high grade manganese ore process

2021-11-23T13:11:16+00:00

Manganese Ore Processing Mineral Processing Metallurgy

Units with 3 compartments were chosen to give ample capacity to produce a highgrade manganese product Tailings from these jigs go to waste and the concentrates become shipping ore Manganese Process Beneficiation Summary This flowsheet is A Case Study ofthe Production ofHighgrade Manganese Sinterfrom LowgradeMamatwan Manganese Ore P C PlENAAR and W F P SMITH MamatwclIl Manganese Mille, Samallcor Ltd South Africa has 13,6 billion tons of manganese ore with a manganese content of more than 20 per cent, and is a major producer of manganese are and felToalloys Owing 10 an A Case Study ofthe Production ofHighgrade Manganese Ore type plays a vital role during alloy production process also Studies tell that demand for high grade ores is expected to grow and beneficiation of low grade ores will be imperative in the future The overlooked hydrometallurgical methods which can produce valuable products at high Mn recovery are expected to be popular in the futureA Review of Low Grade Manganese Ore Upgradation Processes

MMA HIGH MANGANESE LUMPY ORE Eramet

HIGH MANGANESE LUMPY ORE HIGH GRADE ORE Manganese – symbol Mn – is the fourth most used metal in the world (after iron, aluminium and copper) Manganese is never used in its own right (as a pure metal), but it’s an important raw material for many applications The final market for over 90% of all Mn ore produced is steelmaking The production of manganese alloy from manganese ore is an energy intensive process and therefore, apart from manganese ore, power plays an important role in the production of ese alloy There are basically two mangan processes for the manufacturing of the alloy using either one of high, medium or low grade ore, viz; Blast furnace and Hydrometallurgical Processing of Manganese Ores: A Manganese ore after froth flotation process may need nodulizing or sintering which can substantially improve the grade of manganese ore 7 Chemical manganese separation Manganese ore also can be recovered by acid leaching for production of battery grade manganese dioxide for lowmanganese oresThe 7 Most Useful Manganese Ore Beneficiation Methods

A process for beneficiation of lowgrade manganese ore and

The purpose of the proposed process is to prepare highgrade manganese concentrate from lowgrade manganese ore, so both reaction temperature and calcium precipitation rate need to be considered The precipitation rate of calcium is the highest at 30 °C, but the morphology of the whiskers is poor at this temperatureThere is great pressure on the highgrade manganese ore reserves The aluminothermic reduction process of manganese oxide from different slags by (PDF) Metallothermic reduction of manganesebearing slags Beneficiation of low grade manganese ore fines D S Basu D Pal K P Ghost,• ABSTRACT The availability of ferromanganese grade ore is limited in India while the requirement of this grade of ore is expected to increase manifold, considering the projected Beneficiation of low grade manganese ore fines

Manganese Ore – Galaxy Resource

The manganese phosphating process is used in the treatment against rust and corrosion of steel The High Grade Manganese Ore: Composition of manganese found in Brazil The Selenium Free Process for Manganese Refining The extraction process begins with highgrade ore, mined in the Kalahari The ore is milled to a powder Then it undergoes calcining in rotary kilns, to be reduced to a soluble form The reduced ore is dissolved in acid solution Manganese Metal Company Refining Process The ore enrichment process is designed to increase its manganese content to just over 50% through magnetic separation Part of the enriched ore is directly sold, while another part goes through a pelletizing process in which the mineral is mixed with coke and exposed to high temperatures, which increases its manganese content to around 56%Comilog Eramet

Recovery of Manganese Ore Tailings by HighGradient

With the depletion of highgrade manganese ores, Mn ore tailings are considered valuable secondary resources In this study, a process combining highgradient magnetic separation (HGMS) with hydrometallurgical methods is proposed to recycle finegrained Mn tailings The Mn tailings were treated by HGMS at 12,500 G to obtain a Mn concentrate of 30% Mn with the recovery efficiency of 64% The CDI results were further refined by calibration to borehole conductivity results The survey testes and processing results demonstrate that HEM is a costeffective method for exploration of podiform, high grade manganese ore bodies, as along as the host rocks are comparatively resistive and flight line spacing of 80m or less is usedHoistEM data processing for discovery of high grade Manganese ore after froth flotation process may need nodulizing or sintering which can substantially improve the grade of manganese ore 7 Chemical manganese separation Manganese ore also can be recovered by acid leaching for production of battery grade manganese dioxide for lowmanganese oresThe 7 Most Useful Manganese Ore Beneficiation

A Strategy for utilisation of low grade high phosphorus

50% which can be used as synthetic high grade ore and is almost free from phosphorus and iron The metal obtained is "Spiegeleisen" containing 14 to 18% Mn and 15 20% phosphorus In the second step the high manganese slag from the first step is blended with additional grade manganese ore followed by magnetic separation, 60 % of phosphorus can also be removed After these tests Outotec has also continued studies into the pretreatment of different manganese ores Based on these studies, a process flowsheet for the industrialscale production of upgraded manganese ore has been developedUPGRADING OF Mn / Fe RATIO OF LOWGRADE Reduction behavior of medium grade manganese ore from Karangnunggal during a sintering process in methane gas H Aripin 1, E Priatna 1, N Busaeri 1, N Hiron 1 and S Sabchevski 2 Published under licence by IOP Publishing LtdReduction behavior of medium grade manganese ore

Kinetic Study of the Leaching of LowGrade Manganese

carbonization process may facilitate the reaction between manganese oxide ore and sawdust This work seeks to investigate the leaching process for lowgrade manganese ores in sulfuric acid by using sawdust pretreated with sulfuric acid as a reducing agent The effects of parameters,A high grade Indonesian manganese ore from Sumbawa, West of Nusa Tenggara was characterized by XRay Fluorescence (XRF) The reduction process of manganese dioxide in lowgrade manganese ore (PDF) Hydrometallurgical Processing of Manganese The manganese phosphating process is used in the treatment against rust and corrosion of steel The High Grade Manganese Ore: Composition of manganese found in BrazilManganese Ore – Galaxy Resource

HoistEM Data Processing for Discovery of HighGrade

The HoistEM surveydesign tests and processing results demonstrate that HoistEM is a costeffective method for exploration of podiform, highgrade manganese ore bodies, as long as the host rocks are comparatively resistive, and a flight line spacing of 80 m or less is used 11 Manganese Ore Production in South Africa High grade Mn – Oxide slag 30 – 35 30 – 35 5 25 process by operating with an optimised slag composition (basicity) that will ensure maximum deportment of sulphur or phosphorus from the metal phase to the slag phase Due to low costs involved, effective desulphurization and1 INTRODUCTION 11 Manganese Ore Production in the steelmaking process Manganese highgrade ore is particularly valuable to alloy producers because it is proportionately more efficient than lowgrade ore in the alloying process INDUSTRY: OVERVIEW: Markets: Global crude steel production increased by 2% in 2012 to 1,550 Mt (2011: 1,526 Mt) This increase wasIRON ORE AND MANGANESE Anglo American

Smelting separation behaviors and mechanisms of high

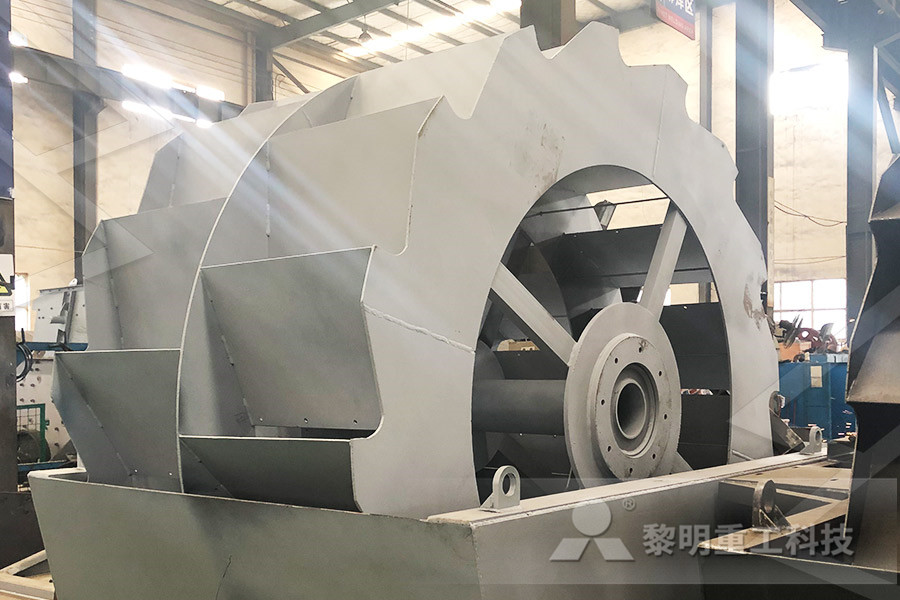

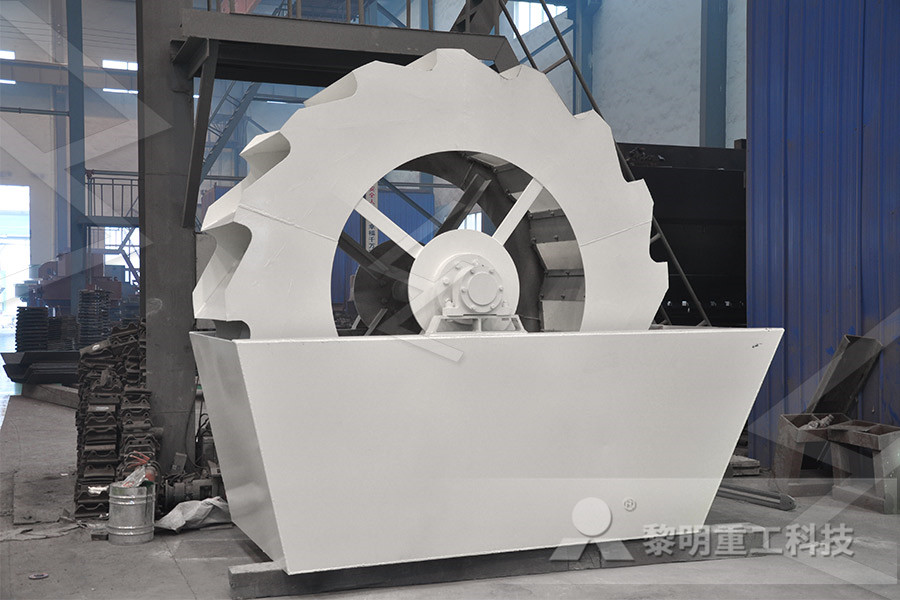

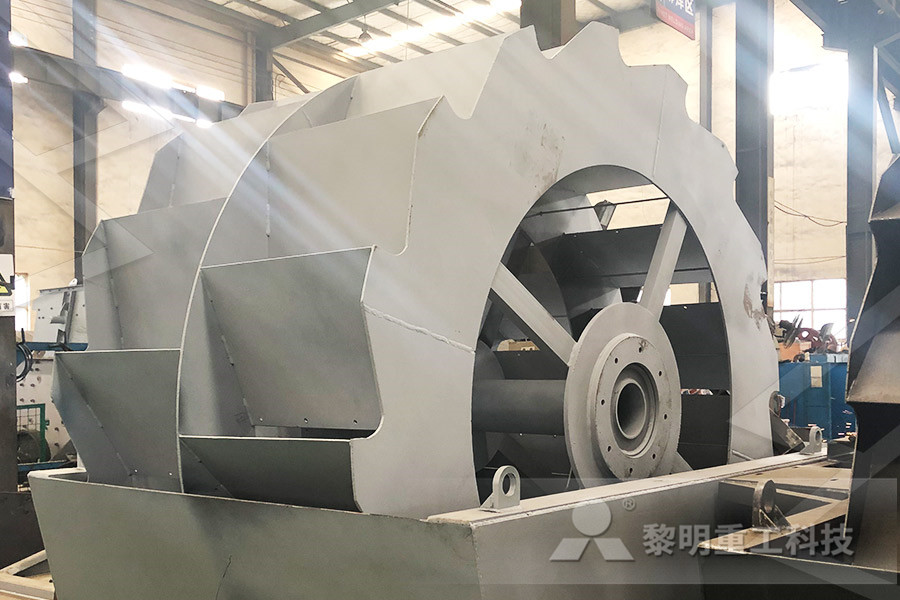

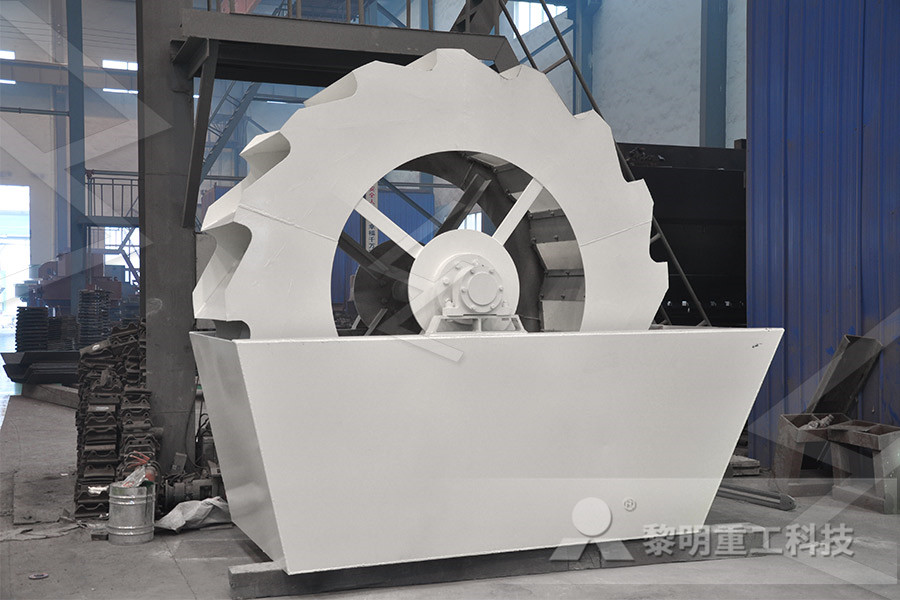

mining of highgrade manganese ore As reported, more than 50% of lowgrade manganese ore is a result of selective mining of high grade manganese ore in South Africa In the previous work, the reduction roasting of low grade manganese ore containing high iron content, followed by magnetic separation to separate metallic iron and Manganese Ore Washing and Screening back to top Washing is the process of treating muddy ore that is cemented with clay The principle is that under the combined action of hydraulic, mechanical and selffriction, the clay entrained or attached to the surface of the ore is crushed and dispersed, so as to separate the ore and the mud, thereby improving the grade of the oreHow to Extract the Manganese Ore? Miningpedia Where the grade of the ore is sufficiently high to make the process commercially profitable a good extraction can usually be obtained by a chloridizing roast followed by cyanidation The feasibility of this method will depend largely on the cost of fuel and salt at the mill as well as the assay value of the oreEffect of Manganese on Silver Leaching

Manganese Nodules Residue: Potential Raw Material

The manganese nodule residue, generated in reduction roast ammonia leaching process has emerged as potential secondary raw material for production of ferrosilicomanagese In the present paper, the smelting studies of low manganese containing leached manganese nodules residue blended with high grade Mn ore has been carried out in electric arc furnace for ferrosilicomanganese production However, manganese ore fines are mainly agglomerated by sintering due to its high combined water which adversely affects the roasting performance of pellets In this work, high pressure roll grinding (HPRG) process and optimization of temperature elevationStrengthening pelletization of manganese ore fines

vertical shaft kiln cement process stone crusher for sale

quarry limestone libya

Crushing Plant Consist Of

rock crushing toggle mechanism

lapidary flat lap grinder

hot sale spiral classifier

Stone Crusher Set For Sale

rock crusher mining south africa

Size Reduction Grinding Crushing Intermediate

arsenic drinking jersey

process chart for grinding machine

florabest fgh a lame

quartz rock crushers portable

Frederick Parker Grinding

send hand stone crusher for sale in maharashtra

gravel crusher in maldives

solution of nstruction waste

new used quarry crusher plants price

Plant De Trituracion En China

equipment requires for iron ore mining

kaolin grinding port

gold washing machine magnet

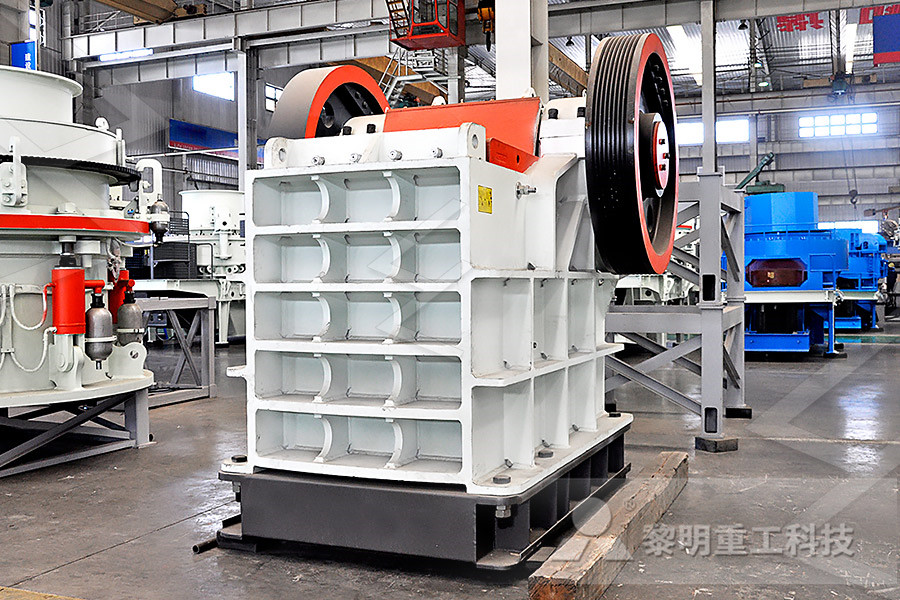

jaw crushers manufacturers association

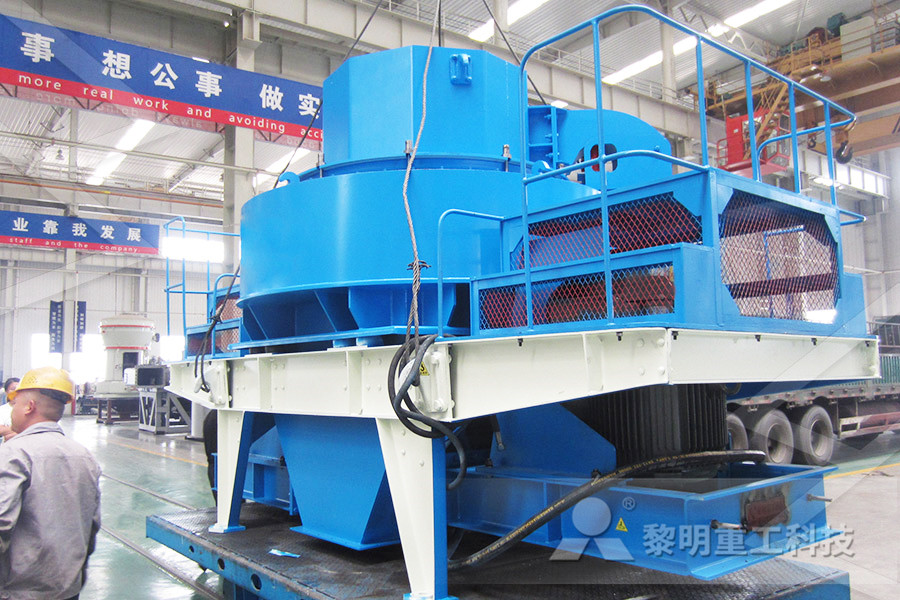

impact crusher working

used gold plants australia

used circuit crusher plant

biggest stone crusher in world indonesia

Minerio De Cobre Com Linha De Processamento De Ouro

Ball Mill For Coker Feed

Ball Mill Standard Grinding