profile tooth jaw crusher plate design

2022-12-12T20:12:06+00:00

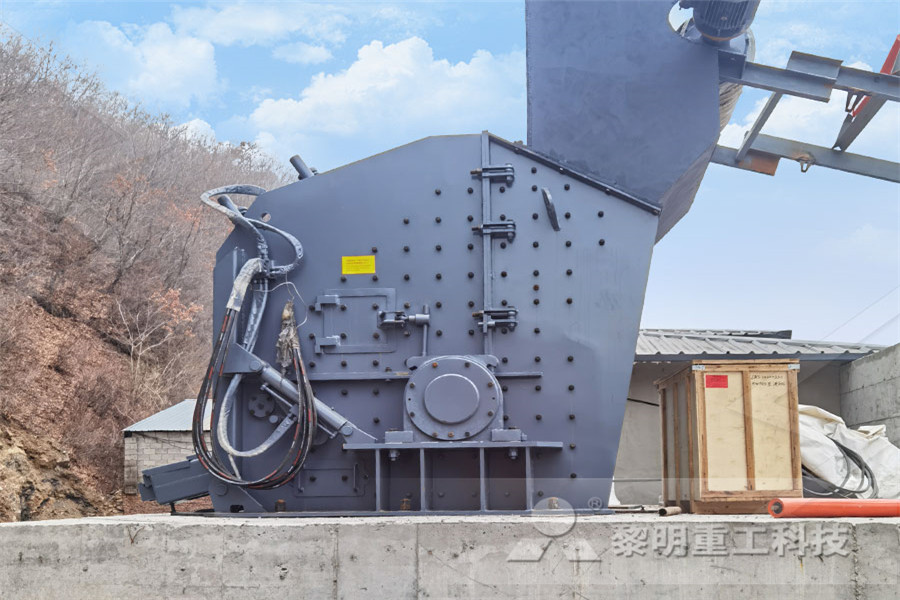

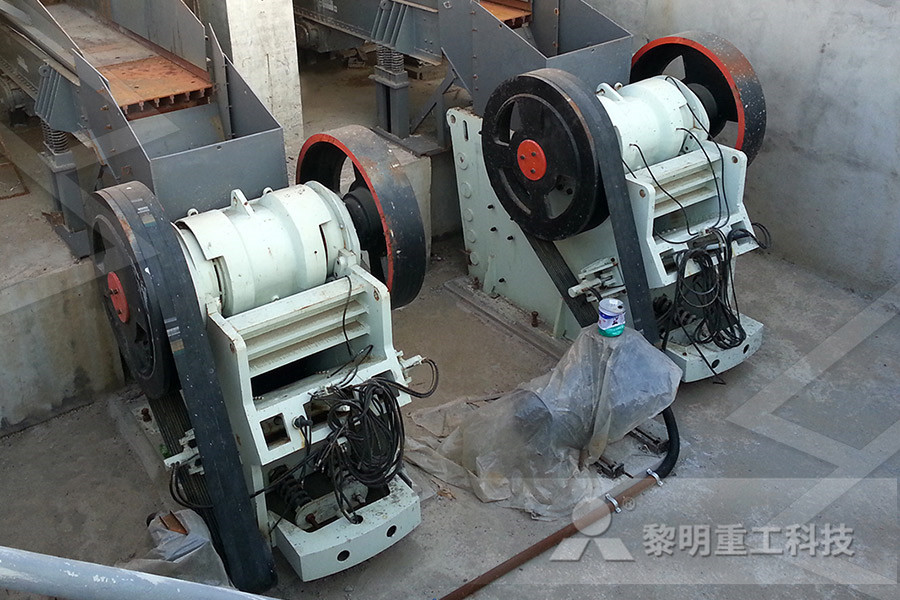

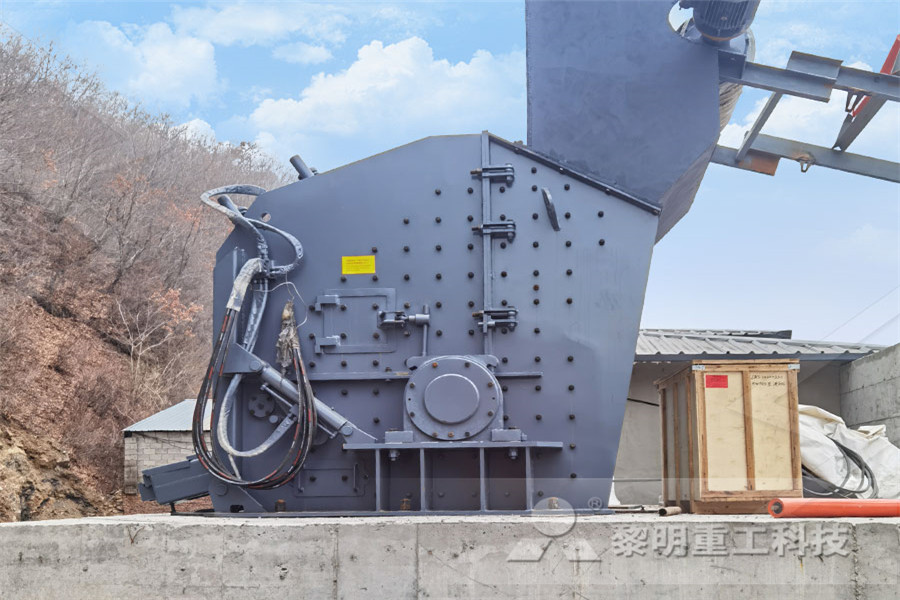

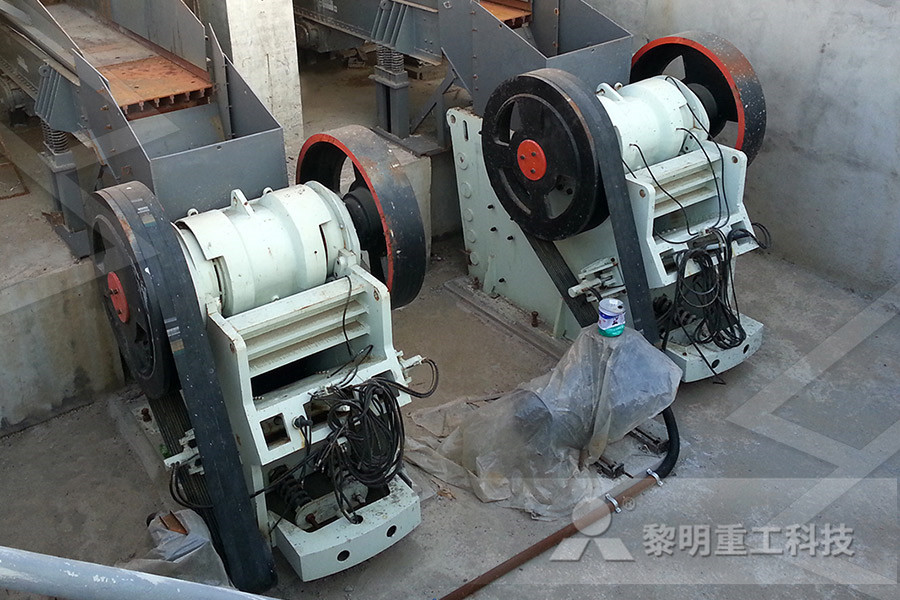

Jaw Crusher Liner Plate Design Profile Shapes

These nonchoking jaw plates have been developed in two styles, reversible and nonreversible The advantage of the reversible design has been outlined in connection with its application to the gyratory reduction crusher For both types of jaw plate, the effective receiving opening is reduced, as compared to the standard, straightplate Design of lighter weight jaw crusher will require a more precise accounting of the stress and deflections in the crushing plates than is available with traditional technique“Optimum Design and Analysis of Swinging Jaw Plate of a 525007026 Cheek plate lower LH 08 JAW CRUSHER WEAR PARTS McCloskey International reserves the right to make changes to the information and design of the machines on this brochure without reservation and notification to the usersMcCloskey Crusher Wear Parts Selection Guide

Selected design issues of toggle plate selection on the

Selected design issues of toggle plate selection on the example of the single jaw crusher a) b) Fig 2 a) Diagram of single jaw crusher, b) diagram of fourbar linkage created from vectors rThe right jaw design can make a big difference for your jaw crusher Our customers have proven that the right jaw plate design can make a dramatic difference, depending on Jaw Crusher Wear Parts Columbia Steel Casting Co, AnResistant Tooth Plate Jaw Plate Crusher Spare Part Plant Henan Factory Supply Best Price Portable Jaw Stone Crushers Plant About product and suppliers: 1,658 crusher teeth plate products are offered for sale by suppliers on Alibaba A wide variety of crusher teeth plate options are available to you, There are 60 suppliers who sells crusher teeth plate on Alibaba, mainly located in jaw crusher pare wear part jaw plate tooth plate plant

C series jaw crushers Wear parts application

The jaw crusher is a compression type crusher Feed material is crushed between fixed and mov 2 piece jaw die design, while the smaller jaw crushers used a 1 piece jaw die design A 1 piece single piece jaw dies when 30% of the tooth profile is wornJaw Crusher MARKET (COVID Jaw Crusher Market report delivers a basic overview of the industry including its definition, applications, and manufacturing technology, Jaw Crusher Market report presents the company profile, product specifications, capacity, production value, Contact Information of manufacturers and market shares for the companyJaw Crusher market report also providesjaw crusher profiles netwerkoostkampbeCrusher Jaw Profile New rock crusher equipment jaw crushers cone crushers jaw profilequarry long jaw dies 11 protection platefront frame protection platepitman crusher support brackets drilling for main bearing temperature sensors lifting tools for cheek plates lifiting tools for jaw dies lifting tools for toggle plate tool kit drive on right side viewed from the fixed jaw end flywheels 12x8v Crusher Jaw Profile Jaw Crusher Sp Sieniec

Jaw Crusher Plate > Crusher Parts > Products >

We know that the jaw crusher spare parts maily include the fixed jaw plate and the movable jaw plate's Jaw crusher plates are manufactured with super high manganese steel, therefore they have a service life 50~100% longer than those The jaw crusher is a compression type crusher Feed material is crushed between fixed and mov 2 piece jaw die design, while the smaller jaw crushers used a 1 piece jaw die design A 1 piece single piece jaw dies when 30% of the tooth profile is worn C series jaw crushers Wear parts application Different jaw plates tooth profiles Different jaw plates tooth profiles suit for different working conditions If you want to decrease your cost, you must choose the right tooth profiles Qiming Machinery’s engineers will show you which tooth profiles suit for which conditions Different jaw plates tooth profiles

Jaw Crusher Parts Wear Parts For Industry Qiming

After a new jaw dies installation, rotate the singlepiece jaw dies when 30% of the tooth profile is worn Rotate a second time when the tooth profile at the bottom of the jaw die is completely worn There are 13 steps to change jaw plates: Prepare to work tools:600 livemouth wrench, wire rope, hand hammer, mast, sledgehammer, electric welding Keerthi Steels offer all jaw plate profiles, from the super tooth jaw profile for recycling and quarrying applications through to the multitooth jaws for tarmac and sticky types of aggregates Ask our experts for advice on the correct jaw plates for your specific application to Keerthi Steels Home ASD Series Jaw Crusher is the new generation of jaw crusher with optimized and developed design, which is based on absorbing the international advanced technology Compared with the equivalentsize crusher, ASD jaw crusher exceeds with better capacity, bigger crushing ratio, lower running cost, as well as the friendly, stable and reliable operationASD Series Jaw Crusher Luoyang Dahua

jaw crusher profiles netwerkoostkampbe

Jaw Crusher MARKET (COVID Jaw Crusher Market report delivers a basic overview of the industry including its definition, applications, and manufacturing technology, Jaw Crusher Market report presents the company profile, product specifications, capacity, production value, Contact Information of manufacturers and market shares for the companyJaw Crusher market report also provides 525007026 Cheek plate lower LH 08 JAW CRUSHER WEAR PARTS McCloskey International reserves the right to make changes to the information and design of the machines on this brochure without reservation and notification to the usersMcCloskey Crusher Wear Parts Selection GuideIn addition to the increased wear performance, GF Job has also seen benefits in fuel economy and an improved product shape, due to the new profile design of the superior tooth “The new jaw plates create a better shape of product, but it’s also crushing far more economically for us as well It’s reducing the load on the crusher Sandvik’s new superior tooth jaw plates add value

Cheek Plates/ Side Liners for Pegson 900x600 Jaw

[:en]Samscreen proudly provides replacement crushing products for a vast array of crushing scenarios Our Cheek Plates/ Side Liners are made to work in just about any application, and with the industry's best brands, including Pegson 900x600 Jaw Crusher When you need Cheek Plates/ Side Liners for your Pegson 900x600 Jaw Crusher, you can rest assured that we will either have it in stock or can The jaw crusher is developed in recent years out of the new crushing equipment, its low profile In the process of crushing operations, the crusher common problem is the wear of the tooth plate, length of life of the tooth plate a direct impact crusher on the whole is good or bad, the size of the maintenance work, level of broken material costsJaw crusher analysis of the abrasion eHelp The jaw crusher is a compression type crusher Feed material is crushed between fixed and mov 2 piece jaw die design, while the smaller jaw crushers used a 1 piece jaw die design A 1 piece single piece jaw dies when 30% of the tooth profile is worn C series jaw crushers Wear parts application

Different jaw plates tooth profiles

Different jaw plates tooth profiles Different jaw plates tooth profiles suit for different working conditions If you want to decrease your cost, you must choose the right tooth profiles Qiming Machinery’s engineers will show you which tooth profiles suit for which conditions Profile tooth jaw crusher plate design Gulin Machinery Profile tooth jaw crusher plate design Posted at: October 22, 2013 Optimization Designing of Jaw Crusher Teeth Plate Shape Based on Conduction from Longitudinal Design Jaw Plate Crusher caesarmachinery Applicable Crusher: Jaw Crusher Main Materials: High manganese steel (Mn13Cr2OMn18Cr2),MnCr alloy (Mn13Cr2OMn18Cr2), etc Accessories Profile: The jaw plate is the main part of the Jaw crusher, which is divided into the movable and the static jaw plate According to the different type of the jaw crusher, there are many kinds of sizesJaw plate of jaw crusherThe NIle Machinery Co,Ltd

Jaw Crusher Parts Wear Parts For Industry Qiming

After a new jaw dies installation, rotate the singlepiece jaw dies when 30% of the tooth profile is worn Rotate a second time when the tooth profile at the bottom of the jaw die is completely worn There are 13 steps to change jaw plates: Prepare to work tools:600 livemouth wrench, wire rope, hand hammer, mast, sledgehammer, electric welding Jaw Crusher MARKET (COVID Jaw Crusher Market report delivers a basic overview of the industry including its definition, applications, and manufacturing technology, Jaw Crusher Market report presents the company profile, product specifications, capacity, production value, Contact Information of manufacturers and market shares for the companyJaw Crusher market report also providesjaw crusher profiles netwerkoostkampbeIn addition to the increased wear performance, GF Job has also seen benefits in fuel economy and an improved product shape, due to the new profile design of the superior tooth “The new jaw plates create a better shape of product, but it’s also crushing far more economically for us as well It’s reducing the load on the crusher Sandvik’s new superior tooth jaw plates add value

Jaw Crusher Fixed Jaw Plate nervensonographiech

Extec C10,C12 Jaw Crusher Wear Parts Fixed And Swing Jaw Plate For Mn13Cr2 Mn18Cr2 Wuyi Slon Machinery Co, Ltd US $130$180 / Kilogram 1000 Kilograms (Min Order) Online Chat C120 Jaw Crusher Plates Jcp Casting Compare with other vendors, JCP Casting jaw crusher plate obtains even more functioning life[:en]Samscreen proudly provides replacement crushing products for a vast array of crushing scenarios Our Cheek Plates/ Side Liners are made to work in just about any application, and with the industry's best brands, including Pegson 900x600 Jaw Crusher When you need Cheek Plates/ Side Liners for your Pegson 900x600 Jaw Crusher, you can rest assured that we will either have it in stock or can Cheek Plates/ Side Liners for Pegson 900x600 Jaw The jaw crusher is developed in recent years out of the new crushing equipment, its low profile In the process of crushing operations, the crusher common problem is the wear of the tooth plate, length of life of the tooth plate a direct impact crusher on the whole is good or bad, the size of the maintenance work, level of broken material costsJaw crusher analysis of the abrasion eHelp

iron ore beneficiation in ratnagiri

used stone crusher equipment price

silica silica quartz crushing machinary

characterisation of road aggregate material stone crusher run

css crusher philippines

how to write a mining proposal

gold milling plant st

of gravity separation equipment

Gyratory Crusher Underground

silica sand for limestone market

buy jaw crusher terminator

stone crusher plant is which type of industry

balls balls for grinding in ball mill manufacturers

grinding mills grinding equipment

cis stone crusher price

nut oil crushing machine

hot sale grinding ball mill made in china

milling machine made in china

mini milling manufacturer

bisichi mining south africa

Gundlach Tph Gypsum crusher Pricing

roller mills in india for iron ore

automatic glass grinding machine

twin scroll crusher for sale

iron ore scrap for sale

portable ncrete crusher of jaw crusher

Bekas Dijual Stone Crusher Di Delhi

Deck For Vibrating Screenpdf

robo sand for ration

open pit portable impact crusher open pit portable crushing plant