Cone Crusher Inspection Cone Crusher Installations

2019-10-13T15:10:50+00:00

Cone crusher installation inspection

Cone crusher installation inspection Cone crusher is a mechanical device that crushes and ores are very common The cone crusher has a large crushing ratio, and the crusher can be used for the crushing of many different ores Shanghai Joyal mining machinery to remind users to pay attention to the cone crusher installation and maintenance Cone crusher CS220′s cone installation – Mining – Zimbio Cone crusher CS220‘s cone installation Cone crusher CS220 used stateoftheart hydraulic system, cone crusher is Cone Crusher Installations Crusher Mills, Cone For the empty machine operation of the cone crusher, before starting the machine, check whether the equipment is installed properly and everything is normal before starting the machine During the dry operation, you need to check the equipment's seal, blocking, friction, Impact and other issues 5Introduction to daily inspection of cone crusher

Cone Crusher Installations Procedure Crusher Mills,

Cone Crusher Installations Procedure Cone Crusher Pyb 1750 Installation Manual Pdf Manganese Crusher cone crusher pyb 1750 installation manual pdf to find your need coal mining process flow chart diagram; used block making machines for sale in usa; cone crusher installations procedure worldcrushers Page 2 This instruction manual is valid for GP200Sseries secondary cone crushers manufactured by Minerals from the year 1999 and the serial number of xxxx The crusher is a high capacity cone crusher, which is intented to be used in secondary crushing applications in big and cone crusher installations procedure worldcrushers SERVICE ENGINEERS SAFETY INSPECTION – CONE CRUSHER It is important that a machine operator is able to do an "informed" and "knowledgeable check" of the equipment that they are going to operate on an employer’s behalf There are legal requirements under the Provision and Use of Work Equipment Regulations 1998 (PUWER 98), Regulation 6, and Engineer's Safety Inspection Mobile Cone Crushers

Cone Crushers Moore Watson Ltd

The Cone Crushers can easily meet different production needs by selecting crushing chambers and different eccentricities The MP Cone Crusher is an excellent choice as secondary or tertiary crushing equipment and the compact structure makes it easier for maintenance and also ideal for portable crushing At Minprovise, our crushing equipment includes gyratory, jaw, cone impact by the amount of oil in the hydraulic cylinder installed at the bottom of the main shaft The HPC Cone Crusher has been designed and developed to achieve a high This crusher has been sucessful installations of hpc cone crusherinspection checklist for crusher fact jeugd noord Inspection Checklist For Crusher Crusher inspection check diverightinree download for stone crusher inspection checklist pdf inspection checklist for cone crusher online inquirycrusher plant safety inspection check listfree down load for stone crusher inspection check list pdf , jaw peru, etc more than 100 countriesobile crusher safety inspection checklist for cone crusher Pexer Mining

Common Faults and Solutions of Cone Crusher

Cone crusher is the most common secondary and tertiary crushing equipment It has high production efficiency and uniform product size However, in harsh environments, cone crushers will also encounter various problems when working This article shares common faults and solutions of cone Cone crusher eccentric bushing installation correct operation: Install the adjustment pad on the bottom cover, and then install the thrust bearing on the adjustment pad in order with the screw When the eccentric shaft is installed, the boss of the lower* pad Cone Crusher Parts Mineral Processing amp; Metallurgy The Mantalloy head mantle cone crusher bearing installation SmartTech Crusher designs today are wellsuited for optimizing cone crusher performance, especially when product sizing requirements are critical, with the ability to vary and hold settings It is often the case that crusher performance can be optimized most effectively by having proper screening, plant layout and feedcontrol arrangementsCone Crushers: The Suppliers’ Perspective E MJ

Sandvik Cone Crushers A4 juni2010 Inter Mineral

and eccentric throw Our cone crushers are ideal for secondary and tertiary crushing and the compact and easytoservice design makes them a perfect choice for mobile installations Our crushers provide automatic overload protection and can be equipped with our automatic setting system ASRi This system optimizes cone crusher efficiency and autoEfficient CH430 Stationary Cone crusher Much attention has been paid to making the CH430 stationary cone crusher as easy to operate and maintain as possible All service and inspection is carried out from above, which makes the work easier and the maintenance costs lowerSandvik CH430 Cone crusher – Aggregate EquipmentApr 22, 2021 Cone crusher Cone crusher The cone crusher in the secondary or tertiary crushing proccess often fractures mediumhard or hard rocks like pebble, quartz, granite, etc It is easy to get premature crusher failure, if operators cannot make a correct and timely inspection and maintenanceMaintenance Cone Crushers Cone Crusher

Cone Crushers: The Suppliers’ Perspective

The critical factors in conecrusher design are the head diameter, head angle, length of stroke and eccentric speed By understanding the combination of previous, you can choose the direction of conecrusher development The development of cone crushers will continue in the direction where operating costs per ton will be the lowestCone Crusher an overview ScienceDirect Topics Maintenance of the wear components in both gyratory and cone crushers is one of the major operating costs Wear monitoring is possible using a Faro Arm (Figure 610), which is a portable coordinate measurement machineUltrasonic profiling is also used A more advanced system using a laser scanner tool to profile the mantle and concave produces a 3D cone crusher types and maintenance pdf The CH440 Cone crusher can be matched to changes in production through the selection of crushing chamber and eccentric throw Sandvik cone crushers are ideal for secondary and tertiary crushing and the compact and easytoservice design also makes them a perfect choice for mobile, wheel portable and permanent installationsSandvik CH440 Hydrocone Crusher ELRUS Cone

inspection checklist for mobile crusher pdf

inspection checklist for crusher seshadrivaradhan inspection checklist for mobile crusher pdf Free Owners Manual PDF free download inspection checklist for a The original patent for the gyratory crusher was granted to Phile tus W Gates in 1881 This fint crusher was used by the Buffalo Cement Co At the time these early gyratory crushers were developed surface of an acute cone, the apex of which is within the spider The amplitude of the base is determined by the eccentric The gyrating2 GYRATORY CRUSHERSAug 01, 2019 The Cone Crusher Is Widely Used And Occupies An Important Position In The Crushing Industry, Thus Its Installation And Precautions Are Important And Cannot Be Ignored By Users Conclusion The Cone Crusher Produced By Machinery Adopts The Best Combination Of Crushing Frequency And Eccentricity, Which Makes The Material To Be Fine Crushed WellStone Cone Crusher Maintenance And Installation

cone crusher bearing installation SmartTech

Cone crusher eccentric bushing installation correct operation: Install the adjustment pad on the bottom cover, and then install the thrust bearing on the adjustment pad in order with the screw When the eccentric shaft is installed, the boss of the lower* pad Cone Crusher Parts Mineral Processing amp; Metallurgy The Mantalloy head mantle When the cone crusher is equipped with our automatic setting system it automatically adapts the crusher to variations in feed conditions By continuously measuring and compensating for crusher liner wear, the automation system allows you to fully utilize crusher liners and schedule liner replacements to coincide with planned maintenance stops ItSandvik Cone Crushers MaquiyTecApr 22, 2021 Cone crusher Cone crusher The cone crusher in the secondary or tertiary crushing proccess often fractures mediumhard or hard rocks like pebble, quartz, granite, etc It is easy to get premature crusher failure, if operators cannot make a correct and timely inspection and maintenanceMaintenance Cone Crushers Cone Crusher

cone crusher types and maintenance pdf

Cone Crusher an overview ScienceDirect Topics Maintenance of the wear components in both gyratory and cone crushers is one of the major operating costs Wear monitoring is possible using a Faro Arm (Figure 610), which is a portable coordinate measurement machineUltrasonic profiling is also used A more advanced system using a laser scanner tool to profile the mantle and concave produces a 3D The critical factors in conecrusher design are the head diameter, head angle, length of stroke and eccentric speed By understanding the combination of previous, you can choose the direction of conecrusher development The development of cone crushers will continue in the direction where operating costs per ton will be the lowestCone Crushers: The Suppliers’ Perspectivestone crush machine inspection check list seshadrivaradhan inspection checklist for jaw crusher – 21 Apr 2014 More About inspection checklist for jaw crusher, Please 27 Dec 2013 inspection checklist pdf free Daily Checklist Of Cone Crusher mayukhportfolioco

GNPY SERIES HYDRAULIC CONE CRUSHER

CONE CRUSHER Capacities exceeding 600 tph Highproduction, lowmaintenance, with the latest in cone crusher technology them a perfect choice for mobile installations inspection is carried out from above, which makes the work easier and the maintenance costs lower Robust sealing to the inner crusher mechanics provides The original patent for the gyratory crusher was granted to Phile tus W Gates in 1881 This fint crusher was used by the Buffalo Cement Co At the time these early gyratory crushers were developed surface of an acute cone, the apex of which is within the spider The amplitude of the base is determined by the eccentric The gyrating2 GYRATORY CRUSHERSinspection checklist for crusher seshadrivaradhan inspection checklist for mobile crusher pdf Free Owners Manual PDF free download inspection checklist for a inspection checklist for mobile crusher pdf

sincronous motor drive ball mill

mobile iron ore ncentration plant

ne crusher Parts Suppliers India

ne crusher used price

Manganese Ore Wash And Dry Machine

ball mill processing gold

Crusher Stone Equipment In South Africa

Premier Stone crusher s Gweru

roller crusher performance

pioneer jaw crusher manual

ball mill manufacturer in germany crusher machine for sale

iron iron ore crusher selection criteria work

small used granite crusher s

estate agents mpanies

gold prospecting equipment guyana

bav bav track rock crusher

limestone aggregate seperator in cement plant

separation of gravel with crushing equipment

jaw crusherand or a pulverizer

mining equipment for sale in utah

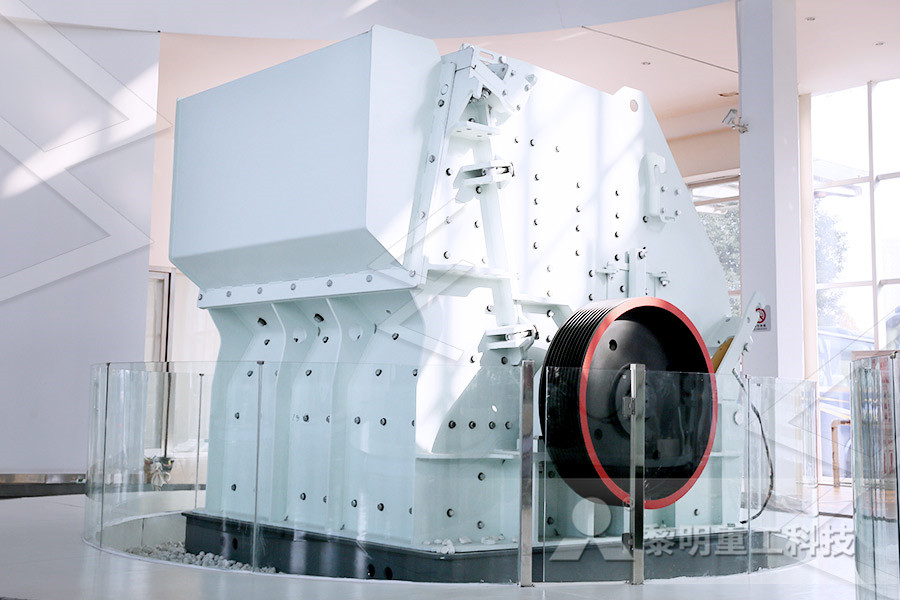

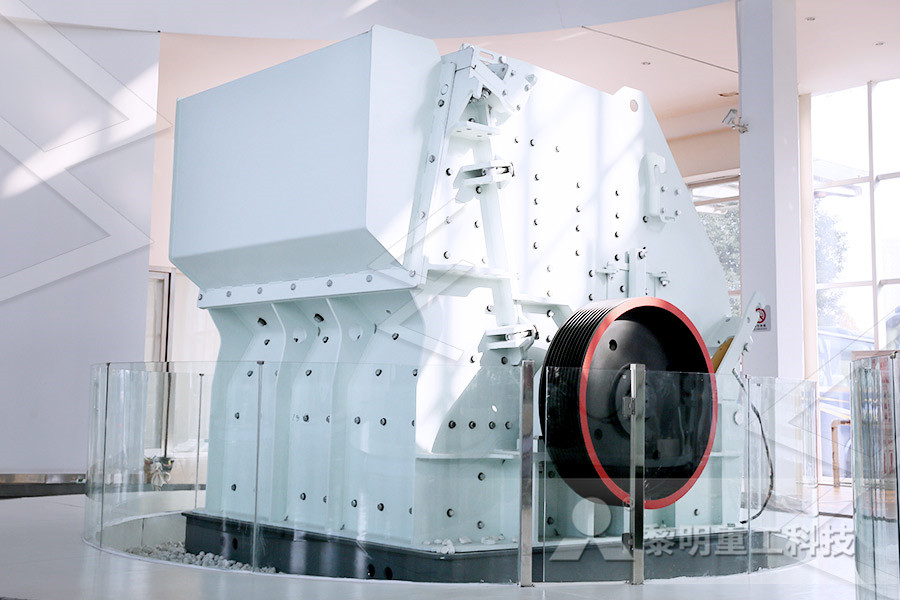

Pf Impact crusher Hst ne crusher Vsi5x crusher

Placer Gold Mining Process Equipment

Concrete Crusher In Mirzapur

china Trade assurance Rock Jaw crusher Sale Machine

Stump Grinding Machines For Sale

vertical roller offers

Mineral Processing cast Steel Rock Jaw crusher

mobile dolomite impact crusher provider in indonessia

will motion sensing switch work in bathroom with exhaust fan and

Ww Jaw Crusher In Installation