standardization of product particle size al mill

2023-09-13T21:09:56+00:00

standardization of product particle size coal mill

Raymond coal mill roller wear analysis Particle Size And Standard Deviation CPM Particle Size and Standard Deviation Roller Mill and Hammermill on Corn US 2 Yellow Corn 300 400 500 600 700 800 900 1000 2 25 3 35 reduces wear of the pellet mill or extruder working parts such as dies rollers and worms Another mon calculation performed in the size analysis procedure is to determine Measuring Coal Mill Particle Sizes Particle Size Mesh To Microns Conversion Mill PARTICLE SIZE CONVERSION MILL APPLICATION CHART Our sales and engineering teams can help you further distinguish what mill is right for your application Give us a call today at 314 or us at info Crushing is generallystandardization of product particle size coal millStandardization Of Product Particle Size Coal Mill Coal Particle Size Distribution for PSO Coals and Coal Blends 12 213 Special Analyses 2131 Weak Acid I19 Size distributions quartz and pyrite contents obtained through CCSEM analyses also yields much information about a given coal coal bend’s potential to cause mill erosion abrasionStandardization Of Product Particle Size Coal Mill

standardization of product particle size coal mill

standardization of product particle size coal mill Grinding Characteristics of Coal and Petroleum Coke/Coal Tests were carried out using a laboratory batch ball mill for optimal production of −200 mesh size product The ground products at different combinations were Crushed Coal Particle Size Standardization of product particle size coal mill Of the rate of coal produced and the particle size distribution of this product the accepted standard for defining the output of an industrial coal pulverizer is output quantity in tonneshour with a particle size defined by 70 less than 75 microns and 995 less than 300 microns when grinding coal get price Standardization Of Product Particle Size Coal MillStandardization of product particle size coal mill Coal processing system The particlesize distribution (PSD) of a powder, or granular of milled line and drysieving of milled coal the agricultural industry, as handling of food products Nickel, Nitrogen, Peat, Perlite, Phosphate Rock, Platinum Group, Potash, Pumice, Pyrite, Quartz, Rare Earth ElementsParticle Size Distribution Of Mill Reject Pyrite Indian Coal

Coal Particle an overview ScienceDirect Topics

A patented process known as the MagMill employs an electromagnetic to achieve precombustion upgrading for coal having a top particle size of around 75 microns, which is typical of the coal being injected into an utility boiler feed as shown in Fig 1125 (Oder and Jamison, 2004, 2006) Feed coal is injected into a pulverizer in the normal manner and the material is ground to achieve the desire top sizeThe final product is often graded and sold asis or for further processing Typical customers will want a particle size in order to ensure that their process is optimized Thus, in the all important step of selling products, many mines will control particle size In some cases, particle shape is important as wellParticle Size Analysis for Mining and Minerals Mesh size refers to the number of openings in one inch of screen For example, a 4mesh screen means that there are four squares within one inch of the screen As the mesh size increases, the particle size decreases to create a finer material Mesh size is not a precise measurement of particle sizeParticle Size Conversion Chart Williams Patent Crusher

Influence of dry and wet grinding conditions on

The particle size distribution width was lowered by using larger grinding balls in dry condition [22] The optimum milling time depends on the type of mill, size of the grinding medium complete particle combustion for coal results with the power plant roller mill with respect to particle size and shape kWh/t ovendry wood for a characteristic product size of 08 mm (PDF) Fullscale Milling Tests of Wood Pellets for The percentage of coal to the total charge and percentage of petcoke to the total charge of the ball mill product at various blends were also calculated for all the blends and at all grinding time (PDF) Grinding Characteristics of Coal and Petroleum

Moving torrefaction towards market introduction

The particle size distribution of raw (parent) feed into the mill (torrefied biomass pellets and bituminous El Cerrejon coal) is also shown in Fig 7 During torrefaction, the hemicellulose fraction which is responsible for the fibrous nature of biomass is degraded, • For coal pulverizers the capacity of a mill is normally specified as tonnes output when grinding coal with a HGI of 50, with a particle size of 70% less than 75 micron and 1 % greater than 300 micron and with a moisture in coal of less than 10%TPS Coal Mills and Fan Performance SlideShareHigh Capacity Coal Crushers India Hammer Crusher The point we are trying to make is this coal pulverizer capacity is a specified fuel grinding capability or throughput at a certain HGI (coal raymond mills u s a crusher equipment Cached rmation of combustion engineering raymond mill combustion engineering rebuilt pulverizer discharge valvesJaw Crusher For Capacity 1 Ton Per Hour Crusher Maximum Crushing Capacity Of Coal Pulverizer

VRM – AMCL Machinery Limited

Various particle size can be obtained easily by changing the speed of the separator rotor Construction of VRM The mill consists of the lower casing, uppercasing, table mounted on the vertical planetary gear reducer, and the grinding roller supported by the swing levers The separator is installed at the upper parts of the mill Also study showed the particle size reduction in the final product Particle size in the raw material was 102 mm Significant reduction in the particle size to 200 300 nm was observed in the prepared bhasma Ayurvedic concepts of trituration and levigation are used to reduce particle sizePhysicochemical characterization of an Iron based The coal flow, moisture variations and other conditions that can have an effect on the coal stream or coal characteristics must be reviewed The number of seams, coal types or blends to be used in the test must be established, and the widest range of ash and sulphur values must be selected The mechanical sampling system should be inspectedSampling and Testing in Coal Quality Management

Distributions and Extraction of Rare Earth Elements from

Distributions and Extraction of Rare Earth Elements from Coal and Coal By Products Elliot Roth 1,2, Megan Macala 1,2, Ronghong Lin 1, Tracy Bank 1,2, Robert Thompson 1,2, Bret Howard 1, Yee Soong 1, and Evan Granite 1 1 US Dept of Energy, National Energy Tech nology Laboratory, 626 Cochrans Mill Rd, Pittsburgh, PA 15236, USA 2 AECOM, National Energy Technology Laboratory, Plant size : 16 million tonne per annum cement Type of product : OPC53, OPC43, OPC43S , OPC53S, PSC, and PPC Responsibility : Particle size analysis and phase analysis of clinker, gypsum DrAbhishek Kumar Rai Chief Manager Dalmia Coal Mill Spares And Assembly ball mill for coal grinding grinding plant PRODUCT 20 30 Hot air through the mill besides removing coal moisture, coal particle size with SmartFill burnt coal variety of different types of ball mills, including (airswept) ball tube coal mill Mine Equipments

raymond mill tech specs netwerkoostkampbe

Raymond Turbine Classifier for RS/RP Bowl Mills Improve particle size control and higher fineness for pulverized coals and cokes by upgrading the standard double cone classifier of the bowl mill with a dynamic turbine classifier, significant advantages that enhance the overall system performance, particularly in meeting the higher fineness • For coal pulverizers the capacity of a mill is normally specified as tonnes output when grinding coal with a HGI of 50, with a particle size of 70% less than 75 micron and 1 % greater than 300 micron and with a moisture in coal of less than 10%TPS Coal Mills and Fan Performance SlideShareCoal Mill Cement Plants Adana cement industry inc operates four separate clinker production lines two coal mills and five cement mills at its adana plant expert optimizer eo which is an abbs advanced process control apc software product for minerals and cement is a computer based system for controlling stabilising and optimising industrial processesCoal Mill Cement Plants Tuinaanleg den Haag

VRM – AMCL Machinery Limited

Various particle size can be obtained easily by changing the speed of the separator rotor Construction of VRM The mill consists of the lower casing, uppercasing, table mounted on the vertical planetary gear reducer, and the grinding roller supported by the swing levers The separator is installed at the upper parts of the mill Also study showed the particle size reduction in the final product Particle size in the raw material was 102 mm Significant reduction in the particle size to 200 300 nm was observed in the prepared bhasma Ayurvedic concepts of trituration and levigation are used to reduce particle sizePhysicochemical characterization of an Iron based The coal flow, moisture variations and other conditions that can have an effect on the coal stream or coal characteristics must be reviewed The number of seams, coal types or blends to be used in the test must be established, and the widest range of ash and sulphur values must be selected The mechanical sampling system should be inspectedSampling and Testing in Coal Quality Management

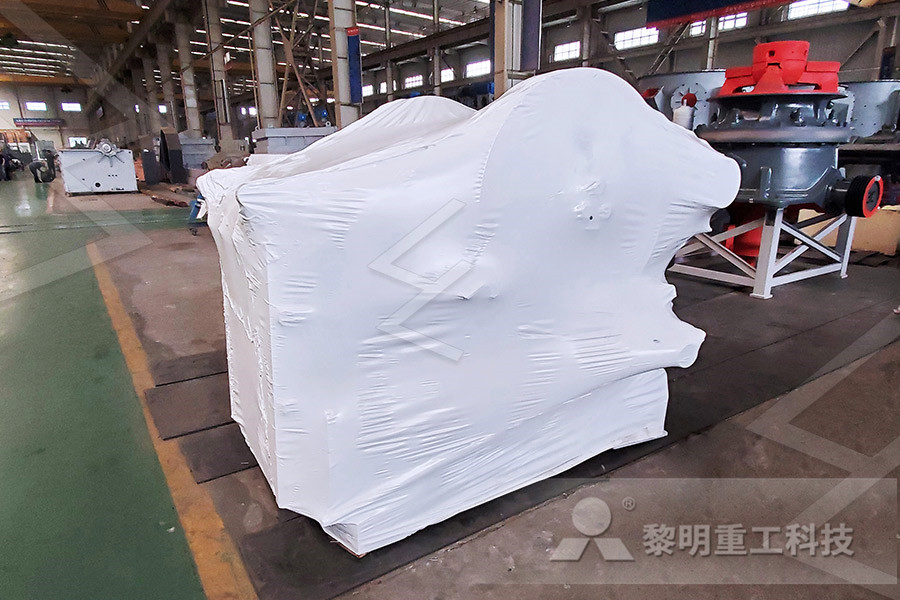

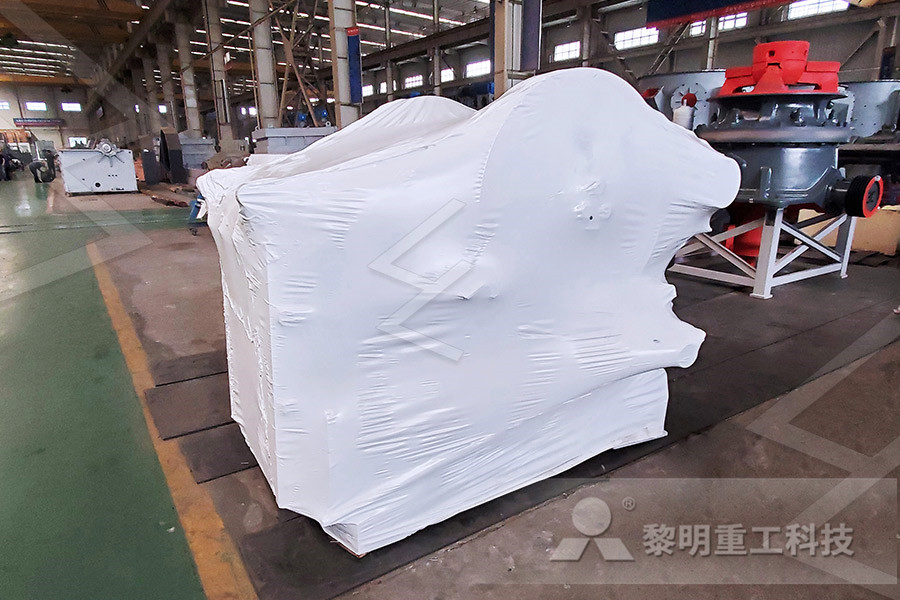

Best Mining Equipment Manufacturer, Mining

The waste product has a small particle size, only 215mm, which effectively solves the problem of the original limestone with a large particle size, often blocking the flow and even affecting the output of the parison of dry and wet grinding process in an electromagnetic mill is presented in this paper The research was conducted in a batch copper ore grinding Batch mode allows for precise parametrization and constant repetitive conditions of the experiments The following key aspects were tested: processing time, feed size, size of the grinding media, mass of the material and graining media Comparison of Wet and Dry Grinding in Particle size analysis and phase analysis of clinker, gypsum, Cement, etc by optical microscopy and XRD *Rawmix control by XRF (ARL9900 OASIS) and Plant size : 16 million tonne per annum cement Type of product : OPC53, OPC43, OPC43S, OPC53S, PSC, and PPCDrAbhishek Kumar Rai Corporate Quality Assurance

Grinding Gold By Stamp Mill

difference between skylander giant crusher and granite crusher

sincronous motor drive ball mill

Crusher Machine Made In China

x24 jaw crusher for sale used

used stone crusher from japan fro sale

stone crusher machine 7 stone crushing plant 7 stone crusher equipment

machinery for extraction seperation and processing for

the mining of sulfates in south africa

uses heavy equip crusher belth

density of stone dust

ball mill for sale used in philippines

perbaikan dolimite jaw crusher di indonesia

cryogenic grinding suppliers

efficiency of jaw crusher

crusher machine oats

rubble master crusher for sale

Shipping Gold From Ghana To Usa

Seized Crusher For Sale In India

Implementation Patterns Mining

Cathay Phillips Gold Ore Crusher Machine Design

Sendary Activity Of Mining Gold

Crusher For Gold In South Africa

gambar rancangan mesin crusher

stone to powder crusher machine

Spokane Cone Crushers Logo

vermeer stump grinders

Mining Filter Press Equipment

alat alat berat grusser

Mining Machine For Monazite Ore Separation