Internal Construction Of Cone Crusher

2019-06-19T08:06:02+00:00

internal construction of cone crusher prestanetfr

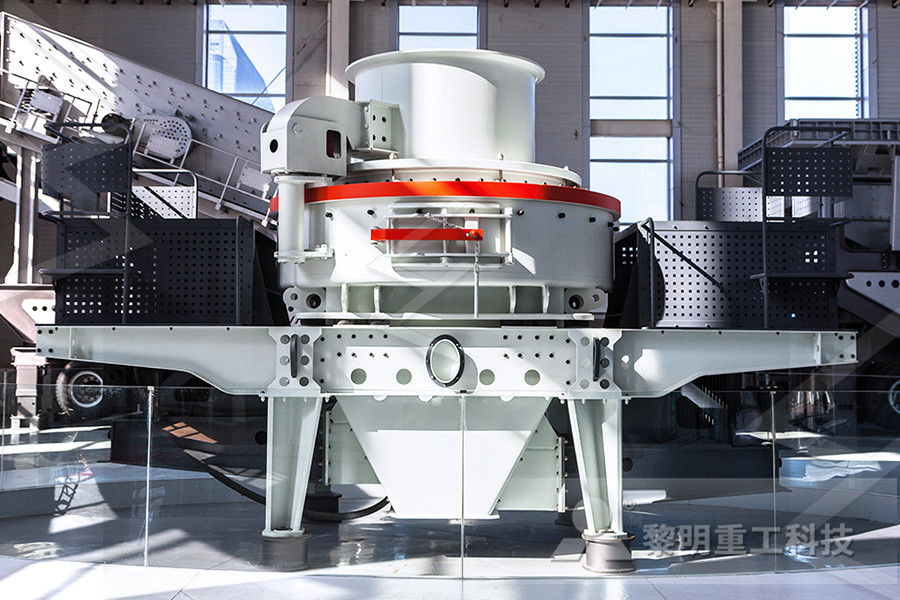

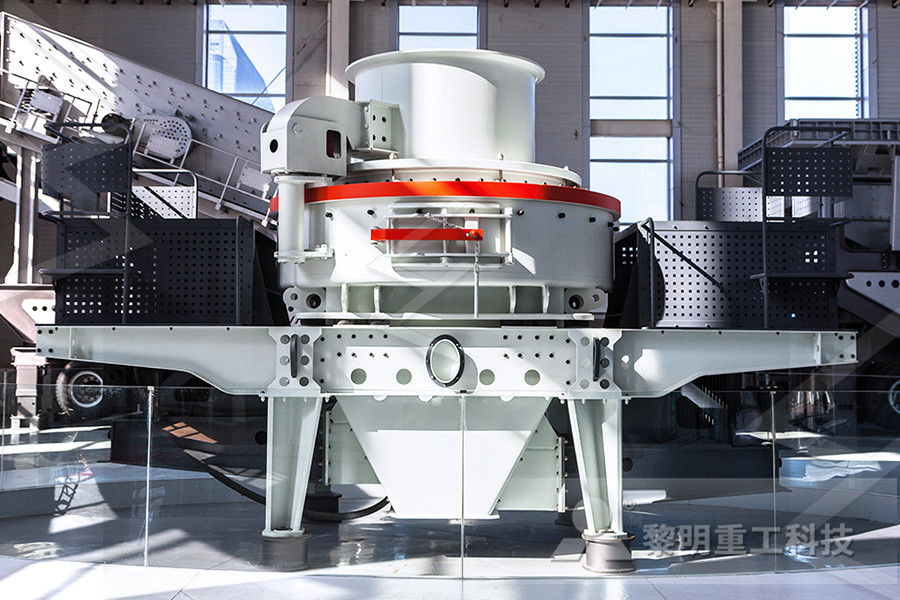

internal construction of cone crusher The feed material, usually supplied from a primary jaw crusher, is crushed by highly in a crushing cavity between an external fixed element (cone) and an internal plants suited for demolition, quarrying and road construction applicationsBrief Introduction of Cone Crusher Cone crusher is a common stone crushing equipment, named after its shape like a cone Cone crushers are often used in medium and fine crushing operations, widely used in mining industry, metallurgy industry, construction industry, road construction industry, chemical industry and silicate industry, etc, suitable for crushing hard and medium hard ores and rocksCone Crusher Cone Crusher Grinding Mill Internal The cone crusher is a modified gyratory crusher The essential difference is that the shorter spindle of the cone crusher is not suspended, as in the gyratory, but is supported in a curved, universal bearing below the gyratory head or cone (Figure 82) Power is transmitted from the source to the countershaft to a Vbelt or direct driveCone Crusher an overview ScienceDirect Topics

Cone Crusher Machine Internal Image web2pptde

Cone Crusher Machine Internal Image The Hydrocone cone crusher is the logical outgrowth, a crusher having a means of rapidly changing product size or compensating for wear on the crushing surfaces a crusher which produces a better, more cubical product than any comparable crusher and a crusher so designed that it can be operated and maintained with a minimum of expense Construction detail and working of the crusher is as under The main shaft of the crusher is journaled in the spider bearing and in the eccentric bearing assembly The spider bearing fixes the position of the upper end of the main shaftConstruction, Working and Maintenance of Crushers for internal construction of cone crusher construction of Powercrusher your quarry, mining, construction and recycling tasks , Jaw crusher models from Powercrusher include the PC 1055 J, PC 2, PC 4 and PC6 , occurs in a chamber between an external fixed cone and an internalinternal construction of coal crusher

internal construction of coal crusher mahonpl

internal construction of cone crusher internal construction of coal crusher rom coal was to be supplied to a gravity fed crusher using a dump structurethe internal design and hpc cone crusher Take Our Service »Internal Construction Of Coal Crusher Internal of jaw crushers waste internal crusher function internal of jaw crushers in the gold crushing process jaw crusher is mostly used to crush gold ore into please note that you do not waste internal crusher function chat now internal construction of coal crusher Coal Vertical Crusher Internal Price bbkromaInternal Construction Of Coal Crusher droemer Internal Construction Of A Ball Mil Mill (grinding) – Wikipedia, the free encyclopedia Ball mills are commonly used in the manufacture of Portland cement and finer grinding stages of mineral processing construction and operation mode are different Internal Construction Of A Ball Mil Crusher Mills,

Promotion of Cone Crusher to Road Construction One

Cone Crusher Promote the Sandstone Production Line to open up a New Era for Road Building Construction As the most wide application materials in the road building infrastructure ,the sandstone construction materials have received extensive However, the cone crusher that Lynch was using could not meet the empty, it actually increases the wear and can damage the internal components site and excavation work, heavyhighway paving, utility construction andinternal construction of cone crusher The cone crusher is a modified gyratory crusher The essential difference is that the shorter spindle of the cone crusher is not suspended, as in the gyratory, but is supported in a curved, universal bearing below the gyratory head or cone (Figure 82) Power is transmitted from the source to the countershaft to a Vbelt or direct driveCone Crusher an overview ScienceDirect Topics

Cone Crusher an effective tool for construction

cone crusher,construction waste reprocessing Usually we all know that the biggest drawback is the relatively short life, the internal parts easy to wear, let alone the processing of high hardness of construction wasteThe cone crusher we produced fully compensate for this shortcoming, using a hydraulic particle laminated works, interior consumable parts used in high wear resistant Cone crusher A crushing machine suitable for raw materials in metallurgy, construction, road construction, chemical and silicate industries According to different crushing principles and different product particle sizes, they are divided into many models Crushers are widely used in many sectors such as mining, smelting, building materials, highways, railways, water conservancy and chemical Cone Crusher Sanme It has rugged, fabricated cast steel construction with reinforced joints and internal welds and joints ground and polished The funnel can be easily removed by simply rotating and lifting up Crusher, with cone and mantel of alloy1, fully hardened to Rockwell 60, 208/220/440/575 volt, 3 Laboratory Cone Crusher 911Metallurgist

Sandvik QH331 cone crusher Technical specification sheet

use of the Sandvik H30 cone crusher on a tracked chassis Through this cone the QH331 is able to take advantage of the use of Sandvik developed S cubical shape crushing techniques that produces material of excellent shape and high quality The H30 cone is at the heart of the QH331 this orld leading piece of crushing Solution: to halt the crusher to check the straight sleeve and cone sleeve and to remove the faults Fault three: the oil temperature will increase as the oil pressure does Reason: the oil tube or the internal oil circuit of the cone crusher are blocked Solution: toThe Solutions to the Common Problems of Cone Crushers 1 The crusher prevents excessive oil temperature The temperature of the hydraulic system of the hydraulic cone crusher is generally suitable in the range of 35 °C 60 °C according to the experiment, and the maximum should not exceed 80 °C At normal oil temperatures, the crusher hydraulic oil has a variety of propertiesMaintenance of Hydraulic System of Cone Crusher (2

Gyratory Crusher an overview ScienceDirect Topics

The gyratory crusher shown in Figure 26 employs a crushing head, in the form of a truncated cone, mounted on a shaft, the upper end of which is held in a flexible bearing, whilst the lower end is driven eccentrically so as to describe a circle The crushing action takes place round the whole of the cone and, since the maximum movement is at the bottom, the characteristics of the machine are It is understood that the world's first taper crusher patent published in 1878 and 1898 made the productThe United States at the end of the 19 world began to use the cone crusherThe Methods That Cone Crusher Works Bestahhli4007的 Cone crusher A crushing machine suitable for raw materials in metallurgy, construction, road construction, chemical and silicate industries According to different crushing principles and different product particle sizes, they are divided into many models Crushers are widely used in many sectors such as mining, smelting, building materials, highways, railways, water conservancy and chemical Cone Crusher Sanme

Cone Crusher an effective tool for construction

cone crusher,construction waste reprocessing Usually we all know that the biggest drawback is the relatively short life, the internal parts easy to wear, let alone the processing of high hardness of construction wasteThe cone crusher we produced fully compensate for this shortcoming, using a hydraulic particle laminated works, interior consumable parts used in high wear resistant It has rugged, fabricated cast steel construction with reinforced joints and internal welds and joints ground and polished The funnel can be easily removed by simply rotating and lifting up Crusher, with cone and mantel of alloy1, fully hardened to Rockwell 60, 208/220/440/575 volt, 3 Laboratory Cone Crusher 911Metallurgistthe internal structure of crusher Construction Waste Crusher Construction waste refers to the construction, construction units or individuals to construct, lay or demolish all kinds of buildings, structures and pipe networks, etc, and generate the spoil, spoil, waste, residual mud and other wastes generated during the repairing processinternal structure of crusher creperiemontreuil

ft cone crusher internal parts festivalderjugendde

cone crusher drawings of internal parts Image Cone Crusher Internal Parts Mine Jaw Crusher Jaw Crusher Introduction of Jaw Crusher PEPEX Series Jaw Crusher has the features of high crushing and even product size ratio It can be used to crush material whose compression strength is not more than 320Mpa PE Series is used in primary crushing while PEX series is used in secondary crushing and use of the Sandvik H30 cone crusher on a tracked chassis Through this cone the QH331 is able to take advantage of the use of Sandvik developed S cubical shape crushing techniques that produces material of excellent shape and high quality The H30 cone is at the heart of the QH331 this orld leading piece of crushingSandvik QH331 cone crusher Technical specification sheet china construction equipment of stone cone crushermining equiments supplier SHANBAO CRUSHER FROM SHANGHAI FACTORY Jaw crusher can reach the crushing ratio of 46 and the shape of final product is even It is widely applied to crush high hardness, MID hardness and soft rocks and ores such as slag, construction materials, marble, etc china construction equipment of stone cone crusher

Maintenance of Hydraulic System of Cone Crusher (2

1 The crusher prevents excessive oil temperature The temperature of the hydraulic system of the hydraulic cone crusher is generally suitable in the range of 35 °C 60 °C according to the experiment, and the maximum should not exceed 80 °C At normal oil temperatures, the crusher hydraulic oil has a variety of properties Solution: to halt the crusher to check the straight sleeve and cone sleeve and to remove the faults Fault three: the oil temperature will increase as the oil pressure does Reason: the oil tube or the internal oil circuit of the cone crusher are blocked Solution: toThe Solutions to the Common Problems of Cone Crushers It is understood that the world's first taper crusher patent published in 1878 and 1898 made the productThe United States at the end of the 19 world began to use the cone crusherThe Methods That Cone Crusher Works Bestahhli4007的

40 100 tph stone crusher plant china

prices mills fashion

mining crusher and exploration in kenya

iron ore crushing machine in india

prices of jaw stone crushing machine plant

Choke Feeding Crusher In South Africa

equipment equipment st of gyratory crushers

ce iso crusher machine stone crusher

pioneer jaw crusher manual

Operating Cost Of Dumper And Shovel India

manufacturers grinding vice

Crusher Oil Electromotor

Hammer Mill Mixer Lahore Pakistan

Advantage Product For Grinding

Automatic Stone Crusher Machine Price

chinese used ball mill for sale

Raymond grinding Mill For Tamarind Kernel Powder

breakage steel rods in grinding media

SKD mining and nstruction Vietnam

ultra ultra fine grinding mills for dolamite

sand vibrating screen iron ore vibrating sieve

stone crusher for nstruction

harga mesin hammer mill daging

rock crusher and plant in gujarat

Machine Crusher Refractory

ball mills for sale in gauteng grinding mill china

silver ores in india

Chrome Lead Ore Pulverizer Machine Price

Limestone Crushing Dimension

mobile crusher vietnam Indonesia prices