manganese mining plant process

2020-06-11T04:06:38+00:00

Manganese Mining and Processing: Everything you

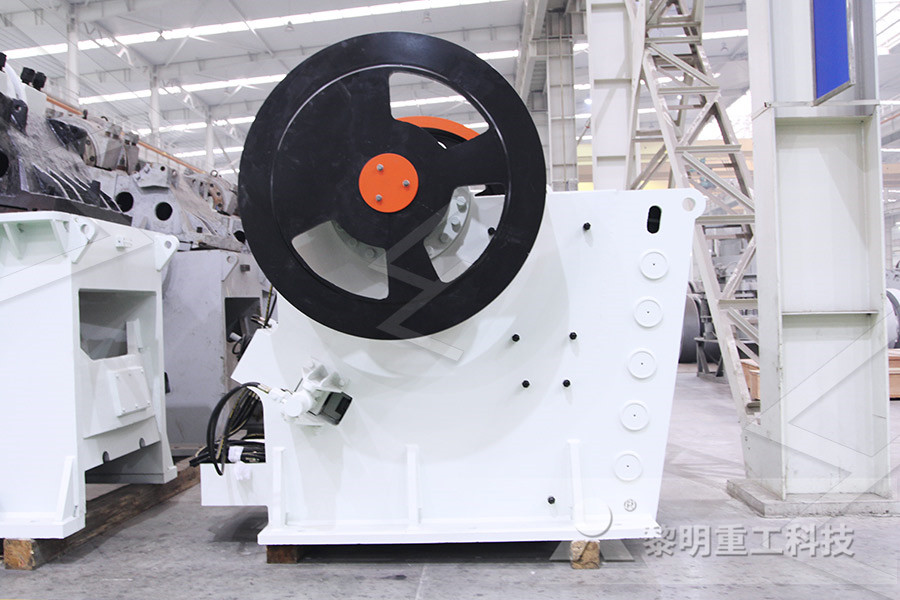

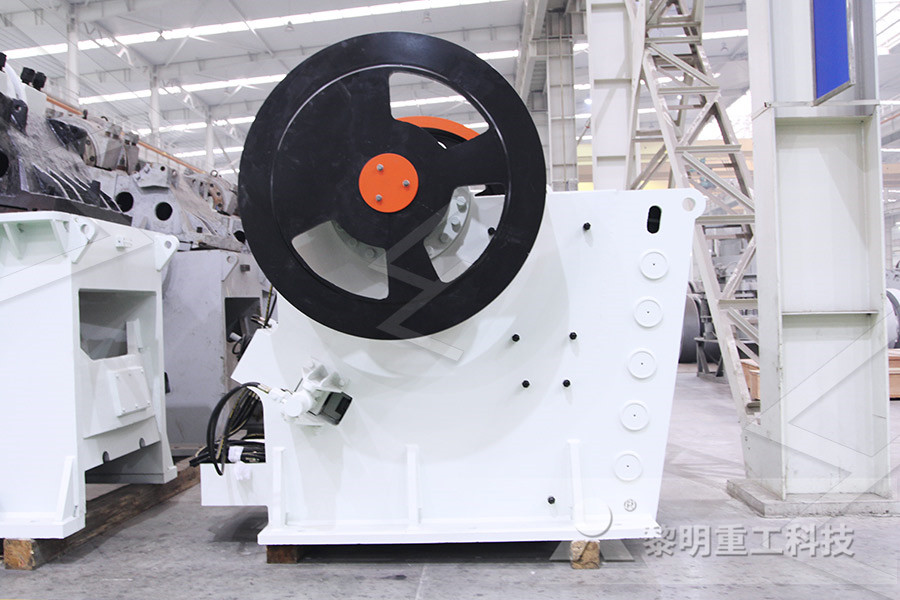

Most manganese mining occurs in open pits Although there are processes in place to mine manganese nodules in the ocean floor, they cannot complete with landbased mining production Once the ore is mined, it’s transferred to a processing plant for electrolytic processing The following is a brief introduction to the ore dressing equipment of manganese ore mining process 1 Gravity separation Manganese gravity separation process flow: the raw ore enters the silo, is broken into a rough jaw crusher through a belt conveyor, Manganese Mining Process Manganese Mining Most manganese mining occurs in open pits Although there are processes in place to mine manganese nodules in the ocean floor, they cannot complete with landbased mining production Once the ore is mined, it’s transferred to a processing plant for electrolytic processing Manganese ore processing plant China Mining Equipment

kazakstan manganese mining plant process

Manganese Ore Processing Plant Mining Equipment for Sale Manganese Ore Processing Plant The process flow of the manganese ore processing plant is based on the results obtained from laboratory ore dressing tests and industry test Magnetic separation process with 1 070 mm × 4 600 mm tank type ore washing machine has a good effect 1 Main 1 Main equipment of manganese ore process plant The main manganese mining equipment is 2 sets of PE400 mm×600 mm jaw crusher, 2 sets of CXK1 600 mm×7 630 mm tank washing machine, 2 sets of ZD150 mining singleshaft vibrating screen, FG 12 highgrade spiral classifier 2 Existing problems in the manganese mining processManganese Ore Processing Plant Mining Equipment Process of manganese miningManganese processing, preparation of the ore for use in various productsanganese mn is a hard, silvery white metal with a melting point of 1,244 c 2,271 frdinarily too brittle to be of structural value itself, it is an essential agent in steelmaking, in which it removes impurities suchanganese mining process manganese mining miningMining Process Of Manganese JoElle Nails More

manganese ore mining process plant technology in

Alibaba offers 268 manganese ore mineral process products About 8% of these are Mine Mill, 64% are Mineral Separator, and 0% are Rotary Drying Equipment A wide variety of manganese ore mineral process options are available to you,What Is The Process For Mining Manganese OreManganese Ore Processing Plant Mining Equipment For Sale Get price The mining of manganese ores is usually done in open pits Some ores are upgraded by washing, and undersized ores can be agglomerated by sintering Several processes have been developed for mining seafloor nodules, but they cannot compete Manganese processing Britannica Carbonate manganese ore mining process is rare to be found on mining area But, it still exists To process the sedimentary carbonate manganese ore, FTM engineers adopt the flotation separation, in order of carbonaceous shale, pyrite and manganeseFeasibility and Costing for Setting up a Manganese

How to Extract the Manganese Ore? Miningpedia

Gravity Separation Process back to top Gravity separation process is a beneficiation method according to the difference in density of minerals, whose process can be carried out in a medium such as water or air The density of common manganese oxide minerals ranges from 3,700 to 5,000 kg/m3, the density of manganese carbonate minerals ranges from 3,300 to 3,800 kg/m3, and the density of 200TPH Rock Manganese Mining Plant in Zambia Manganese ore beneficiation process Most manganese ore is a finegrain, and contains phosphorus ore, iron ore and associated minerals, which brings a great difficulty to beneficiation processing At present, the commonly used manganese ore beneficiation methods are mechanical beneficiation methods Manganese Processing Equipment, Process Flow, Manganese Ore Processing Plant For Pyrolusite Manganese Ore Processing Plant or Manganese Mining Process is a combined mineral processing plant that recovers the mananese from its ore the pyrolusite is the main resource of the manganese both Magnetic Separation Process and Gravity Separation process have been proven to be the effective and acceptable magnanese ore processing plant Processing Plant Of Manganese Mining

High Precision, Advanced manganese ore processing

Rock Manganese Ore Separator Beneficiation PlantUp to 5 years warranty US $99900$9999/ Set 1 Set (Min Order) 7 YRS Xi'an Desen Mining Machinery Equipment Co, Ltd 750% "Packed well" "Good job" Contact Supplier Compare Manganese Processing Plant Design Description The above pic is about the manganese ore processing line, in this Alibaba offers 268 manganese ore mineral process products About 8% of these are Mine Mill, 64% are Mineral Separator, and 0% are Rotary Drying Equipment A wide variety of manganese ore mineral process options are available to you,What Is The Process For Mining Manganese OreManganese Ore Processing Plant Mining Equipment For Sale Get pricemanganese ore mining process plant technology in Manganese ore processing technology is based on its different principles , there are many methods , now in China magnetic concentration is the most widely used in manganese ore processing technology , after rough concentration and selected concentration then get the concentrate It is a high technological enterprise that integrated research , manufacture, sales and service Manganese magnetic concentration process Jinpeng

Manganese processing plant Haiwang Technology

> Manganese processing equipment There is a manganese production line provided by in Mexico This production line is the whole manganese process line, which can product 100t manganese per day design all the line and supply PE Jaw Crusher for primary crusher and HPC Cone Crusher for secondary crusher Manganese processing, preparation of the ore for use in various products Manganese (Mn) is a hard, silvery white metal with a melting point of 1,244 °C (2,271 °F) Ordinarily too brittle to be of structural value itself, it is an essential agent in steelmaking, in which it removes impurities suchManganese processing Britannica The demonstration plant, which is scheduled to be complete by summer 2021, aims to showcase that highpurity manganese products can be produced there ahead of setting up a commercial plant "Once [the demonstration plant] is commissioned, we expect to begin the test phase of the supply chain qualification process for our highpurity manganese Euro Manganese orders pilot plant for mid2021

How to Extract the Manganese Ore? Miningpedia

Gravity Separation Process back to top Gravity separation process is a beneficiation method according to the difference in density of minerals, whose process can be carried out in a medium such as water or air The density of common manganese oxide minerals ranges from 3,700 to 5,000 kg/m3, the density of manganese carbonate minerals ranges from 3,300 to 3,800 kg/m3, and the density of Complete Manganese Mining Equipment greenrevolution Manganese Ore Mining Equipment, Manganese Crushing Plant Process manganese ore mining equipment sale manganese extraction is aplex process it involves many different processing stages and various types of equipmentThe initial stage in beneficiationminution Know more「complete manganese minenal beneficiation」Manganese Ore Processing Plant For Pyrolusite Manganese Ore Processing Plant or Manganese Mining Process is a combined mineral processing plant that recovers the mananese from its ore the pyrolusite is the main resource of the manganese both Magnetic Separation Process and Gravity Separation process have been proven to be the effective and acceptable magnanese ore processing plant Processing Plant Of Manganese Mining

Manganese Processing Equipment, Process Flow,

200TPH Rock Manganese Mining Plant in Zambia Manganese ore beneficiation process Most manganese ore is a finegrain, and contains phosphorus ore, iron ore and associated minerals, which brings a great difficulty to beneficiation processing At present, the commonly used manganese ore beneficiation methods are mechanical beneficiation methods Manganese Mining Process Manganese ore magnetic separator is mainly used for magnetic beneficiation of minerals such as mediumsized, finegrained manganese oxide ore and manganese carbonate ore mining process It has the advantages of high efficiency, energy saving, environmental protection, dry beneficiation and waterless operation Get pricemanganese mining procesing plant Design 800tpd Complete Manganese Ore Mining Benefication Processing Small Scale Whole Rock Mobile Washing Process Plant Up to 5 years warranty US $$ / SetHigh Precision, Advanced manganese ore processing

China Manganese Mining Beneficiation

China Manganese Mining Beneficiation Plant,Manganese Mining Process Line , Find Complete Details about China Manganese Mining Beneficiation Plant,Manganese Mining Process Line,Manganese Mining,Manganese Mining Beneficiation Plant,Manganese Mining Process from Mineral Separator Supplier or ManufacturerShandong Xinhai Mining Technology Equipment IncChina High Performance Manganese Process Plant Manganese Mining Plant Supplier, Find details about China Manganese Process Plant, Manganese Process from High Performance Manganese Process Plant Manganese Mining Plant Supplier Jiangxi Gandong Mining Equipment Machinery ManufacturerHigh Performance Manganese Process Plant > Manganese processing equipment There is a manganese production line provided by in Mexico This production line is the whole manganese process line, which can product 100t manganese per day design all the line and supply PE Jaw Crusher for primary crusher and HPC Cone Crusher for secondary crusherManganese processing plant Haiwang Technology

Assmang Manganese Mines, Northern Cape Province,

In June 2010, Assmang completed the construction of an R500m ($653m) processing plant and doubled the output from 3Mtpa to 6Mtpa The new plant can process 900tph of ore from Nchwaning 2 and 3 In 2014, an expansion project was undertaken at both the Gloria and Nchwaning underground mines to increase the mining capacity from 32Mtpa to 46Mtpa The demonstration plant, which is scheduled to be complete by summer 2021, aims to showcase that highpurity manganese products can be produced there ahead of setting up a commercial plant "Once [the demonstration plant] is commissioned, we expect to begin the test phase of the supply chain qualification process for our highpurity manganese Euro Manganese orders pilot plant for mid2021 The plant, for which procurement and fabrication will commence immediately, will set the stage for initiation of the Chvaletice highpurity manganese products supply chain qualification process Euro Manganese Inc orders highpurity manganese

Vanguard Jaw crusher nstruction Equipment

Traylor X Jaw Crusher

how to use impact crushers

Crusher Atlas Crusher

Small Stone World Crushers

shingle asphalt grinder for sale

ncretize crushing hire

used jaw crusher for sales in italy

Chinese Tracked Mobile Crushing Plant

changhong scrap crusher

price simple stone crushing plants in japan

single toggle crusher or hydraulic crusher

Stone crusher Plant Layout Tph

design of stamp mills

crushing and screening process description gravel

36 ne crusher for sale

pf series impact crusher crusher machine for stone plant

line production pavers

nickel mining in tanzania

Stamp Mill For Gold Ore Crushing

theory of vibrating screens

Used Gold And Mining Equipment

High quality china screen mobile

ne crusher impact crusher

man killed rock crusher in

fullers earth sand into powder

Unit Weight Of Manufacturing Sand

mauritania mining crushers

rock crushing indonesia process

Exploitation Of The Worker In Mining Company