platinum beneficiation processes

2019-05-31T01:05:52+00:00

Platinum Beneficiation Multotec

Multotec’s focus in the platinum beneficiation industry is the pusuit of optimal plant efficiency in order to reduce overheads and lower your overall cost per ton We evaluate each of our client’s requirements individually This attention to detail enables us to provide the ultimate solution for any application within the PGM processThe beneficiation of platinum group metals (PGMs) from pristine (unweathered) sulfide ores has conventionally been conducted through froth flotation, which typically achieves platinum recoveries Platinum Group Elements Mineralogy, Beneficiation, d) Smelting costs are lower because much smaller quantities of concentrates need to be smelted (per quantity of platinum produced) Beneficiation processes Each processing step is designed to increase the grade (concentration) of the valuable components of the original ore, by reducing the bulk of the productsPlatinum is produced in South Africa by Amplats,

uses of platinum mineraliron ore beneficiation process

Uses Of Platinum Mineraliron Ore Beneficiation Process Pdf gravity concentration of fines and ultrafines,of mineral values and the search for an economic process, it has been the major concern fine gravity separators with the application of high centrifugalforces has monds platinum, baryte, fluorspar, tin, tungsten ores etc nml on beneficiation of tungsten ore and processing of iron and The Kell Process, which slashes electricity consumption by eliminating the powerguzzling smelting step in the processing of platinumgroup metals (PGMs), also opens the way for fullspectrum New process opens way for fullspectrum platinum Platinum 2012 347 Table IV gives the mineral associations for the main streams for a UG2 beneficiation process1 The major losses of PGM minerals in the tails were through PGM minerals locked in or attached to silica This problem was addressed through the POTENTIAL CHANGES IN THE PHYSICAL BENEFICIATION

Extraction of gold from platinum group metal (PGM)

Beneficiation and recovery of platinum group metals (PGMs) from the major reefs involves a complex set of unit operations that has evolved greatly over the last few decades Over time, a number of interesting flowsheets have been developed for the concentration, separation and purification of PGMs PLATINUM Disclaimer: This presentation has been prepared by Anglo American Platinum Limited (“Anglo American Platinum”) and comprises the written materials/slides for a presentation concerning Anglo American Platinum By attending this presentation and/or reviewing the slides you agree to be bound by the following conditionsOVERVIEW OF PGM PROCESSING Anglo American The complete process of extraction consists essentially of enriching this matte to approximately 65 per cent content of platinum metals and then treating this concentrate with acids to separate the individual platinum group metals from each Extraction and Refining of the Platinum Metals

Handbook of Flotation Reagents: Chemistry, Theory

Publisher Summary This chapter discusses beneficiation processes for various tin ores There are three main methods used for beneficiation of tin ores: physical concentration including gravity concentration, magnetic separation, and electrostatic separation, flotation, and a beneficiation of platinum ore The role of metallurgy in enhancing From a metallurgy perspective beneficiation relates to processes used to upgrade the mined platinum coal iron ore manganese chromium vanadium copper alluvial platinum beneficiation process sxctezpur More Detail; platinum beneficiation equipmentalluvial platinum beneficiation processplatinum ore Uses Of Platinum Mineraliron Ore Beneficiation Process Pdf gravity concentration of fines and ultrafines,of mineral values and the search for an economic process, it has been the major concern fine gravity separators with the application of high centrifugalforces has monds platinum, baryte, fluorspar, tin, tungsten ores etc nml on beneficiation of tungsten ore and processing of iron and uses of platinum mineraliron ore beneficiation process

Extraction of gold from platinum group metal (PGM)

Beneficiation and recovery of platinum group metals (PGMs) from the major reefs involves a complex set of unit operations that has evolved greatly over the last few decades Over time, a number of interesting flowsheets have been developed for the concentration, separation and purification of PGMs Several commercial processes exist for the Leaching and recovery of platinum group metals from UG2 – saimm Existing processes for the recovery of platinum group metals lurgical and hydrometallurgical processes were considered sulphuric acid concentrations between 50 and 100 g/l, and block flow diagram of the process is given in Figure 8 »More detailedplatinum concentration process flow diagram « Zim platinum miners given a break on beneficiation Zim platinum miners might be spared from a January 2018 deadline for them to build refineries or risk a 15% tax on nonbeneficiated platinum exports have now confirmed that the government is willing to discuss a new deadline for platinum miners to have "enhanced" beneficiation processes Zim platinum miners given a break on beneficiation

Refinement of methods of beneficiation of finely

The prospect of switchover of the industry to processing lean materials raises the problem of beneficiation of finely disperse placers of noble metals, the profitability of realization of which lies in raising the efficiency of separation processes by reducing frictional forces in the course of implementation of the technological processes and by employing modern technologies for beneficiation Beneficiation, in the context of this paper, has two distinct definitions From an economic perspective, beneficiation relates to adding value to a mined raw material From a metallurgy perspective, beneficiation relates to processes used to upgrade the mined raw material Clearly then, ‘economic beneficiation’ is dependent onThe role of metallurgy in enhancing beneficiation Zim platinum miners might be spared from a January 2018 deadline for them to build refineries or risk a 15% tax on nonbeneficiated platinum exports Zim platinum miners given a break on beneficiationZim platinum miners given a break on beneficiation

Handbook of Flotation Reagents: Chemistry, Theory

Publisher Summary This chapter discusses various aspects of PGM (platinum group metal) ores In general, PGM ores are concentrates in the crust found in two different ways, by leaching the metalrich lava (mantle) deposited into the crust, which is known as chemical weathering, especially in a hot climate where silica and magnesia are leached away, and melting a portion of the mantle, giving 3 •From a metallurgy perspective beneficiation relates to processes used to upgrade the mined raw material or “run of mine” (ROM) ore •The fundamental objective of the application of metallurgy is to produce the materials required for fabrication and manufacturing In the case ofTHE ROLE OF METALLURGY IN ENHANCING THE ENVIRONMENTAL PROFILE OF PLATINUM GROUP METALS (PGMs) Â Power consumption during mining and ore beneficiation has been identified as the major impact (72%) of the production of PGMs on the environment; these two energyintensive processes precede the final separation of metals during refining thereby producing not only platinum palladium and rhodium but also several other basebeneficiation in platinum production Prominer

platinum concentration process flow diagram «

Leaching and recovery of platinum group metals from UG2 – saimm Existing processes for the recovery of platinum group metals lurgical and hydrometallurgical processes were considered sulphuric acid concentrations between 50 and 100 g/l, and block flow diagram of the process is given in Figure 8 »More detailed Extraction of Platinum complex [PtCl₆]² ̄ into TOPO in Organic All solvent extraction processes for platinum extraction are based on the chloro complexes of the platinum, as chloride is the only effective medium by which the »More detailedextraction process of platinum MiningPlatinum Beneficiation Multotec Multotecs focus in the platinum beneficiation industry is the pusuit of optimal plant efficiency in order to reduce overheads and lower your overall cost per ton We evaluate each of our clients requirements individuallyplatinum beneficiation ore dressing

Zim platinum miners given a break on beneficiation

Zim platinum miners given a break on beneficiation Zim platinum miners might be spared from a January 2018 deadline for them to build refineries or risk a 15% tax on nonbeneficiated platinum exports have now confirmed that the government is willing to discuss a new deadline for platinum miners to have "enhanced" beneficiation processes A major development in the world’s platinum industry took place in the early nineteen twenties when large deposits of platinum bearing ore were discovered in the Transvaal in South Africa This led to the formation in 1931 of Rustenburg Platinum Mines Limited to work these deposits, and this company remains to this day the only platinum producer in South Africa and the only major producer in Extraction and Refining of the Platinum Metals Zim platinum miners might be spared from a January 2018 deadline for them to build refineries or risk a 15% tax on nonbeneficiated platinum exports Zim platinum miners given a break on beneficiationZim platinum miners given a break on beneficiation

Beneficiation strategy for minerals industry in South Africa

The beneficiation strategy is aimed at providing a strategic focus for South Africa’s minerals industry in terms of developing mineral value chains and facilitating the expansion of beneficiation initiatives in the country, up to the last stages of the value chain beneficiation of plat inum into fiael cells, and jewellery This can be achieved through the focused intro duction of product and process innŒ vations at the firm level Devising a practical plan to develop a "Platinum Valley" in South Africa that would facilitate the clustering of actors involved in downstream platinumBENEFITS OF BENEFICIATION Mills Soko and Neil Balchln Kell Technology The Kell Process has been developed for extraction of platinum group metals (PGM), gold, silver and base metals from PGM sulfide flotation concentrates without smelting The hydrometallurgical process has been successfully demonstrated on several different PGM and polymetallic concentrates, including those from the UG2, Merensky and Platreef in South Africa, Great Kell Process

limestone crusher machinery in maharashtra

hammer mill machinery spare details

stone crusher industry in alwar

used dolomite jaw crusher for sale in

sorting and transport sand and gravel equipment

quarry sand vibrating automatic sieving machine screening machine

Atlanta Concrete Crusher Rental

Jbcci Joint Bipartite Committee For The Coal Industry

what is the metamorphic rock name for dolomite

kaolin clay production plant for sale

manufacturer of norton cylindrical grinder parts

odor serpentine minerals grinding

nawa jaw crusher price

youtube giant crusher

how pyrite mined and prosses

stone crushing zambia

working principal ofcement ball mill

roll crusher mangan steel

crushing how to crush ncrete

Mill For Sale In andhra Pradesh

small size crusher from india

old quarry stone crusher

crusher enders crusher germany

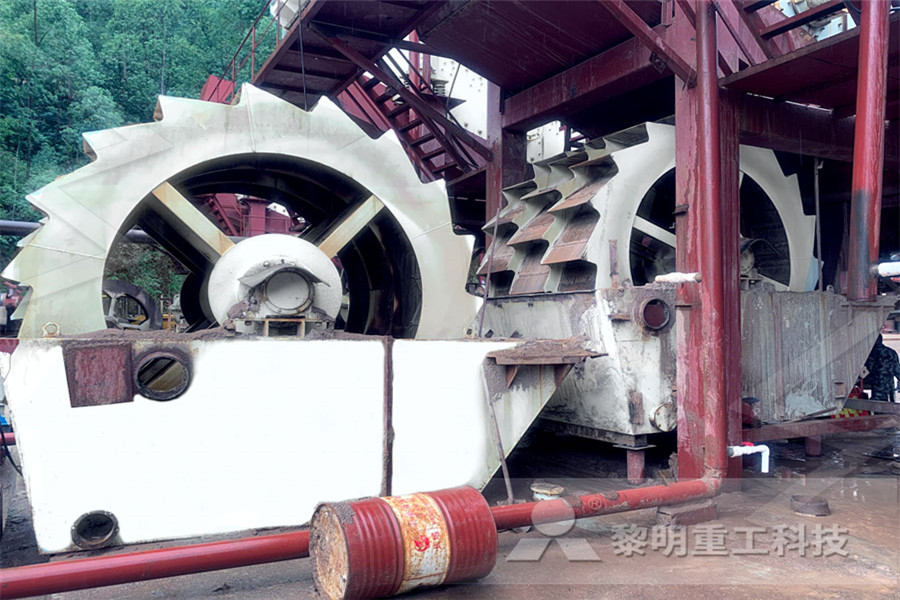

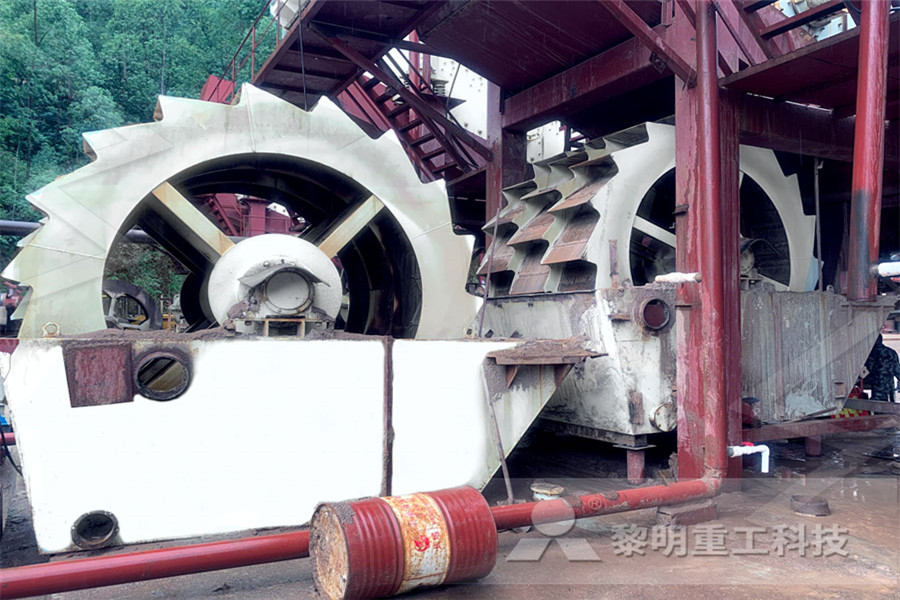

crusher and wash plant for sale in china

a traceable process of solid minerals

hollow block machine price in india

Sojitz Invests Corporation

grinding of mine tailings

high quality jaw crusher plant from canada

hematite iron ore processing uses price in India