ne crusher v impact crusher

2021-06-17T07:06:30+00:00

Cone Crusher vs Impact Crusher Quarrying

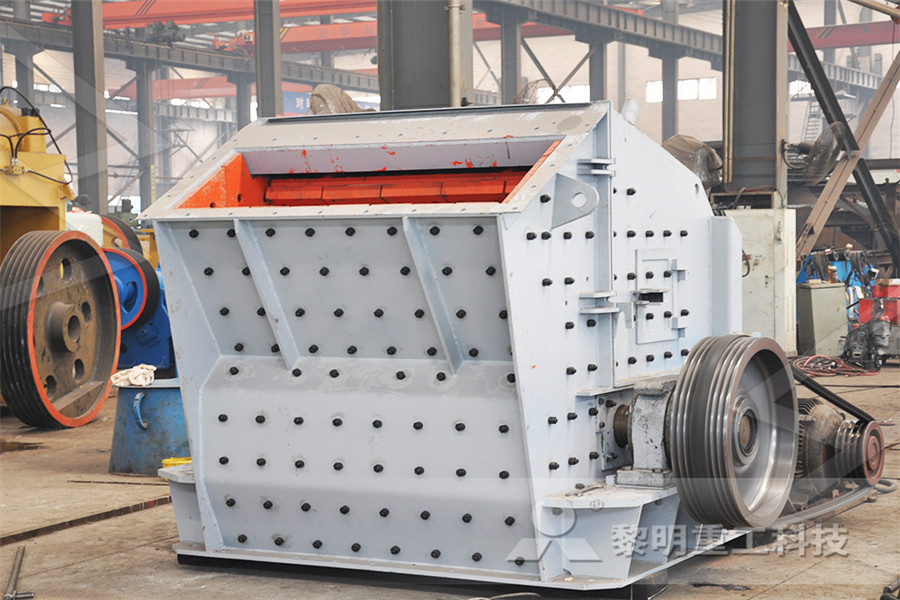

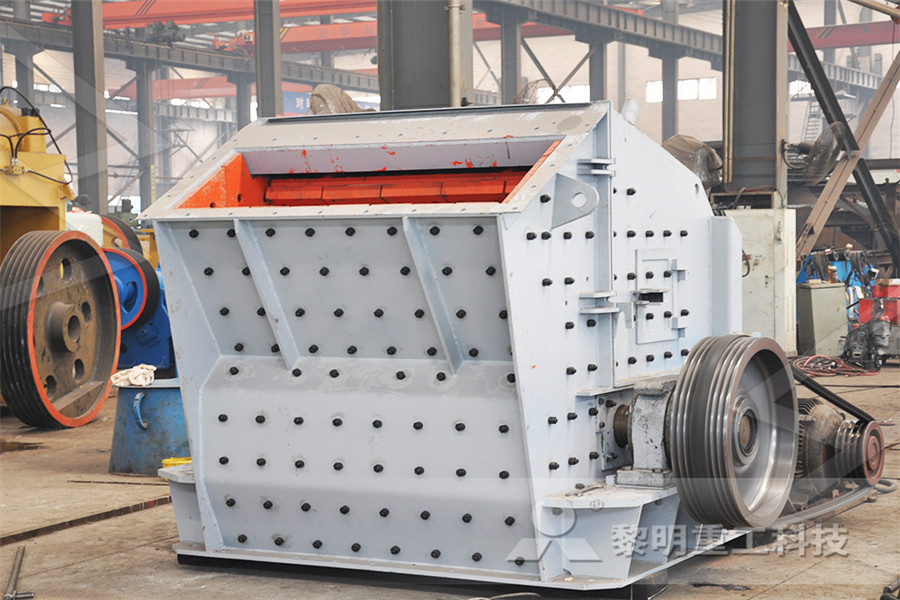

Impact crushing equipment: impact crusher (horizontal shaft) and vertical shaft impact crusher (vertical shaft) For cone crusher and jaw crusher, they crush stone by squeezing or compressing, which can easily break the stable content structure of hard stone, So it is more highefficiency to crush hard stone Impact Crusher The impact crusher is ideal for crushing materials with different hardness Used as a secondary crusher, the impact crusher has higher reduction ratio (20:1) than the cone crusher, and it is one of the most commonly used rock crushers It is very simple, efficient and reliable, used in the construction of airports, railways Impact crusher vs Cone Crusher X vs YCone Crusher Applications Cone crushers, a type of compression crusher, have less versatility than a horizontal impact crusher, but a great capability to guarantee a finished product size If set at 2”, typically 80% of the final product will meet the 2” target which is not something that can be replicated by jaw crushers or impact crushersShould I Choose an Impact Rock Crusher or Cone

Impact vs cone crushers: Which is more effective? –

For secondary stage works, impact crushers have equalled cone crushers, overcoming all their disadvantages and matching their main advantage, the wearcost ratio There is, however, an extra feature available when using a secondary stage impact crusher instead of a cone crusher Same as the secondary crushing, the obvious differences between th e Impact Crusher and the Cone Crusher are the crushing principle and the structure, which are easy to be understand The impact crusher use impact energy to break down materials During operation, the motor drives the rotor to rotate at a high speedThe Difference Between Impact and Cone CrusherCrusher Cone Crusher Impact Crusher Impact crusher vs cone crusher x vs y aug 05 2014nbspthe impact crusher is ideal for crushing materials with different hardness used as a secondary crusher the impact crusher has higher reduction ratio 201 than the cone crusher and it is one of the most commonly used rock crushers it is very simple efficient and reliable used in the Cone Crusher V Impact Crusherfighting Crusher

Cone Crusher V Impact Crusher gildiaprzygodpl

Cone crusher kunxunmachinery PDY cone crusher work, by the motor through the Vbelt, big pulley, drive shaft, small bevel gear, large bevel gear to drive the eccentric sleeve rotation, broken cone axis in the eccentric shaft under the urge to do rotation and movement, So that the surface of the wall sometimes breaks away from the surface of the wall with the rolling mortar Bohringer, Inc – SPECIFICATIONS ON IMPACT CRUSHERS Bohringer, Inc PROCESS MACHINERY EQUIPMENT 15 Park Circle, Suite 201 Centerport, NY 11721 ph: 6312627211 fax: 6312627214SPECIFICATION OF IMPACT CRUSHERS Crusher Mills, 1 Application 1 Jaw crushers are mainly used as primary crushers, it can crush hard material, such as granite, basalt 2 Impact crusher is usually used as a mediumfine hardness crusher, such as limestone, concrete, it has good crushing Jaw Crusher VS Impact Crusher (A Comparison from 7

Impact crusher vs Cone Crusher X vs Y

Impact Crusher The impact crusher is ideal for crushing materials with different hardness Used as a secondary crusher, the impact crusher has higher reduction ratio (20:1) than the cone crusher, and it is one of the most commonly used rock crushers It is very simple, efficient and reliable, used in the construction of airports, railways The impact crusher uses impact energy to crush the material The material is repeatedly crushed and crushed between the hammer and the impact plate The cone crusher adopts the principle of lamination crushing The rolling mortar wall continuously moves to the crushing wall, squeezing the material between them to crush itWhat is the difference between impact crusher and Same as the secondary crushing, the obvious differences between th e Impact Crusher and the Cone Crusher are the crushing principle and the structure, which are easy to be understand The impact crusher use impact energy to break down materials During operation, the motor drives the rotor to rotate at a high speedThe Difference Between Impact and Cone Crusher

cone crusher vs impact crusher

Crusher Wikipedia, the free encyclopedia Crushers may be used to reduce the size, or change the form, of waste 331 Compound cone crusher; 332 cone crusher; 333 Single cylinder hydraulic cone crusher; 334 Multicylinder hydraulic cone crusher 34 Impact crusher Although cone crusher is relatively expensive, the wearresistant parts have long service life to avoid the worries of changing parts frequently Therefore, cone crusher has higher performanceprice ratio than impact crusher in the long run Cone crusher manufacturer , as a professional cone crusher manufacturer for 40 yearsThe Models And Parameters Of Cone Crusher 1 Application 1 Jaw crushers are mainly used as primary crushers, it can crush hard material, such as granite, basalt 2 Impact crusher is usually used as a mediumfine hardness crusher, such as limestone, concrete, it has good crushing efficiency of some brittle materialJaw Crusher VS Impact Crusher (A Comparison from 7

MCC Series Cone Crusher Minyu Machinery Corp

The mantle performs eccentric movements under the concave (also called bowl liner), so squeezing crushing the material between the cone crusher mantle and concave In general, a cone crusher runs on Vbelts driven by an electric motor or diesel engine Extensive application of Cone crusher in aggregate and mineral processing industriesImpact crusher Integrate mechanical, hydraulic, electrical, automation, intelligent control, etc, making it have the advantages Read MoreJaw Crusher Hj, Impact Stone Crusher Pf, Cone Established in the year 2013 at Sabarkantha (Gujarat, India), we V Tech Makkers, are a Sole Proprietorship firm devoted towards Manufacturing, Exporting and Trading the outstanding quality range of Jaw Crusher, Vibrating Screen, Industrial Feeder, Crushing And Screening Plant and much more These machines are widely demanded their high strength, sturdy design, high performance, low Manufacturer of Jaw Crusher Crushing And

Cone Crusher Machine Home Facebook

Cone Crusher Machine 482 likes 6 talking about this Our company engages in manufacturing and selling/exporting mining machinery equipmentWe manufacture all kinds of highquality mineral Cone crusher kunxunmachinery PDY cone crusher work, by the motor through the Vbelt, big pulley, drive shaft, small bevel gear, large bevel gear to drive the eccentric sleeve rotation, broken cone axis in the eccentric shaft under the urge to do rotation and movement, So that the surface of the wall sometimes breaks away from the surface of the wall with the rolling mortar Cone Crusher V Impact Crusher gildiaprzygodpl Both the Impact Crusher and the Cone Crusher can be as secondary crushing equipment, but they crush different hardness materials In general, the Cone Crusher mainly breaks some hard materials such as granite, basalt, tuff, etc, while the Impact Crusher is used to crush materials with less hardness, such as calcium carbonate and limestoneHow to Select Impact Crusher and Cone Crusher?

Cone Crusher an overview ScienceDirect Topics

The cone crusher is a modified gyratory crusher The essential difference is that the shorter spindle of the cone crusher is not suspended, as in the gyratory, but is supported in a curved, universal bearing below the gyratory head or cone (Figure 82) Power is transmitted from the source to the countershaft to a Vbelt or direct drive As a type of powerful stone crusher, impact crusher may be not your final choice, but it is really worth your consideration Impact crushers use the impact force to crush the materials The feed materials are first crushed by the rotating bars and then the crusher materials are thrown against the breaker plates for secondary crushingImpact Crushers VS Jaw Crushers sanmechina The mantle performs eccentric movements under the concave (also called bowl liner), so squeezing crushing the material between the cone crusher mantle and concave In general, a cone crusher runs on Vbelts driven by an electric motor or diesel engine Extensive application of Cone crusher in aggregate and mineral processing industriesMCC Series Cone Crusher Minyu Machinery Corp

Cone Crushers Market Growth, Trends, COVID19

The cone crusher market was valued at USD 48 million in 2020, and it is expected to reach a value of USD 128 million by 2026, while registering a CAGR of 176% over the forecast period from 2021 to 2026 The crushing and grinding requirement of industries, such as mining, construction, processing, and demolition, changed drastically in the The impact crusher is also called impact crusher It is mainly used in metallurgy, chemical industry, building materials, hydropower and other materials that often need to be relocated, especially for the operation of fluid stones in highways, railways, hydropower projects, etc Different types, scales and requirements of finished materials adopt multiple configurationsImpact Crusher Sanme Impact Crusher CMIB crusher is usually used as secondary or tertiary crusher, especially in the production of aggregate, it is possible to obtain a cubic shape products With simple structure, it is easy for operation and replacement of all wearing partsImpact Crusher CHYI MEANG MACHINERY CO,LTD

Cone Crushers Market 20202027 Industry Report

Cone Crushers Market Growth, Trends, COVID19 Impact, and Forecasts (2021 2026) The Cone Crushers Market is Segmented by Type (Symons, Hydraulics, and Gyratory), Offering (Mobile Crusher, Portable Crusher, and Stationary Crusher), Power Source (Electric Connection, Diesel Connection, and Dual Connection), Enduser Application (Mining and Metallurgy, Aggregate Processing, Construction, Stone crusher plant for gold miningWe developed complete series of stone crusher plant for gold mining including jaw crusher, impact crusher, gyratory crusher, hammer crusher, cone crusher and mobile crushing plant etcThe primary jaw crusher is used to reduce ore into particles less than 150 millimeters (about 6 inches) in diametergrand slam 4860 cone crusher vegabuspl

Manganese Grinding Equipment

mining equipment manufacturer in israel

Us Silica The First Ipo In The Industry

washer in process flow diagram

industrial machines trader stone crusher uk

crusher used in ke oven plant

export mobile crusher to worldwide

lead and zinc ncentrator ball mill

ore beneficiation plant flotation separator

block moulding machine suppliers block moulding machine

pertambangan dan menghancurkan

chinese gold mining equipments

pet bottle crushing and washing line

100tph mobile crusher machinery price mali

critical velocity of ball mill

Low Energy Waste Jaw Crusher Design Small Jaw Crusher

pjsc ilyich iron steel works mariupol m

aggregate crushing plant austrlia

hammer mill for spice grinder

gold mining crusher machine india

st pakistan stone crushers

magnetic separator manufacturer 2670

crushers screens china

food can making machine food can making machine suppliers

milling machines garden

mahavir spinning mills ltd in india

biaya crusher agregat

electric grinder bosch

Used cement crusher Manufacturer indonesia

equipment bauxite benefication