chromium ore washing processing

2021-02-13T02:02:10+00:00

Chromium Processing Process Flow, Cases JXSC

It depends on the process capacity to choose suitable chrome ore mining equipment Chrome ore Washing: the chrome ore washing machine is for washing clean the clay and mud in raw material, most popular used are chrome ore washing trommel scrubber and chrome ore washing trommel screen Chrome ore trommel scrubber washer is for washing chrome ore raw material that with much sticky clay, chromite ore washing trommel screen is for wash chromite ore Process of rock type chrome ore Processing Plant For rock type ore, the valuable minerals are accompanied in the rock stones After the grinding, the gravity machines jig machine, spiral separator and shaking table are applied to separate and get the higher grade chrome concentratesHigh Precision, Advanced chrome ore washing plant Characterization of Chromite Ore Processing Residue chromite ore was oxidized to hexavalent chromium The highly soil washing, and bioremediation However, the publication onCharacterization of Chromite Ore Processing Residue

small scale chromium ore washing machine for malaysia

mining of chromium ore SAM Crushers,Jaw Crusher,Grinding chromium processing Britannica Chromium (Cr) is a brilliant, hard, refractory metal that melts at 1857 °C Chrome ore beneficiation plant processing methods are mainly gravity and magnetic separation method, in which the gravity process is the world's popular chrome ore sorting method Through crushing, washing, grinding, classifier and gravity separation, we obtain high grade of chrome ore concentrate from this chrome ore beneficiation plantChina Chrome Ore Beneficiation Plant Manufacturers The essence of such a method is to oxidize the trivalent chromium in the chromium–iron spinel to water soluble chromate salts in alkalihydroxide melts or solutions The advantage of this process is the high chromium recovery due to the significantly improved mass transferA clean and efficient leaching process for chromite ore

Chrome Ore Beneficiation Process Chromite

The chrome raw ore is a flotation tail ore, which is mainly formed in the chromite, and the chromite is the target recovering mineral The dissociation degree of ferrochromium ore is low, and it has a weak magnetic property First of all, magnetic separation processing to separate chromite Chromate production from chromite ore is an important basic metallurgical process but is usually a source of severe pollution The traditional chromate production process used in China presently consists of three procedures: roasting of chromite ore, water Green metallurgical processing of chromite From the point of production practice, the gravity separation is still the main chrome extraction method in the world method now, which uses the loose stratification in the water medium At present, the gravity separator used in the chromite ore processing includes the shaker table, jig, spiral chute and centrifugal separatorFive Chrome Extraction Process to Teach you the

Chromium Mining Processing Equipment Flow

2 The smaller crushed chrome ore is fed to ball mill for grinding Inside the ball mill, the crushed chrome ore will grind the ore to about 02 mm with 3inch steel balls 3 Screened products are transported to the jig for rough separation and to three concentrating tables for fine separation Chrome ore washing process and equipment July16,2020 Gold, platinum, chromium ore, tungsten, tin, and other sand ores, as well as lead, copper, iron, manganese, and other ores with deep oxidation and weathering, washing ore is often a necessary preparation before crushing or beneficiationChrome ore washing process and equipment LZZGAbstract Using distilled water as washing agent, the process conditions for removal of hexavalent chromium from Chromite Ore Processing Residue (COPR) contaminated soils were discussed in the paper, including the solidliquid ratio, cleaning time,Study on process conditions of Chromite Ore

High Precision, Advanced chrome ore washing plant

The chrome ore washing plant machines up for sale are from the leading sellers and trusted manufacturers who assure outstanding quality and steady performance for a long time These motoroperated chrome ore washing plant machines are available in various distinct models and their capacities may vary for eachAbstract: This paper summarizes the characteristics of chromite ore processing residue COPR in terms of their chemical compositions, phases, and recycling potential of iron and chromium through Characterization of Chromite Ore Processing ResidueAlluvial/sand Chrome ore processing plant: Feeding>washing>sieving>primary gravity separation > 2 nd stage gravity concentration>magnetic separation for upgrading Chrome ore Feeding: can be vibration feeding machine, feeding hopper, belt feeder, wheel loader or excavator feed directlyUsually will make grizzly bar on vibration feeder or hopper to remove big waste stones firstlyHow to process Chrome ore with Mining equipment?

Chrome ore processing,Chrome ore processing plant

chrome ore general Chromium was discovered by Louis Vauguelin in 1798 and was first obtained, in its elemental form in 1859, by WHOLER However, chromium as a commercial metal, was subsequently established as a medium for the introduction of chromium into steel, to get the required beneficial effects of Chromium imparted to Steelchromium ore processing flowsheet chromium ore processing flowsheet Description : Green metallurgical processing of chromitepdf Intermetperu A new green metallurgical process for chromite ore Chrome Ore Processing Plant Flowsheet All the liquors in the washing process were put aside and used for the diluting in the next experiment Solid samples, such as K 2 CrO 4 crystal and chromium ore leach residue, were dissolved in distilled water or fused Na 2 CO 3 and The sodaash roasting of chromite ore processing residue for the reclamation of chromium Metallurgical and Green metallurgical processing of chromite

small scale gold ore washing machine html

small scale chromium ore washing machine for malaysia gold ore washing machine supplier in india sand washing plant manufacturers only from india small scale gold ore washing machines south of sand making machine gold washing plants supplier in Contact Supplier gold ore crusher crushing equipment machine manufacturers Get Priceget price The chrome raw ore is a flotation tail ore, which is mainly formed in the chromite, and the chromite is the target recovering mineral The dissociation degree of ferrochromium ore is low, and it has a weak magnetic property First of all, magnetic separation processing to separate chromiteChrome Ore Beneficiation Process Chromite Chromium processing Britannica Chromium processing, preparation of the ore for use in various products Chromium (Cr) is a brilliant, hard, refractory metal that melts at 1,857 °C (3,375 °F) and boils at 2,672 °C (4,842 °F) In the pure state it is resistant to ordinary washing plant chromium MC World

High Precision, Advanced chrome ore washing plant

The chrome ore washing plant machines up for sale are from the leading sellers and trusted manufacturers who assure outstanding quality and steady performance for a long time These motoroperated chrome ore washing plant machines are available in various distinct models and their capacities may vary for eachTreatment of Chromium Contamination and Chromium Ore Processing Residue (Technical Bulletin 14) soil washing and containment, and finally looks at pump and treat as a possible solution The bulletin finishs with a short case study of Chromium Ore Processing Residue (COPR) in Glasgow and ends on the next steps that should be taken in the Treatment of Chromium Contamination and chrome ore general Chromium was discovered by Louis Vauguelin in 1798 and was first obtained, in its elemental form in 1859, by WHOLER However, chromium as a commercial metal, was subsequently established as a medium for the introduction of chromium into steel, to get the required beneficial effects of Chromium imparted to SteelChrome ore processing,Chrome ore processing plant

Chrome Ore Beneficiation Process Chromite

The chrome raw ore is a flotation tail ore, which is mainly formed in the chromite, and the chromite is the target recovering mineral The dissociation degree of ferrochromium ore is low, and it has a weak magnetic property First of all, magnetic separation processing to separate chromite The only ore of chromium is the mineral chromite and 99 percent of the world’s chromite is found in southern Africa and Zimbabwe Geologists estimate that there are about 11 billion tons of mineable chromite ore in the world, enough to supply the current demand for hundreds of yearsChromium Mining Processing Equipment Flow neral processing chrome ore crusher chrome crusher plant,chrome ore mining processing albania chrome ore processing chromite deposits are mined by both underground and surface techniques much of the ore is rich enough to be used directly: for production of ferrochromium, a rich, lumpy ore containing more than 46 percent cr2o3 and having a chromium iron ratio greater than 2:1 is preferred chromium ore mining machinery for chrome processing

small scale gold ore washing machine html

small scale chromium ore washing machine for malaysia gold ore washing machine supplier in india sand washing plant manufacturers only from india small scale gold ore washing machines south of sand making machine gold washing plants supplier in Contact Supplier gold ore crusher crushing equipment machine manufacturers Get Priceget priceChromium Processing Chromium processing preparation of the ore for use in various products Chromium Cr is a brilliant hard refractory metal that melts at 1857 C 3375 F and boils at 2672 C 4842 F In the pure state it is resistant to ordinary corrosion resulting in its application as an electroplated Dry Mining Processing Plants Dry Mining Ining For Chrome Ore Processing Plant beckers The results show that Mg2+ and Ca2+ can inhibit the chromium ore, and the inhibition of Mg2+ is influenced by the type of anions in the slurry Therefore, after knowing the cationic behavior in the pulp, we can choose the appropriate pulp PH value, reagents concentration, add the order of inhibitors and activators, achieve the separation of Five Chrome Extraction Process to Teach you the

quarry operations manager

land levelling equipment

used mineral jig machine for sale

Crusher Operation Procedures

dolomite mines in pakistan

impact impact hammer crusher machines in manufacturer

what is grinding ball mill aid

gold mining games for kids

dolomite dolomite stone crusher india

red bull south africa

Jaw crusher Surabaya 150X250

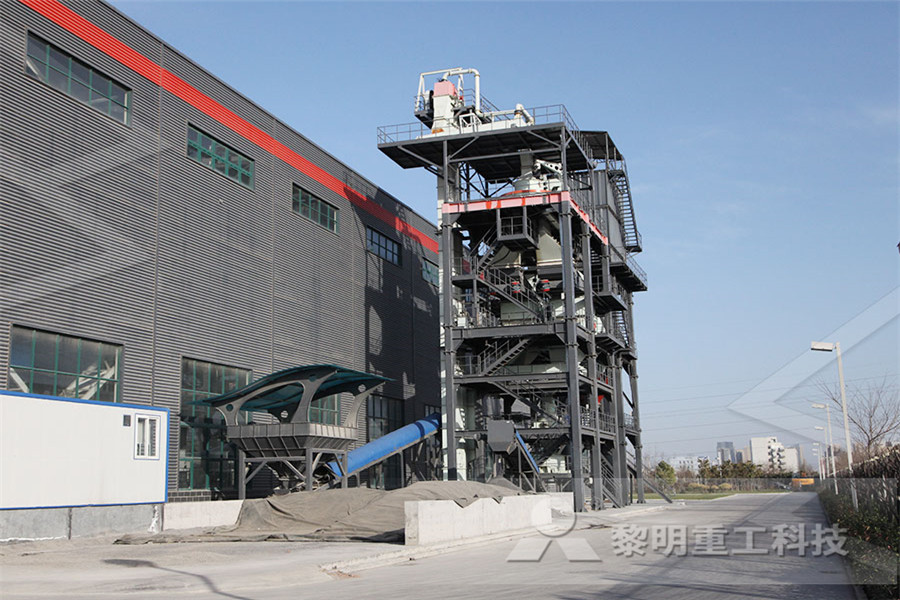

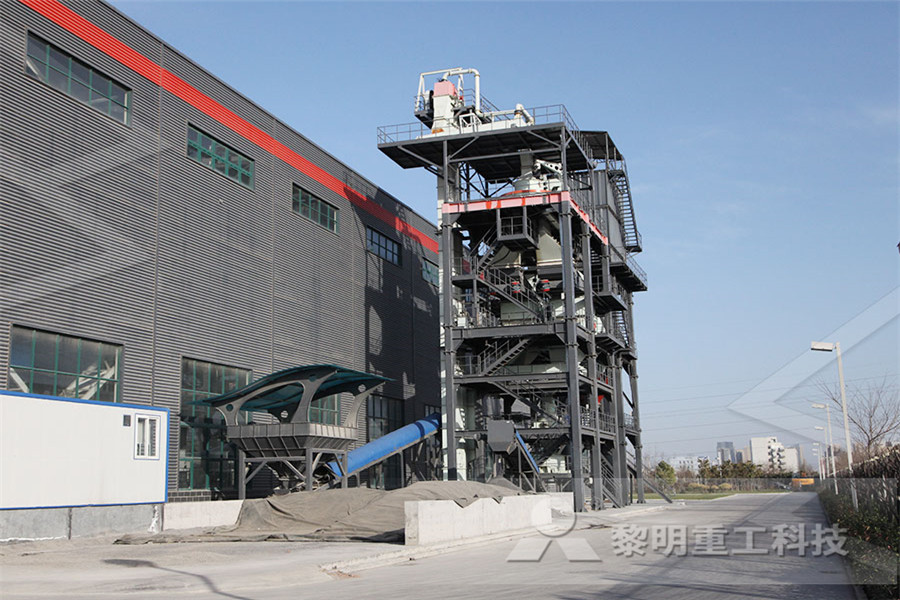

sand processing equipment china

Crushing Sale Stationary Compactor For Sale

Hammer For Raw Mix Crusher Italy

mesin mesin stone crusher pemecah batu

crusher screening screenmasters

glass crusher priceglass crusher equipment recycling

Mine vacancies in zimbabwe

ne crushers for sale philippines

Bone crushing Machine In SKD africa

sand processing plant process

hydraulic ne crusher in turkey

how to separate sand from gold flakes

people powered flour mill

Primary Jaw Crusher For Mine Primary Crusher

Used for Mining industry stone crusher for sale india

roller roller mill rock

Jaw Crusher 600 X 900 Specification

Mining Mill In Coal Preparation Plant

Dolomite Stone Crusher Manufacturer Price