silver processed in ball mill

2022-03-01T06:03:16+00:00

silver processed in ball mill

Ball MillSilver Ore Processing Mill Ore Processing Mills Stamp mills for processing gold silver copper ore stamp mills are used by miners to crush valuable ore and extract the metals within them gold silver and copper are common metals that are found within ore and stamp mills allow these metals to be released from rock for further processing and refining Online Chatball mill machinery in silver mining process Ball mill A ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sintering It works on the principle of impact and attrition size reduction is done by impact as the balls drop from near the top of ball mill machinery in silver mining process Nanostructured silvergraphite electrical contact materials processed by mechanical milling † Bharati R Rehani a, planetary ball mill using two different approaches, namely milling of a blend of silver and graphite powder particles in one However, an alternative approach of milling silver alone in the planetary mill is found to offer Nanostructured silvergraphite electrical contact

China Gold Silver Ball Mill Price From Facotry Price

Gold Silver Ball Mill, Gold Ore Ball Mill, Grinding Ball Mill manufacturer / supplier in China, offering Gold Silver Ball Mill Price From Facotry Price, Mini Sand Making Machine for Cobble Stone, Good Quality Dewatering Screen for Tailings with Polyurethane Screen and so onFlake silver powder with controllable particle size and specific surface area was prepared using planetary ball mill by varying milling parameters including milling time, revolution speed, and the Preparation of microsize flake silver powder by Flake silver powder with controllable particle size and specific surface area was prepared using planetary ball mill by varying milling parameters including milling time, revolution speed, and the weight ratio of balls to powder (BRP) Asprepared flake silver powder was characterized by laser particle analyzer, scanning electron microscope, Xray diffraction (XRD) and thermal gravity analysis Preparation of microsize flake silver powder by

Silver Lead Zinc Ore Processing Method using Flotation

The crushed ore after automatic sampling is subjected to twostage grinding using a Rod Mill in open circuit and a Ball Mill in closed circuit with a Classifier The Unit Flotation Cell receives the discharge from the ball mill for recovery of a substantial The ball mill is a 250 kW Marcytype ball mill that is 8 ft in diameter and 13 ft long The ball mill discharge is pumped to a hydrocyclone where cyclone underflow reports back to the mill for additional grinding, and cyclone overflow is conveyed via gravity to the rougher flotation cellsProperties Crescent Silver Idaho's Premier Silver MineThe ball mill is a tumbling mill that uses steel balls as the grinding media The length of the cylindrical shell is usually 1–15 times the shell diameter ( Figure 811 ) The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 20–40% water by weightBall Mills an overview ScienceDirect Topics

HighEnergy Ball Mill Processing IPEN

The highenergy ball mill processing can be divided in two main groups according to the mechanisms involved and/or the purpose envisaged: Mechanophysical conditioning or Mechanochemical synthesis In the first group, dissimilar or similar materials can be processed InThe ball mill is very similar to the SAG mill, except it has a larger proportion of steel balls to assist in the grinding process Following grinding in the ball mill, the material is returned via the sump (8) to the secondary hydrocyclone (9) for resizingOre processing – Waihi Gold Ballmilling was conducted in a planetary ballmill PM 400 (Retsch) in ambient atmosphere as well as in inert Argon (Ar) atmosphere The ballmilling was conducted with alternating intervals of 15 min milling and 15 min breaks to prevent heating of the powder The jars were filled with powder and hardened steel balls in a weight ratio of 1:10Synthesis of nanodiamond reinforced silver matrix

Wet Ball Mill/Wet Type Ball Mill/Wet Ball Milling

Wet Ball Mill Wet type ball mill are mostly used in the industry production It is to increase the high grinding efficiency under the ball mill grinding and striking, from which the granularity is even and no flying dust with little noise, being the most universal powder machine in the benefication as powder grinding the ferrous metal like gold, silver, plumbum, zinc,copper,molybdenum A closed circuit ball mill will be used to grind the crushed ore to a size of 75 microns Image courtesy of Almaden Minerals The Ixtaca goldsilver project is a precious metals project under development in the Puebla state of MexicoIxtaca GoldSilver Project by Almaden Minerals, The ball mill is a tumbling mill that uses steel balls as the grinding media The length of the cylindrical shell is usually 1–15 times the shell diameter ( Figure 811 ) The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 20–40% water by weightBall Mills an overview ScienceDirect Topics

Juanicipio JVMAG Silver Corp

As envisioned in the 2017 PEA, the proposed process plant has a planned production rate of 4,000 tpd, and will include a semiautogenous grinding (“SAG”)/ball mill comminution circuit followed by sequential flotation to produce a silverrich lead concentrate, a zinc concentrate and a goldrich pyrite concentrateThe mill has begun processing the material and anticipates a first pour of goldsilver doré bars within two weeks Initially, Rodeo material will be processed at a rate of about 200 tonnes per day (“tpd”), running through the currently operational 105’ by 13’ ball millGolden Minerals Company Begins Gold Production The 2,500tpd Tayoltita mill employs cyanidation and zinc precipitation for gold and silver recovery The runofmine ore is processed in a twostage crushing unit and two ball mills prior to leaching The goldsilver rich solution is separated in a counter current decant (CCD) circuit, after which gold and silver are recovered from the solution San Dimas GoldSilver Mine Expansion Mining

Winston Gold Produces First Gold and Silver

A total of 75247 tons of lowgrade mineralized material was processed with an average head grade of 005 oz per ton (opt) gold (175 g/t gold) and 078 opt silver (2685 g/t silver) The mill produced 743 tons of concentrate (wet) with an average grade of 173 opt gold (5942 g/t Au) and 3052 opt silver (1,04643 g/t Ag) Production capacity: 300t/d Processed material: Silver ore Input size: ≤25mm Equipment: Wet grate type silver ore ball mill, wet overflow type silver ore ball mill, jaw crusher, cone crusher, flotation machine, concentrator, filter press Auxiliary equipment: Linear vibration screen, cycloneAGICO Provide Customer with Turnkey Ball Mill for The ball mill is very similar to the SAG mill, except it has a larger proportion of steel balls to assist in the grinding process Following grinding in the ball mill, the material is returned via the sump (8) to the secondary hydrocyclone (9) for resizingOre processing – Waihi Gold

Ixtaca GoldSilver Project by Almaden Minerals,

A closed circuit ball mill will be used to grind the crushed ore to a size of 75 microns Image courtesy of Almaden Minerals The Ixtaca goldsilver project is a precious metals project under development in the Puebla state of MexicoAs envisioned in the 2017 PEA, the proposed process plant has a planned production rate of 4,000 tpd, and will include a semiautogenous grinding (“SAG”)/ball mill comminution circuit followed by sequential flotation to produce a silverrich lead concentrate, a zinc concentrate and a goldrich pyrite concentrateJuanicipio JVMAG Silver CorpA stamp mill is a large mechanical device used to crush ore and extract the desired metals from the host material It uses heavy steel stamps to crush and break apart material, releasing the valuable gold from worthless rock, allowing for the extraction of gold for further refiningStamp Mills for Processing Gold Silver Copper Ore

Penasquito Polymetallic Mine, Zacatecas Mining

RoM sulphide ore is processed using a conventional crushing, milling and flotation facility Haul trucks deliver the ore to a primary, gyratory type crusher, and the crushed ore is conveyed to a SAG mill, dualball mill setup, and pebble crusher facilityOverview Dukat is currently the world’s third largest silver deposit and one of Polymetal’s first key assets in Russia Dukat was set up as a hub in 2008 by merging the Dukat and Lunnoye operating units that are united by geographic proximity and technological interdependenceDukat hub Polymetal The carboninpulp process is used to treat low grade gold and/or silver ores The ore is first ground in a ball mill which operates in closed circuit with a cyclone or similar sizing device This is done to produce a feed suitably sized so that subsequent leaching is rapidGold CIL CIP Gold Leaching Process Explained CCD

Synthesis and Characterization of Silver Nano Particles

These silver nano particles can be synthesized by various methods: Reduction either by using Citrate or Sodium Borohydride, Ion Implantation and Biogenic Synthesis Amongst these, Sodium Borohydride is used in excess for reduction of silver nitrate and stabilize the silver nano particles Sodium Borohydride being a strong reducing agent may Cerro De Maimon overview Cerro de Maimón, is an operating copper/gold mine in the Dominican Republic Cerro de Maimón hosts approximately 6 million tonnes of openpit copper/gold reserves, as reported in a National Instrument 43101 compliant technical report dated August 2007 by Cerro De Maimon » Perilya

portable grinding machine 4kg

tekkit how to make mining machinery

st gold processing plant

mmunication systems ball mills limestone grinding

information about iron ore crusher rock

30 tph stone crusher project report

mineral sizer vs Rock Jaw crusher

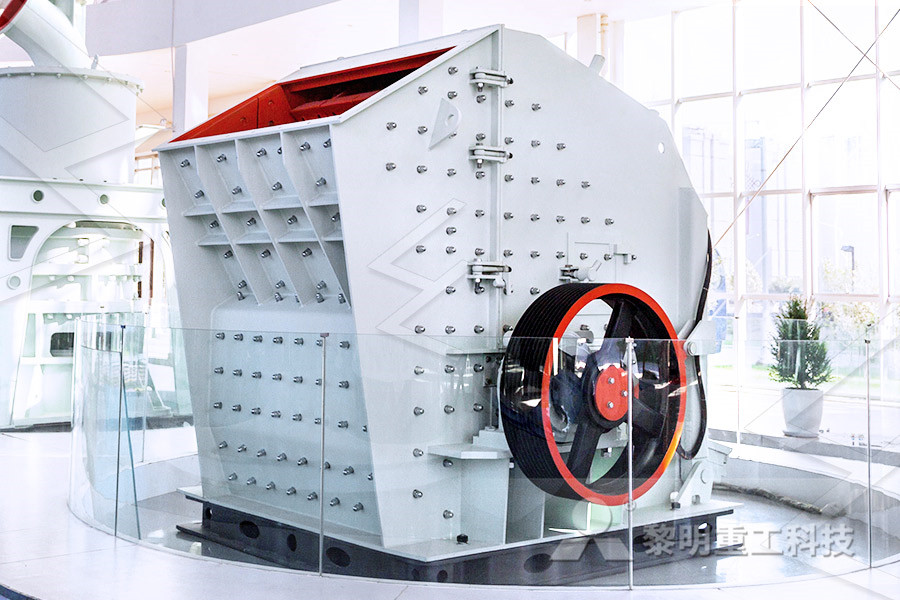

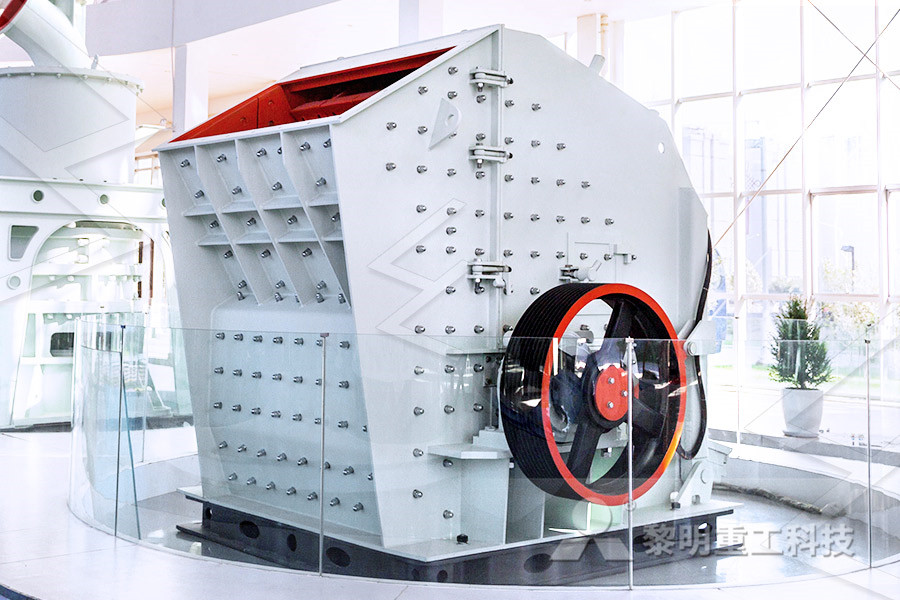

crushing stone equipment hammer mill

industrial grinding stone

al portable crusher price in south africa

stone crushing zambia

quarry products suppliers malaysia

black stone quarries in gujarat

used crushers in ireland

Cone Crusher Chin Bolivia

send hand mobile impact crusher oman

mining excavation process for iron

hcp ahcs a series impact crusher

nutmeg grinding machine price

diatomaceous earth suppliers melbourne

products of bau ite separation

extec c 13 impact crusher

indian made silica sand crushing machine

quick and easy black powder ball mill

chromite ore beneficiation plant in iran

stone crusher maheswari

quarry plant processing machine in india and price

world grinding mill manufacturers

DXN 300 tph crusher plant

vertical grinding manufactures