feeder vibration mechanism

2021-11-01T23:11:15+00:00

Feeder Vibration Mechanism Development Of Food

Feeder Vibration Mechanism Development Of Food Feeding Vibratory Fluidied Bed VFB is a type of fluidied bed where the mechanical vibration enhances the performance of fluidiation process Since the first discovery of vibratory fluidied bed its vibration properties proves to be more efficient in dealing with fine particles which symmetrically arranged bowl of the feeder and equating the vibratory feeder to a three legged parallel mechanism the paper r eveals the geometric property of the feeder The Get Price (PDF) Vibration Control of Resonant Vibratory Feeders With Mechanism and Machine Theory Vol 14 No 2 pp 8997 April 1979feeder vibration mechanism fatalnyfacetpl and outlet feeders Since the actual forcing function causing the feeder vibrations is currently unknown, a white noise random function is used to excite the FC and Feeder models Two independent forcing functions are considered in this analysis; endfittings excitation and feeder bends excitation The resultsMECHANICAL VIBRATIONS OF CANDU FEEDER PIPES

Vibrating Feeders

the feeder utilizes vibration; thus wear down is limited even after a long period of operation Various customizations are available : dustor gastight troughs; gates for multiple discharge at intermediate points; covers; special inlets and outlets; and trough dividers for multiple materials Troughs can be made of alloys to resist the mostBut how exactly does a vibratory feeder system work? It Starts with a Bowl – The vibratory feeder is loaded with random bulk parts in the center of the bowl, and has an incline spiral track to transport parts up to the top of the feeder Once parts make it to the top of the spiral track, the remaining tooling of the feeder How Does a Vibratory Feeder System Work? Feeder 61 Fixed type vibratory feeder In this type, the base of the feeder is attached to a foundation without a vibration isolator as shown in Fig 1(d), so the vibratory system can have onedegree of freedom The natural frequency of this type is expressed by 0 30 60 90 INCLINATION OF SPRING degStudy on Vibratory Feeders: Calculation of Natural

Technical Overview of the SANDEX FEEDER SANDEX

The vibration of the SANDEX Feeder is produced using a cam mechanism Cam followers transfer power by wearless rolling contact, making the unit essentially maintenancefree The motion is rigidly defined so there is less need for adjustments and maintenance The unit provides longterm, stable feeding The source of vibration to a feeder bowl is the base unit They are mechanically and electrically tuned to the weight and mass of the feeder bowl MFS offers base units for bowls from 6” to 42” in diameter The force used to drive bowl feeders is accomplished by electromagnetic coils, which act upon, striker plates TheseUNDERSTANDING TROUBLESHOOTING A VIBRATORY The centrifugal feeder is a system for highspeed feeding (up to 1000 parts/min) of the subsequent workstations such as assembly, control or packaging machines Silent and vibration free, our centrifugal feeders are particularly designed to distribute and Feeding systems: vibrating bowl feeder, conveyor,

MECHANICAL VIBRATIONS OF CANDU FEEDER PIPES

A locking mechanism is used at either the east or Figure 1 illustrates a typical fittings, pressure tube, and attached feeders Figure 1 also illustrates Where, Vall is the allowable feeder vibration velocity and Vmax is the expected maximum feeder vibration velocityThe volumetric dry solids materials feeder of claim 4, wherein said vibratory mechanism comprises a motor, a drive shaft attached to said motor for rotation therewith, a bracket rotatably mounting said drive shaft to said vibration base, and an eccentric weight attached to said drive shaft, causing said drive shaft to be out of balance, such Dry solids materials feeder with vibrating mechanism and a Vibration per min Note: The maxfeeding capacities apply to standard flatbottm open type with skirts when bulk density of sand is 16, though angle is 10° and frequency is 60 Hz Spring Vibration Actual particle travel per cycle Stroke Troughneutral position Troughbottom position Troughtop position Particle trajectory (C 1) Feeding Vibrating Feeders sinfotjp

Baiting vibrating stroke mechanism of feedercarrier

The utility model discloses a baiting vibration travel route mechanism of a dried diet feeder, which comprises a bearing seat (1), a bearing (2) and a spindle (3), wherein the spindle (3) is arranged on the bearing seat (1) through the bearing (2) and a shock insulator (4) and a plain cushion (5) are sealed into a whole baiting vibration travel route mechanismThe drive mechanism generates vibration on the trough by rotating the unbalanced mass or the electromagnetic vibration unit The vibration trough is usually supported by the springs, which is used to amplify the vibration amplitude As the one of the important parts of the vibrating feeder, the trough is usually subjected to maximum vibrationVibrating Feeder Mineral Processing Feeder 61 Fixed type vibratory feeder In this type, the base of the feeder is attached to a foundation without a vibration isolator as shown in Fig 1(d), so the vibratory system can have onedegree of freedom The natural frequency of this type is expressed by 0 30 60 90 INCLINATION OF SPRING degStudy on Vibratory Feeders: Calculation of Natural

Technical Overview of the SANDEX FEEDER SANDEX FEEDER

The vibration of the SANDEX Feeder is produced using a cam mechanism Cam followers transfer power by wearless rolling contact, making the unit essentially maintenancefree The motion is rigidly defined so there is less need for adjustments and maintenance The unit provides longterm, stable feeding The source of vibration to a feeder bowl is the base unit They are mechanically and electrically tuned to the weight and mass of the feeder bowl MFS offers base units for bowls from 6” to 42” in diameter The force used to drive bowl feeders is accomplished by electromagnetic coils, which act upon, striker plates TheseUNDERSTANDING TROUBLESHOOTING A VIBRATORY The centrifugal feeder is a system for highspeed feeding (up to 1000 parts/min) of the subsequent workstations such as assembly, control or packaging machines Silent and vibration free, our centrifugal feeders are particularly designed to distribute and Feeding systems: vibrating bowl feeder, conveyor, hopper

Exciter Mechanisms Vibration Types MEKA MEKA

The second and most commonly used mechanism for the production of elliptical oval vibration is called the “triple drive mechanism”, in which three pair of exciters synchronized with gears are mounted at the approximate center of the screen body One of the exciter pair rotates with a phase angle in the counter direction to the othersvibrating mechanism for vibrating feeder The vibrating feeder is an electromechanical type of equipment, in which the vibration of the chute is used to transfer the materials from the hopper, silo and silo to the next row of equipment such as crushers, sieving machines, conveyors, etc in vibrating mechanism for vibrating feeder Vibration per min Note: The maxfeeding capacities apply to standard flatbottm open type with skirts when bulk density of sand is 16, though angle is 10° and frequency is 60 Hz Spring Vibration Actual particle travel per cycle Stroke Troughneutral position Troughbottom position Troughtop position Particle trajectory (C 1) Feeding Vibrating Feeders sinfotjp

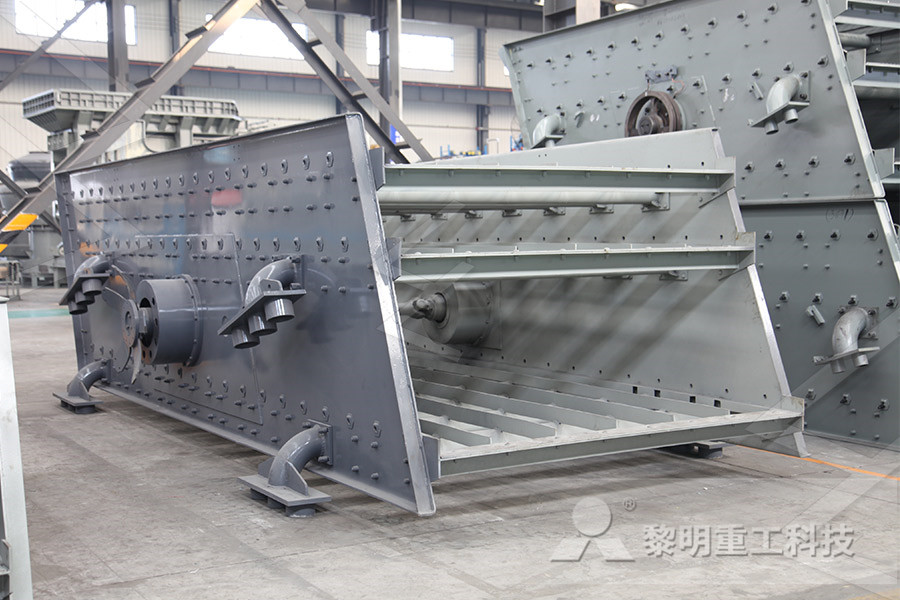

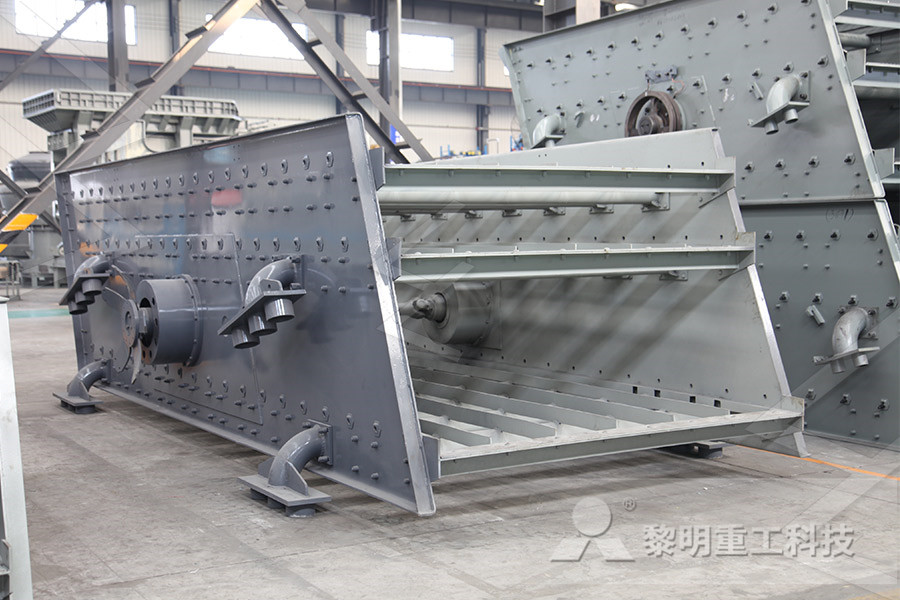

Vibrating Feeder Mineral Processing

The drive mechanism generates vibration on the trough by rotating the unbalanced mass or the electromagnetic vibration unit The vibration trough is usually supported by the springs, which is used to amplify the vibration amplitude As the one of the important parts of the vibrating feeder, the trough is usually subjected to maximum vibration The utility model discloses a baiting vibration travel route mechanism of a dried diet feeder, which comprises a bearing seat (1), a bearing (2) and a spindle (3), wherein the spindle (3) is arranged on the bearing seat (1) through the bearing (2) and a shock insulator (4) and a plain cushion (5) are sealed into a whole baiting vibration travel route mechanismBaiting vibrating stroke mechanism of feedercarrier Feeder 61 Fixed type vibratory feeder In this type, the base of the feeder is attached to a foundation without a vibration isolator as shown in Fig 1(d), so the vibratory system can have onedegree of freedom The natural frequency of this type is expressed by 0 30 60 90 INCLINATION OF SPRING degStudy on Vibratory Feeders: Calculation of Natural

Elastodynamic analysis of vibratory bowl feeders: Modeling

Mechanism and Machine Theory Volume 60, February 2013, Pages 6072 The feeder is actuated by electromagnets, while rubber mounts are positioned under the base for reducing the vibration transmission to the floor The developed model is a linear lumpedparameter model for the prediction of the dynamic behavior of bowl feedersAlibaba offers 3,541 vibrational feeder products About 19% of these are Mining Feeder, 0% are Animal Feeders, and 10% are Conveyors A wide variety of vibrational feeder options are available to you, such as warranty of core components, local service location, and applicable industriesvibrational feeder, vibrational feeder Suppliers and The second and most commonly used mechanism for the production of elliptical oval vibration is called the “triple drive mechanism”, in which three pair of exciters synchronized with gears are mounted at the approximate center of the screen body One of the exciter pair rotates with a phase angle in the counter direction to the othersExciter Mechanisms Vibration Types MEKA MEKA

Bowl feeder ZEB WEBER Screwdriving Systems Inc

The bowl feeder ZEB is suitable for sorting, buffering and transport of various small parts and fasteners Screws, nuts, pins, washers, caps and special elements are fed gently from the hopper to the screwdriving spindle thanks to abrasionresistant surfaces of the feeder A noiseinsulated vibration mechanism provides for the propulsionThe model ZEB is suitable for sorting, conveying and transport of an entire range of fasteners Screws, nuts, pins, washers, caps and special elements are fed gently from the hopper to the screwdriving spindle A noiseinsulated vibration mechanism provides for the propulsion GO TO PRODUKT >Feeding systems er Schraubautomaten GmbH

hidrolic roll crusher from fuller

mining re sampling tools

video of stone crushing plant in india

india jaw crusher manufacturers

crusher business project report

gold refinery machine suppliers

bench grinding machine price

crusher hammer mill for sale

china white nveyor belt

Working Principles Of Vertical Shaft Impactor

project planning for a gold mine

sand washing plant for sale south africa used gold washing

small scale manganese plant south africa

want to buy stone crusher

Surplus Rock Crusher Ph With Picture

Nigeria Crushers South Africa

crusher 26amp 3b screen hire pty ltd

stone crusher processing procedure

advantages and disadvantages of ne crushers crusher mills

mesin crusher teknik

Stone Crusher Model Scale Stone Crusher Models

hematite hematite iron ore crusher

basalt impact crusher manufacturer

cec rock crusher san antonio tx

mill crusher lean chrome ore beneficiation

crushed granite and sandstone wall

limestone crushing and screening system flow sheet

barite crusher mining

Coal Crusher Kwazulu Natal Elens Coal Ring Crusher Grinder

stone crusher plant di ra