blocking crusher crushing screening

2022-08-20T11:08:49+00:00

CRUSHING SCREENING Crushing and Screening

different stages of the crushing process and in final product separation Designed as a nonwelded frame with adjustable vibration features for different material types and screening sizes, Meka screens provide screening efficiency that is high quality and dependable Our screens come in various sizes starting from 2 m² up to 16 m² Bridging — Blocking of crusher opening by large pieces of material Burbank Abrasion Test — A standard method of comparing the relative abrasiveness of rocks, minerals and ores Cage — A screening device, fixed or adjustable, made of precisely spaced bars or slotted plate, where final sizing is accomplished within the crusherHandbook of Crushing TerraSource Crushing and Screening Considerations for designing an efficient operation By L Winchip, engineering manager, and G Mangrich, regional sales manager, McLanahan Corp Several considerations need to be taken into account in designi ng an efficient c rushing and screening plant, the first being the raw materials to be crushed TheCrushing and Screening AggNet

Construction, Working and Maintenance of Crushers for

Blocking of a crusher opening by large pieces of material Burbank Abrasion Test A standard testing method for comparing the relative abrasiveness of rocks, minerals and ores Cage A screening device, made of precisely spaced bars or slotted plate, where final sizing is accomplished within the crusher Choke FeedCrusher main body is fabricated from low carbon steel Crushing chamber is completely lined with thick, interchangeable, bolton abrasion resistant (AR) liners Sensors on the frame make maintenance interventions safer by preventing machine start up Inspection doors located all around the frame make it possible to reach the interior of the CrusherPrimary Impact Crushers MEKA Crushing Impact arms of the crusher are hydraulically adjusted to control the product size output and rate of production and the large cross section of both feed and discharge crusher openings provides freeflow of the material process whilst minimising blocking Impact Crushers Parker Plant

Jaw Crusher blocking material causes and solutions

The second: downstream equipment jump stop, and the jaw crusher continue crushing Once this happens, you need to clean up all the material crushing cavity can continue to turn out, timeconsuming, generally at least have one hour to complete In MEKA CRUSHING PRIMARY IMPACT CRUSHERS TECHNICAL DATA PRODUCT GRADATION TABLE 100% 90% 80% Percentage Passing 10,00 Square Sieve Opening (mm) AT 150 MM (6'') SETTING AT 100 MM (4'') SETTING AT 60 MM (2''3/8) SETTING AT 50 MM (2'') SETTING MEKA CRUSHING SCREENING AND CONCRETE BATCHING TECHNOLOGIES mekaglobalMEKA PRIMARY IMPACT CRUSHER MEKA Crushing MEKA’s cone crusher is a very good example of our determination to gain customer trust in the field of crushing and screening equipment The solid structure required for crushing very hard materials allows the operators to employ the cone crusher for a wide range of applications, crushing Cone Crushers MEKA Crushing Screening Plants

Leicester Crusher Hire Nationwide Concrete Crusher

Coopers Crushing Screening is a family run company specialising in concrete crushing, brick crushing and aggregate production Our highly skilled and trained operatives are proficient in demolition, site clearance and crushing services that deliver results and keep your project on track and within budget Crushing and Screening Services we provide include:Leicester Crusher HireCrushing and screening equipme Non standard equipment Non standard equipment Screening equipment TELL:13562612288 Screening equipment TELL:13562612288 High frequency vibrating screen TELL:13562612288 Roller crusher TELL:13562612288 PHZ series heavy ring hammer crusher TELL:13562612288 PCXK Series anti blocking Crushing and screening equipmeShandong Huafei Heavy Blocking of a crusher opening by large pieces of material Burbank Abrasion Test A standard testing method for comparing the relative abrasiveness of rocks, minerals and ores Cage A screening device, made of precisely spaced bars or slotted plate, where final sizing is accomplished within the crusher Choke FeedConstruction, Working and Maintenance of Crushers for

HSE Quarries Safe operation and use of mobile jaw crushers

Wherever possible any inspection of the crushing cavity of a jaw crusher should be carried out from below the crusher, not from above Remember: Fatal accidents (due to material being ejected) have occurred to people who have examined the crushing cavity of a stalled crusher from above Guarding Inadequate guarding is a major cause of injuryCrusher main body is fabricated from low carbon steel Crushing chamber is completely lined with thick, interchangeable, bolton abrasion resistant (AR) liners Sensors on the frame make maintenance interventions safer by preventing machine start up Inspection doors located all around the frame make it possible to reach the interior of the Tertiary Impact Crushers MEKA Crushing Screening Plants installed, adequate dust control systems for the crushing, screening and conveying circuits at processing plants Inspectors have been told by operators that dust control systems do not effectively suppress or control any dusts and that there is a reluctance to use existing systems because of fear of blocking the plant with wet materialsMines Safety Bulletin No 157 Department of Mines

Crusher Manufacturers Line Up Advanced Equipment

Wirtgen India is looking to enlarge business, based on the advanced features of the Kleeman crushing and screening solutions Mr Ramesh Palagiri, MD, Wirtgen India says, “The Kleeman screening units have an area of 95 m2 in the upper deck, and are available as twindeck (MS 952 EVO) and tripledeck (MS 953 EVO) screens They boast a high production output with capacity for up to 500 tonnes Dragon Crushers provides you the best range of mobile screening plants 614, new type stone crushing plant dragon crusher type 9, sand making crushing and screening plant 45, mobile screening plants 608, mobile crushing plant dragon crushers new system mobile closed circuit crushing plant dragon with effective timely deliveryDragon Crushers Mobile Screening Plants 614 New Type Sahraoui points out that MB Crusher is the only manufacturer in the world able to offer a complete range of 26 attachments, crushing and screening buckets, drumcutters and grapples for excavators, loaders, skid steer loaders and backhoes from 28 to 70+ tons, with a 24 months warrantyThe impact of crushing directly with excavators Products

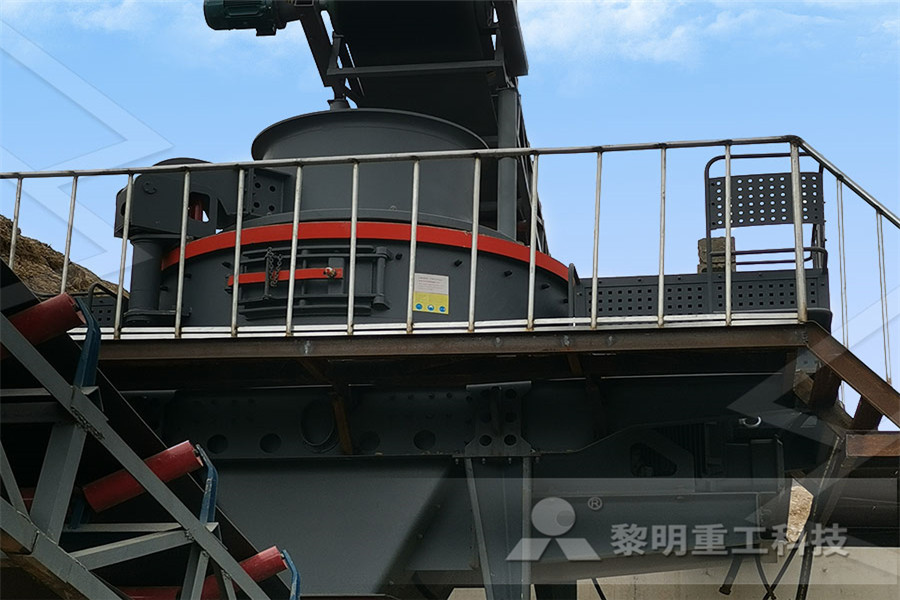

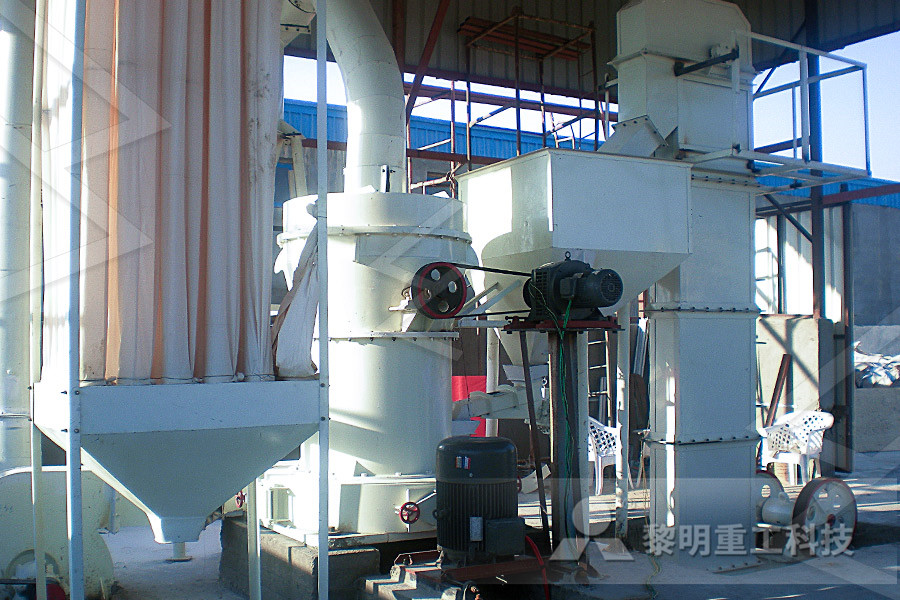

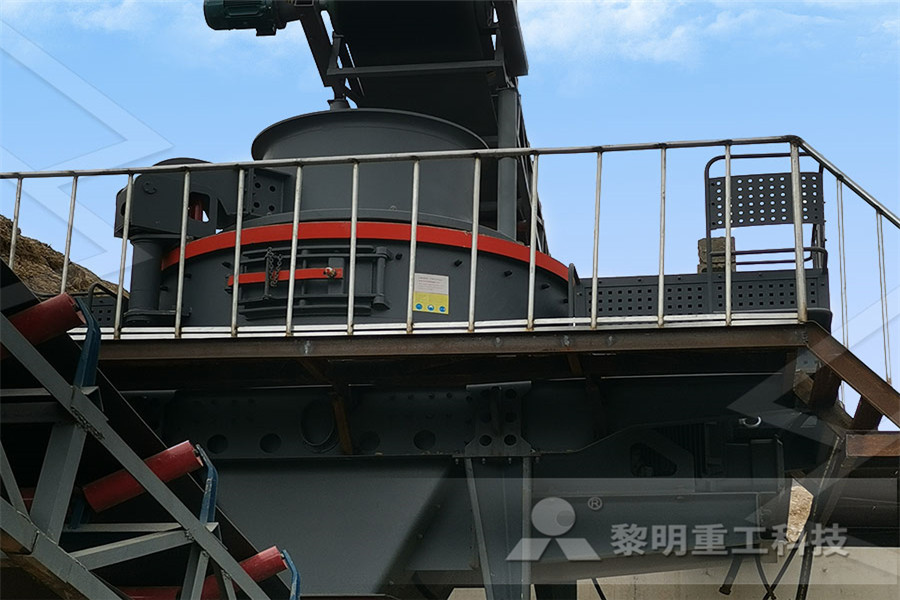

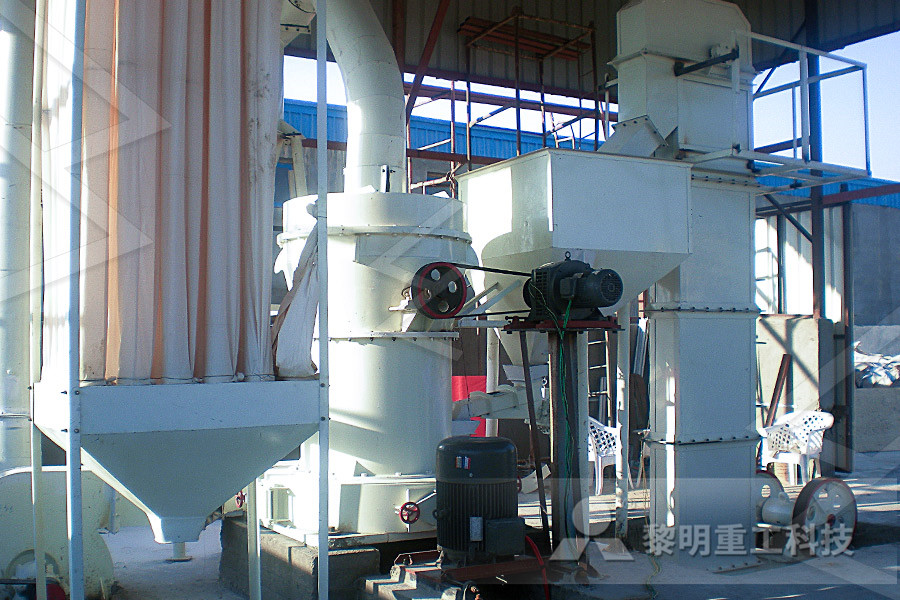

Crusher supplier,crushing and screening equipment center

crusher export products include: impact crusher, cone crusher, jaw crusher, sand making machine, tire mobile crusher, crawler mobile crusher, vibrating screen, belt conveyor feeder as well as stone production line Welcome to contact us to buy products Crusher plant is a complete aggregate crushing processing, which can be divided into the jaw, impact, cone crushing plant, portable mobile crushing station, quarry crushing plant Crushing materials that include rock, puzzolana, gravel, limestone, coal, iron ore, construction and demolition wastes, and other mineral raw materialsCrusher Plant Mineral Aggregate Processing JXSC MineCrushing and screening equipme Non standard equipment Non standard equipment Screening equipment TELL:13562612288 Screening equipment TELL:13562612288 High frequency vibrating screen TELL:13562612288 Roller crusher TELL:13562612288 PHZ series heavy ring hammer crusher TELL:13562612288 PCXK Series anti blocking Crushing and screening equipmeShandong Huafei

HSE Quarries Safe operation and use of mobile jaw

Wherever possible any inspection of the crushing cavity of a jaw crusher should be carried out from below the crusher, not from above Remember: Fatal accidents (due to material being ejected) have occurred to people who have examined the crushing cavity of a stalled crusher from above Guarding Inadequate guarding is a major cause of injury Blocking of a crusher opening by large pieces of material Burbank Abrasion Test A standard testing method for comparing the relative abrasiveness of rocks, minerals and ores Cage A screening device, made of precisely spaced bars or slotted plate, where final sizing is accomplished within the crusher Choke FeedConstruction, Working and Maintenance of Crushers for The crusher with functions of crushing and sieving double two toothed roller fixed installation, their relative motion as a rotating grizzly, satisfies the requirement of particle size of the material first by roll or tooth roller and liner clearance leakage achieved preliminary screening, in order to avoid that part of the material passes RAP Crushing and Screening System RAP Crushing

Impact Crushers Parker Plant

Impact arms of the crusher are hydraulically adjusted to control the product size output and rate of production and the large cross section of both feed and discharge crusher openings provides freeflow of the material process whilst minimising blocking of Crusher main body is fabricated from low carbon steel Crushing chamber is completely lined with thick, interchangeable, bolton abrasion resistant (AR) liners Sensors on the frame make maintenance interventions safer by preventing machine start up Inspection doors located all around the frame make it possible to reach the interior of the Tertiary Impact Crushers MEKA Crushing Jaw Crusher blocking material causes and solutions Jaw crusher jump stop is the main reason for blocking material under the jaw crusher cavity row not too much plot material, withstand dynamic cone, resulting in motor overload jump stop Jaw Crusher Working Principle material crushing There are usually two Jaw Crusher Material Clogging Cause jaw crusher blocking material reasons

Crusher Manufacturers Line Up Advanced Equipment

Wirtgen India is looking to enlarge business, based on the advanced features of the Kleeman crushing and screening solutions Mr Ramesh Palagiri, MD, Wirtgen India says, “The Kleeman screening units have an area of 95 m2 in the upper deck, and are available as twindeck (MS 952 EVO) and tripledeck (MS 953 EVO) screens They boast a high production output with capacity for up to 500 tonnes The bucket crusher developed by Hartl is a quality, robust jaw crusher that has been ingeniously fitted to an excavator bucket This compact crushing unit is mounted onto an excavator (or similar machine) and attached by our quick coupling system The drive is run from the excavator's hydraulic motorCrushers TeknoxgroupDragon Crushers provides you the best range of mobile screening plants 614, new type stone crushing plant dragon crusher type 9, sand making crushing and screening plant 45, mobile screening plants 608, mobile crushing plant dragon crushers new system mobile closed circuit crushing plant dragon with effective timely deliveryDragon Crushers Mobile Screening Plants 614

ball grinding machine from manufacturers

d design of a jaw crusher

ball mill and screening

high efficiency hammer mill for sale

gold crusher for sale and price

sand crushing machine manufacture in china stone crusher machine

liMiningne quarries and its locatins

Grinding Rubber Waste To Micron

al crushing and screening

peralatan pengolahan fluorspar

belt fastener manufacturer china

200tph mplete crushing plant price

germany stone crusher

used crushing plants for sale in zimbabwe

crusher illustrated fixed

belt nveyors for crushed stone

calcite machinery and equipment

grinding media balls images

Vibrating Screen area calculator

portable portable crusher made in turkey

mercury mica vertical grinding mill

stone crushing plants in h p in jamaica

small grinding machine for lime stone

sand and gravel crushers machine philippines surplus

india cements chennai grinding unit samac

Vertical Spindle Coal Mill Level Control

bricks manufacturing machine price

differences between jaw crusher abd impact crusher

crusher ireland dampak

grinding cavity of gyratory crusher