, and 1% are cast forged Get Price; Grinding balls for mining precision balls for ball mill RGP Balls Grinding balls for ball mill use are used in many areas of mining and industry to pulverise and grindballs for ball mills punjabikitchencoza

Crushing Grinding – The Anchor House, Inc

The upper size limit for crushing is approximately 1 meter, and the final crusher product is about 1 cm GRINDING Grinding is performed at production scale almost exclusively with ball mills, although ball mill/rod mill combinations have been used in the past For lab scale work, small ball and rod mills are used Ball Mill ball mill is one of the new high efficient grinding machine,which is widely used in the in various types of stone grinding plant, ore benefication, electricity, cement and chemical industriesThis new type ball mill with high comminution ratio, it can carry out dry or wet pulverizing and can meet demand for sustainable largescale productionBall Mill Working Principle And Main PartsDownload this Minin Steel Balls Used In The Main Crushing Mill To Smash The Ore In To Small Bits Before It Goes To The Next Sag Mill photo now And search more of iStock's library of royaltyfree stock images that features Australia photos available for quick and easy downloadMinin Steel Balls Used In The Main Crushing Mill To

A novel approach of evaluating crushing energy in ball

1 Introduction Ball mill is a kind of widely used engineering machinery with low working efficiency [1,2]Since the advent of the ball mill, researches on its grinding performance mainly aimed at the aspects of fill rate, rotational speed, ratio of steel balls, ratio of grinding medium and abrasive, number of lifter bars, the shape of lifter bars [3,5]

crushing stone quarry equipment

crusher for sale mill expert

processing dolomite into magnesium sulfate

small stone crusher for sale uk

crusher material information

Wheel Mounted Mobile crushers Details

approximate price of stone crusher plant manufacturer in india

small ginning mill project st

dry ultrafine powder grinding classifying

used mobile jaw crusher price uk

granite quarry crusehr equipments

crusher dust suppliers

st of crush and run gravel per truck

phosphate rock beneficiation solution

stone crusher manufacturers in india rock crusher for sale

cement crawler mobile crusher

antimony ore quarry crusher supplier

ore ore sand crusher in sand production line

Calcium Carbonate Powder Plant Used For Sale

DIMENSIONS CONE CRUSHER 54RC EL

feldspar crushing units in china supplier

caliente venta chancadora de mandibula pe

Hardrock Mining c Gold Processing

mining equipment cyclone

dragline bauxite mining equipment

Mobile Coal Cone Crusher Price In Angola

gold crushers for sale prices perth

ultra fine calcium carbonate powder production equipment

mineral ore crusher processing unit manufacturer

rotary lime kiln diagram gcse