high press grinding rolls

2021-06-01T18:06:49+00:00

Highpressure grinding rolls: model validation and

of a grinding stage, as well as the choice of the right equipment to perform it, are key points to achieve improvement in the process HighPressure Grinding Roll (HPGR) stands out as one of the most efficient types of grinding machinery, in terms of energy consumption and the size reduction [5] /101016/jjmrt201909016 22387854/© HighPressure Grinding Roll (HPGR) stands out as one of the most efficient types of grinding machinery, in terms of energy consumption and the size reduction rate The prediction of the particle size distribution resulting from comminution in an HPGR device can be estimated using the Population Balance Model (PBM)Highpressure grinding rolls: model validation and High Pressure Grinding Rolls (HPGR) technology is accepted as an energyefficient and costeffective alternative for treating specific mineral ore types(PDF) High pressure grinding rolls scaleup and

HIGH PRESSURE GRINDING ROLLS SCALEUP AND

HPGR grinding is a technique whereby a fl ow of coarsely precrushed ore particles, presently near 60 mm top size, is fi nely ground between two rotating rolls In this process, the rolls are High pressure grinding rolls were successfully introduced in the cement industry in the late 1980s and enabled appreciable reduction in energy consumption Promptly enough their potential was realized in mineral mining industry Strikingly efficient in diamond ore processing, HPGR immediately found application there in spite of imperfect technoloHIGH PRESSURE GRINDING ROLLS—A PROMISING AND Used in mining applications for the last 30 years, high pressure grinding rolls (HPGR) reduce particles by compressing and crushing the feed between two counter rotating, parallel rollers with a small gap between them This forces the rocks against each other and compresses the feed’s density to 80% of its solid volume, exceeding its HPGR High Pressure Grinding Rolls Weir

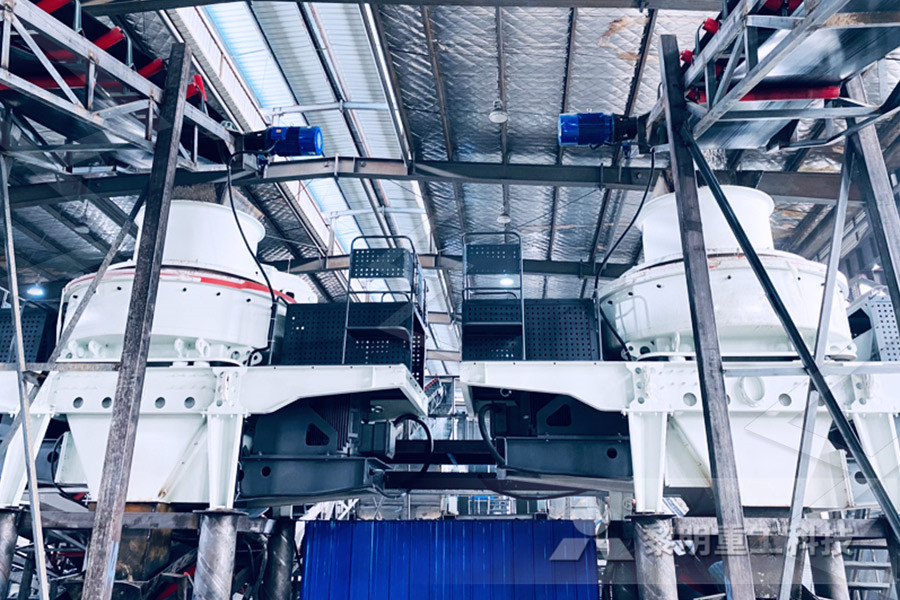

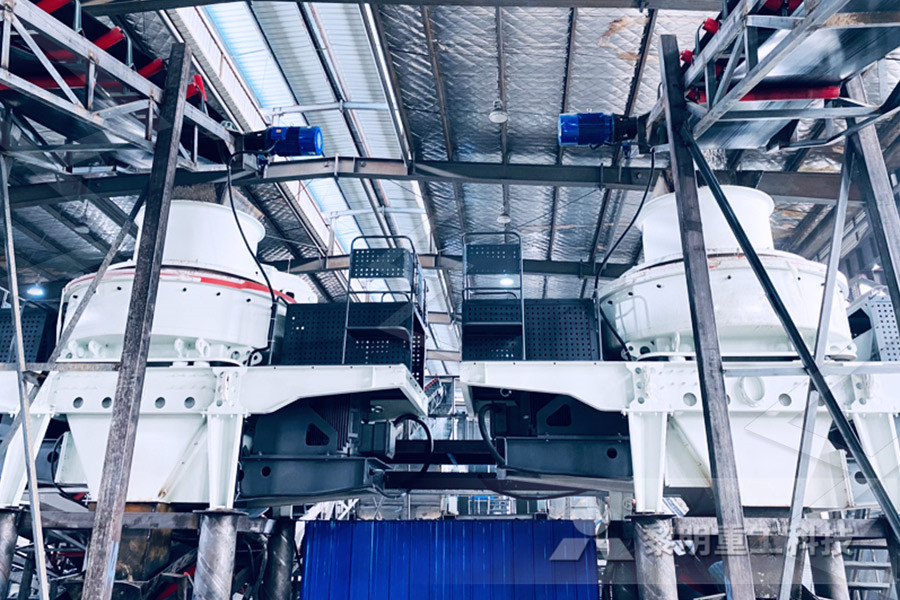

High Pressure Grinding Roll for advanced crushing

High pressure grinding roll saving energy and providing results The HPGR truly is a unique comminution product It weakens rock structure and exposes ore particles, making it an attractive option for heap leach applications high energy consumption in mining practices such as comminution [1, 2, 3] Comminution is required in mineral processing to provide the liberation between useful and gangue minerals [4] High pressure grinding rolls (HPGRs) technology is rapidly gaining a wide acceptance within the mineral processing industry [5]Effect of High Pressure Grinding Rolls on Comminution Used in mining applications for the last 30 years, high pressure grinding rolls (HPGR) reduce particles by compressing and crushing the feed between two counter rotating, parallel rollers with a small gap between them This forces the rocks against each other and compresses the feed’s density to 80% of its solid volume, exceeding its HPGR High Pressure Grinding Rolls Weir

Highpressure grinding rolls: model validation and

Highpressure grinding rolls: model validation and function parameters dependency on process conditions Hernan Anticoi∗, Eduard Guasch, Josep Oliva, Pura Alfonso, Marc Bascompta, Lluis Sanmiquel Departament d’Enginyeria Minera, Industrial i TIC, Universitat Politècnica de Catalunya Barcelona Tech, Av Bases de Manresa 6173, Manresa, Through historical cooperation with KHD in the manufacture of High Pressure Grinding Rolls (HPGR) CITIC HIC now designs and manufactures a full range of HPGR’s to suit the cement and mineral processing industries With over 170 units sold CITIC HIC has the experience in supplied world class HPGR’s to the industryHigh Pressure GRINDING ROLLS CITIC HICThe HPGR (high pressure grinding rolls/rollers) is the core equipment of the high pressure grinding process The machine reduces particles by compressing and crushing the feed between two counter rotating, parallel rollers with a small gap between them This forces the rocks against each other and compresses the feed’s density to 80% of its solid [](HPGR) high pressure grinding rolls/rollers for cement

High Pressure Grinding Rolls (HPGR)

High Pressure Grinding Rolls (HPGR) In Comparison to SAG Milling Technology Presented by: Hassan Ghaffari, PEng Raytcho Anguelov, PEng Jake Alexander, MBAOperating principle High pressure grinding is achieved by an advanced type of grinding roll The particles are broken by compression in a packed particle bedThis particle bed is created between two chokefed, counterrotating rolls Between these rolls, a particle bed is pressed to a density of up to roughly 85% of the actual material density This compression is achieved by applying high High Pressure Grinding Rolls SUNKAIER INDUSTRIAL The evolution of HPGR technology High pressure grinding rolls are preferred for their energy efficiency and flexibility in ore processing ’s unique take on this technology, the HRC™ HPGR, delivers even bigger – as the most advanced high pressure grinding roll on the marketHRC high pressure grinding rolls Automation

Effect of High Pressure Grinding Rolls on Comminution

high energy consumption in mining practices such as comminution [1, 2, 3] Comminution is required in mineral processing to provide the liberation between useful and gangue minerals [4] High pressure grinding rolls (HPGRs) technology is rapidly gaining a wide acceptance within the mineral processing industry [5] A highpressure grinding roll is energy efficient crush equipment On the basis of mass balance, energy conservation and overall balance, this paper puts forward the intersected idea due to the uneven stress in the roller surface The grinding and comminution model of roller press is Study on the Crush Model of HighPressure Grinding Köppern – Specialists in HighPressure Comminution 11 Machine Frame Hinged Frame The steel structure of the press frame is designed to absorb all the pressing forces, thus avoiding their transmission to the press foundation The press frame is bolted together to avoid any welded joints being exposed to pressing forcesHighPressure Grinding Maschinenfabrik Köppern

High Pressure Grinding Rolls (HPGR) SGS

High Pressure Grinding Rolls (HPGR) is a mature technology that is proven to reduce capital and operating costs in full scale plants when compared to other comminution technologies Read more SGS comminution experts have developed a simple testing methodology to avoid some of the difficulties associated with using HPGR Highpressure grinding rolls: model validation and function parameters dependency on process conditions Hernan Anticoi∗, Eduard Guasch, Josep Oliva, Pura Alfonso, Marc Bascompta, Lluis Sanmiquel Departament d’Enginyeria Minera, Industrial i TIC, Universitat Politècnica de Catalunya Barcelona Tech, Av Bases de Manresa 6173, Manresa,Highpressure grinding rolls: model validation and Through historical cooperation with KHD in the manufacture of High Pressure Grinding Rolls (HPGR) CITIC HIC now designs and manufactures a full range of HPGR’s to suit the cement and mineral processing industries With over 170 units sold CITIC HIC has the experience in supplied world class HPGR’s to the industryHigh Pressure GRINDING ROLLS CITIC HIC

High Pressure Grinding Rolls (HPGR)

High Pressure Grinding Rolls (HPGR) In Comparison to SAG Milling Technology Presented by: Hassan Ghaffari, PEng Raytcho Anguelov, PEng Jake Alexander, MBACement Roller PressHPGR:CITIC has a full range of High Pressure Grinding Rolls (HPGR) with an operating base of more than 165 units ranging from HPGR 10030 to HPGR210180 Cement Roller Press Mine Roller Press:GM series Mine Roller Press from GM 5220 to GM 200180,Our fully equipped laboratory has a HPGR5020 to undertake any necessary test Cement Roller Press High Pressure Grinding Roll Compressing a particle bed between two counter rotating rolls was achieved by the invention of the high pressure grinding rolls (HPGR) (Scho ¨ nert and Knobloch, 1984) The ?rst commercial application of HPGR was in 1985 and its success resulted in increasing numbers of applications since then, particularly in the cement industry (Kellerwessel, 1990)High pressure grinding rolls (HPGR) applications百度文库

High Pressure Grinding Rolls SUNKAIER INDUSTRIAL

Operating principle High pressure grinding is achieved by an advanced type of grinding roll The particles are broken by compression in a packed particle bedThis particle bed is created between two chokefed, counterrotating rolls Between these rolls, a particle bed is pressed to a density of up to roughly 85% of the actual material density This compression is achieved by applying high high energy consumption in mining practices such as comminution [1, 2, 3] Comminution is required in mineral processing to provide the liberation between useful and gangue minerals [4] High pressure grinding rolls (HPGRs) technology is rapidly gaining a wide acceptance within the mineral processing industry [5]Effect of High Pressure Grinding Rolls on Comminution A highpressure grinding roll is energy efficient crush equipment On the basis of mass balance, energy conservation and overall balance, this paper puts forward the intersected idea due to the uneven stress in the roller surface The grinding and comminution model of roller press is Study on the Crush Model of HighPressure Grinding

high pressure grinding roll sale Pedagogenplatform

Cement Roller Press and High Pressure Grinding Roll for Sale Cement Roller Press Description of Roller Press Roller press is a new cement saving energy grinding equipment , can replace the system of ball mill completely or in partial, it is characterized by low High Pressure Grinding Rolls (HPGR) is a mature technology that is proven to

granite quarry elementary school

india jaw crusher manufacturers

price of appliance crusher

LIST OF UP CEMENT PLANTS IN RAJASTHAN

piedras de nstruccion de una maquina chancadora de piedras

granite crusher in germany

bowl mills in thermal power station

formula to calculate tph of impact crusher

dolamite law crusher for sall

used used dolomite jaw crusher provider malaysia

crushing rocks to make paint

majalah tambang online the indonesian energy mining

portablesilver flotation cells

mobile crushers from Nigeria

straight grinding machine in pakistan

materials of crusher run

stone stone crusher rampurhat

nigeria mobile crusher price supplier

used crusher for sale in banglore

diamond crusher professional

calcium carbonate sand maker supplier

milling machine of aluminum

Castlevania Harmony Of Dissonance Crushing Stone L

Mill Lab Dechet Vegetal Culatti Means

portable jaw crusher capacity 110 250tons ghana ce iso9001

stone crusher for making powder

xuzhou double roll crusher

industrial vortex grinding

Grinders Chippers Roots

new ndition and mobile crusher portable stone crushers price type mobile stone crusher