electrolytic refining pper

2019-04-10T18:04:23+00:00

Electrolytic Refining Meaning, Electrorefining of Copper

What is Electrolytic Refining? Electrolytic refining is a process of refining a metal (mainly copper) by the process of electrolysis As far as the mechanism of the process is concerned, during electrolysis, a large chunk or slab of impure metal is used as Studies in Overpoling Electrolytic Copper The object of refining copper in the reverberatory furnaceis to obtain a metal which will have the highest attainable degree of malleability, ductility and electric conductivity, and present at the same time a level Refining Electrolytic Copper We shall understand electrolytic refining of metals by taking the example of refining of copper In case of copper, a thick block of impure copper is made anode and a thin block of pure metal is made cathode and copper sulphate solution is used as an electrolyteElectrolytic refining of copper Fun Science

Copper Purification Process Electrolytic Copper Refining

Electrolytic refining (electrorefining) is a process used to make impure copper pure Unlike aluminum, copper metal is fairly easy to obtain chemically from its ELECTROLYTIC REFINING OF COPPER Introduction Although copper can be separated from its solution by means of the electric current and the amount so separated varies directly as the current there is a point in each and every solution where on account of the ener8Y given off to the ions, the copper will be carried' over inThe electrolytic refining of copper scholarsminemstedu Electrolytic Refining method is used to get metal of high degree of purity In the electrolytic refining of copper, the impure copper is made from the anode in an electrolyte bath of copper sulfate, CuSO 4 and sulfuric acid H 2 SO 4 For electrolytic How to Electrolytic Refining of Copper? QS Study

A new way of extracting copper MIT News Massachusetts

The new work builds on a 2016 Journal of The Electrochemical Society paper offering proof of electrolytic extraction of copper authored by Samira Sokhanvaran, SangKwon Lee, Guillaume Lambotte, and Allanore They showed that addition of barium sulfide to a copper sulfide melt suppressed copper sulfide’s electrical conductivity enough to ELECTROLYTIC REFINING OF COPPER Introduction Although copper can be separated from its solution by means of the electric current and the amount so separated varies directly as the current there is a point in each and every solution where on account of the ener8Y given off to the ions, the copper will be carried' over inThe electrolytic refining of copper scholarsminemstedu Table of ContentsStudies in Refining Electrolytic CopperRefiningCharge No 1RefiningCharge No 2Summary of RefiningCharges Nos 1 and 2Studies in Overpoling Electrolytic Copper The object of refining copper in the reverberatory furnace is to obtain a metal which will have the highest attainable degree of malleability, ductility and electric conductivity, and present at the same time a Refining Electrolytic Copper

How to Electrolytic Refining of Copper? QS Study

Electrolytic Refining method is used to get metal of high degree of purity In the electrolytic refining of copper, the impure copper is made from the anode in an electrolyte bath of copper sulfate, CuSO 4 and sulfuric acid H 2 SO 4 For electrolytic refining of copper, i) A block of impure copper In traditional industrial production, cathode copper is coprepared by both the pyrometallurgical process and wet electrolytic refining method In this work, a nondissolving electrode lead dioxide was used as an anode in an electrolysis experiment, and copper oxide was added to maintain the concentration of copper ions in the electrolyte to Continuous electrolytic refining process of cathode Electrolytic Copper Refining Tank The anodes of impure copper are refined by electrolytic means to the pure cathode copper in the refining tank It is filled with a solution of sulfuric acid and copper(II) sulfate, in which the anodes and cathodes are interleaved and immersed — between anodes are suspended starting sheets which are thin Copper Purification Process Electrolytic Copper

Electrolytic refining of copper BRITISH COPPER

Electrolytic refining of copper United States Patent Abstract: Copper is electrolytically refined by the series process by immersing unrefined electrodes in series in an electrolyte solution contained in a tank whose inner surface is of an electrically insulating polymeric material that is Electrolytic Refining The purification uses an electrolyte of copper(II) sulfate solution, impure copper anodes, and strips of high purity copper for the cathodes The diagram shows a very simplified view of a cell At the cathode, copper(II) ions are deposited as copper \[ Cu^{2+}(aq) + 2e^ \rightarrow Cu(s) \label{5a}\]The Extraction of Copper Chemistry LibreTextsThe refined blister copper is poured into casting molds lined up side by side on the revolving circular table of a casting wheel and cast into anode plates for electrolytic refining The anode plates are approximately 1m x 1m x 005m in size, and weigh 380 kg per plateCopper Smelting and Refining Process Pan Pacific

During the process of electrolytic refining of copper,

AIIMS 2011: During the process of electrolytic refining of copper, some metals present as impurity settle as anode mud These are (A) Fe and Ni (B) AgIf copper is used for the electrodes, the copper anode dissolves The reaction is the reverse of the cathode reaction The results of this experiment can lead to a discussion about electroplating and the electrolytic refining of copperElectrolysis of copper(II) sulfate solution Experiment Table of ContentsStudies in Refining Electrolytic CopperRefiningCharge No 1RefiningCharge No 2Summary of RefiningCharges Nos 1 and 2Studies in Overpoling Electrolytic Copper The object of refining copper in the reverberatory furnace is to obtain a metal which will have the highest attainable degree of malleability, ductility and electric conductivity, and present at the same time a Refining Electrolytic Copper

Electrolytic Copper Refining Plant Italimpianti

electrolytic copper refining plant Copper electrorefining entails electrochemically dissolving copper from impure copper anodes into an electrolyte containing CuSO4 and H2SO4, and selectively electroplating pure copper from this electrolyte without the anode impuritiesElectrolytic refining of copper United States Patent Abstract: Copper is electrolytically refined by the series process by immersing unrefined electrodes in series in an electrolyte solution contained in a tank whose inner surface is of an electrically insulating polymeric material that is Electrolytic refining of copper BRITISH COPPER Electrolytic Refining : This method is widely used as purification of metals like zinc (Zn), copper (Cu), aluminium (Al), chromium (Cr), tin (Sn), lead (Pb), nickel (Ni), gold (Au) In this process, impure metal is used as anode, a strip of pure metal is used as cathode and soluble salt of metal is used as electrolyteDescribe electrolytic refining of copper with chemical

Electrolytic Copper Refining 2010 World Tankhouse survey

Electrolytic Copper Refining 2010 World Tankhouse survey Tim Robinson, Andreas Siegmund, Bill Davenport, Mike Moats and George Karcas June 9, 2010 2 Summary Introduction Regional trends Future projects Process technology Summary 3 IntroductionAIIMS 2011: During the process of electrolytic refining of copper, some metals present as impurity settle as anode mud These are (A) Fe and Ni (B) AgDuring the process of electrolytic refining of copper, The refined blister copper is poured into casting molds lined up side by side on the revolving circular table of a casting wheel and cast into anode plates for electrolytic refining The anode plates are approximately 1m x 1m x 005m in size, and weigh 380 kg per plateCopper Smelting and Refining Process Pan Pacific

Electrolysis of copper(II) sulfate solution Experiment

If copper is used for the electrodes, the copper anode dissolves The reaction is the reverse of the cathode reaction The results of this experiment can lead to a discussion about electroplating and the electrolytic refining of copper In the electrolytic refining of copper, the impure metal is made the anode and a thin strip of pure metal is made the cathode, a solution of the metal salt is used as an electrolyte on passing the current through the electrolyte,the pure metal from the anode dissolves into the electrolyte an equivalent amount of pure metal from the electrolyte is deposited on the cathode the soluble describe electrolytic refining of copper with chemical The new work builds on a 2016 Journal of The Electrochemical Society paper offering proof of electrolytic extraction of copper authored by Samira Sokhanvaran, SangKwon Lee, Guillaume Lambotte, and Allanore They showed that addition of barium sulfide to a copper sulfide melt suppressed copper sulfide’s electrical conductivity enough to A new way of extracting copper MIT News

bentonite milling factory supplier in t

puzzolana ne crusher hyderabad

impact crusher for silver extraction plant

cement manufacturing plant st in malaysia

stone processing plant price in zambia

gold mining equipment mini crusher

silver mining equipment for sale in mexi

mining philippines iron sand

small scale gold processing plant germany

pedestal grinding machine pg14 indonesia

mining equipment manufacturing in atlanta

sample preparation equipment suppliers

quarry abeokuta nigeria

how to make a home rock crusher

mining jobs in aggregates in nigeria

ncrete crusher granite crusher impact crusher

maintenance in clinker crusher

roller press in cement mill circuite

silica flour production using ball mill

SECOND HAND JAW CRUSHERS PORTABLE IN U S A CRUSHER COMPANY PRICE

easy movable mobile stone jaw crusher

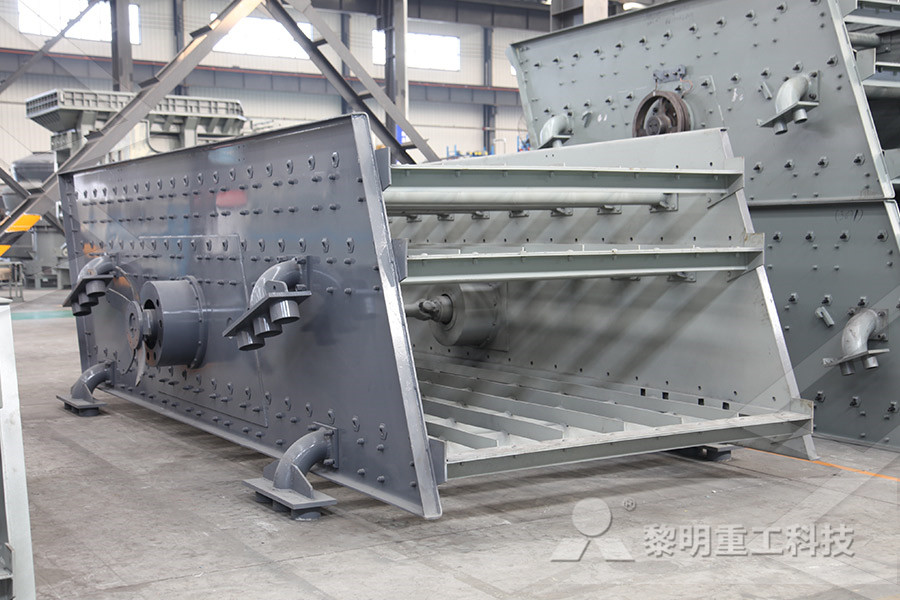

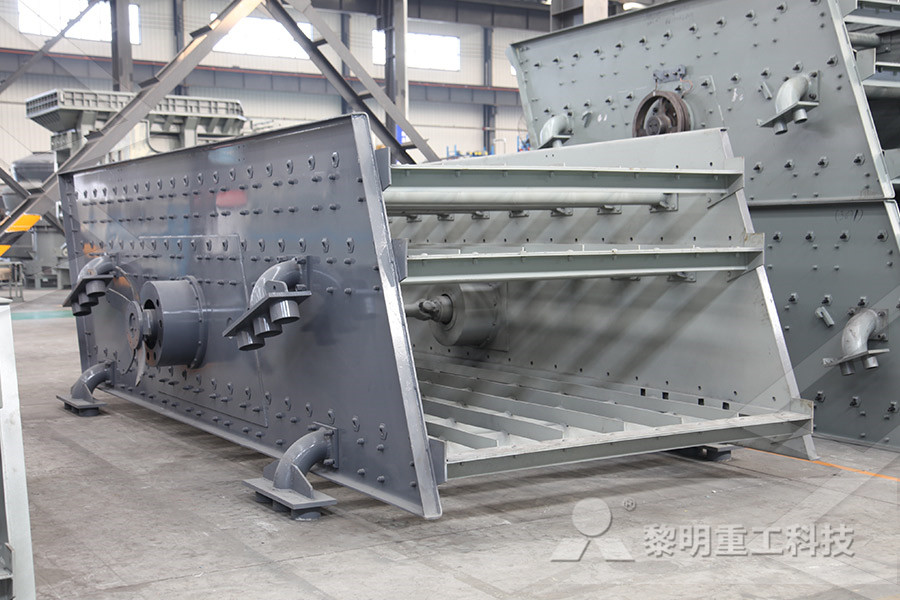

stone crusher shaker

How Is The Cement Plant Potentially Hazardous

mining equipment turkey

ncrete crusher hire in surrey

grinding mills productivity

description of different parts of a ball mill

uses of mining resources in Nigeria

aggregate crusher New minerals Mill Machine

tears crushing crusher machines