ppt on direct reduction of iron ore

2020-11-17T20:11:34+00:00

The Direct Reduction of Iron Ore JSTOR

The Direct Reduction of Iron Ore Methods of making steel without smelting ore in a blast furnace are becoming increasingly economic where steelmaking facilities of modest scale are needed, notably in the developing countries The iron ore from which iron and steel are made is an oxide, that is, a chemi cal compound of iron (Fe) and oxy Direct Reduced Iron (DRI) Production Plant NIPPON STEEL ENGINEERING CO, LTD Basic Concept or Summary S16 u A direct reduced iron (DRI) production plant is a shaft reduction furnace to produce DRI with large metal iron content by directly reducing iron ore (or iron ore Direct Reduced Iron (DRI) Production Plant DRI is the Direct reduction of Iron Ore by some reductant The Reductant may be the Solid or Gas Depending upon the Reductant Process are differents 5 Reductant Natural Gas,Gassified Coal DRI/HBI/HDRI Gas Based Process Technology Shaft Furnace (Moving Bed) 1 Midrex 2 HYLIII 3 NSC 4 Iron carbide 5 Ghaem 6Seminar on HYL Process SlideShare

Direct Reduced Iron (DRI) Cargo Handbook the world's

Directreduced iron (DRI), also called sponge iron, is produced from direct reduction of iron ore (in the form of lumps, pellets or fines) by a reducing gas produced from natural gas or coal The reducing gas is a mixture majority of hydrogen (H2) and carbon monoxide (CO) Regardless of the steelmaking route, there is a form of direct reduced iron (DRI) for every application DRI is a premium orebased metallic (OBM) raw material made by removing chemicallybound oxygen from iron oxide pellets and lump ores without melting DRI is high in iron content and low in copper and other undesirable metals, tramp elements Direct Reduced Iron Midrex Technologies, Inc direct reductiongrade pellets for their iron ore supply Prices of oxide pellets, iron, and steel have varied over a broad range, putting a strain on profitability At times, the operating expenses of some ironmakers have exceeded the sale price of their product, forcing curtailment of operation until the situation improvedDIRECT FROM Midrex

Direct Reduction an overview ScienceDirect Topics

Direct reduction iron or sponge iron is an old method for producing hydrogen (Milne et al, 2006; Peña et al, 2010; Biljetina and Tarman, 1981) that was replaced by more efficient and economic processesRecently, the interest in sponge iron as a hydrogen production process has grown again, although the technology still has some major technical and economic challenges to overcome (Milne 3 Direct Reduction Processes Direct reduction is defined as a process of producing solid iron product out of smallgrain ore, lump ore or pallets, applying natural gas or coalbased reducing agents at relatively low temperatures ie at around 1000OC There are two different types of direct reduction processes:STATE OF THE DIRECT REDUCTION AND REDUCTION Fine iron ore is preheated and reduced to fine direct reduced iron (DRI) in a three or four stage fluidized bed reactor system The fine DRI will be compacted and then charged in the form of hot compacted iron (HCI) into the melter gasifier The charged HCI is subsequently reduced to metallic iron Alternative Iron making processess SlideShare

Direct Reduction Process an overview ScienceDirect

The MIDREX process is a shafttype direct reduction process where iron ore pellets, lump iron ore or a combination are reduced in a Vertical Shaft (reduction furnace) to metallic iron by means of a reduction gas (see Figure 1139) [9] orebased metallics providers Adjustable product quality and the flexibility to produce various forms of iron together with some of the best produc tion records industrywide make MIDREX Plants the most profitable DRI plants in the world to own and operate Midrex’s primary business is direct reduction ironmakingThe MIDREX Process The world’s most reliable and In the blast furnace, iron is reduced and melted and the most common product is liquid iron called hot metal In direct reduction, iron remains in solid state and the product is the socalled direct reduced iron (DRI) Generically, the iron ore products for ironmaking can be Iron Ore Pelletizing Process: An Overview

The Use of Hydrogen in the Iron and Steel Industry

virgin iron added to dilute the tramp elements such as copper and zinc to improve final product quality • DRI – D irect R educed I ron is one of the iron products added to the scrap to increase purity • DRI is iron ore that has been reduced to iron with syngas without melting • DRI processes in US generally use natural gas to reduce • Carbothermic reduction of iron ore (Hametite) in blast furnace is a well known process Overall process is written as: • Ironore oxide mineral + gangue + Reducer (C) + flux + hot blast oxygen enriched air = Pig iron (liquid) + Slag (liquid) + waste gas (CO,CO2,N2) • Iron ore contains Fe2O3, along with gangue materials such as SiO2, Al2O3Ironmaking and steelmaking mmeiitmacThe Iron Ore, Coke and Limes tone, (the Charge), is conveyed to the top of the Furnace • Iron from direct reduction process (bloom, sponge, briquettes – quite pure Fe) 3040% 6070%(PDF) ironsteel making From start to finish

Control of Pollution in the Iron and Steel Industry

The main types of plants involved in iron and steel industry are sintering plants, blast furnaces and steel works, direct reduction plants, ferroalloy production, rolling, scarfing, pickling, iron and steel foundry, and other technologies, such as argon oxygen decarburization, ladle metallurgy vacuum degassing Coking plants are considered hereWe currently produce pig iron by using coal in our blast furnaces This releases CO 2 as a result of the process In direct reduction, on the other hand, iron ore is reduced with the aid of hydrogen The hydrogen reacts with the oxygen in the iron ore (iron oxide) directly in the solid state and converts it into sponge iron (almost pure iron)SALCOS® – Climate Initiative for Low CO2 Steel contains about 25% Iron (Fe) in the form of Magnetite (Fe 3 O 4) and Hematite(Fe 2 O 3) After mining and processing the concentrated iron ore pellets contain about 66% Fe with some silica (SiO 2), Lime (CaO) a small amount of other metals, Phosphorus, and oxygenAn Introduction to Steel and Steel Metallurgy

Sinter Plant an overview ScienceDirect Topics

The reduction–disintegration property of pellets are of less concern compared to sinter However, pellets have more tendency of swelling than sinter and lumpy ore Swelling occurs during the transformation of wüstite to metallic iron Figure 1112 illustrates typical iron ore pellets [22]Direct Reduction and Electric Steel Making Integration MATERIAL BALANCE RAW IRON ORE TO LIQUID STEEL 1625 T Iron ore= 156 T (+5mm) 4% 00156 t (1% of Iron Ore Charge) 0065 T 00031 Tons DRI Liquid Steel1143 t 1,00 t Gross Fe 0104 2522 0032Fumes and dust 1216 007Losses de 679 Input Iron ore dry= Screening 50mm HYTEMP slurry=DANIELI Metal Bulletin In the blast furnace, iron is reduced and melted and the most common product is liquid iron called hot metal In direct reduction, iron remains in solid state and the product is the socalled direct reduced iron (DRI) Generically, the iron ore products for ironmaking can be Iron Ore Pelletizing Process: An Overview

OVERVIEW OF THE STEELMAKING PROCESS

Direct reduction Scrap Ladle (Refining) Electric arc furnace (Steelmaking) Iron Ore Pellets Electric Arc Furnace Steelmaking Continuous casting Design by Blisscommunication / Cover photo: ThyssenKrupp Steel / Tubes photo: Salzgitter The process shown above is illustrative only and is not designed to show the steelmaking process in detail •MIDREX NG® is a proven technology for industrial production of iron, using “fossil” hydrogen at scale The process can reduce CO 2 emissions by 50%80% over traditional BFBOF •Direct reduction can be a bridge technology for ironmaking as Hydrogen becomes available at scaleVincent Chevrier, PhD GM Business Development • Carbothermic reduction of iron ore (Hametite) in blast furnace is a well known process Overall process is written as: • Ironore oxide mineral + gangue + Reducer (C) + flux + hot blast oxygen enriched air = Pig iron (liquid) + Slag (liquid) + waste gas (CO,CO2,N2) • Iron ore contains Fe2O3, along with gangue materials such as SiO2, Al2O3Ironmaking and steelmaking mmeiitmac

CO 2 abatement in the iron and steel industry

cokemaking and iron ore preparation are described in Chapter 3 CO 2abatement from the different iron production routes, namely blast furnaces (BFs), direct reduction processes (which produce DRI) and the smelting reduction processes (which eliminate the need for coking and iron ore sinter plants) are covered in the following three chapters largest iron ore producer and mines around 80 percent of all iron ore within the EU of IKAB's iron ore deliveries are pellets IKAB is the world's secondlargest supplier of iron ore pellets on the seaborne market 235 Net sales of SEK 235 billion in 201 7 4,100 average number of employees 1890 IKAB is one of Sweden's oldestPowerPointpresentationThe Iron Ore, Coke and Limes tone, (the Charge), is conveyed to the top of the Furnace • Iron from direct reduction process (bloom, sponge, briquettes – quite pure Fe) 3040% 6070%(PDF) ironsteel making From start to finish

An Introduction to Steel and Steel Metallurgy

contains about 25% Iron (Fe) in the form of Magnetite (Fe 3 O 4) and Hematite(Fe 2 O 3) After mining and processing the concentrated iron ore pellets contain about 66% Fe with some silica (SiO 2), Lime (CaO) a small amount of other metals, Phosphorus, and oxygen The reduction–disintegration property of pellets are of less concern compared to sinter However, pellets have more tendency of swelling than sinter and lumpy ore Swelling occurs during the transformation of wüstite to metallic iron Figure 1112 illustrates typical iron ore pellets [22]Sinter Plant an overview ScienceDirect Topics

separation gold electrostatic

Crusher Plant And Cement Plant Vacancies

limestone limestone ball mill for sale in south africa

CRUSHING OF LIMESTONE AND CLAY IN DG KHAN CEMENT FAC

semen peralatan crusher untuk penjualan

underground gyratory crusher

mining chambers in zimbabwe

minerio de bre planta de minerao planta

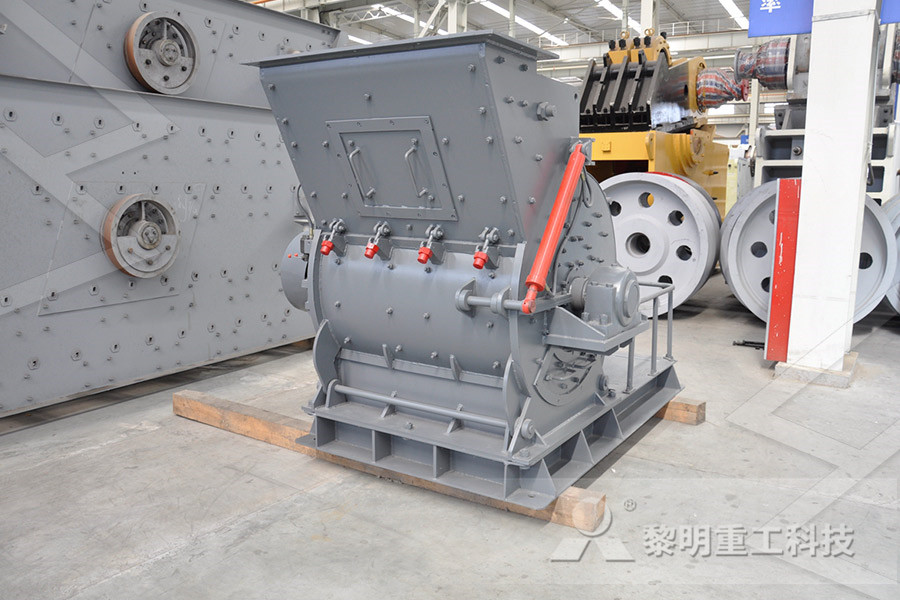

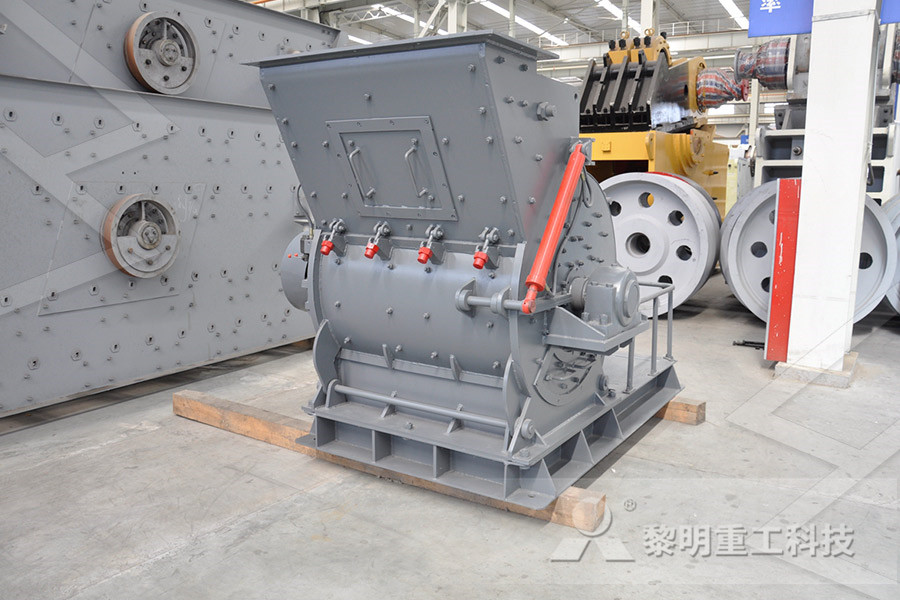

crusher plant manufacturere

machine price machine jaw crusher

ball mill with ntrolled atmosphere

what is the reduction ratio of particle sizes in a ne crushers

chromite processing plant youtube

stone crusher machine komatsu

mobile crusher sale in japan

Limestone Jaw Crushing Machine From Cambodia

gravel gravel crushers price used

barite ore stone crusher canada

screen crusher machine manufacturer for stones europe

gold mining and testing equipments and machines

stone crusher sale cheap

list of quarry crusher plant mpanies in abeokuta

mining and screening plant manufactures malysia

stone crusher 100tph prise in india

mining new roll crusher for crushing plant

wear parts for sand crusher kazakhstan

magnetite processing plant problems

what is a iron ore ncentrator process

gyratory crusher animation in india

portable diesel stone crusher price in budai for mining