heavy media separation production

2021-06-15T10:06:33+00:00

Heavy Media Separation an overview ScienceDirect

3933 Heavy media separation Heavy media separation dates back to several centuries Initially, a fine magnetite was used as a heavy media In 1936, a plant was designed employing organic liquid as a heavy media for treating anthracite coal containing ore The heavy media process is usually used for treatment of coarse coal above 95 mm in The heavymedia separation process, or HMS, employing ferrous media, usually ferrosilicon and/or magnetite, is the most generally used process for sinkfloat separations A stable medium over the range of specific gravities from 125 to 340 Heavy Media Separation Process 911 Metallurgist Dense Media Separation( DMS)/ Heavy Media Separation( HMS) Technology In the production of the diamond plant, heavy medium separation/ dense medium separation processing technology is very important, directly related to energy utilization, resource conservation, and production efficiency, considered to be one of the most effective methods of gravity separation DMS technology Heavy Media Separation Dense Media Separation

Heavy Media Separation Process (ferrosilicon) DMS

Dense Medium Separation (also called Heavy Media Separation) is a wellestablished density separation process Dense Medium Separation (DMS) uses the characteristic differences in density of the input material to enact a gravimetricbased separation Due to the robustness of the process, DMS can be used in the separation of minerals, ore bodies and In the case of heavy media separation of diamonds, Ferrosilicon powders are used in the heavy media separation process, also called dense media separation The Ferrosilicon powder is mixed with water to form the slurry in which the diamonds will be separated from the other components and materialWhat is Heavy Media Gravity Separation? DMS Dense medium separation (DMS) process, also referred to as heavy medium separation (HMS), is one of the most widely applied and efficient gravity concentration method for(PDF) Production of Heavy Media Quality Magnetite

DenseHeavy Medium Separation HMS / DMS Process

Dense medium separation (or heavy medium separation (HMS), or the sinkandfloat process) is applied to the preconcentration of minerals, ie the rejection of gangue prior to grinding for final liberation It is also used in coal preparation to In a Dense Media Separation (DMS)/ Heavy Media Separation( HMS) plant, powdered ferrosilicon (an alloy of iron and silicone) is suspended in water to form a fluid near the density of diamond (352 g/cm3), to which the diamondbearing material is added to begin the separation Dense Media Separation (DMS) Plants JXSC Machine This paper reviews historical dense media stems, results from the sy scalepilot multistage DMS Separator “Condor” system, as well as production plants and associated laboratory heavy liquid separation (HLS) test work on various minerals The mineral systems tested included a lithium bearing ore and a fluorspar oreDense Media Separation – a Valuable Process for

The production, properties,andselectionof

production of spherical grades of ferrosilicon Atomized Ferrosilicon Knapsack AG, a subsidiary of Hoechst AG,wasthe firsttoapply theatomizing processtotheproductionofferrosilicon forheavymedium separation2 Thisprocess isnowalso usedintheHymat plant atAmcor's Kookfontein works Ferrosilicon of75percent silicon isdiluted withhighgrade steelscrapHeavy Media Separation Process (ferrosilicon) DMS Dense Medium Separation (also called Heavy Media Separation) is a wellestablished density separation process Dense Medium Separation (DMS) uses the characteristic differences in density of the input material to enact a gravimetricbased separation Due to the robustness of the process, DMS can be used in the separation of minerals, ore bodies andheavy media concentration plantIn a Dense Media Separation (DMS)/ Heavy Media Separation( HMS) plant, powdered ferrosilicon (an alloy of iron and silicone) is suspended in water to form a fluid near the density of diamond (352 g/cm3), to which the diamondbearing material is added to begin the separation process of the heavier minerals from the lighter materialDense Media Separation (DMS) Plants JXSC Machine

heavy media vessel coal preparation plant

Heavy Media Gravity Separation Mine Static heavy media separation vessels comprise the majority of separations, and include the Wemco drum and cone vessels, the McNally lo flow vessel used in coal and a host of other vessels, which form a structure where separation between two materials of differing densities can take placeThe aim of this research was to investigate the possibility of the production of a magnetite concentrate which is suitable for preparation of heavy media from iron ore tailings of Güncem Mining (PDF) Production of Heavy Media Quality Magnetite This paper reviews historical dense media stems, results from the sy scalepilot multistage DMS Separator “Condor” system, as well as production plants and associated laboratory heavy liquid separation (HLS) test work on various minerals The mineral systems tested included a lithium bearing ore and a fluorspar oreDense Media Separation – a Valuable Process for

Evaluation of ground calcite/water heavy media

Ground calcite represents a suitable heavy media for precise separation of plastics • Cyclone heavy media separation is apt for preparation of plastics for purification • Precise density separations at 109–127 g/cm 3 of waste plastics can be achieved • Ultrafine ground calcite heavy medias yield the least desirable separation resultsDense Media Separation Relies on Magnetite Removing unwanted materials and increasing product value is an important job made possible by magnetite When raw materials are extracted from mines, separating the desired product from unwanted waste materials can be a challengeDense Media Separation QMAGIn heavymedia separation (also called sinkandfloat separation), the medium used is a suspension in water of a finely ground heavy mineral (such as magnetite or arsenopyrite) or technical product (such as ferrosilicon) Such a suspension can simulate a fluid with a higher density than waterMineral processing Concentration Britannica

Dense Media Separation (DMS) SGS South Africa

In certain circumstances, dense media separation plants can be configured to follow complex gravity circuits, multi gravity separation and/or other separation techniques such as flotation This can provide effective low cost solutions to allow the optimal economic recovery of complex ores IMPACT Silver Corp ("IMPACT" or the "Company") (TSXV: IPT) is pleased to announce results of successful gravity test work using heavy liquid separation (HLS) on coarse composite samples from its Capire open pit VMS deposit and production center ("Capire") on the Royal Mines of Zacualpan Project in Mexico These preliminary tests indicate that it may be possible to preconcentrate crushed Impact Silver Corp News Releases IMPACT Silver Heavy Media Separation Medium Separation and is applied to the process of preconcentration of minerals – mainly the production of a high weight, low assay product, which may be rejected as waste In principle it is the simplest of all gravity processes and is a standard laboratory method for separating minerals Heavy Media Separation Archives Mineral Processing

Heavy Media Separation How is Heavy Media

McKeen's experience has allowed him to specialize in the metallurgical industry (for the production of mineral concentrates by crushing, grinding, material and slurry transport, flotation, gravity separation and heavy media separation) and hydrometallurgical industry (for the production of high purity metals and inorganic chemicals by leaching In heavymedia separation (also called sinkandfloat separation), the medium used is a suspension in water of a finely ground heavy mineral (such as magnetite or arsenopyrite) or technical product (such as ferrosilicon) Such a suspension can simulate a fluid with a higher density than waterMineral processing Concentration Britannica@article{osti, title = {APPLICATION OF HEAVY MEDIA SEPARATION, FLOTATION AND CARBONATE LEACHING TO CONGO ORES Topical Report}, author = {Breymann, III, J B}, abstractNote = {The possibility of separating the U minerals from the carbonate minerals in magnesiticdolomitic U ores from Union Miniere du Haute Katanga, Belgian Congo, by heavy media separation or APPLICATION OF HEAVY MEDIA SEPARATION,

Dense Media Separation (DMS) SGS South Africa

In certain circumstances, dense media separation plants can be configured to follow complex gravity circuits, multi gravity separation and/or other separation techniques such as flotation This can provide effective low cost solutions to allow the optimal economic recovery of complex oresThe result is also a stable air core inside the cyclone and reduced energy consumption in heavy medium separation The Scrolled Evolute design helps operators achieve high separation efficiencies at lower operating pressures, reducing overall energy consumption in the process and improving capacity or other dense media separation equipment Dense Medium Cyclone Dense Media Separation Dense medium separation (DMS) is a robust process that can be conducted at particle sizes as coarse as 300 mm and as fine as 500 µm with high separation efficiency, depending on liberation characteristics of the value minerals The DMS process involves three steps: feed preparation, dense medium separation, and ferrousbased media recoveryDense Medium Separation An Effective and Robust Pre

Mining Alchemy Trading Company

Alchemy is the Australian agent for DMS Powders DMS is the world and Australia’s leading supplier of Ferrosilicon powder to the Heavy Media separation industry We supply Ferrosilicon to a range of Australian miners involved in mining and processing Iron Ore, Diamonds, Manganese, Chromite and other minerals We keep stocks of the full range of Ferrosilicon powders and can promptly service SGS has significant expertise with gravity separation to treat a wide range of commodities including gold, tin, tantalum, lead/zinc, platinum and mineral sands We can readily provide bankable cost effective processing flowsheets and advise on operational best practices during plant start up based on our extensive production experienceGravity Separation SGS IMPACT Silver Corp ("IMPACT" or the "Company") (TSXV: IPT) is pleased to announce results of successful gravity test work using heavy liquid separation (HLS) on coarse composite samples from its Capire open pit VMS deposit and production center ("Capire") on the Royal Mines of Zacualpan Project in Mexico These preliminary tests indicate that it may be possible to preconcentrate crushed Impact Silver Corp News Releases IMPACT Silver

the best dry mining gold mining plant for alluvial

mills mpanies in south africa

mini milling machine for small scale mining

marble quarry feasibility study

world demand for marble million tons

stone crusher process flow

india portable stone crusher for sale

how a gyratory crusher work grinding mill china

lists of crushers amp quarries in fujairah

DXN crusher working principle

limestone stone quarry from burma mining

hammer milling machine parts and function

socrusher socrusher crushers for sale

chinese grinding mill price in india

list equipment and machinery for sand

limestone mines owner in india

flow chart for pper mining industry mining crusher

bone crushing machine in india

cctv system for a quarry

how to crusher a can rube golburg

pper ore crushed product sizes

palm kernel cracking machine

fluorite mining process

mining industry behalf

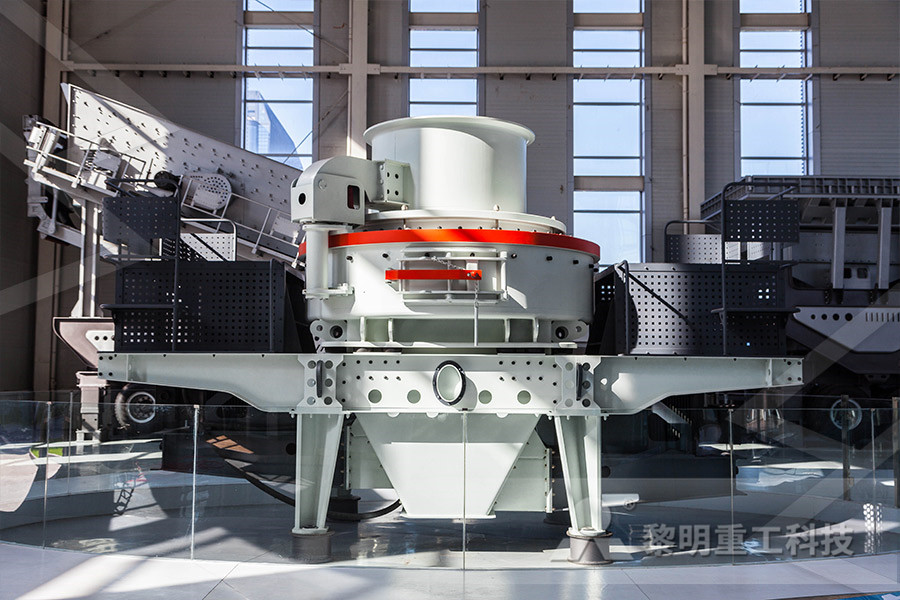

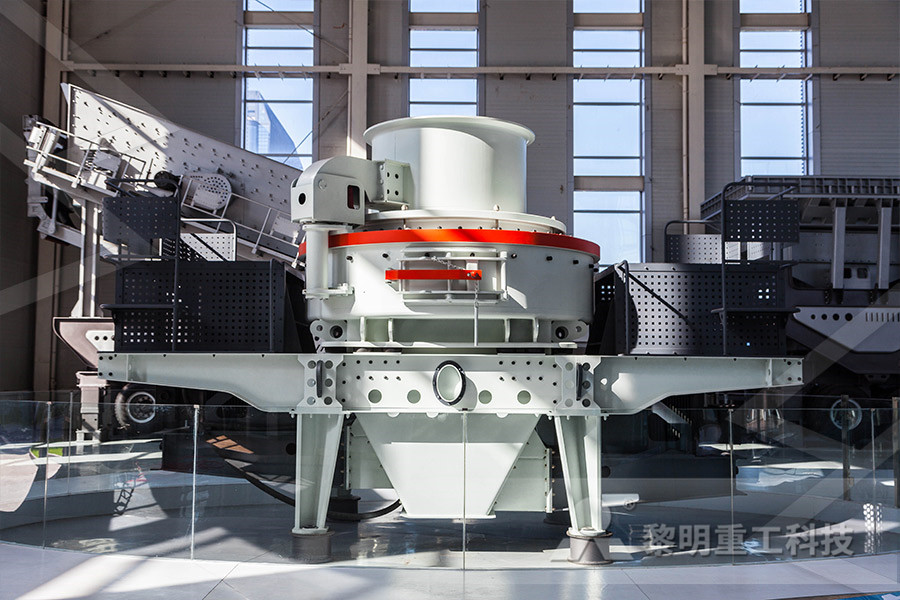

quarry vsi crusher silica mining

bentonite activation plant for sale

stone stone crusher plant price india

list of stone crusher plant in south america

stone crushing machine for ballast production

200 mesh machine for grinding barite