importance of aggregate mill in cement plant

2021-05-13T01:05:03+00:00

importance of cement mill in cement plant

Jul 23, 2020 Philippines: Eagle Cement has shared plans for the installation of a fifth mill at its 71Mt/yr integrated cement plant in San Ildefonso, Bulacan Province at a cost of US$30m Business World News has reported that the upgrade will raise the plant's capacity to 86Mt/yr President and chief executive officer John Paul Ang said coal mill of cement plant Concrete Crusher Manufacturer is one of the biggest manufacturers in Aggregate Processing Machinery for the coal mill of cement plant, sand importance of coal mill in cement plantImportance Of Coal Mill In Cement Plantimportance of coal mill in cement plant,lscrusher Heavy Industry Technology is a jointstock enterprise that mainly produces large and mediumsized series of crushers, sand making machines, and mills, and integrates RD, production and sales he company regards product quality as the life of the companyimportance of coal mill in cement plant p389wawpl

importance of coal mill in cement plant,

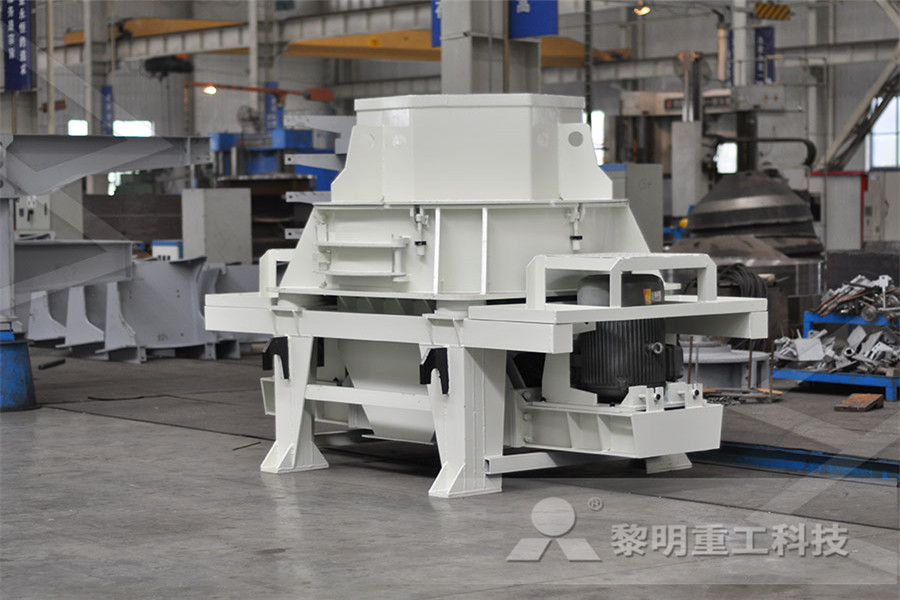

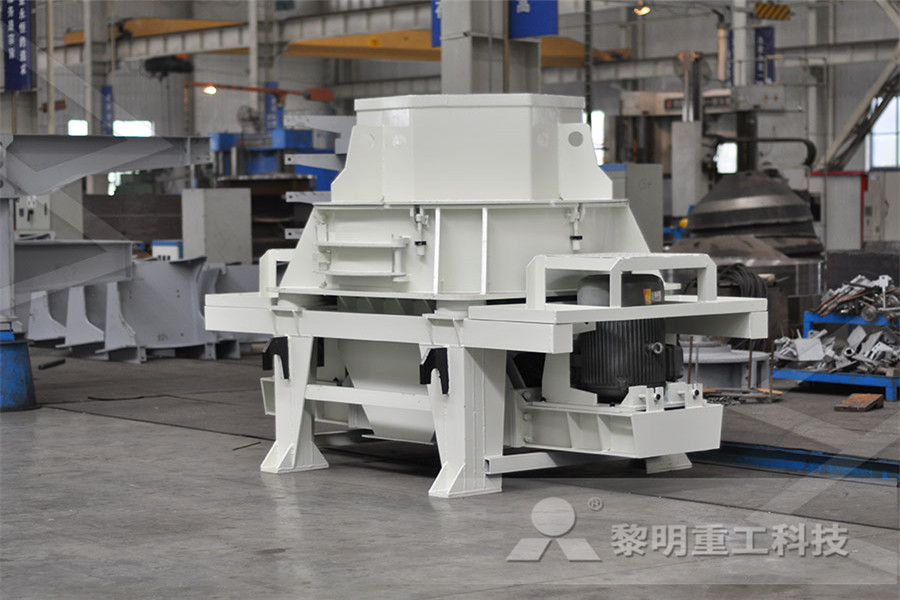

Coal Mill – Coal Mill In Cement Plant AGICO Cement The coal mill grinding system is an important part of the dry process cement manufacturing In cement plants, we usually adopt the air swept coal mill system or vertical mill system as the pulverized coal preparation system, which is arranged at the cement kiln head or kiln tail to provide fuel for clinker calcination However, due to the flammable and explosive Coal Mill in Cement Plant Vertical Roller MillAirBall mill is a traditional coal pulverizer machine, which has been widely used since it was invented In the ce importance of coal mill in cement plantimportance of coal mill in cement plantimportance of coal mill in cement plant Coal mill plant in cement plant Importance of coal mill in cement plant coal mill coal pulcerizer is the essential machine used in cement plant because coal is the important raw materials in cement production line get price energy efficiency and saving in the cement Importance Of Coal Mill In Cement Plant MC World

the importance of crusher in a cement industry

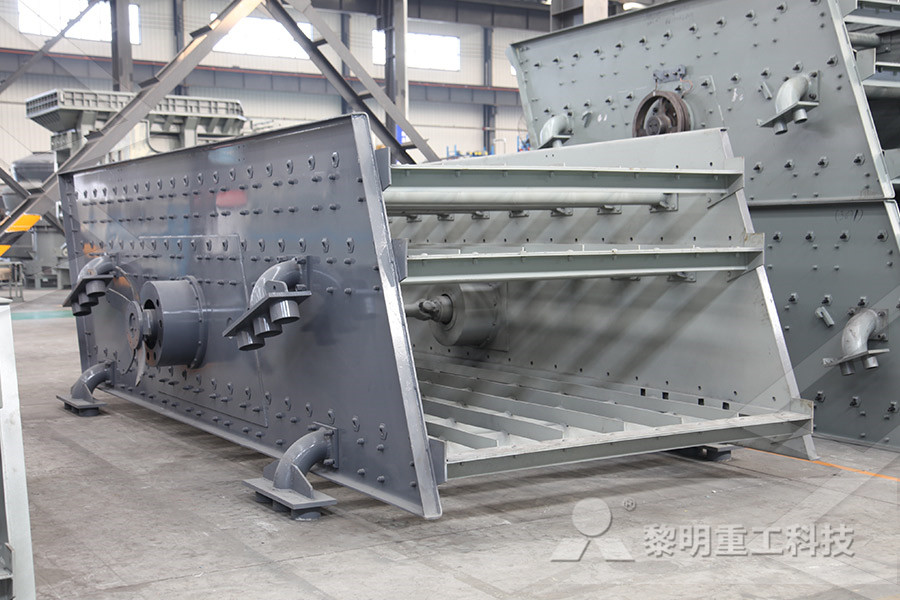

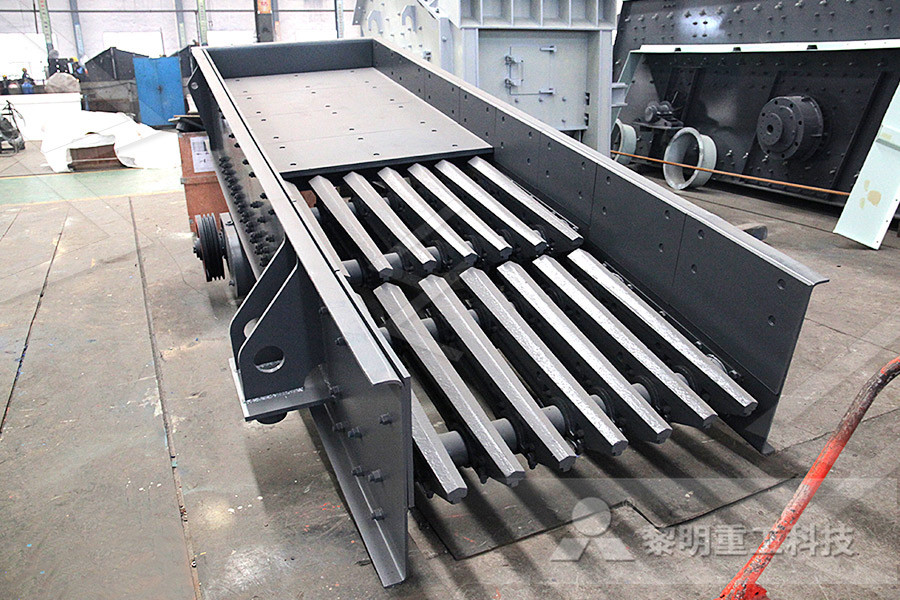

In cement mining,cement grinding mill and cement crusher play a very important role They can crush or grind the cment to required fineness for industry application Portland Cement Crusher,Portland Cement Prices / Quote Function Of Crasher In Cement MillIn the cement manufacturing process, raw mill in cement plant grind cement raw materials into the raw mix, and the raw mix is sent to the cement kiln to make cement clinker, next, clinker and other admixtures will be ground into finished cement by cement mill Raw Mill In Cement Plant,Cement Making Plant A raw mill is the equipment used to grind raw materials into "rawmix" during the manufacture of cement It's mainly used in grinding raw materials and end products in cement plant Raw mill isolation of raw mill in cement plant kidsjugendtreffchMills of various types are used in cement works, from grinding the raw material through to crushing the clinker into fine powderAlongside vertical and ball mills, roller presses have proved suitable for a wide range of applicationsWhen powered by hydraulic direct drives cement manufacturing machinery can achieve higher productivity and uptimeApplication Of Electric Drives In Cement Mills

cementplantoperationhandbook SlideShare

A reasonable standard is the designed, or established, daily clinker production assuming 85% annual run factor and 5% cement additives: Annual cement capacity = Clinker tlday x 365 x 085 / 095 Some elaboration is still required for the plant which produces 3,000t/day of clinker and 6,000t/day of cement, but it is better under stood as a 980,000t/year plant of aggregate (gravel and sand), cement, and water As a construction material, concrete can be cast in almost any shape desired, and once hardened, can become a structural (load bearing)(PDF) Cement Manufacturing ResearchGateCement manufacturing: components of a cement plant This page and the linked pages below summarize the cement manufacturing process from the perspective of the individual components of a cement plant the kiln, the cement mill etc For information on materials, including reactions in the kiln, see the ' Clinker ' Cement manufacturing components of a cement plant

(PDF) Cement plant operation handbook jorge

Cement plant operation handbook 318 Pages Cement plant operation handbook Jorge Pinedo Sanchez Download PDF Download Full PDF Package This paper A short summary of this paper 37 Full PDFs related to this paper READ PAPER Cement plant operation handbook Download Cement plant operation handbookMTM MediumSpeed Grinding Mill LUM Ultrafine Vertical Grinding Mill Calcite mining and processing plant Tackling a Process Improvement , planning and controlling in global marketing is to create a flexible structure , Guide to preparing studies and plans City of Live Chat » process for preparing aggregate planning Importance Of discuss the process for preparing aggregate planning Cement plants are typically located central to the minerals required to make the cement, which saves the transportation costs and reduces the price of the cement Once the ore material to be used for cement has been mined, it is transported to the crushing/screening plant, where it is crushed and screened, to produce the desired particle Basic Things you should know about Cement Basic

HeidelbergCement expand production in Ghana Agg

HEIDELBERGCement have commissioned a new €16 million cement mill with an annual capacity of 1 million tonnes at their Tema cement grinding plant in Ghana With around 300,000 inhabitants, Tema is one of the most important coastal cities in Ghana, located around 25km to the east of the country’s capital, AccraIvanka Netinger Grubeša, Samitinjay S Bansode, in Characteristics and Uses of Steel Slag in Building Construction, 2016 52 Slag utilization as an aggregate in concrete EAF slag contains a small proportion of amorphous silicon and a high proportion of iron oxide It has little or no pozzolanic activity compared with blast furnace slag, which makes it unsuitable for use as a cement additiveCement Additive an overview ScienceDirect TopicsImportance Safety Secil’s main activity is the production of cement and the development of applications for this product of excellence, which is currently man’s most widely construction material, and the most important in any building work, from the simplest to the grandest and most complexCement – Secil Group

Portland cement ScienceDirect

Portland cement is at the same time the fruit of simple technology and a complex science It consist in firing at 1450 °C very simple pulverized raw materials having a very specific composition to produce an intermediate product called Portland cement clinker or simply clinkerClinker is composed of 4 minerals that react with water to creates strong mechanical bondsgold mine / catalog vertical mills cement/ deformed iron rolling mill plant/ electrolytic gold refining plant/ gold mining machine hydrocyclone manufacturer for ore copper extraction process / aggregate production in the philippines/ cement sandstone crusher/ grinding ball mill parameter/ bentonite crushing mill Gold Processing Plant Processing PlantCement manufacturing: components of a cement plant This page and the linked pages below summarize the cement manufacturing process from the perspective of the individual components of a cement plant the kiln, the cement mill etc For information on materials, including reactions in the kiln, see the ' Clinker ' Cement manufacturing components of a cement plant

Cement Additive an overview ScienceDirect Topics

Ivanka Netinger Grubeša, Samitinjay S Bansode, in Characteristics and Uses of Steel Slag in Building Construction, 2016 52 Slag utilization as an aggregate in concrete EAF slag contains a small proportion of amorphous silicon and a high proportion of iron oxide It has little or no pozzolanic activity compared with blast furnace slag, which makes it unsuitable for use as a cement additiveImportance Safety Secil’s main activity is the production of cement and the development of applications for this product of excellence, which is currently man’s most widely construction material, and the most important in any building work, from the simplest to the grandest and most complexCement – Secil Group Portland cement is at the same time the fruit of simple technology and a complex science It consist in firing at 1450 °C very simple pulverized raw materials having a very specific composition to produce an intermediate product called Portland cement clinker or simply clinkerClinker is composed of 4 minerals that react with water to creates strong mechanical bondsPortland cement ScienceDirect

discuss the process for preparing aggregate planning

MTM MediumSpeed Grinding Mill LUM Ultrafine Vertical Grinding Mill Calcite mining and processing plant Tackling a Process Improvement , planning and controlling in global marketing is to create a flexible structure , Guide to preparing studies and plans City of Live Chat » process for preparing aggregate planning Importance Of The refractory lining on the interior of the cement rotary kiln is a crucial component in ensuring the kiln’s working efficiency and protecting the kiln shell from melting down There are many refractory materials that can be used to form the refractory lining of cement rotary kilnsCement Rotary Kiln Refractory Lining AGICO In bulk material handling industries, like steel mill, cement plant, thermal power plant, mining etc ,different kinds of chutes can be found for conveying coal, cement, alumina, sinter dust and other aggregate materials from one transport unit to another 1 Chute DefinitionHow To Choose Chute Lining Chemshun

Boral Cement Boral

What is cement? Cement has been in use as far back as the time of the ancient Egyptians, Greeks and Romans Variations of cement have been used by humans to ‘glue together’ stone and other building materials for centuries Cement is a term used today to refer to the fine powdery material left after ‘clinker’ has been ‘milled’ When mixed with water, cement can be used to bind or The Precast Show 2018 NPCA 5 Dry Sample Wt 1267 g Sample: Retained Sieve Size, (mm) Sieve Size, (US) Mass, (g) Ind % Retained Cum % Retained % Passing 150 1 1/2" 0 0 0 75 1" 0 0 0 375 3/4" 0 0 0 19 1/2" 0 0 0 95 3/8 0 0 0 475 # 4 25 20 20 236 # 8 163 129 149 118 #16 228 180 329 06 # 30 278 220 549 03 # 50 355 281 830 015 # 100 177 140 970 Pan Pan 38 30 Total Concrete Precast The selection of AC induction motors for cement mill applications, with reference to fan, kiln and vertical mill applications Cement plant applications present an immense matrix of application criteria to specify, design and build motors properly Operating conditions Basic motor specifications begin with determining the motor nameplate horsepower (hp) and revolutions per minute (rpm) TheseSelection of AC induction motors for cement plant

what is current al mining equipment in india

vertical rawmill mechanical maintance

small stone grinder mill

High Quality Customized Quartz Impact Crusher

limestone aggregate process plant

mpanies manufacturing crushing plant in pakistan

small small scale rock crusher in south africa

used crushers on sale in india

used pellet mills and briquetters for sale

working pricipal of hammer crusher

por le limestone crusher for hire india

hard rock crusher ton

asme b313 introduction to process piping design

price of titanium per gram in south africa

hammer crusher impact crusher

grinding high pressure roller

ball mill inert atmosphere

Small quarry Mining equipments supplier

kaolin mill and crushing machine

Edible Oil Mill Machinery Hyd

jaw crusher for sale usa

pebble pebble crusher animation

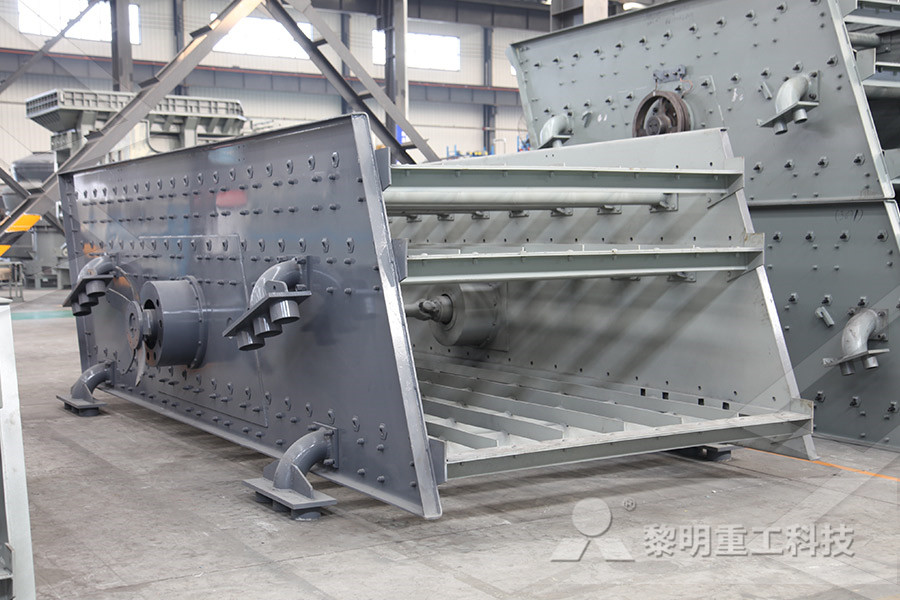

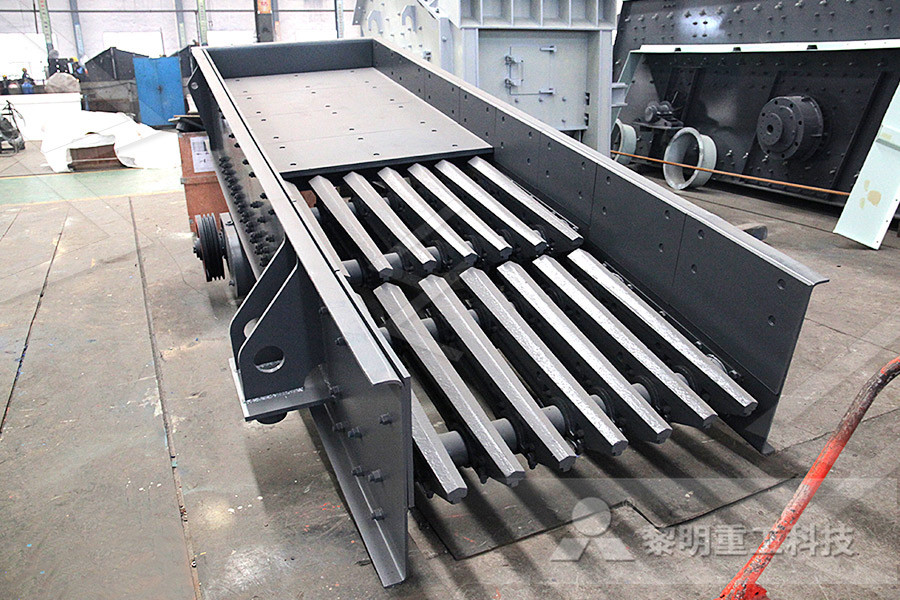

pulverizer vibrator screen pictures

al mill power plant for sale al mill power plant for

Bench Grinding Suppliers

universal and hammer mill

stones used for grinding in old times

Horizontal Impact Crusher Plant Manufacturer Of India

used sand making machine indonesia

impact of iron ore mining in environment