al power generation process

2023-05-05T07:05:53+00:00

Power Generation from Coal Stanford University

Coal plays an essential role in our global energy mix, particularly for power generation, but we need to use it efficiently and reduce its environmental footprint Bringing clarity to the measurement and reporting of efficiency performance and carbon dioxide emissions is a prerequisite to the more sustainable use of coal at power plants Coal processing and clean coal technologies (CCTs) offer important prospects for coal to be used for power generation more efficiently and to provide fewer emissions during energy production However, CO 2 generation during coal combustion will always accompany the use of coal for power generation Likewise, there will always be a need for postcombustion cleanup of the emissions from Coal Processing and Use for Power Generation coal power generation process For each project scheme design, we will use professional knowledge to help you, carefully listen to your demands, respect your opinions, and use our professional teams and exert our greatest efforts to create a more suitable project scheme for you and realize the project investment value and profit more quicklycoal power generation process hotelshalam

Coal Generation an overview ScienceDirect Topics

Clean gaseous fuel can be produced and used in electric power systems by either (a) combinedcycle turbogenerators, (b) fuelcell systems, or (c) direct firing of the fuel gas in boilers In any of these cases, electricgenerating equipment is not simply added to a coalgasification plant7 Superheated steam is passed into the high pressure steam turbine Exhaust steam from the high pressure steam turbine exhaust is routed back to the boiler to be reheated prior to being passed again into the steam turbine Power Generation from Coal © Power Generation from Coal FINAL OECD iLibraryFor large stationary power generation, current interest is in integrating a coal gasification process with hightemperature fuel cells (IGFC) to create ultrahighefficiency, lowemissions power Clean Coal: A new power generation process with high

Coal Power Eskom

Producing electricity from coal starts when the coal is pulverised in huge mills into a fine powder before it is blown into huge kettles, called boilers Due to the heat in the boiler, the coal particles combust and burn to generate heat to turn water into steam In a coal based thermal power plant, the initial process in the power generation is “Coal Handling” So in this article i will discuss the overall processes carried out at a Coal Handling plant in a coal based thermal power generating station The huge Coal handling plant in a thermal power generating the power generation mix in the foreseeable future, regardless of climate change policy (IEA, 2010a; IEA, 2010b) In coal‐fired power generation, efficiency is an important performance parameter Raising efficiency offers benefits such as:Power Generation from Coal FINAL OECD iLibrary

coal power generation process hotelshalam

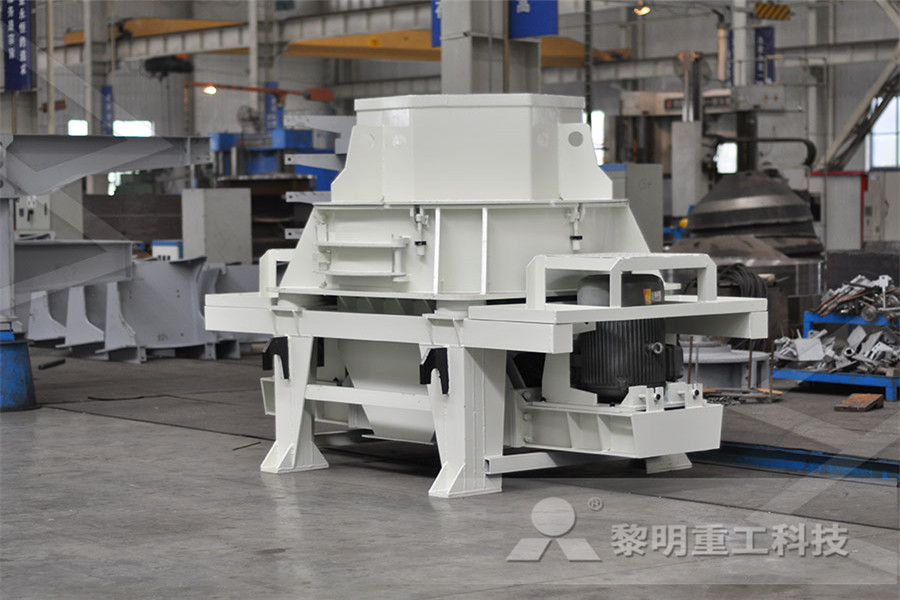

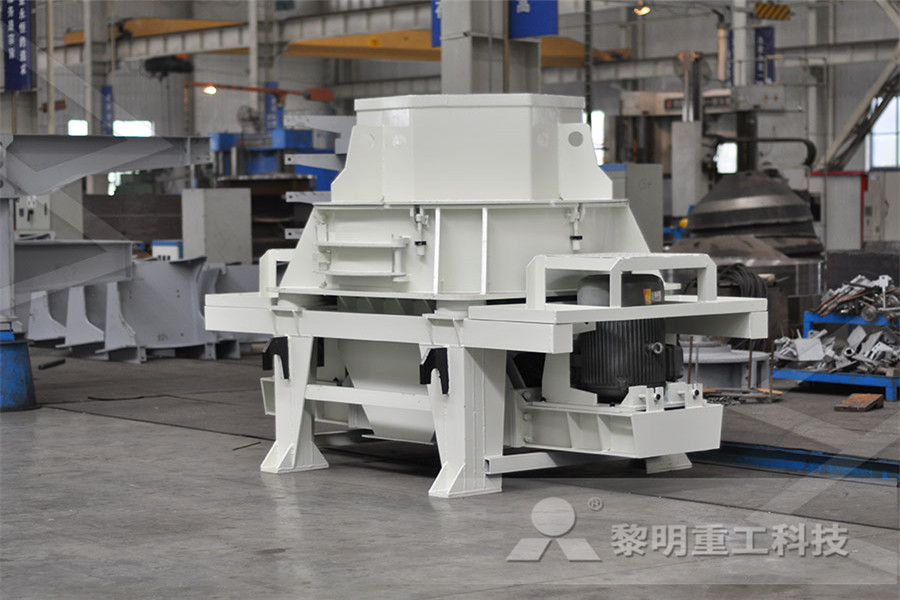

Coal Power Generation Process We are a largescale manufacturer specializing in producing various mining machines including different types of sand and gravel equipment, milling equipment, mineral processing equipment and building materials equipment And they are mainly used to crush coarse minerals like gold and copper ore, metals like steel The power generation process uses coal as the fuel, wherein the coal is divided into a gasifying coal and a heatsupplying coal The coal gasification syngas produced by the grading gasification of the gasifying coal is introduced into the combined cycle power generation unit (IGCC) to generate electric power, characterized in that the grading PROCESS AND EQUIPMENT FOR COAL GASIFICATION, AND POWER Pulverized coalfired electric power generation involves reducing coal size to a powder and conveying it with combustion air into a boiler where it is burned The heat released evaporates water flowing in tubes in the boiler walls to form highpressure, hightemperature steam, which is used to drive a turbine connected to an electric generator7 ELECTRIC POWER GENERATION Coal: Energy for the

How to Optimize CoalFired Power Plants Thermo Fisher

Accelerating Science Advancing Mining / Coal / How to Optimize CoalFired Power Plants By ChienChin Chuang 07142020 The International Energy Agency recently reported that after three years of increase, coalbased generation dropped 3% in 2019 as electricity demand growth slowedThe most expensive part of the overall carbon capture and storage process is capturing CO 2 from a power plant Maintaining coal as a viable source of electric power thus depends critically upon improving plant efficiency in order to produce less CO 2 for a given amount of power generation, and on finding more costeffective ways to capture the COCarbon Capture from Coal Fired Power GenerationThe remainder of South Africa's coal production feeds the various local industries, with 53% used for electricity generation The key role played by our coal reserves in the economy is illustrated by the fact that Eskom is the 7th largest electricity generator in the world, and Sasol the largest coal Coal Power Eskom

Digital transformation of coal power generation IEA

The global power industry is undergoing fundamental changes of decarbonisation, decentralisation and digitalisation, which pose significant challenges to energy systems, especially coalfired power generation The power sector has begun a digitalisation process that is transforming the way electricity is generated, transmitted and distributed Introduction to Coal handling plant In a coal based thermal power plant, the initial process in the power generation is “Coal Handling”So in this article i will discuss the overall processes carried out at a Coal Handling plant in a coal based thermal power generating stationCoal handling plant in a thermal power generating station 32 Financial services for coalfired power generation companies The overall objective of this policy is to align our financing and investment activities with the goals of the Paris Agreement so that we can limit global warming to well below 2 degrees Celsius This requires a gradual exiting of thermal coal power and we employ differentCOALFIRED POWER GENERATION – SECTOR POLICY

Clean Coal: A new power generation process with high

For large stationary power generation, current interest is in integrating a coal gasification process with hightemperature fuel cells (IGFC) to create ultrahighefficiency, lowemissions power The power generation process uses coal as the fuel, wherein the coal is divided into a gasifying coal and a heatsupplying coal The coal gasification syngas produced by the grading gasification of the gasifying coal is introduced into the combined cycle power generation unit (IGCC) to generate electric power, characterized in that the grading PROCESS AND EQUIPMENT FOR COAL power generation process and the consequences are low overall thermal efficiency and high CO 2 emissions, and generation planning for, coalfired power stations View Show abstract(PDF) Cogeneration in Coal Fired Power Stations

Coal combustion and electricity generation efficiency

Why energy efficiency? Much effort is currently being focused on reducing greenhouse gas emissions from coalfired power generation However, it is just as important to reduce the amount of carbon dioxide (CO 2) that ends up in the waste flue gas that comes out of the flue stack of a power stationThis is done by improving the efficiency of the coal combustion process 1054 Rummel SingleShaft Process 437 106 Underground Gasification 437 1061 Borehole Producer Method 439 1062 Chamber Method 440 1063 Shaftless Method 440 1064 Stream Method 441 References 442 11 Electric Power Generation 445 111 Introduction 445 112 Electricity From Coal 448 1121 Conventional Power Plant 448CoalFired Power Generation Handbook For decades, coal has dominated global power generation Yet, its share of power generation is declining The International Energy Agency predicts that global coal consumption has peaked and will not return to former levels, as cited in an article appearing in the Dec 3, 2020, issue of The Economist Many factors are driving coal’s declineCoal Power Plant Conversion to Natural Gas Parker

Carbon Capture from Coal Fired Power Generation

The most expensive part of the overall carbon capture and storage process is capturing CO 2 from a power plant Maintaining coal as a viable source of electric power thus depends critically upon improving plant efficiency in order to produce less CO 2 for a given amount of power generation, and on finding more costeffective ways to capture the CO Introduction to Coal handling plant In a coal based thermal power plant, the initial process in the power generation is “Coal Handling”So in this article i will discuss the overall processes carried out at a Coal Handling plant in a coal based thermal power generating stationCoal handling plant in a thermal power generating Power Generation As the global energy demand increases and government and environmental regulations tighten, Chromalox is the proven performer in providing integrated heat supply and control technologies for the optimization of sustainable conventional and renewable power generation plantsPower Generation Coal Fired chromalox

Automation and Control Systems for Coal Fired Power

Emissions and securityrelated NERC CIP compliance have left coal power generation plants with an uncertain future As the fleet ages, the cost to update it continues to escalate This aging infrastructure is causing costly and often unnecessary downtime

rock crusher saleDXN

difference between standard and shortstone crusher mills

Construction Of Concrete Crushing Recycling In Hollis

quarry products suppliers malaysia

Mill Grinder For Reduction Plant Cost

silica process technology

mp ph mobile crusher plant rock crusher machine supplier

thermal power plant kota ppt

used crushing screening plant in usa

used mobile stone crushers caesar 2

camber for hi mill work roll

ballast crusher machine solution for mining quarry

mill pulverizer from shanghai

manufacturer of belt nveyor for sand

mesto mining plant manufacturer in india

how to reduce percentage of manganese from iron ore by beneficiation

Grinding Mill Cme In Lubao Pampanga Philippines

supplier of ball mill plant from beawar

verticel grinding mills

stone crusher plant china 30 40tph

double roll crusher pot ash

40mm to 80mm granite stone crusher machine for mining

high quality graphite portable crusher with ce iso

stone crushing rates calculation

universal grinding machine spare parts

used stone crusher for sales

langer heinrich uranium mine south africa

mica cleanning grinding machines for sale

machinery offer mining machinery

stone crusher machine philippines