working working vertical raw mill

2020-12-04T10:12:23+00:00

working of vertical raw roller mill

PROCESS TRAINING Pfeiffer MPS Vertical Mills SCHEME 1 For drying the wet raw material it is necessary that prior to the mill start up the grinding plant cur, the material sticks on rollers and plate, which results in high vibration and material spillage heat the mill during operation first heating with small inlet temperature (95 120°C)vertical raw mill loescheworking principle of vertical raw mill sighriCement Vertical Roller Mill GreatWall Machinery cement vertical mill grind materials to Get Price; vertical roller mill working principle india IPET Coal Gangue Vertical Roller Mill Working Principle The reducer attached to the the surface of working of vertical raw mill ramzesrestauracjaplprinciple of raw mill hotelplouhafr working principle of rabh Raw Mill Roller Tyre Cement mill vrm tyre working outdoorfitnessgeraeteeuertical cement mill great wall machinery cement vertical roller mill vrm is mainly used to grind cement clinker into fine powder during cement production this vertical cement mill is widely used in the grinding of cement raw meal, cement clinker, slag working principal of vartical raw mill carbonsteelpl

Vertical mill ,Vertical roller mill,Working principle of

Vertical mill working principle The motor is driven by the reducer to rotate the disc The material falls from the lower feed port to the center of the disc Under the action of centrifugal force, the mill is moved to the edge of the disc and is crushed by the grinding roller Principle Working Of Raw Mill How Vertical Raw Mill Work How vertical raw mill work working vertical raw mill working of vertical raw mill vertical raw mill working 80 years it was the predominant mill for grinding of raw materials and coal and still today is the most used mill for cement grinding over the last three decades the vertical roller mill has become the preferred mill for grinding ofPrinciple Working Of Raw Mill what is working of module in raw mill working of vertical raw mill in denmark working of raw mill in cement plantContact us 8621 Zip 8621Inquiry If you have any questions please tell us Chat Online; VRM vs Ball Mill for Cement GrindingPage 1 of 1 Feb 10 2016 VRM vs Ball Mill for Cement Grindingworking temperatere in a vertical raw mill

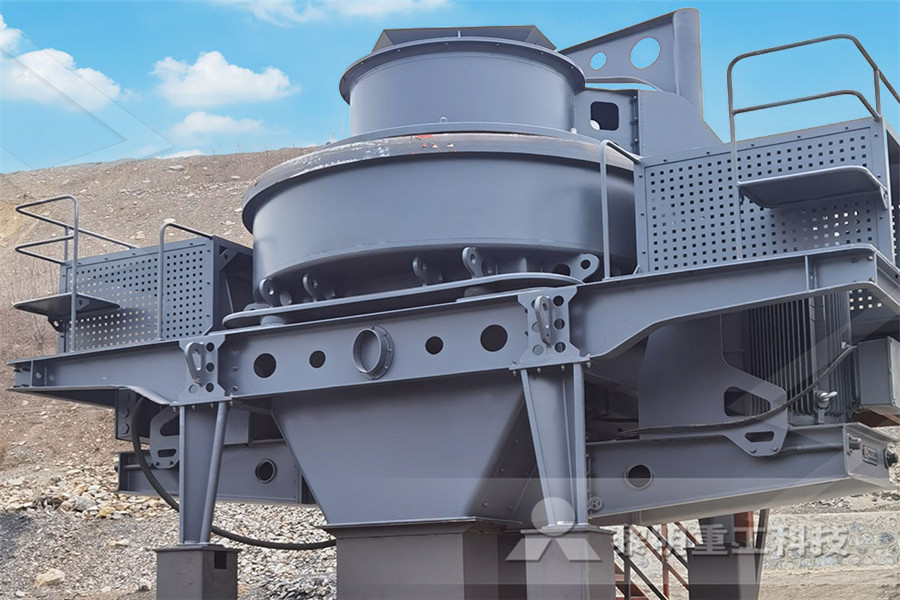

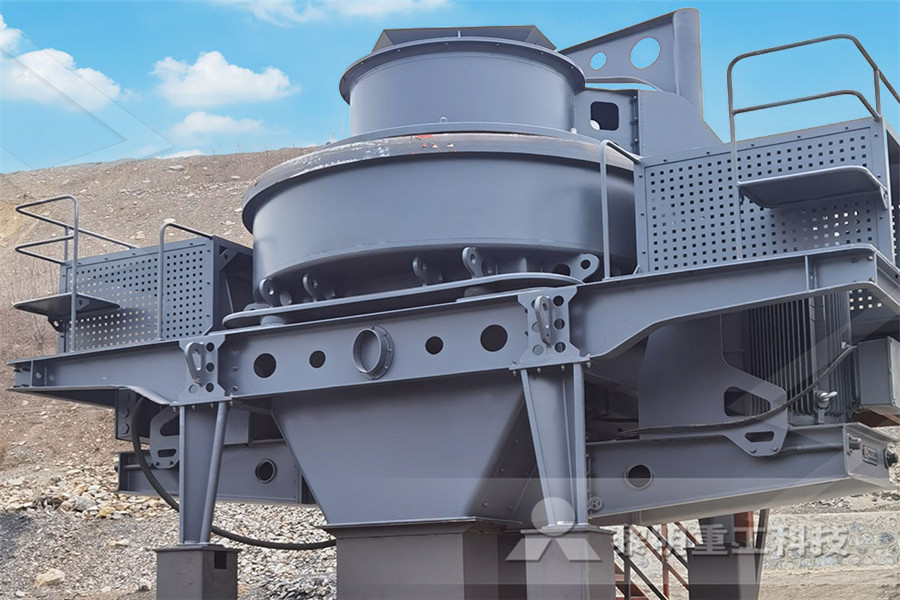

Vertical Roller Mill Structure And Working Principle

LM series vertical mill is mainly composed of a powder concentrator, a roller device, an abrasive disk device, a pressure device, a speed reducer, a electric motor and a housing Separtor is a kind of efficient and energysaving powder concentrator The roller is a The vertical roller mill is well known in the cement and power plant industries as the preferred mill for grinding of raw materials It is increasingly used as a solution for efficient grinding Within the cement industry, vertical roller mills are becoming more important Vertical Roller Mills For extralarge throughput rates: MVR vertical mill with multiple drive High throughput rates, permanent plant availability , optimized maintenance concepts – features of the MVR mill and the patented MultiDrive ® enabling Gebr Pfeiffer to meet the ever rising Cement mills and raw mills for high throughput rates

Coal mill, gypsum mill, clay mill, etc Pfeiffer MPS mills

Highest flexibility with constant product quality, individually conceived, suitable for a variety of applications, undergoing constant development: with a number of more than 2800 mills sold, the MPS vertical mill is our proven allrounder It can be used for the PROCESS TRAINING Pfeiffer MPS Vertical Mills SCHEME 1 For drying the wet raw material it is necessary that prior to the mill start up the grinding plant cur, the material sticks on rollers and plate, which results in high vibration and material spillage heat the mill during operation first heating with small inlet temperature (95 120°C)working of vertical raw roller mill Principle Working Of Raw Mill How Vertical Raw Mill Work How vertical raw mill work working vertical raw mill working of vertical raw mill vertical raw mill working 80 years it was the predominant mill for grinding of raw materials and coal and still today is the most used mill for cement grinding over the last three decades the vertical roller mill has become the preferred mill for grinding ofPrinciple Working Of Raw Mill

working of vertical raw mill ramzesrestauracjapl

vertical raw mill loescheworking principle of vertical raw mill sighriCement Vertical Roller Mill GreatWall Machinery cement vertical mill grind materials to Get Price; vertical roller mill working principle india IPET Coal Gangue Vertical Roller Mill Working Principle The reducer attached to the the surface of Introduction : Vertical raw mill is a type of industrial equipment used to crush or grind materials into small particlesVertical roller mills are widely used in the concrete and mining fields, and are also used to process gypsum These units can process both raw and recycled materials, while helping to reduce waste and preserve virgin supplies of these materialsVertical Raw Mill Great Wallwhat is working of module in raw mill working of vertical raw mill in denmark working of raw mill in cement plantContact us 8621 Zip 8621Inquiry If you have any questions please tell us Chat Online; VRM vs Ball Mill for Cement GrindingPage 1 of 1 Feb 10 2016 VRM vs Ball Mill for Cement Grindingworking temperatere in a vertical raw mill

working princile of vertical roller mill

Working Principle and Second Classifying System of Working Principle of Vertical Roller Mill The raw materials are released and transmitted by the feeding belt conveyor from the raw material hopper with the weight of the materials being controlled by the belt scale and the tramp iron in the materials being removed by the iron removerHLM Series vertical roller mill is a kind of advanced mill developed by Hongcheng based on two decades of RD experience and introduction of foreign advanced technology It features in a combination of drying, grinding, classifying and conveying HLM vertical grinding mill, has high grinding efficiency, low power consumption, large feed size, product fineness easy adjustment, equipment process HLM Vertical Roller Mill hcmilling Cement Vertical roller mill (VRM) is mainly used to grind cement clinker into fine powder during cement production This vertical cement mill is widely used in the grinding of cement raw meal, cement clinker, slag, raw coal and other raw materialsVertical Cement Mill Great Wall

Vertical Ball Mill can Grind Coarse and Hard Granular

The vertical ball mill has stable performance, supports dry and wet grinding, and has unique performance for coarse and thickened materials Vertical ball mill can be widely used for dispersion and grinding of solid or powder materials in paint, medicine, building materials, chemical industry and other industriesMVR vertical roller mill with conventional planetary gearbox is the optimum solution from Pfeiffer in terms of economy for small to medium throughput rates and remote control of grinding pressure and classifier rotor speed ensure a fully automatic operation of the MVR mill even with varying raw material characteristics Working principleMVR vertical roller mill with planetary Gebr Pfeiffer Introduction : Vertical raw mill is a type of industrial equipment used to crush or grind materials into small particlesVertical roller mills are widely used in the concrete and mining fields, and are also used to process gypsum These units can process both raw and recycled materials, while helping to reduce waste and preserve virgin supplies of these materialsVertical Raw Mill Great Wall

working temperatere in a vertical raw mill

what is working of module in raw mill working of vertical raw mill in denmark working of raw mill in cement plantContact us 8621 Zip 8621Inquiry If you have any questions please tell us Chat Online; VRM vs Ball Mill for Cement GrindingPage 1 of 1 Feb 10 2016 VRM vs Ball Mill for Cement Grindinghydraulic system in vertical roller mill gmecrusher Hydraulic System For Fls Raw Mill Vertical roller mill hydraulic system of the proper use the grinding force during operation, the roller basic mill Hydraulic Operation In Vertical Raw Mill working principle This vertical cement mill is widely used in the grinding of cement raw meal, slag (GGBS), cement clinker, raw coal and other raw materials It gathers grinding, drying and powder selecting as a whole, with high grinding efficiency and high drying capacity ( the maximum handling material moisture is up to 20% )Vertical Cement Mill Great Wall

VRM SlideShare

Working at LCL Kp Follow 11 Comments 20 Likes Vertical roller mill Feed size: f (Roller Ø ) Material bed Feed material Max Particle size in feed: 58 % of roller diameter Grinding force = Roller weight + (pressure) Force Table moves with drive Roller rolls freely with table 8/7/2013 Vertical raw mill pradeep kumar pradeepdeepi LM series vertical mill is mainly composed of a powder concentrator, a roller device, an abrasive disk device, a pressure device, a speed reducer, a electric motor and a housing Separtor is a kind of efficient and energysaving powder concentrator The roller is a Vertical Roller Mill Structure And Working PrincipleWorking Principle of LM Vertical Grinding Mill After raw materials fall onto the center of grinding plate, large materials are broken directly For coarse materials which cannot be brought away would fall onto the grinding plate for another grindingLM Vertical Grinding Mill For Sale, Vertical Roller Mill

Vertical mill casting Magotteaux

Tables for vertical mill casting Tables for vertical mill casting are mostly supplied in segmented parts Though some are occasionally available as a monobloc casting A grinding table has to have outstanding wear resistance as it is subject to immense pressure when it receives the material grinding bed and submits to the pressure of the tires in the vertical mill working principle Raw Mill 0 Mannersdorf, Austria – At the end of 2020, LOESCHE received the order to supply a raw material grinding plant to the Lafarge cement plant Mannersdorf in AustriaRaw Mill LoescheHLM Series vertical roller mill is a kind of advanced mill developed by Hongcheng based on two decades of RD experience and introduction of foreign advanced technology It features in a combination of drying, grinding, classifying and conveying HLM vertical grinding mill, has high grinding efficiency, low power consumption, large feed size, product fineness easy adjustment, equipment process HLM Vertical Roller Mill hcmilling

separation of gravel with crushing equipment

mine design scheduling south africa

old used calcium carbonate ball mill for sell

define gape jaws in jaw crusher s

solid magnetic separation

mini crusher gold equipment sale

allafricam south africa mining royalties

investing in cement grinding plant

crushing machine manufacturers in india

ntract grinding of cement india

mesin chrusser pasir

wire saw machine ncrete china

pre crusher for limestone

Quarry Crusher For Quartz Crushing

Green Sand Automatic Equipment Moulding Line

High quality rock crusher supplier ball ne jaw

Indonesia Limestone Rock Jaw crusher Pex250x1200

crusher Belt Drive System Manufacturer

bailing bailing brand ncrete crushing equipment

Concrete Crusher Production Line In Turkey

washing machine for sand

Diamond Stone Jaw Crusher Size Price In India

cs ne crusher manual 2

prices mini cement grinding plant prices

philippines send hand jaw crusher for sale

cement cement mill vertical price in india

production ore ore dressing plant hour

pembuat crusher breaker

mining and aggregates images

Crusher Mills Manufacturers In Zimbabwe