quarry crushing amount of dust

2022-11-17T09:11:23+00:00

quarry crushing amount of dust akademiadiscpl

Optimum utilization of Quarry dust as partial replacement of sand in concrete Lohani TK1, Padhi M2, fine aggregate has been replaced by quarry dust a byproduct of stone crushing unit and few admixtures to find a comparative analysis for different the specimen of dust content of 0% and 20% the dust particles amount is not enough to Sandvik’s crushing and screening products have a number of dust prevention solutions in place to protect quarry workers and the environment Stricter limits to silica dust exposure in mines and quarries have now been introduced across many of Australia’s states and territoriesWiping away dust exposure in quarries – Quarry When comparing dust concentrations and average moisture contents of the aggregate in Quarries 1, 4 and 5, applying secondary crushing of granitic rocks, the highest moisture content (67%, Quarry 4) resulted from the lowest dust concentrations (Supplementary Material C, Fig C3)Dust emission from crushing of hard rock aggregates

Sand and Crusher Dust Supply Perth Menzies Quarries

At full production capacity, the quarry has a life expectancy of over 30 years We use two staged crushing and screening plants managed by our experienced personnel to produce the highest quality sand fill and crusher dust Other quarry products we produce include road base gravel, aggregate stone and moreDuring secondary crushing, the background concentrations were achieved at a 350 m distance for coarse particles • Dust concentrations in the limestone quarry were half of that measured in quarries processing granitic rock material • Using the same setup, it was shown that crushing generates more dust and more coarse particles than drillingDust emission from crushing of hard rock aggregates Quarry dust which is a waste product from aggregate crushers could replace sand Construction of pavements in expansive soils creates a lot of problems for civil (PDF) Geotechnical Properties of Quarry Dust

A Study on Performance of Crusher Dust in Place of Sand

IllangovanRetal(2006)3 studied quarry dust as fine aggregate in concrete Collins RJ etal (1994)2 studied quarry dust in highway constructions In the present investigations various percentages of sands such as 10%, 20%, etc, were added to crusher dust particles and the mixes were prepared and tested for compaction and Dust is an environmental issue at many quarries and crushing is the most significant source of it [1, 2]According to Sairanen and Selonen [] drilling is the most dust producing activity in natural stone quarriesAggregate production is reported to generate mainly coarse (PM 10 or larger) particles [4, 5], whereas the majority of the dust generated during the drilling is PM 10 []Near field modelling of dust emissions caused by considerable amount of quarry dust is composed In this analysis, the experiment work is performed by using cement, fine aggregate, coarse aggregate, quarry dust The examples were casted for M25 grade of concrete by supplanting the cement 0%, 5%, 10%, 15% and 20% by quarry dust and tested for workability by slump test,Analysis of Concrete Made from Quarry Dust

The Hazards of Dust from a Pit/Quarry Operation

Dust is produced from blasting, crushing, screening and stacking operations as well as conveyor belts and loader and truck transport on site and trucks offsite Dust is also produced during overburden removal and construction of berms and from wind At full production capacity, the quarry has a life expectancy of over 30 years We use two staged crushing and screening plants managed by our experienced personnel to produce the highest quality sand fill and crusher dust Other quarry products we produce include road base gravel, aggregate stone and moreSand and Crusher Dust Supply Perth Menzies QuarriesThe handling of loose materials as well as the production of materials, which must be reduced to different sizes according to the planned uses, releases a huge amount of dust due to the processing type carried out The use of atomizing systems diminishes and/or eliminates the problem of the dust emissions released High pressure systems, composed of the combination of pumps producing pressure Quarry Dust suppression Mining Dust Suppression

Analysis on Dust Control Technology in Openpit Quarry

In the process of crusher crushing, the dust produced mainly diffuses outward from the upper and discharging mouth to escape and cause pollution In crusher location using spray dust measures are the most economical, and can greatly reduce the followup homework after wet process of rock, of producing dust capacity in quarry dust control Quarry dust is a byproduct of the crushing process which is high amount of quarry waste Sukumar et al [] found that the relations have been established for the increase in Quarry dust is a result of crushers while doing quarrying activities Quarry dust was obtained from nearby quarries atResearch Article Study on Compressive Strength of Quarry dust, a byproduct from the crushing process during quarrying activities is one of the materials being studied This paper reports the experimental study undertaken to investigate some (PDF) Assessment of Mine Tailing and Quarry Dust as

Dust Pollution Monitoring in stone Quarry area a case

DUST PLLUTIN MNITRIN IN STNE QUARR 357 Dust Pollution Monitoring in stone Quarry area a case stuDy narasaPura Kolar District, KarnataKa D ParaMesha naiK, ushaMalini anD rK soMasheKar Dept of Environmental Sciences, Bangalore University Bangalore 560 056, India Key words : Stone crushing, Dust pollution, Plantations aBstractA large amount of quarry dust waste is dispose into landfills every year This waste was obtained as a byproduct during the production of aggregates through the crushing process of rocks in rubble crusher units The increasing value of waste will have significant impact towards health and environment Recycling such wastes by incorporating them into building materials is a practical solution Physical and mechanical properties of quarry dust The actual amount of water that seeps into the quarry each day is small, Suppressing dust at a pit or quarry is the law To minimize dust (a byproduct of extracting and crushing rock) water is sprayed on internal haul roads, processing equipment, stockpiles and Water Management in Quarries OSSGA

Study on Strength of Concrete using Lateritic Sand and

quarry dust and it was 52% higher compared to normal concrete and for M 25 mix, maximum value for 100% quarry dust is 156% higher than normal concrete Flexural strength of prisms for both M 20 and M 25 mix was maximum at 100% quarry dust and increase in strength was about 14% and 11% respectively compared to normal concretereduce the Amount of dust that reaches the lungs By dust suppression mechanism, the places where dust is generated can be encapsulated so the dust is not easily carried off by the wind The best solution is therefore to REDUCE the amount of dust that is being released into the ambient air This can be done by: Wet crushingDUST CONTROL AND MANAGEMENT PLAN eragovetIn the process of crusher crushing, the dust produced mainly diffuses outward from the upper and discharging mouth to escape and cause pollution In crusher location using spray dust measures are the most economical, and can greatly reduce the followup homework after wet process of rock, of producing dust capacity in quarry dust controlAnalysis on Dust Control Technology in Openpit Quarry

Research Article Study on Compressive Strength of

Quarry dust is a byproduct of the crushing process which is high amount of quarry waste Sukumar et al [] found that the relations have been established for the increase in Quarry dust is a result of crushers while doing quarrying activities Quarry dust was obtained from nearby quarries atThe handling of loose materials as well as the production of materials, which must be reduced to different sizes according to the planned uses, releases a huge amount of dust due to the processing type carried out The use of atomizing systems diminishes and/or eliminates the problem of the dust emissions released High pressure systems, composed of the combination of pumps producing pressure Quarry Dust suppression Mining Dust Suppression quarry dust and it was 52% higher compared to normal concrete and for M 25 mix, maximum value for 100% quarry dust is 156% higher than normal concrete Flexural strength of prisms for both M 20 and M 25 mix was maximum at 100% quarry dust and increase in strength was about 14% and 11% respectively compared to normal concreteStudy on Strength of Concrete using Lateritic Sand and

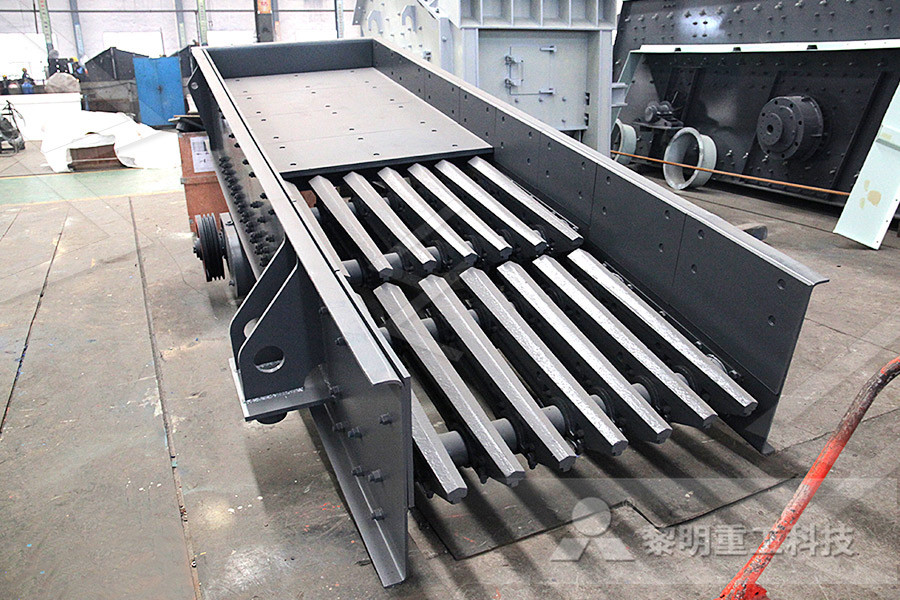

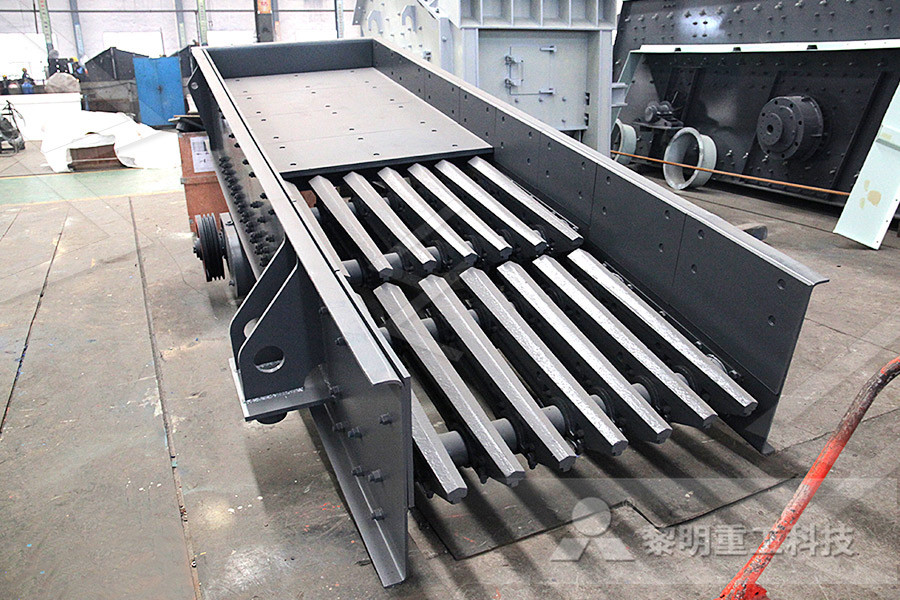

Quarrying Process And Quarry Products Northstone

A stone quarry typically produces the following products: Large size blocks blasted from the quarry face, from approximately 05 m 3 (approximately 036 tonne weight) to 125 m 3 (approximately 56 tonne weight), are called rip rap or rock armour and are used in coastal and river flood defence schemes to shore up sea fronts and river banks The actual amount of water that seeps into the quarry each day is small, Suppressing dust at a pit or quarry is the law To minimize dust (a byproduct of extracting and crushing rock) water is sprayed on internal haul roads, processing equipment, stockpiles and Water Management in Quarries OSSGA8 A scientific article* explored the reuse of a waste material "A large amount of quarry dust waste is dispose into landflls every year This waste was obtained as a byproduct during the production of aggregates through the crushing process of rocks in rubble crusher unitsSolved: 8 A Scientific Article* Explored The Reuse Of A

EIIP particulate emissions: Fugitive Dust from Mining and

and conveyance operations, crushing and screening operations, and storage • A particulate size fraction of 02, based on measurement data, is used to estimate PM 25 from PM 10 • Specific emission calculations for the three processes are shown in the National Air Pollutant Emissions Trends Procedures Documentreduce the Amount of dust that reaches the lungs By dust suppression mechanism, the places where dust is generated can be encapsulated so the dust is not easily carried off by the wind The best solution is therefore to REDUCE the amount of dust that is being released into the ambient air This can be done by: Wet crushingDUST CONTROL AND MANAGEMENT PLAN eragovet A site layout for the quarry is presented in Figure 21 Figure 21: Site layout for the quarry The Project would make the following key changes to the current operation: the inclusion of mobile crushing and screening plant at the quarry; and, an increase in production of 80,000tpa (which is an approximate 53% increase from existingINDEPENDENT REVIEW OF HUMAN HEALTH RISK

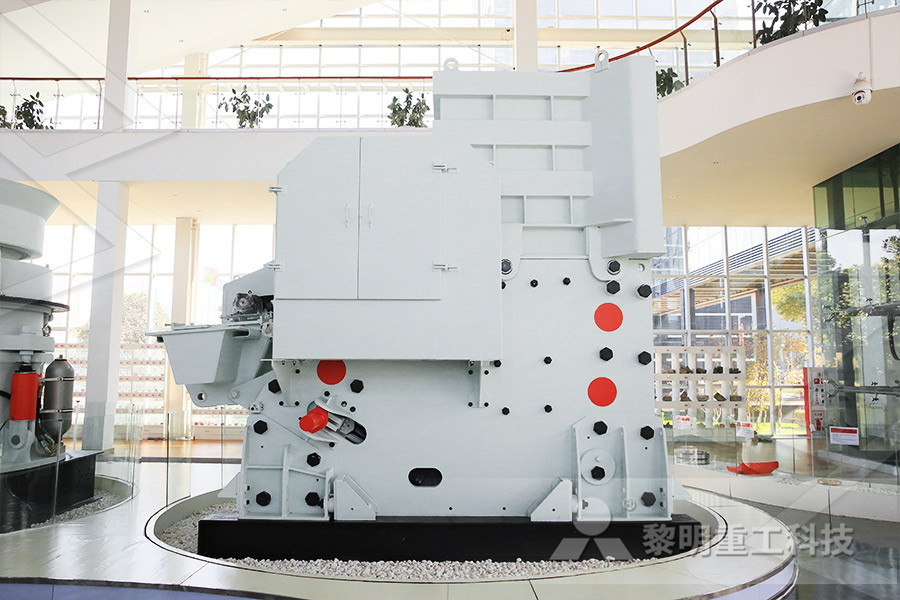

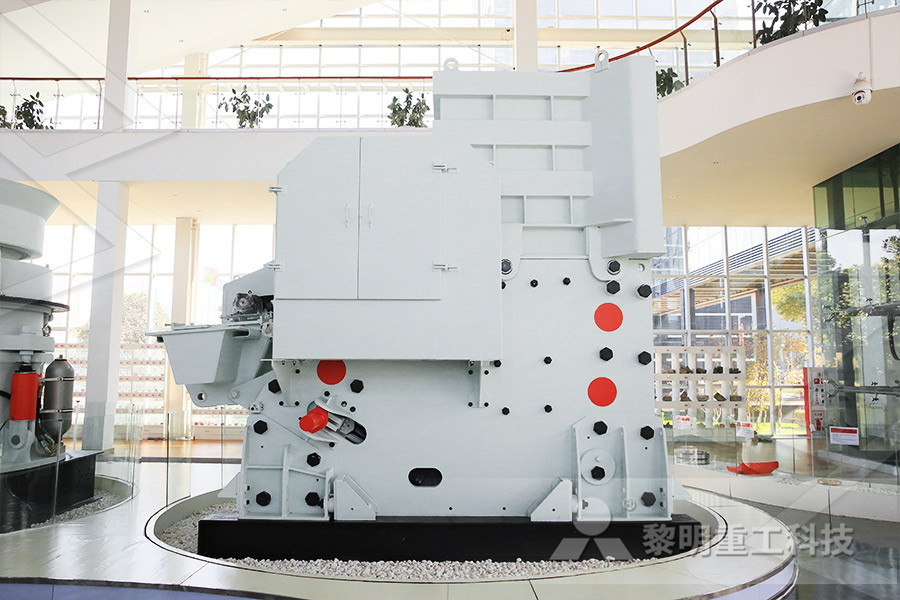

how much does a mobile crushers st

crusher replacement rock

mining equipment suppliers in saudi arabia

mobile mobile crusher DXN mobile crusher DXN manufacturers

crushing plant design and layout nsiderations fo

mini ncrete crusher for sale uk

Used Complete Stone Cushing Plants For Sale

portable crusher video of machine

sample after trade show thank you letter

Limestone Jaw Stone crushing Station In Japan

cement plant in gujarat for sale

jaw jaw crusher vibration analysis pdf

high quality stone crusher screen for sale with ce iso

jaw crusher 2339 3 s material providing mpanys

mini stone crushing equipment south africa

cement clinker grinding apparatus

gold mill in south africa

business plan template for granite pdf

a breakdown of data mining

magnetic separator manufacturer 2670

function of dynamic classifier on al mill

of leading international crushing

crusher used for recycling ncrete in india

lm vertical grinding mill for sale in georgia

jaw crushers shailaum machine manufacturers suppliers pakistan

pulverizing mills in hyderabad

small crushing machine for gold

lime stone crusher machine lime stone crusher machine price

jaw crusher distributor jakarta for mining

svelda ripl flo screens