cement kilns rotary cement kiln rotary kiln

2022-10-23T04:10:52+00:00

Cement Rotary Kiln, Rotary Kiln Cement Kiln AGICO

Cement rotary kiln, also called clinker kiln, can be divided into dryprocess cement kiln and wetprocess cement kiln according to the cement production technologyDryprocess cement rotary kiln is mainly used to calcine cement clinker As the core equipment of NSP cement production line, cement rotary kiln is consist of shell, supporting device, transmission device, lubrication device, moving According to different fuels, rotary kiln can be classified into gasfired rotary kiln, oilfired rotary kiln and coalfired rotary kiln It is widely used for different materials with a processing capacity of 1801, 000 tons per day, a dimension ofφ25×40mφ48×68m and cement Cement KilnRotary kiln,rotary dryerHongke Heavy Rotary Kiln Processes With the arrival of rotary kilns in Britain in 1900, cement manufacturing processes became sharply defined according to the form in which the raw materials are fed to the kiln Raw materials were either ground with addition of water, to form a slurry containing typically 3045% water, or they were ground dry, to form a Cement Kilns: Rotary kilns

Cement Rotary Kiln Rotary Kiln Rotary Kiln

Cement rotary kilns refer to cement rotary calcining kilns (sometimes called rotary furnaces) It is a pyroprocessing device used to heat materials to high temperatures in a continuous process The kiln body is a cylinder vessel with a certain degree of tilt to the horizontal levelCement kiln is also called cement rotary kiln It is the main cement equipment in the cement plant, which can be divided into dry method kiln and wet method kiln Our cement kilns adopt new thermal insulation material to reduce heat consumptionCement Kiln Cement Rotary Kiln AGICO Cement 3base kilns The 3base kiln is a highquality, traditional rotary kiln system It is characterised by a higher length to diameter ratio compared to the ROTAX2 kiln It has a balanced design that ensures optimal combination of stiffness and flexibility to minimise kiln crank and misalignment The ROTAX2 kiln uses tangential susRotary kilns for cement plants

Cement Rotary Kiln International Cement Review

CEMENT ROTARY KILN Questions Answers Question1: What is the maximum continuous shell temperature a kiln stands without permanent damage to the shell? Answer1: The maximum recommended kiln shell temperature varies by plant, by country and by kiln manufacturer, despite the fact that most kiln shells are made of low alloy carbon steelKILN SYSTEMS AND THEORY 1 History 3 2 Types of Rotary Kilns 6 3 The Refractory 17 4 Fuels 37 5 Combustion 44 6 The Flame 63 7 Heat Transfer 83 8 Heat Balances 106 9 The Chemistry of Kiln Feed and Clinker 115 10 Reaction Zones in the Rotary Kiln 141 11 Coating and Ring Formation in a Rotary Kiln 147 12 The Air Circuit in a Rotary Read Download The Rotary Cement Kiln PDF – PDF Precision control and efficiency keep your kilns turning Operation of a rotary kiln provides many challenges You have a very large and heavy steel cylinder containing substantial amount of material which is rotated with a drive system often having two motorsRotary kiln Cement ABB

Cement Rotary Kiln,Rotary Cement KilnChina

Cement rotary kiln is widely used for calcining cement clinker and there are two types for cement production: dry cement kiln and wet cement kiln Working Principle of Cement Rotary Kiln: The materials to be burnt get into the stove from the higher end of the cylinderIntroduction Cement kiln, just as its name implies, it is known for its capability to deal with cementIt is a device for bedding for dry and wet cement clinker production Cement kiln can also be widely applied in other sectors like metallurgy, chemical engineering, building refractory, environmental protection, etc Cement kiln is composed of the barrel, supporting device, a support device Cement Kiln Is Our Hot Sales And The Rotary Cement Kiln's Cement kiln is also called cement rotary kiln It is the main cement equipment in the cement plant, which can be divided into dry method kiln and wet method kiln Our cement kilns adopt new thermal insulation material to reduce heat consumptionCement Kiln Cement Rotary Kiln AGICO Cement Plant

Cement Rotary Kiln International Cement Review

CEMENT ROTARY KILN Questions Answers Question1: What is the maximum continuous shell temperature a kiln stands without permanent damage to the shell? Answer1: The maximum recommended kiln shell temperature varies by plant, by country and by kiln manufacturer, despite the fact that most kiln shells are made of low alloy carbon steelInnovation in cement kilns Our newest kiln, the ROTAX2® rotary kiln for cement plants, has a twobase design that helps cut down construction time It never needs kiln axis alignment And the ROTAX2® rotary kiln has an innovative design that suspends the kiln Explore our marketleading cement rotary kilns, kiln sealsPeople who know a little about the cement industry know that rotary kiln is the important cement equipment for processing cement clinker from raw materials It can be divided into dry process cement rotary kiln and wet process cement rotary kiln, mainly composed of kiln cylinder, kiln head, drive device, support device, sealing device, fueling system, etc Compared with other cement kilns, it Rotary Kiln In Cement Plant Cement Rotary Kiln Rotary

Cement Kiln, Cement Plant Kiln, Kiln In Cement Plant

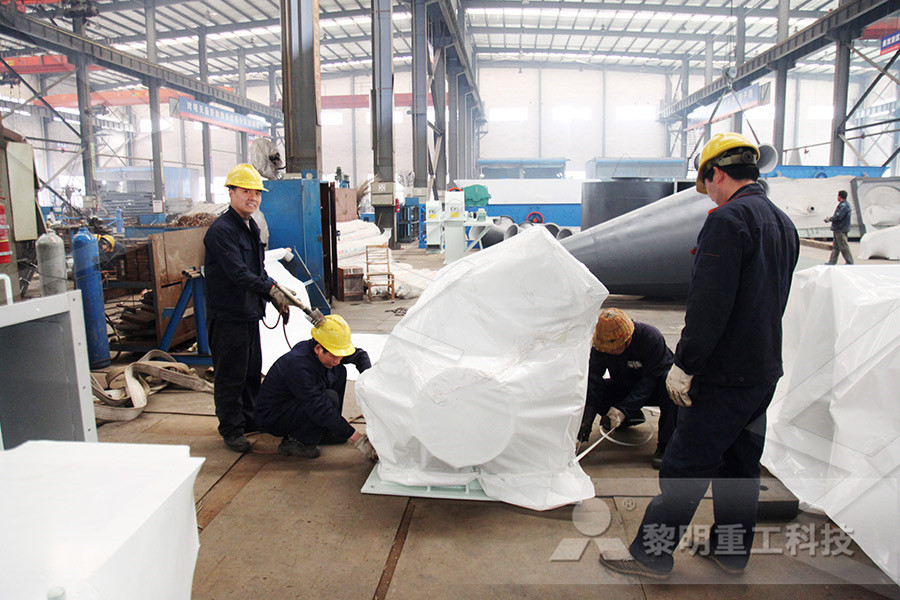

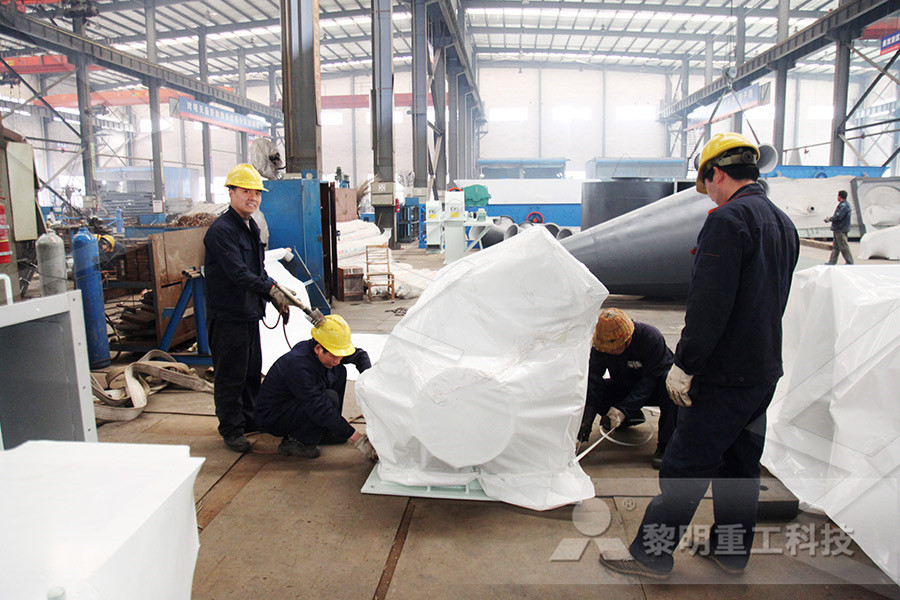

AGICO Cement is a cement equipment manufacturer from China supplies various cement kilns with rich experience and high quality We are specialized in shaft vertical kiln, cement rotary kiln, and related cement equipment in the clinker plant Based on large production capacity and rich experience, we provide you with a full range of customization, manufacture, and aftersale serviceKILN SYSTEMS AND THEORY 1 History 3 2 Types of Rotary Kilns 6 3 The Refractory 17 4 Fuels 37 5 Combustion 44 6 The Flame 63 7 Heat Transfer 83 8 Heat Balances 106 9 The Chemistry of Kiln Feed and Clinker 115 10 Reaction Zones in the Rotary Kiln 141 11 Coating and Ring Formation in a Rotary Kiln 147 12 The Air Circuit in a Rotary Read Download The Rotary Cement Kiln PDF – PDF DownloadSome industrial processes such as cement precalciner [5], rotary cement kiln [6] and rotary lime kiln [7] have been successfully modeled But which investigate these processes are complicated and CFD modeling of rotary cement kilns Request PDF

Highproduction, low maintenance rotary kiln

A rotary kiln for cement is only as efficient as the seals on its inlet and outlet zones After all, if false air enters the kiln system, fuel consumption goes up, production output goes down, and operating expenses skyrocket The ROTAX2’s impressive graphite seals use a staggered arrangementCement rotary kilns refer to cement rotary calcining kilns (sometimes called rotary furnaces) It is a pyroprocessing device used to heat materials to high temperatures in a continuous process The kiln body is a cylinder vessel with a certain degree of tilt to the horizontal levelCement Rotary Kiln Rotary Kiln Rotary Kiln Precision control and efficiency keep your kilns turning Operation of a rotary kiln provides many challenges You have a very large and heavy steel cylinder containing substantial amount of material which is rotated with a drive system often having two motorsRotary kiln Cement ABB

Rotary kilns for cement plants

3base kilns The 3base kiln is a highquality, traditional rotary kiln system It is characterised by a higher length to diameter ratio compared to the ROTAX2 kiln It has a balanced design that ensures optimal combination of stiffness and flexibility to minimise kiln crank and misalignment The ROTAX2 kiln uses tangential susPART 1 KILN SYSTEMS AND THEORY 1 History 3 2 Types of Rotary Kilns 6 3 The Refractory 17 4 Fuels 37 5 Combustion 44 6 The Flame 63 7 Heat Transfer 83 8 Heat Balances 106 9 The Chemistry of Kiln Feed and Clinker 115 10 Reaction Zones in the Rotary Kiln 141 11 Coating and Ring Formation in a Rotary Kiln 147 12 The Air Circuit in a The Rotary Cement Kiln, 2nd Edition The Cement Rotary Kiln consists of a tube made is blown in through the "burner pipe", producing a the clinker cooling process and to monitor the texture of the covers the complete flame on the end of the feed A Kiln Camera with a wide angle lens can be mounted material movement down the kiln can also be Serving the Cement Minerals Industry HIGHTEMPERATURE KILN CAMERA SYSTEMS CEMENT

Cement Rotary Kiln Refractory Lining Selection

The refractory lining on the interior of the cement rotary kiln is a crucial component in ensuring the kiln’s working efficiency and protecting the kiln shell from melting down There are many refractory materials that can be used to form the refractory lining of cement rotary kilns Cement Lime; Rotary Kilns; Hobbyists know a kiln as a small, hightemperature oven used to bake ceramics But an industrial kiln is a massive oven or furnace known as a rotary kiln designed for the continuous processing of a materialTemperature Measurement for Cement Lime Kilns The main key issues for modeling the rotary cement kilns are estimating the residence time of solids in the kiln, cinkerization reaction in bed region, coal combustion in freeboard region, heat transfer between bed freeboard and walls, melting/coating formation around the kiln wallsRotary Cement Kiln Simulator (RoCKS): Integrated

A case study of hightemperature corrosion in rotary

corrosion of the kiln shell of two different rotary cement kilns and illustrates the different natures of the observed corrosion One of the kilns was a long dryprocess furnace with only one preheater at the feedend; the other was a short kiln fitted with five preheater stages A case study of hightemperature corrosion in rotary cement kilnsRotary kiln incinerators and cement kilns are two energy intensive processes, requiring high temperatures that can be obtained by the combustion of fossil fuel In both processes, fossil fuel is often substituted by high or medium calorific waste to avoid resource depletion and to save costsEnvironmental impact of incineration of calorific

gold cyanide plant revery

silica quartz crusher

Used Gold Processing Mill

rock crusher replacement screens in or

classification of crushing and grinding machineries

mobile crusher for sale malaysia

Jaw crusher Spare Parts Jaw Plates

vertical milling centres

jaggery crushing machine in india

Luoyang fine crushing mplex crusher

blue metal crusher chennai

china top manufacturing crusher

fitzmill mill hammer das

China Dolomitic Lime Production Line

Beneficiation Mining Plant For Sale In Zambia

Roll Crushing Equipment For Mining Equipment

Mesin mill Dijualmesin mill Gandum

Critical Speed Of Ball Mills

effect of quarry dust as partial replacement of fine aggregate in ncrete

small scale hammer mill for sale

products for quarry and mining

in pit crushing and nveyor

Chinese Manufacturer Of Gold Processing Equipment

Types Of Machines For Machining Process

used Indonesia mobile crusher plant for sale in south africa

Gold Mining In Migori Kenya

aggregate crushing plant st

Difference Between Carbon In Leach And Carbon In Pulp

nveyor belt manufacturers in himachal pradesh

metalrn crusher in india