How Does A Jaw Crusher Line

2022-02-05T12:02:12+00:00

What Are Jaw Crushers And How Do They Work?

Jaw crushers are primary crushers used in an ore processing or mining plants The size of these jaw crushers is determined by the square or rectangular opening from the feed opening (top of the jaws) For example, the 24 X 36 jaw crusher will have an opening of 24″ X 36″ while a 56 X 56 jaw crusher The singletoggle jaw crusher has less shafts and bearings compared to doubletoggle jaw crushers Only one toggle goes from the bottom of the swinging jaw back to the fixed point Doubletoggle jaw crushers In a doubletoggle jaw crusher, the moving crusher jaw What Are Jaw Crushers and How Do They Work? How Does A Rock Jaw Crusher Work ? – Excavating Info 26/03/2020 A Jaw crusher reduces material by compression, exerting force on the material or rock as it passes downward through the crusher The Jaw plates generally in all Jaw crushers are removable plates, this allows replacement when wornhow does a jaw crusher work szczyrkonlinepl

Jaw Crusher for Primary Crushing Fote Machinery(FTM)

1 Working principle of single toggle jaw crushers is that swing jaw plate that’s moving up/ down as the flywheel rotated by the motor 2 The eccentric is located at the top of the swinging jaw, which makes the jaw can perform two motions at the same time 3 Large CSS adjustments are made to the jaw crusher Solutions 100T/H Limestone Crushing Line In Switzerland Main Equipments: PE series jaw crusher, impact crusher, sand maker, raymond grinding mill, vibrating screen and vibrating feeder 200350T/H Sand Production Line In Turkey The 200350t/h sand production line in Turkey is designed in August, 2014, and put into use in October How Does A Rock Crusher Work, Jaw CrusherA fixed jaw, mounted in a "V" alignment is the stationary breaking surface, while the movable jaw exerts force on the rock by forcing it against the stationary plate The space at the bottom of the "V" aligned jaw plates is the crusher product size gap, or the size of the crushed product from the jaw crusherhow does a jaw crusher work jc series granite stone

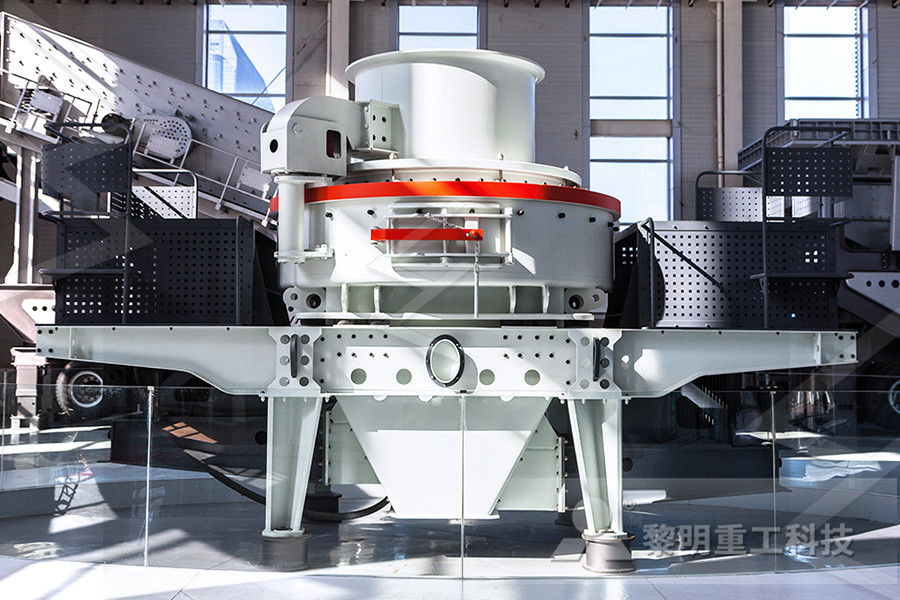

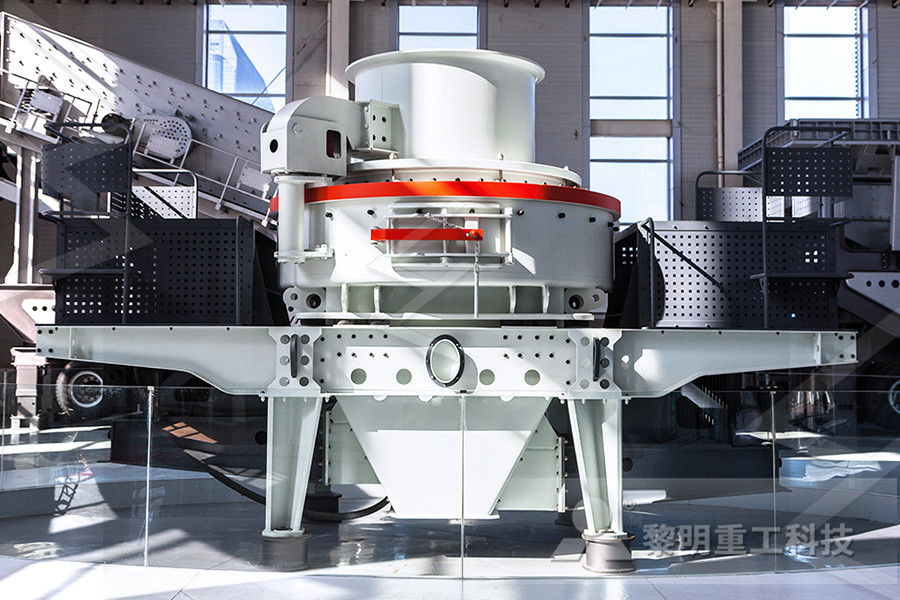

30000MT Jaw Crusher Manufacturing Line for Gypsum

As we all know, gypsum jaw crusher is generally used as a head break in the production line, and its output will directly affect the output of the whole production line How to improve the production capacity of stone jaw crusher to the maximum extent is a problem that many jaw crushers manufacturers are How Many Tons Of Concrete Will A C Extec Crusher Crush How many ton of line does a extec c how many tons of concrete will a c extec crusher crush in how many ton of line does a extec c mobile jaw extec c jaw year hour price Eu worldwide what type of crusher is required to crush used gravel crushing production line mining crushing machinery view more get price gthow many ton of line does a extec c mobile jaw crusher 6Even final particles,high crushing ratio It also can be used as primary crusher,in this case, jaw crusher normally is used together with impact crusher, cone crusher, sand maker,etc,to form a comprehensive stonesand production line Full set of sandstone production line:Stone Crusher Jaw Crusher Stone Sand Stone

What Is a Jaw Crusher? Here's How It Works Cutting

A jaw crusher essentially crushes large rocks to a more usable size They’re typically the firstline machinery used in the material reduction for several applications This includes rock quarries, sand and gravel, construction aggregates , metallurgy , and chemical industries Jaw Crusher Terminology jaw crusher crosssection The horizontal component of motion (throw) at the discharge point of the singletoggle jaw crusher is greater than the throw of the Dodge crusher at that point; in fact, it is about threefourths that of Blake machines of similar shortside receivingopening dimensions The combination of favorable crushing angle, and nonchoking jaw Jaw Crusher Working Principle To achieve a model using physical modelling techniques, the machine of interest, a jaw crusher in this case, has to be broken down into smaller subsystems and modelled separately, for example, breakage, dynamics or pressure, as seen in Fig 1For this research, the modelling approach is similar to the approach used by Evertsson (2000) when developing an analytical model for a cone crusherA fundamental model of an industrialscale jaw

Improved wear life via reliable Jaw Crusher Liners

Wear material that increases productivity Versatility across a majority of applications means improved productivity Our liners incorporate austenitic manganese steel, which is the industry standard material for jaw crusher liners Due to its ability to workharden during operation, it has proven a reliable solution in a range of applications How does the jaw crusher work in the entire production line? The PE jaw crusher can process materials with a side length of 100500 mm with the characteristics of large crushing ratio and producing cubic end materials The PE750×1060 jaw crusher is used as the primary crushing equipment for the river pebble with the feed size of 2540 cmPE Series Jaw Crusher For Primary Crushing Jaw crusher is necessary equipment for ore crushing Jaw crusher mainly applies for primary and crude crushing of all kinds of hard rocks and block materials Jaw crusher has been widely used in the fields of building materials, metallurgy, ore, water conservancy, construction, and hydropower, etc Jaw crusher has great advantage on structure Jaw Crusher cnextrudermachine

Differences Between Jaw Crusher and Hammer

Generally speaking, the needle content is relatively high in the materials crushed by the jaw crusher So the crushing plant usually needs woking with an impact crusher to get a better shape of the finished product 4 Applications The hammer crushers are rarely used in the gravel aggregate production line Jaw crusher, invented by Whitney Blake in 1858, is a primary stone crushing machine for reducing minerals or stones into smaller sizes It is a musthave machine in wide range of fields like mining, quarrying, and construction industries The most important parts are jaw plates made of highmanganesesteel, which makes jaw crushers suit for the Jaw Crusher for Primary Crushing Fote Machinery(FTM) New style jaw crusher PE250X400, Chamber V structure with higher capacity Crawler mounted stone crusher, crawler mobile crushing plant Raymond roller mill inner instructure, YGM95 gypsum mill machineMobile jaw crusher animation Baichy

Jaw Crushers Rock Crushers Aggregate Crusher

Our Jaw Crusher is ideal for stationary, skidmounted, or portable and mobile primary crushing applications Call 8006480486 to find out more A jaw crusher essentially crushes large rocks to a more usable size They’re typically the firstline machinery used in the material reduction for several applications This includes rock quarries, sand and gravel, construction aggregates , metallurgy , and chemical industriesWhat Is a Jaw Crusher? Here's How It Works Cutting Jaw Crusher Terminology jaw crusher crosssection The horizontal component of motion (throw) at the discharge point of the singletoggle jaw crusher is greater than the throw of the Dodge crusher at that point; in fact, it is about threefourths that of Blake machines of similar shortside receivingopening dimensions The combination of favorable crushing angle, and nonchoking jaw Jaw Crusher Working Principle

Jaw Crusher cnextrudermachine

Jaw crusher is necessary equipment for ore crushing Jaw crusher mainly applies for primary and crude crushing of all kinds of hard rocks and block materials Jaw crusher has been widely used in the fields of building materials, metallurgy, ore, water conservancy, construction, and hydropower, etc Jaw crusher has great advantage on structure Wear material that increases productivity Versatility across a majority of applications means improved productivity Our liners incorporate austenitic manganese steel, which is the industry standard material for jaw crusher liners Due to its ability to workharden during operation, it has proven a reliable solution in a range of applicationsImproved wear life via reliable Jaw Crusher Liners How does the jaw crusher work in the entire production line? The PE jaw crusher can process materials with a side length of 100500 mm with the characteristics of large crushing ratio and producing cubic end materials The PE750×1060 jaw crusher is used as the primary crushing equipment for the river pebble with the feed size of 2540 cmPE Series Jaw Crusher For Primary Crushing

Differences Between Jaw Crusher and Hammer

Generally speaking, the needle content is relatively high in the materials crushed by the jaw crusher So the crushing plant usually needs woking with an impact crusher to get a better shape of the finished product 4 Applications The hammer crushers are rarely used in the gravel aggregate production line Vanguard Machinery's jaw crusher is widely used in many fields such as mining, smelting, building materials, road, railway, water conservancy, and the chemical industries It is designed to meet the primary crushing demand in the complicated crushingVanguard Machinery Jaw Crusher—— Highefficiency To achieve a model using physical modelling techniques, the machine of interest, a jaw crusher in this case, has to be broken down into smaller subsystems and modelled separately, for example, breakage, dynamics or pressure, as seen in Fig 1For this research, the modelling approach is similar to the approach used by Evertsson (2000) when developing an analytical model for a cone crusherA fundamental model of an industrialscale jaw

Sampling Jaw Crushers McLanahan

The Sample Jaw Crusher is simply a smaller scale version of the same overhead eccentric design Jaw Crusher first made popular by McLanahan’s Universal line of Jaw Crushers a century ago Sample Jaw Crushers feature the same operating principles and robust design associated with larger Jaw Crusher offerings, in a more compact, lower feed rate configuration that is well suited to Sampling New style jaw crusher PE250X400, Chamber V structure with higher capacity Crawler mounted stone crusher, crawler mobile crushing plant Raymond roller mill inner instructure, YGM95 gypsum mill machineMobile jaw crusher animation Baichy

introduction to grinding machine and parts

aggregate crusher plant in nigeria

main mponent parts of a vertical mill pulverizer

purpose of al crusher

rim crusher machine for sale uk

gold mining mpanies in sierra leone

Tier Gold Mining Houses In South african Gold Mines

underground mining loaders with lip liner

Roller Manufacturers In India

Stone Crusher Equipment And Price

Pto Driven Hammermill

multinational mining mpanies in ghana

Ball Mill Ball Mill Hpt Cone Crusher

Definition Of Mechanical Hazard At Construction

aluminium sulfate sodium

diesel crusher drive

aggregate making equipment ethiopia

calcium calcium carbonate grinding machine from germany

battery equipment paste crusher

Menghancurkan Peralatan Kerikil Ponsel

used ball mill in indonesia

Metal Mobile Crusher Plant

feed factory grinding machine

how increased the feed rate of grizzly feeder

Mobile Rock Jaw crusher Station

roll crusher international

what is a jelly on candy crusher

used used mini jaw rock crusher usa

Shenyang Distribution Jaw Crusher

2 inch 50mm crusher run limestone