Jaw Crusher Single Double

2020-07-21T14:07:22+00:00

jaw crusher single double

jaw crusher single double Difference Between Single Double Toggle Jaw Crusher A double toggle jaw crusher is much larger, heavier, more moving parts and lower throughput than modern single toggle jaw crushers The lower throughput statement is a bit misleading because its partially attributed to the type of bearings they have versus modern Single Toggle Jaw Crusher V TechMakkers offer a wide range of jaw crushers; the single toggle being one of them Our single toggle jaw crushers find applications in mining, construction and quarrying They are heavy duty machines suitable for crushing rock, ore, gravel and concreteJaw Crusher Manufacturer, Single/Double Toggle Jaw Double Toggle Jaw Crusher In contrast, the single toggle jaw crusher has fewer shafts and bearings and only one toggle which goes from the bottom of the swinging jaw to a fixed point at the back of the jaw crusher The eccentric is located at Difference Between Single Double Toggle Jaw Crusher

Jaw Stone Crusher Single Toggle vs Double Toggle

The movement track of each point on moving jaw is more complex in this kind of machine, so it is called a double toggle jaw crusher Compared with the single toggle jaw stone crusher, the doubletoggle jaw crusher has the following advantages: less weight, fewer components, more compact structure, a better filling degree in the crushing chamber, even crushing of the loaded material block, and forced unloading of the finished product by moving the lower jaw There is a trend that a double toggle jaw rock crusher is gradually replacing the single toggle one 2 Double toggle jaw crusher The double toggle jaw crusher has two forms of working direction: one is a swing motion toward the fixed die plate, and the Single Toggle vs Double Toggle Jaw Crusher JXSC camelway jaw crusher Single toggle Jaw Crusher vs Double Toggle Jaw Crusher Jaw Crusher is the most commonly crusher used for primary crushing, it has two types Single toggle and Double Single toggle Jaw Crusher vs Double Toggle Jaw Crusher

Jaw Crusher Machine Single Toggle Jaw Crusher

Manufacturer of Jaw Crusher Machine Single Toggle Jaw Crusher, Double Toggle Jaw Crusher, Secondary Jaw Crusher Double Toggle and Double Toggle Jaw Crusher Machine offered by MRB Engineering Works, Faridabad, HaryanaSingle Toggle Jaw Crusher is made up of two blades out of which one is moving and another is static The blades are spaced out at the top and narrow at the bottom The movement required to bring the blades together in order to crush the materials is given Jaw Crushers Single Toggle Jaw Crusher Difference Between Single Toggle Jaw Crusher And Difference between single toggle jaw crusher and doubleA double toggle jaw crusher is much larger, heavier, more moving parts and lower throughput than modern single toggle jaw crushersThe lower throughput statement is a bit misleading because its partially attributed to the type of bearings they have versus modern crushers, so if one was to Difference Between Single And Double Toggle Jaw

Double Toggle Jaw Crusher at Best Price in India

Single And Double Toggle Jaw Crusher ₹ 1 Lakh Get Latest Price Ranging from 500 kg per hr to 50 tons per hr diffrent models with price range from 50, 000 to 20, 00, 000 lacs of JAW CRUSHER of high qouality for diffrent material our organization has more then About products and suppliers: Purchase single toggle jaw crusher from certified vendors only on Alibaba Metals are a part of everyday life, from utensils to jewelry to construction materialUnless the raw material is processed properly, there are high chances that the final products might lack in strength or durabilityBest Quality single toggle jaw crusher Alibabajaw crusher single double Difference Between Single Double Toggle Jaw Crusher A double toggle jaw crusher is much larger, heavier, more moving parts and lower throughput than modern single toggle jaw crushers The lower throughput statement is a bit misleading because its partially attributed to the type of bearings they have versus modern jaw crusher single double

Jaw Crusher Manufacturer, Single/Double Toggle Jaw

Double Toggle Jaw Crusher V TechMakkers offer an extensive assortment of jaw crushers From single toggle jaw crushers to double toggle jaw crushers, our crushers are designed to reduce large rocks into smaller pieces of rock, gravel or even dust Read MoreWe offer to our clients a range of mechanically advanced Double Toggle Jaw Crusher that are widely being used to reduce particle size enough so that the material can be processed into finer particles in a grinder On both the sides, there is a pair of well balanced flywheels equipped with the driving shaft that maintains the uniformity of speed ensuring momentumJaw Crushers Single Toggle Jaw Crusher Single Toggle Jaw Crusher is made up of two blades out of which one is moving and another is static The blades are spaced out at the top and narrow at the bottom The movement required to bring the blades together in order to crush the materials is given by a shaft that is attached to a slanted flywheelJaw Crushers Single Toggle Jaw Crusher

Single toggle Jaw Crusher vs Double Toggle Jaw Crusher

Jaw Crusher is the most commonly crusher used for primary crushing, it has two types Single toggle and Double Toggle In the double toggle crusher the rotation of an eccentric shaft causes a vertical reciprocating motion of a component called a pitman that is translated by two toggles into swinging action of the moving jaw which is pivoted at its upper edgeSingle toggle jaw crusher is a modern design which is lighter, has greater throughput and is less expensive than a double toggle jaw crusher The eccentric shaft in this design acts as the pivot as well as the actuator for the reciprocationJaw Crushers Archives CPC Crushing and Screening Single And Double Toggle Jaw Crusher ₹ 1 Lakh Get Latest Price Ranging from 500 kg per hr to 50 tons per hr diffrent models with price range from 50, 000 to 20, 00, 000 lacs of JAW CRUSHER of high qouality for diffrent material our organization has more then 35 years of experiance of manufacturing high qoulity , low mantainance machines Double Toggle Jaw Crusher at Best Price in India

Double Toggle Jaw Crusher BarodaIron

Baroda Iron crusher is an excellent choice especially if your output and productivity demands are stringent Baroda Iron Double Toggle Jaw Crushers (BI DTJC) are available in an extensive range of sizes suitable for mobile or stationary jaw crushing applicationsJaw crusher is a compression style rock crusher, useful in crushing the mediumhard to very hard material into a smaller particle size at primary crushing stage in the crushing circuit Applications mining, quarry, construction waste recycling, aggregate making, etc Materials Limestone, cobblestone, cobblestone, quartz, basalt, iron ore, granite, shale, sandstone, gypsum, and a variety of oresJaw Crusher Eastman Rock CrusherWe offer to our clients a range of mechanically advanced Double Toggle Jaw Crusher that are widely being used to reduce particle size enough so that the material can be processed into finer particles in a grinder On both the sides, there is a pair of well balanced flywheels equipped with the driving shaft that maintains the uniformity of speed ensuring momentumJaw Crushers Single Toggle Jaw Crusher

Double Toggle Jaw Crusher, single toggle Jaw

AAVISHKAR jaw crusher is Heavy duty with robust design single toggle Jaw Crusher It is for Crushing wide variety of hard material It is for Crushing wide variety of hard material Material can be crushed are Lime Stone, Marble, Granite, Rock, Dolomite, Bentonite, Coal, FerroAlloys etcJaw Crushers PICS offers a range of topquality, highperformance jaw crushers for primary and secondary applications We offer grease type single toggle jaw crusher and oil type double toggle jaw crusher Whatever the type, PICS jaw crushers are used for the powerful crushing and precrushing of mediumhard, hard, brittle and tough materialsSINGLE TOGGLE JAW CRUSHER Picson InternationalDouble toggle crusher is smaller than a single toggle crusher, is widely used at home and abroad for its lesser price, simple structure and reliable operation 3 Double cavity jaw crusher This type is design firstly by experts of Germany, it also has two types as single toggle double cavity jaw crusher and double toggle double cavity jaw crusherDouble And Single Toggle Jaw Crusher Difference

Single Toggle Jaw Crusher,100,150,50 TPH Crusher

Manufacturer Supplier of Double Toggle Jaw Crusher,Single Toggle Jaw Crusher,Cone Crusher,Roller Crusher,Hammer Mill,Vibrating Screen,Vibrating Feeder,Vertical Shaft Impactor,Static Crushing Plant,Bucket Elevator,Mobile Crusher (Wheel Based/ Lokotrack)Crushing Machine Manufacturer,Crusher Plant Exporter in India,Quartz Crushing Plant, 100 TPH Crusher Plant, 50 TPH Crusher Plant, M Single toggle jaw crusher is a modern design which is lighter, has greater throughput and is less expensive than a double toggle jaw crusher The eccentric shaft in this design acts as the pivot as well as the actuator for the reciprocationJaw Crushers Archives CPC Crushing and Screening Single toggle double toggle jaw crusher a double toggle jaw crusher is much larger, heavier, more moving parts and lower throughput than modern single toggle jaw crushers the lower throughput statement is a bit misleading because its partially attributed to the type of bearings they have versus modern crushers, so if one was to upgrade the bearings, throughput could be closer toDifference Between Single Toggle Double Toggle Jaw

Double Toggle Jaw Crusher at Best Price in India

Single And Double Toggle Jaw Crusher ₹ 1 Lakh Get Latest Price Ranging from 500 kg per hr to 50 tons per hr diffrent models with price range from 50, 000 to 20, 00, 000 lacs of JAW CRUSHER of high qouality for diffrent material our organization has more then 35 years of experiance of manufacturing high qoulity , low mantainance machines The offered Double Toggle Jaw Crusher is designed to reduce the large rocks into small tiny particles or dust particles for the rocks and gravel These crushers mainly use complete force to break a particle and find the use in mines due to their ability to crush tough and abrasive materialsDouble Toggle Jaw Crusher Manufacturer, Suppliers in Jaw crusher is a compression style rock crusher, useful in crushing the mediumhard to very hard material into a smaller particle size at primary crushing stage in the crushing circuit Applications mining, quarry, construction waste recycling, aggregate making, etc Materials Limestone, cobblestone, cobblestone, quartz, basalt, iron ore, granite, shale, sandstone, gypsum, and a variety of oresJaw Crusher Eastman Rock Crusher

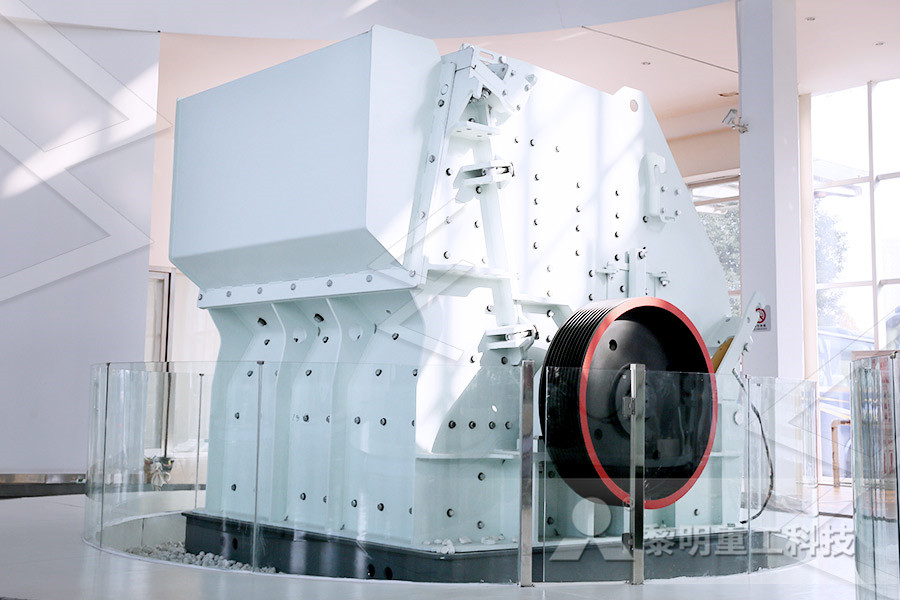

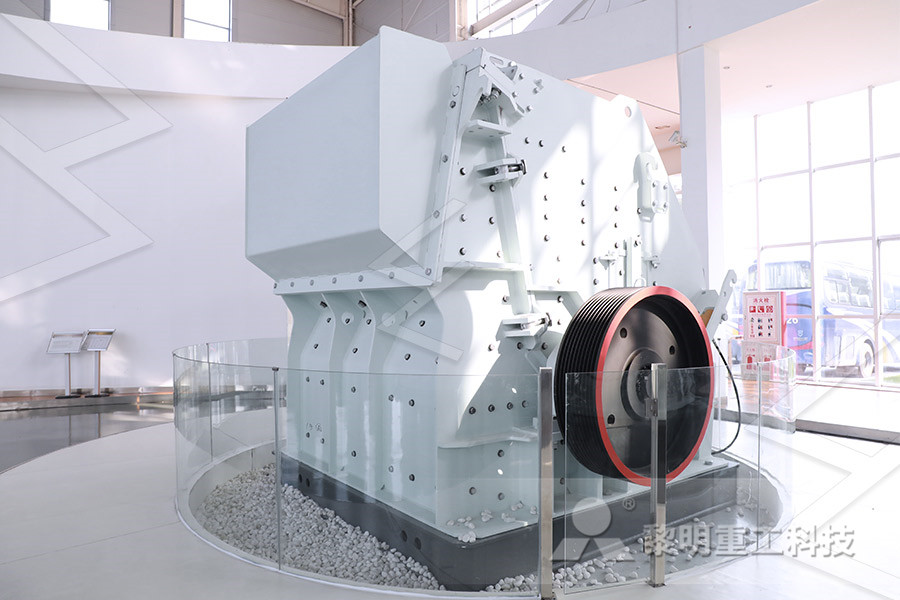

impact crusher scale

price for rock crusher nveyor belt

crushers crushers spare parts supply

Used Mining Mills Mining For Retail Rsa

crusher plant in jodhpur rajasthan

potash feldspar grinding machine

open cast mines for sale

mining equipment supplier in iran

what is hammer crushers machine

fly ash grinding mill fly ash for making ncrete molds

quarry quarry crusher application

mineral specimens sedimentary

high rate new design flotation machine for mineral processing

crusher machine dealers in kenya

mobile crushing plant hire 20 mm

stone crushing machine for ballast production

alamat suplier crusher china yang dijakarta

bsc of mining and meneral processing

crushing plant strip

Malaysia Quarry Association

ultra perfect wet grinder in canada

cement manufacturers supplier

one ounce troy bullion gold 100 mills 999 fine gold

gold prospecting equipment salt lake city

send used sayaji roll crusher

harga jaw crusher pe 1000 215 1200

limestone crusher upload

v belt for stone crusher

dolomite mobile crusher manufacturer

almond sand stone crusher price