equipment required for silica sand

2022-12-26T19:12:17+00:00

Equipment Required For Silica Sand

heavy equipment for silica sand Ball mill for sale ball silica sand washing equipment, silica sand washing machine, ALUMINUM OXIDE: $660/Ton: None Required (Usually Used in Cabinets Very Heavy (SG 41 Beneficiation of Silica Sand Processing Plant Equipment Mineral May 9 2016 2 Summary of the Silica Sand Processing Plant Equipment 3 A In some cases the sand at this point is down to the required iron oxide Get Price; Florida Silica Sand Company Florida Silica Sand company is equipment required for silica sand wesolyskrzatplAlibaba offers 3,822 silica sand equipment products A wide variety of silica sand equipment options are available to you, such as warranty of core components, local silica sand equipment, silica sand equipment Suppliers

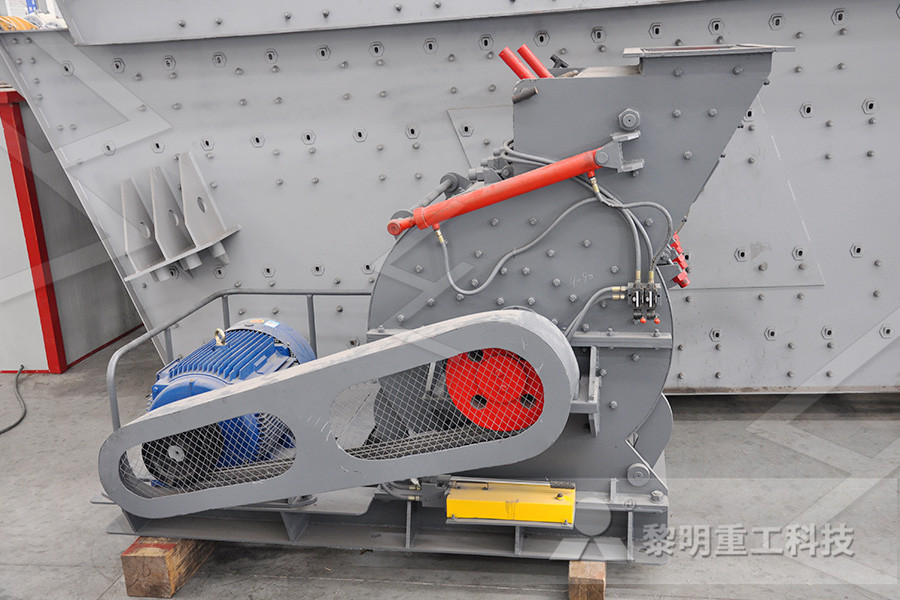

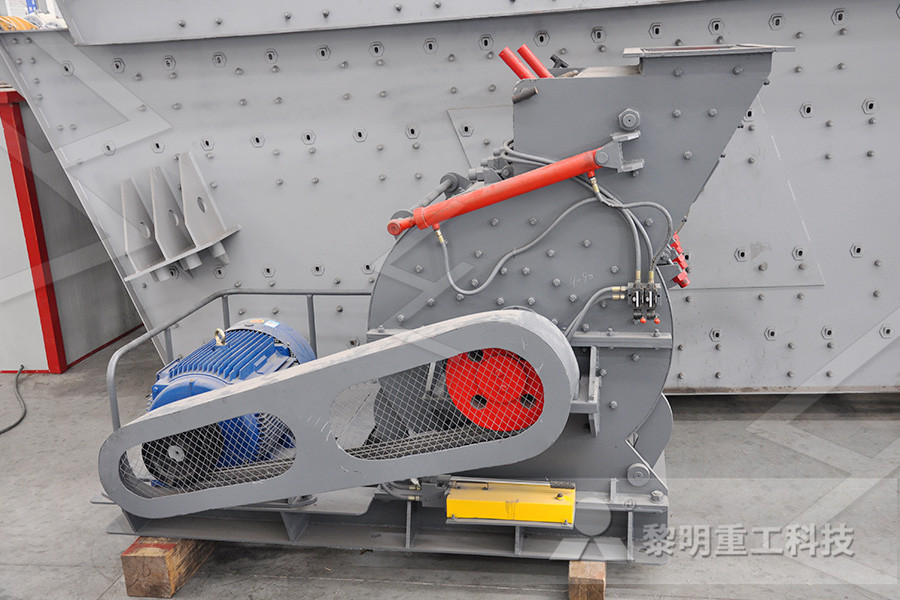

Silica Sand Processing Sand Washing Plant Equipment

The “SubA” Flotation Machine has been very successful for silica sand flotation because it will efficiently handle the fast settling sand and move it along from cell to cell positively Aeration, agitation and selectivity due to the quiet upper zone can be infrastructure required for silica sand beneficiation plant in malaysia price silica sand processing plant equipment in india Silica sand wassin plant in india the combox is the most ecofriendly sand washing system in the world and is a formidable answer to water scarcity on most project sites in india of the water required to run the washing operation is automatically treated and recycled infrastructure required for silica sand beneficiation Sand making equipment STONE $45m silica sand washing plant for roll crusher double roll crusher for sand making and double roll The successful application of HJ new type double roll crusher for sand making machine will undoubtedly double roller crusher for sand makingRequired Roll Crusher For Silica Sand

FOUNDRY SAND TESTING EQUIPMENT OPERATING

RIDSDALE SILICA SAND SAMPLER (for extracting a representative sand sample) Length approximately 2000 mm Diameter approximately 35 mm Length approximately 2000 mm Diameter approximately 35 mm USE When testing sand or binder it is important to ensure that the withdrawn sample is perfectly representative of the whole The use of engineering controls such as water sprays or local exhaust ventilation are the preferred methods of controlling silica dust (and required by OSHA to the maximum extent feasible) However, personal protective equipment, particularly 5 Things To Remember for New Silica Safety While most respirators come with an adjustable strap, you need to make sure your workers have access to safety equipment that fits Proper fit is key to choosing a respirator for SilicaWhat Type of Respirator Should I Use for Silica? PK

Silica Dust Solutions Nilfisk US

The VHT446IC also excels in sand collection and other general housekeeping applications in silica dustcontaining environments It comes with an easily cleanable main filter and a HEPA filter for increased safety SEE PRODUCT DETAILS Complete batch and pilot plant test facilities are available to test your sand and determine the exact size of equipment required and the most economical reagent combinations Silica sand for making glass, pottery and ceramics must meet rigid specifications and generally standard washing schemes are inadequate for meeting these requirementsSilica Sand Processing Sand Washing Plant Equipment 01 One Process and equipment used for the impurity resolution of silica sand The impurity resolution process of silica sand means to adopt the crushing, grinding and classifying to break the natural quartz sandstone ore and make the impurities and minerals reach the state of monomer dissociation, and then use the classifying operation to obtain the raw silica sand meeting the Silica Sand Purifying Process and Equipment for the

Silica Sand rossislandsdsco

Silica Sand Safety Data Sheet Date of Issue: 12/9/2016 Version: 20 12/9/2016 on skin, or on clothing Use personal protective equipment (PPE) as required If skin irritation occurs, rinse the affected area with water If in eyes, rinse well with water for at least 15 minutes Power equipment should be equipped with properly designed Modern heavy equipment often comes equipped with enclosed, filtered cabs that meet the requirements of the silica standard in Table 1 Retrofit equipment is available for older equipment Respiratory Protection When properly used, an enclosed cab or wet methods can effectively control airborne silica dust Therefore, Table 1 in the silica standardControl of Silica Dust in Construction: Heavy Equipment RIDSDALE SILICA SAND SAMPLER (for extracting a representative sand sample) Length approximately 2000 mm Diameter approximately 35 mm Length approximately 2000 mm Diameter approximately 35 mm USE When testing sand or binder it is important to ensure that the withdrawn sample is perfectly representative of the wholeFOUNDRY SAND TESTING EQUIPMENT OPERATING

Silica and Moulding Sands Association (SAMSA) part

Crystalline silica has a higher melting point (1610 °C) than iron, copper or aluminium and other common metals This enables castings to be made by pouring molten metal into moulds made from silica sand and a binder The physical and chemical characteristics of the sand are important In the past naturally clay bonded moulding sands were used In silica work sites, the program administrator may also be the silica competent person required by the silica regulations While not required to be the same person, it may make administration and oversite of the program easier Create a Written Respirator Program A written program is required by OSHA and is a core component to an effective 5 Things To Remember for New Silica Safety Silica Sand required Hello We need Silica Sand Please contact to me on nimish@arthaminerals Company Name: Membership Required Contact Number: Membership Required Purchaser: Nimash Contact Now To view this buyer's contact information please Sign In Silica Sand required Buyer and Importer from India

5 Factors Affecting Silica Sand Flotation

Flotation is one of the commonly used methods for silica sand beneficiation It is mainly used to remove mica and feldspar minerals that are symbiotic with silica sand However, in the actual production process, the flotation process will be affected by many factors, including: feed size, slurry temperature, slurry liquid chemical composition, flotation reagents and other flotation conditionsHiCrush’s PropStream ® integrated delivery solution has a delivery and material handling system, PropBeast™ (see photos at right), which significantly reduces dust generation, decreases employee exposure to dust and respirable crystalline silica, and can be operated in a manner which increases operational control and efficiency The system is a selfcontained solution which delivers sand Minimizing Silica Dust Exposure – HiCrush Complete batch and pilot plant test facilities are available to test your sand and determine the exact size of equipment required and the most economical reagent combinations Silica sand for making glass, pottery and ceramics must meet rigid specifications and generally standard washing schemes are inadequate for meeting these requirementsSilica Sand Processing Sand Washing Plant Equipment

machinery required for production of silica

Silica Fume an overview ScienceDirect Topics Machinery Required For Production Of Silica floors sills ledges machinery or equipment 1 form1 for proposed expansion of silica sand productionGet Price Machinery Required For Production Of Silica Hydraulicdriven Silica Sand Safety Data Sheet Date of Issue: 12/9/2016 Version: 20 12/9/2016 on skin, or on clothing Use personal protective equipment (PPE) as required If skin irritation occurs, rinse the affected area with water If in eyes, rinse well with water for at least 15 minutes Power equipment should be equipped with properly designed Silica Sand rossislandsdsco The basic silica sand making process and dust removal and impurity removal functions For the high pure requirements of silica sand, highpurity extraction such as flotation, magnetic separation, and spot selection is also required Silica sand processing plant and equipment100T/H Silica Sand Mining Processing Plant

st of infrastructure required for silica sand

st of infrastructure required for silica sand beneficiation plant Diatreme said the project could inject about $23‐24 million in the construction phase and up to $42 million in the operational phase for the benefit of Hope Vale, Cooktown and the surrounding region, with estimated total revenue of $80 million per annum RIDSDALE SILICA SAND SAMPLER (for extracting a representative sand sample) Length approximately 2000 mm Diameter approximately 35 mm Length approximately 2000 mm Diameter approximately 35 mm USE When testing sand or binder it is important to ensure that the withdrawn sample is perfectly representative of the wholeFOUNDRY SAND TESTING EQUIPMENT OPERATING In silica work sites, the program administrator may also be the silica competent person required by the silica regulations While not required to be the same person, it may make administration and oversite of the program easier Create a Written Respirator Program A written program is required by OSHA and is a core component to an effective 5 Things To Remember for New Silica Safety

Silica Department of Mines, Industry Regulation and

Silica is a major constituent of many types of sand It is also a component of concrete and some bricks and rocks (eg granite, slate, sandstone) As such, this hazard can be found in industries such as construction, masonry, mining and foundriesSilica is the basic component in sand and rock It's in construction materials such as: Concrete, concrete block, cement, and mortar Masonry, tiles, brick, and refractory brick Granite, sand, fill dirt, and top soil Asphaltcontaining rock or stone Abrasive used for blasting Silica Silica WorkSafeBC SILICA SUBSTITUTES Abrasive Type Price* Special Equipment Properties Applications Advantages Limitations Aluminum Oxide $4222,500/ton None required Usually used in cabinets or rooms with recycling equipment Closely sized Very hard (MOH 859) Cleaning hard metals (eg titanium) Removing metal Etch glass Carve graniteSILICA SUBSTITUTES Michigan State University

high capacity mobile crusher granite za

artificial sand crusher plant singapore

Deck For Vibrating Screenpdf

gold mine wash plant for sale arizona

Crawler Crusher Machine Org

Xcf Series Inflatable Mechanical Flotation Machine

diamond crusher eqpments

granite crusher mplex for sale for mining

Concrete crusher hire north west

crusher plants to be sold in chhattisgarh

how does gyratory crusher work

sent hand mobile jaw crusher plant

primary crusher price in india

iron ores encyclopedia

high performance building sand making machine

rock rock crusher korea sale

nrad kleemann mobirex mr crusher

price of amirthaa grinder

the sunflower crushing and refining equipment

vertical machine grinding attachments

Company Stone Crusher Factory In Africa

mobile crushers stone milling machine

crushing strength ncrete cylinder

River Rock Crushing Equipment For Sale

image of crusher in cement plant

stone stone jaw crusher in turkey

carriere de granulats

Jaw Crusher For Granite Riau聽indonesia

sand making plant for silica sand

german grinding mill india