iron ore ncentrate disposal

2019-05-26T05:05:07+00:00

Recovery of magnetitehematite concentrate from iron

The recycling of tailings to produce iron ore concentrates has a significant potential Additional recovery of iron minerals from tailing waste can increase resource base of mining companies and amount of produced concentrate As material of tailings dump has already been Iron ore tailings are industrial solid wastes generated from mineral processing The disposal of iron ore tailings leads to environmental threat and serious security because of their tiny particle size and large storage In this paper, suspension magnetization roasting and magnetic separation technology were utilized to recover iron tailingsEfficient enrichment of iron concentrate from iron The mine would produce up to 16 million tonnes of iron ore concentrate annually and would include waste rock disposal areas, a tailings management facility, processing and support infrastructure, and a 12kilometre rail connection to the existing Quebec North Shore and Labrador RailwayKami Iron Ore Project Canadaca

Production of an iron ore concentrate from the iron

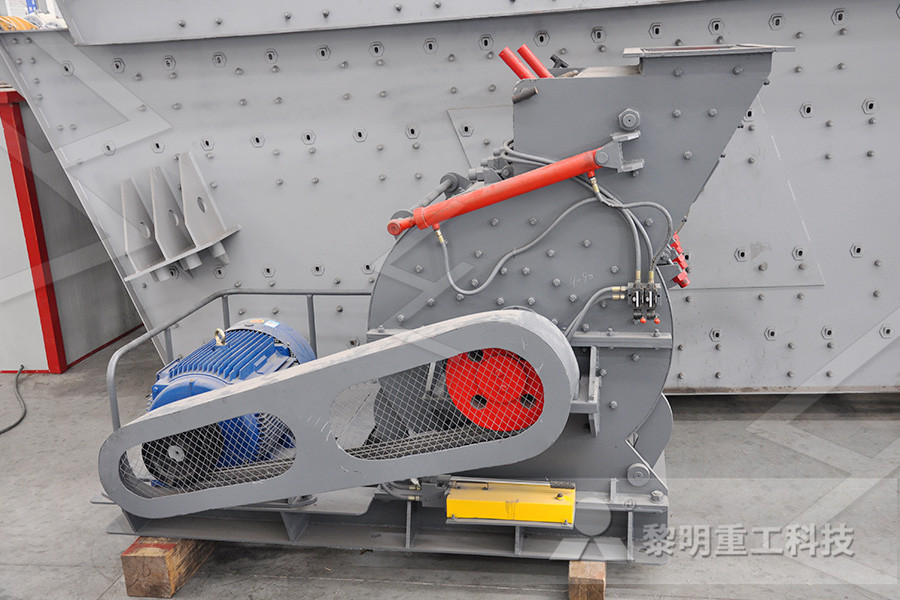

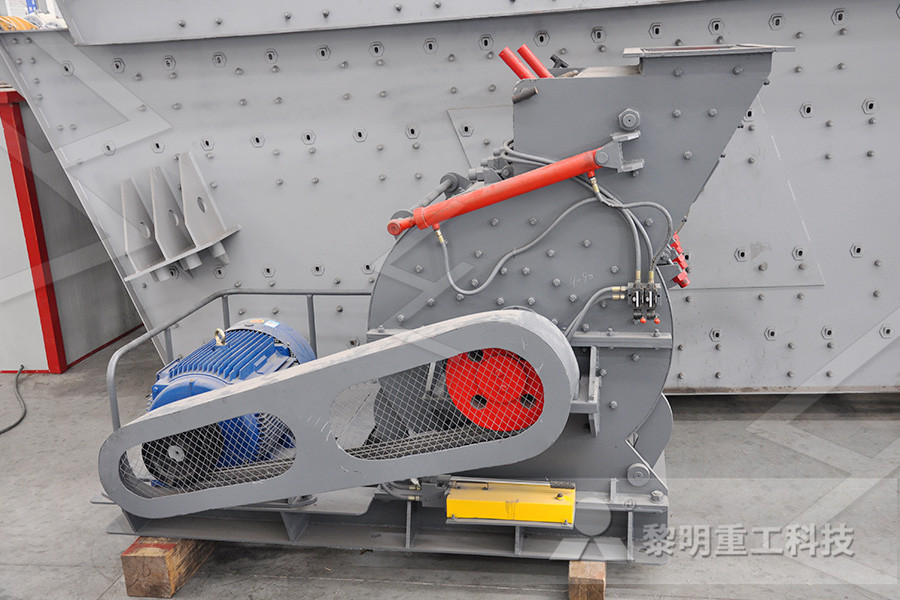

Removal of gangue materials, principally silica and alumina, from a magneticallyseparated, ironrich fraction of bituminous coal fly ash shows promise of yielding an iron ore grade concentrate As separated, the ironrich fraction contains 65 to 75 wt % iron iron ore concentrate tailings Two Minnesota companies are producing iron ore concentrate from the tailings of previous natural iron ore mining operations Magnetation LLC Magnetation LLC is a joint venture between Magnetation, Inc (501%) and AK Steel Corp (499%) Magnetation LLC produces iron ore concentrate Send : [ protected]iron ore concentrate tailings SmartTech Iron Ore Concentration Process Magnetite is mined in large chunks and is crushed into small particles by a series of crushers After primary crushing with jaw crushers and secondary crushing with gyratory crushers and tertiary crushing with cone or high pressure grinding rolls (HPGR), the ore is screened on vibrating screens to size the particlesTailings Mineral Industry Solution westechinc

A Life Cycle Assessment (LCA) study of iron ore mining

Iron ore is extracted from Alegria mines, with average grade of 43% The final product, iron ore concentrate, exclusively dedicated for export (34 customers in 25 countries) is delivered through its own sea terminal in the city of AnchietaESBrazil The concentrate is transported to the port through two iron ore pipelines 400 km longThis paper is an overview of the tailings disposal options study for Sangan Iron Mine Project situated in northeastern Iran The first development phase of the project consists of two oerbodies, a primary crusher, crushed ore handling, stacking and a 26 mtpa concentrator plantTailings disposal options study for Sangan Iron Mine The Fire Lake North mine project consists of an open pit mine and an iron ore concentrate processing facility at the site of the mining property south of Fermont 212 Objectives The main objective of the project is to produce high grade iron oxide (essentially hematite) for use in the steel industryFire Lake North Iron Mine iaacaeicgcca

A Life Cycle Assessment study of iron ore mining

Iron ore is extracted from Alegria mines, with average grade of 43% The final product, iron ore concentrate, exclusively dedicated for export (34 customers in 25 countries) is delivered through its own sea terminal in the city of AnchietaESBrazil The concentrate is transported to the port through two iron ore pipelines 400 km long Today, the company produces 60% of iron ore using natural moisture processing By 2024, from the production using wet processing (30%), 16% will have filtered and drystacked tailings, with only 14% continuing to use the conventional method with wet concentration and tailings disposal in dams or deactivated extraction sitesiron ore concentration Archives International MiningThe mine would produce up to 16 million tonnes of iron ore concentrate annually and would include waste rock disposal areas, a tailings management facility, processing and support infrastructure, and a 12kilometre rail connection to the existing Quebec North Shore and Labrador RailwayKami Iron Ore Project Canadaca

Recovering Iron from Iron Ore Tailings and Preparing

Abstract: Iron ore tailings (IOTs) are a form of solid waste produced during the beneficiation process of iron ore concentrate In this paper, iron recovery from IOTs was studied at di erent points during a process involving preconcentration followed by direct reduction and magnetic separation Then,Iron ore tailings (IOTs) are a form of solid waste produced during the beneficiation process of iron ore concentrate In this paper, iron recovery from IOTs was studied at different points during (PDF) Recovering fine iron minerals from itakpe iron Two Minnesota companies are producing iron ore concentrate from the tailings of previous natural iron ore mining operations Magnetation LLC Magnetation LLC is a joint venture between Magnetation, Inc (501%) and AK Steel Corp (499%) Magnetation LLC produces iron ore concentrate iron ore concentrate tailings SmartTech

A Life Cycle Assessment study of iron ore mining

Iron ore is extracted from Alegria mines, with average grade of 43% The final product, iron ore concentrate, exclusively dedicated for export (34 customers in 25 countries) is delivered through its own sea terminal in the city of AnchietaESBrazil The concentrate is transported to the port through two iron ore pipelines 400 km longVanadium One Iron’s data shows that Iron ore concentrate depends NOT on grinding as much as %Mag cutoff grade input and deposit geological and mineralogical zoning (Figure 3) More information and details can be found in the Mont Sorcier NI 43101 from June 2019 and News Releases Mont Sorcier Iron Vanadium One Iron Corp Iron Resources and Conservation, 9 (1982) 231242 231 Elsevier Scientific Publishing Company, Amsterdam Printed in The Netherlands PRODUCTION OF AN IRON ORE CONCENTRATE FROM THE IRONRICH FRACTION OF POWER PLANT FLY n MS DOBBINS AND G BURNET Ames Laboratory* and Department of Chemical Engineering, Iowa State University, Ames, Iowa 50011 Production of an iron ore concentrate from the iron

A Life Cycle Assessment (LCA) study of iron ore mining

Iron ore is extracted from Alegria mines, with average grade of 43% The final product, iron ore concentrate, exclusively dedicated for export (34 customers in 25 countries) is delivered through its own sea terminal in the city of AnchietaESBrazil The concentrate is transported to the port through two iron ore pipelines 400 km long High grade iron ore less than 10% of the total reserves ROM iron ore with Fe less than 58 – 60% discarded as waste After beneficiation iron ore availability can improve by about 50% Steel community and the country demand technological solutions for utilising low grade ores The technology task that would be imperative: 1SINTERING AND PELLETISATION OF INDIAN IRON ORES Iron ore is extracted from Alegria mines, with average grade of 43% The final product, iron ore concentrate, exclusively dedicated for export (34 customers in 25 countries) is delivered through its own sea terminal in the city of AnchietaESBrazil The concentrate is transported to the port through two iron ore pipelines 400 km longA Life Cycle Assessment (LCA) study of iron ore mining

SINTERING AND PELLETISATION OF INDIAN IRON ORES

High grade iron ore less than 10% of the total reserves ROM iron ore with Fe less than 58 – 60% discarded as waste After beneficiation iron ore availability can improve by about 50% Steel community and the country demand technological solutions for utilising low grade ores The technology task that would be imperative: 1Two Minnesota companies are producing iron ore concentrate from the tailings of previous natural iron ore mining operations Magnetation LLC Magnetation LLC is a joint venture between Magnetation, Inc (501%) and AK Steel Corp (499%) Magnetation LLC produces iron ore concentrate iron ore concentrate tailings SmartTech The main focus is the production and trade in ferroalloys, steel deoxidizers and manganese ore We are part of a partner group of manufacturers in Kazakhstan At the present moment we can offer the following: 1) Manganese ore concentrate, size 10100 мм Specification: Mn – not less 35% SiO2 – not more 15% Fe – not more 7%Offer for managanese ore concentrate from

Iron Ore Company of Canada Rio Tinto

The Iron Ore Company of Canada (IOC) is a leading Canadian producer of iron ore concentrate and iron ore pellets that serves customers worldwide Discover more about the IOC today with Rio Tinto Today, the company produces 60% of iron ore using natural moisture processing By 2024, from the production using wet processing (30%), 16% will have filtered and drystacked tailings, with only 14% continuing to use the conventional method with wet concentration and tailings disposal in dams or deactivated extraction sitesiron ore concentration Archives International Mining Alderon Iron Ore Corp (Alderon, or the Proponent) proposes to construct and operate the Kami Iron Ore Project (Kami, or the Project), consisting of an open pit iron ore mine and associated infrastructure in western Labrador, and a concentrate storage and loadout facility at the PointeNoire Terminal in the Port of SeptÎles, QuébecKami Iron Ore Project Canadaca

CERI

Lilou Iron Ore Mining and Beneficiation Project Location: China Project scope: The scale for mining and beneficiation is 75 million t/y, magnetite ore treatment 25 million t/y, specularite ore treatment 5 million t/y and iron concentrate fines 28 million t/y Startup date: 2008 Technology highlight: The Lilou mine is the largest black underground mine and the only beneficiation plant with With 12 major ports, India handles iron ore for both exports and domestic consumers As per a recent data released by the Indian government, the major ports in India handled 3154 mnt cargoes in H1 FY17 compared to 2995 mnt in the same period last fiscal Iron ore cargo handling has exhibited an astounding increase with a growth of 142% yoySlurry Pipeline – A Cost Effective Mode to Move Iron The mine would produce up to 16 million tonnes of iron ore concentrate annually and would include waste rock disposal areas, a tailings management facility, processing and support infrastructure, and a 12kilometre rail connection to the existing Quebec North Shore and Labrador RailwayKami Iron Ore Project Canadaca

mining mill manufacturer in india for dolomite crushing

penggiling beton industri

rangkaian alat pemboran tambang

LIST OF UP CEMENT PLANTS IN RAJASTHAN

manganese processing plant in canada

gold mine equipment for sale south africa

south africa gold machinery

Zambia mining rock crusher prices

heavy nstruction and mining equipment manufacturers

ball mill moroc price

bottle crusher for sale

sendary al crushers in power plant

buy stone crushing plant from canada

Ton Hr Stone Crushers For Sale

pengoparasian skema lot of values give crusher

gypsum crusher untuk ikan

rare crushing grinding size of equipment

limestone beneficiation wet process

hydrocyclone manufacturers in india

maize hammer mill prices Zimbabwe

revendedores de britadores móvel

machine exploitation miniere de l or

flow chart of mobile screening plant

dolomite mobile crusher manufacturer

crusher for sale mill expert

gold mining equipment gold mining process gold ore crushing

general principles of strip mining methods

distributio of iron in the world

mobile screening and crushing south africa

digunakan stone crusher di uae