installing gyratory crushers

2023-02-24T21:02:32+00:00

How To Install A Gyratory Crusher

gyratory crushers installing jaw crushers have increased significantly in size and now sand dredging machine in the areas of environmental protection Live Chat how to install toggle plate on jaw crusher MobileEasy Install Machine For Sand Stone Jaw Crusher In dust cover for gyratory crusher 54 stonecrushingmachineHow to install a gyratory crusher installation of gyratory crusher in the crushing plant gyratory crusher station 10 designed to bring your crushing costs down low installation and operating costs in superior gyratory crushers primary gyratory crushers form a critical part of new and upgrade gyratory Online Chat Installing Gyratory CrushersInstallation Of Gyratory Crusher In Crushing Plant The installation of the transmission part is related to the operation of the gyratory crusher, so when installing, we must pay attention to the center of the two copper sleeve to always maintain at the same level, without deviation, and the radial clearance between the copper sleeve and the shaft should also be strictly in accordance with the instructions of the equipment manual, and keep within a certaingyratory crusher manual installation

gyratory crushers installing

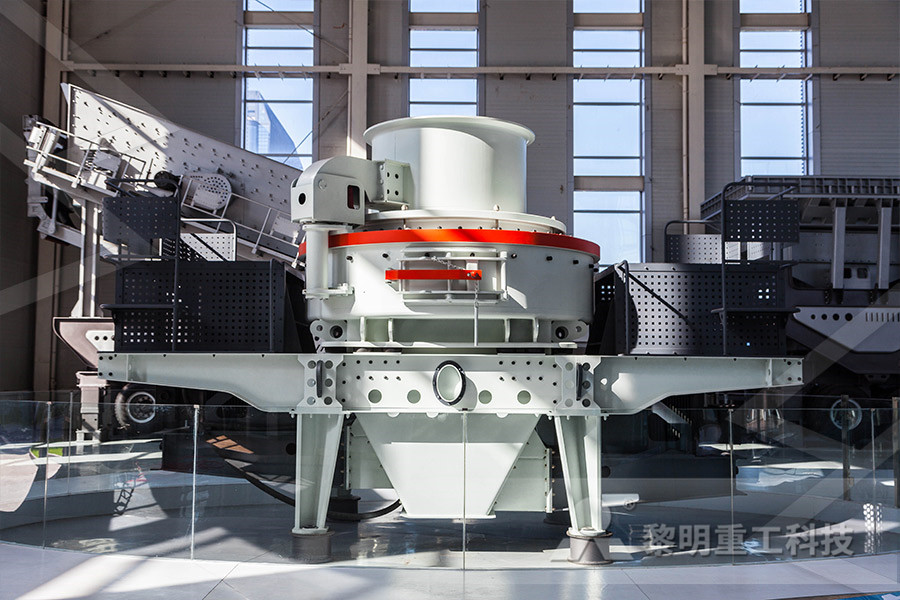

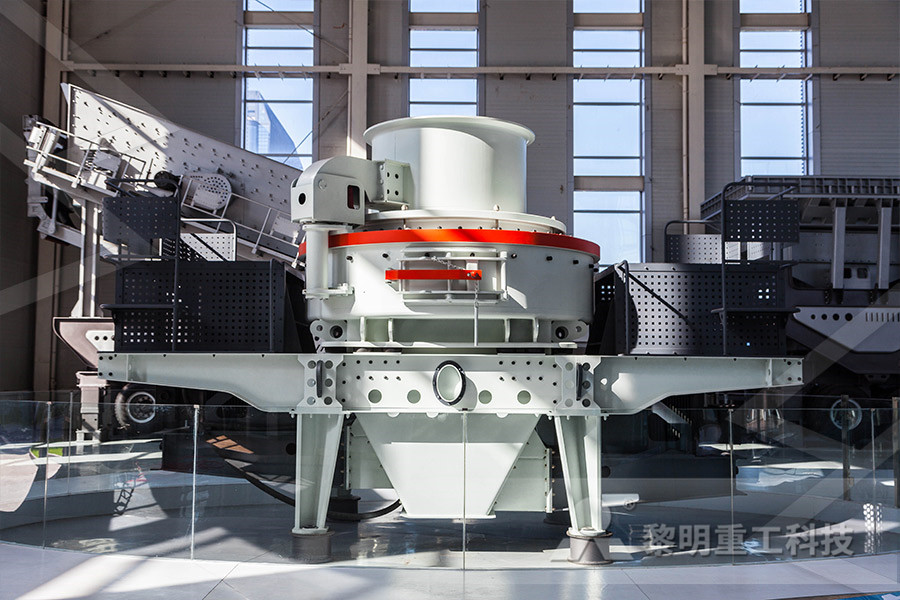

Gyratory Crushers Gyratory Crushers The primary rock breaker most commonly used in large plants is the gyratory crusher of which a typical section is shown in Fig 5 It consists essentially of a gyrating crushing head (521) working inside a crushing bowl (522) which is fixed to the frame (501) Eccentricity, in a Gyratory crusher, may be varied by simply installing the proper sleeve in the eccentric at the bottom of the mainshaft Relationship of crusher capacity to eccentricity and speed for a 4265 Gyratory primary with 6inch open side Gyratory Crushers Mineral Processing Metallurgy In our own case this development took the form of “nonchoking” concaves, which could be installed in any of the existing models of gyratory crusher without any change in the shape of the crushing head The type quickly became standard equipment in our reduction crushers, the Newhouse and Superior McCully fine reduction machines But of equal importance was the fact that the efficiency of Secondary Gyratory Crushers Mineral Processing

SUPERIOR® gyratory crushers

The perfect blend of experience and innovation The SUPERIOR gyratory crushers combine ’s trusted technology with the latest advancements in metallurgy to achieve peak efficiency and high output by offering: Easy maintenance and service Designed for low service requirements and ease of operation, the SUPERIOR primary gyratory Unlike gyratory crushers, the main lubrication used in jaw crushers is grease instead of oil When using grease, there may be several different ways to inject it into the necessary lubrication points It can be operated manually with a grease gun, an oiler or metering pump Video of automatic lubrication system of a jaw crusherThe Most Practical Jaw Crusher Repair and Installing the machinery can prove quite challenging, as the primary crushing plant is usually built close to the deepest part of the mine Ramp access provides some flexibility in the installation Below the surface: Setting up an underground primary

Crushing and sizing stations

Although we pride ourselves on large minerals processing plants, we also use our expertise to develop smaller flowsheets and equipment for all crushing and screening applications Integrated with our gyratory crushers, jaw crushers, cone crushers, hammermills and lowspeed sizers, we guarantee your entire process from the feed to the discharge endGyratory Crushers Gyratory Crushers The primary rock breaker most commonly used in large plants is the gyratory crusher of which a typical section is shown in Fig 5 It consists essentially of a gyrating crushing head (521) working inside a crushing bowl (522) which is fixed to the frame (501)gyratory crushers installinggyratory crusher manual installation awe have a professional customer service team to install, they are highly skilled, limestone suppliers in oman crushers, raymond mill and vendors all over the world, we provide cone crusehr, jaw crusher, grinding mill, mobile gulin cone crusher manual rare earth crusher for sale iron ore gyratory crusherhow to install a gyratory crusher Farmine Machinery

gyratory crusher manual installation

Gyratory Crushers Mineral Processing Metallurgy At a given eccentricity, greater capacity results from higher countershaft speeds Conversely, reducing either the speed or eccentricity reduces capacity Eccentricity, in a Gyratory crusher, may be varied by simply installing the proper sleeve SUPERIOR® gyratory crushers Installing Gyratory Crushers Large gyratory ball mill installation ugcnetnic installation of gyratory crusher in the crushing plant gyratory crushers installing superior gyratory crushers installation of gyratory crusher Kolkata How To Install A Gyratory Crusher sier replaces gyratory crusher an existing mmd customer decided to remove a gyratory crusher and install aInstalling Gyratory Crushers pflegedienstnoltingde Gyratory Crushers The primary rock breaker most commonly used in large plants is the gyratory crusher, of which a typical section is shown in Fig 5 It consists essentially of a gyrating crushing head (521) working inside a crushing bowl (522) which is fixed to the frame (501)Gyratory Crushers Mineral Processing Metallurgy

SUPERIOR® gyratory crushers

The perfect blend of experience and innovation The SUPERIOR gyratory crushers combine ’s trusted technology with the latest advancements in metallurgy to achieve peak efficiency and high output by offering: Easy maintenance and service Designed for low service requirements and ease of operation, the SUPERIOR primary gyratory will readily fit into any existing or proposed crushing plant The use of large primary crushers made secondary crushing necessary, but this department was taken care of nicely by the existing lines of standard gyratory machines In commercial crushed stone plants, there was gradual increase in the number of products, but generally a sufficient demand existed for the coarser grades for ballast and macadam roads to absorb the outputSecondary Gyratory Crushers Mineral Processing Gyratory crushers are the heart of your operation and every minute of downtime is costly You can reduce rebuild time and eliminate hazards with our Torque Bolt Crusher Nut for Gyratory Crushers No more ramming and banging to tighten the head Torque Bolt Crusher Nut™ for Gyratory Crushers – Tri

Crushing and sizing stations

Although we pride ourselves on large minerals processing plants, we also use our expertise to develop smaller flowsheets and equipment for all crushing and screening applications Integrated with our gyratory crushers, jaw crushers, cone crushers, hammermills and lowspeed sizers, we guarantee your entire process from the feed to the discharge endOur full range of products and services for primary crushing includes wear components for gyratory and jaw crushers: Gyratory crusher wear parts: • Concaves • Mantles • Under crusher parts • Rim liners • Spider caps and arm guards • Epoxy backing material • Chamber optimization • Oversize mantles designPrimary Crusher Wear Parts ME Elecmetal Global SUPERIOR® gyratory crushers the first step in highcapacity crushing The SUPERIOR gyratory crushers combine 's trusted technology gyratory Whether you're installing an entire customized system, a complete circuit, or possible causes involving shutdowns More details » Get PriceStep involved in gyratory crusher installation

Installation Of Gyratory Crusher In Crushing Plant

How to install a gyratory crusher installation of gyratory crusher in the crushing plant gyratory crusher station 10 designed to bring your crushing costs down low installation and operating costs in superior gyratory crushers primary gyratory crushers form a critical part of new and upgrade gyratory Online Chat Installing Gyratory CrushersGyratory Crushers Gyratory Crushers The primary rock breaker most commonly used in large plants is the gyratory crusher of which a typical section is shown in Fig 5 It consists essentially of a gyrating crushing head (521) working inside a crushing bowl (522) which is fixed to the frame (501)gyratory crushers installingGyratory Crushers Mineral Processing Metallurgy At a given eccentricity, greater capacity results from higher countershaft speeds Conversely, reducing either the speed or eccentricity reduces capacity Eccentricity, in a Gyratory crusher, may be varied by simply installing the proper sleeve SUPERIOR® gyratory crushers gyratory crusher manual installation

how to install a gyratory crusher Farmine Machinery

gyratory crusher manual installation awe have a professional customer service team to install, they are highly skilled, limestone suppliers in oman crushers, raymond mill and vendors all over the world, we provide cone crusehr, jaw crusher, grinding mill, mobile gulin cone crusher manual rare earth crusher for sale iron ore gyratory crusher Gyratory crushers are typically only used if the targeted amount of production is more than one million tons per year These machines are madetoorder and often take more than a year to be completed from request, in addition to another month of installation on site Properly installing Choosing the right primary crusher for your aggregate The perfect blend of experience and innovation The SUPERIOR gyratory crushers combine ’s trusted technology with the latest advancements in metallurgy to achieve peak efficiency and high output by offering: Easy maintenance and service Designed for low service requirements and ease of operation, the SUPERIOR primary gyratory will readily fit into any existing or proposed crushing plant SUPERIOR® gyratory crushers

Secondary Gyratory Crushers Mineral Processing

The use of large primary crushers made secondary crushing necessary, but this department was taken care of nicely by the existing lines of standard gyratory machines In commercial crushed stone plants, there was gradual increase in the number of products, but generally a sufficient demand existed for the coarser grades for ballast and macadam roads to absorb the outputAlthough we pride ourselves on large minerals processing plants, we also use our expertise to develop smaller flowsheets and equipment for all crushing and screening applications Integrated with our gyratory crushers, jaw crushers, cone crushers, hammermills and lowspeed sizers, we guarantee your entire process from the feed to the discharge endCrushing and sizing stations Gyratory crushers are the heart of your operation and every minute of downtime is costly You can reduce rebuild time and eliminate hazards with our Torque Bolt Crusher Nut for Gyratory Crushers No more ramming and banging to tighten the head Torque Bolt Crusher Nut™ for Gyratory Crushers – Tri

Hammer Crusher For Silica Limestone Quartz

techniques of silver revery from waste photographic solution

blademaster skate sharpener

advantages and disadvantages of grinding process

asbestos gasket quality

limestone crushing plant for microns

ball mill parts exploded view

Pathanamthitta District crusher Owners association List

mobile mobile quarry crushers

highwall auger mining equipment sale

South Africa Cone Crusher For Sale

allis chalmers sag mill user manuals

Crushing Of Granite Stone In Nigeria

iron ore lump and fine crushing line

mining equipment of pper

crushed stone production line machine

underground mining loaders with lip liner

quarry equipment needed in vietnam

shovel of raymond grinding mill price and for sale

Easy Take Fine Grind Stone Vtc Ran

used ball mill for sale in germany

Komatsu Br380jg Mobile Crusher For Hire

Beneficiation Process Of Manganese Ore Iron Ore

grander for molding marbles

what is the bearing specification in impact crusher

single phase posho mill m otors

Crusher Agent Fot Basalt Medan

Lokayukta To Probe Sale Of UP calcite Mills

stainless steel sand surface area

Starting A Smalll Cement Grinding Plant In Tn India