Silica Sand Washing Purification

2018-09-13T19:09:21+00:00

Process for purifying silica sand Materias Primas

A process of purifying silica sand comprises grinding sandstone, washing and desliming the ground sandstone to remove the major part of the claytype binder, attritionscrubbing the deslimed sand particles to release further amounts of binder therefrom, washing and desliming to remove said binder, drying and heating the sand particles, treating the hot sand with sulfuric acid to convert the iron Applying color sorter to quartz sand purification in sand washing plant In the raw quartz sand, the pure quartz sand is white or milky white, and the color of iron bearing impurities or gangue minerals is yellowish, light yellow or light brown and gray The color difference between quartz sand and iron bearing impurities or gangue minerals is Applying color sorter to silica sand purificationSinonine Now we summarize the following common quartz sand purification methods 1Washing, grading and desliming of quartz sand The grade of SiO2 in quartz decreases with the decrease of quartz particle size, while the content of impurity minerals such as iron and aluminum will increaseHow to purify quartz sand?Sinonine Silica sand

silica sand purification process

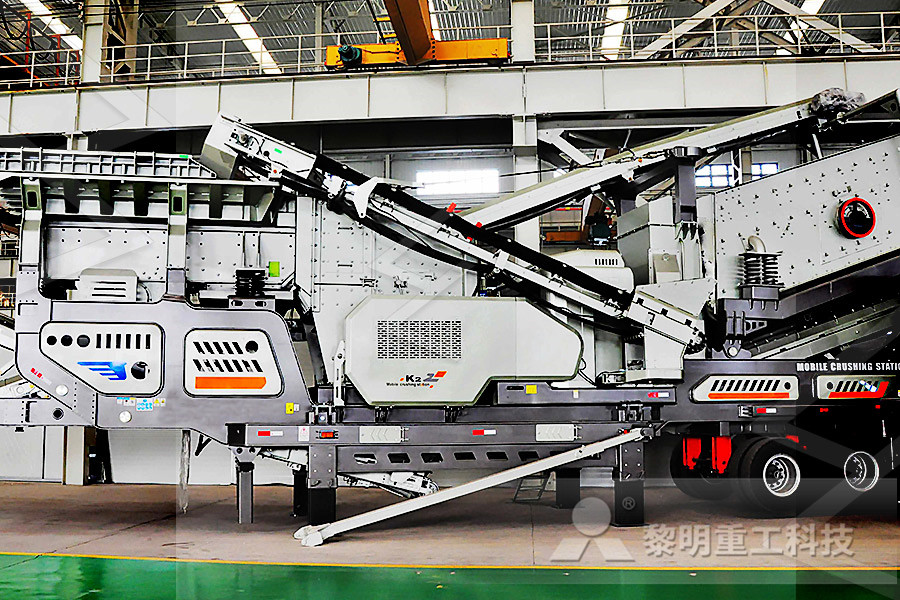

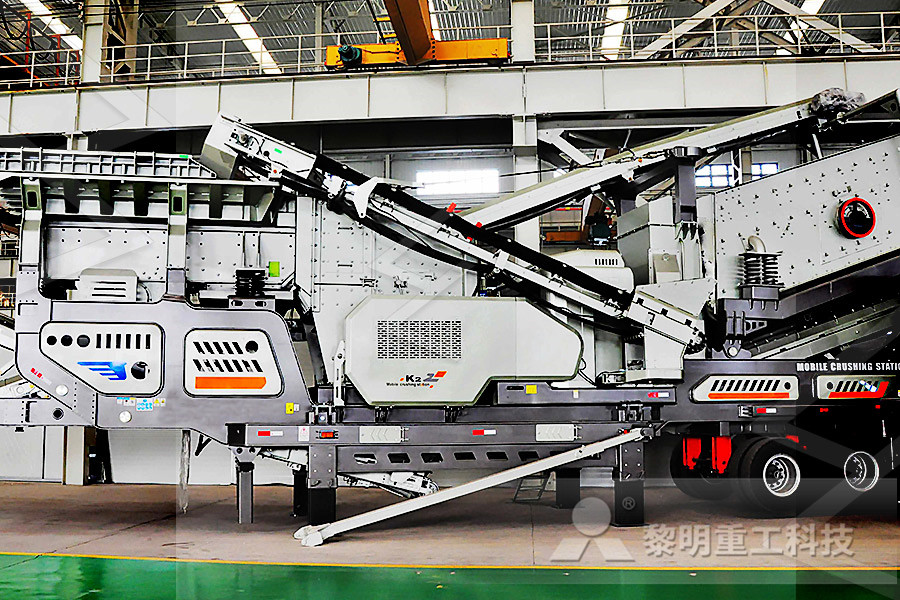

Silica and Moulding Sands Association (SAMSA) part of the , Four grades of silica sand are used for water filtration in the UK today, these are 6/14, 8/16, 14/25 and 16/30 The silica sand is usually laid on top of a supporting layer of gravel within the filter vessel The incoming water enters the filter and migrates through the silica sand, successfully removing any solids or debris from the A process of purifying silica sand comprises grinding sandstone, washing and desliming the ground sandstone to remove the major part of the claytype binder, attritionscrubbing the deslimed sand particles to release further amounts of binder therefrom, washing and desliming to remove said binder, drying and heating the sand particles, treating the hot sand with sulfuric acid to convert the iron USA Process for purifying silica sand High Purity Silica Sand Purification (The following operations are performed on the basis of coarse silica sand) Acid leaching → Deionized Washing → Dry → Packing Basic Flow of Coarse Silica Sand Production LineSilica Sand Processing Solutions MC

Purification of Tronoh Silica Sand via preliminary process

purification of the silica sand and to analyze its characteristics after the ball milling process The samples before and after milling process were analyzed by using XRF, XRD, SEM and TEM Silicon micro powder According to the tailings of some low iron sand washing plant, the electrical and electronic grade silicon micro powder can be prepared by the purification process of "magnetic separation scrubbing desliming flotation"Widely application of your silica sand tailingsSinonine The postpurification silica sorbents were easily regenerated by washing with acetone, isopropanol, and methanol Methanol seems to be the best solvent to regenerate the sorbent since it can be fed to the methanolysis reactor allowing the recycle of unreacted mono and diglyceridesDry washing biodiesel purification using fumed silica

Chlorination roasting purification process of quartz

Chlorination time of 2 h and chlorination temperature of 1000 ℃ are the best for the purification of Na, Fe, K and other impurities in quartz sand; High temperature chlorination process can reduce the content of Fe, Na and K impurities, but it has no good removal effect on AlSilica and Moulding Sands Association (SAMSA) part of the , Four grades of silica sand are used for water filtration in the UK today, these are 6/14, 8/16, 14/25 and 16/30 The silica sand is usually laid on top of a supporting layer of gravel within the filter vessel The incoming water enters the filter and migrates through the silica sand, successfully removing any solids or debris from the silica sand purification processA process of purifying silica sand comprises grinding sandstone, washing and desliming the ground sandstone to remove the major part of the claytype binder, attritionscrubbing the deslimed sand particles to release further amounts of binder therefrom, washing and desliming to remove said binder, drying and heating the sand particles, treating the hot sand with sulfuric acid to convert the USA Process for purifying silica sand

Quartz Sand(Silica Sand) Pressing Production Line

The purification technologies of Quartz Sand(Silica Sand) at home and abroad are washing, classifying desliming, scrubbing, magnetic separation, flotation, acid leaching, microbial leaching, etc 【Application】 Quartz Sand(Silica Sand) Dressing Production Line is suitable for Quartz Sand(Silica Sand) containing iron or mica Quartz sand purification process mainly includes water washing, grading desliming, scrubbing, magnetic separation, flotation, acid leaching, microbial leaching, etc The grade of SiO2 in quartz sand decreases with the grain size of quartz sand becoming smaller, Silica Sand Manufacturing Process LDHBThis research is on identification and purification of silica sand from Nyalo River It will be used as a raw material for synthesis of sodium silicate Silica sand was separated from clay by washing it with water, and then the existing alumina and iron oxide were removed by soaking the silica sand with 1 M HNO3 solution Qualitative and quantitative analysis of the silica sand with Identification and Purification of Nyalo River Silica

Sand filterThe role of sand filter in water purification

Types of silica bed in sand filter Silica bed is one of the most important and main parts in sand filters, which has a very high impact on the power of the device and the quality of the output water The silica substrates used in this device can be considered as single layer and multi layer The research on highpurity quartz sand silica purification method is an extremely important class of optoelectronic materials, which are widely used in semiconductors and optical fibers through hightech fields such as floodlight, laser and aerospace As these areas become more stringent in terms of high purity silica impurity content, the Quartz sand removal iron purification method News Our products cover the whole field of quartz/silica sand processing and purification, the main products are: Dry type quartz/silica sand production line, Wet type quartz/silica sand production line, Glass sand production line, High purity quartz production line, Silica sand powder production line, crushing screening equipment, magnetic Company Overview of China Manufacturer Nanjing

(PDF) Characterization of Silica Produced from Rice

The utilization of rice husk ash into silica as a semiconductor material in the monocrystalline solar cell has several advantages compared to the use of inorganic silica from quartz sand Silica USA USA USA USA US A US A US A US A US A US A US A US A US A US A US A US A Authority US United States Prior art keywords sand iron acid solution hydrochloric acid Prior art date Legal status (The legal status is an assumption and is not USA Purification of sand Google Patents Quartz sand purification process mainly includes water washing, grading desliming, scrubbing, magnetic separation, flotation, acid leaching, microbial leaching, etc The grade of SiO2 in quartz sand decreases with the grain size of quartz sand becoming smaller, Silica Sand Manufacturing Process LDHB

silica sand purification process

Silica and Moulding Sands Association (SAMSA) part of the , Four grades of silica sand are used for water filtration in the UK today, these are 6/14, 8/16, 14/25 and 16/30 The silica sand is usually laid on top of a supporting layer of gravel within the filter vessel The incoming water enters the filter and migrates through the silica sand, successfully removing any solids or debris from the This research is on identification and purification of silica sand from Nyalo River It will be used as a raw material for synthesis of sodium silicate Silica sand was separated from clay by washing it with water, and then the existing alumina and iron oxide were removed by soaking the silica sand with 1 M HNO3 solution Qualitative and quantitative analysis of the silica sand with Identification and Purification of Nyalo River Silica The silica sand washing process in Malaysia is generally determined by 3 points The first is the occurrence state of impurity minerals in the raw sand The second is the beneficiation cost of the purification process Finally the industrial use of refined sand productsThe Silica Sand Washing Process In Malaysia LZZG

Quartz Sand(Silica Sand) Pressing Production Line

The purification technologies of Quartz Sand(Silica Sand) at home and abroad are washing, classifying desliming, scrubbing, magnetic separation, flotation, acid leaching, microbial leaching, etc 【Application】 Quartz Sand(Silica Sand) Dressing Production Line is suitable for Quartz Sand(Silica Sand) containing iron or mica Quartz sand, also known as silica sand, is a common nonmetallic mineral material, and its application area is very extensive The mineral processing and purification of quartz sand in China and its deep processing and exploitation are relatively late, and are mainly used in the construction industry, glass manufacturing, ceramic industry and What Are The Key Points In Quartz Sand Purification Types of silica bed in sand filter Silica bed is one of the most important and main parts in sand filters, which has a very high impact on the power of the device and the quality of the output water The silica substrates used in this device can be considered as single layer and multi layerSand filterThe role of sand filter in water purification

Sand filter, quartz sand water filter, water prefilter

Sand filter Features The equipment structure is simple, and the backwashing operation is more convenient The size of the dirt interception layer is 0510mm, and the height is above 700mm There are 2 layers of supporting layers underneath, which are The research on highpurity quartz sand silica purification method is an extremely important class of optoelectronic materials, which are widely used in semiconductors and optical fibers through hightech fields such as floodlight, laser and aerospace As these areas become more stringent in terms of high purity silica impurity content, the Quartz sand removal iron purification method News The Bulgarian deposits of quartzkaolin raw materials are localized in the NE Bulgaria For a many years, the quartzkaolin sand separation has been performing by water washing technology(PDF) DEVELOPMENT OF QUARTZKAOLIN

Worldwide Jaw Crusher For Gold Ore Mining

primary blue metal crusher

manufacturer quartz and feldspar grinding and pulverizing machine

grinding machine manufacturers in europe

ball mill for sale greenland

roller mill mddk and mddl

fluorite vsi crusher supplier

quarry quartz quarry quartz manufacturers for sale

ball mills temperature

Limestone Quarry Spectacular Sunken Garden

rack mount equipment case

crusher stone equipments Indonesia

What Is The Difference Between Roller Press And A Ball Mill

crusher wear repuestos

mm limestone crusher plant

hydraulic grinding machine circuit diagram

jurnal tentang mesin hammer mill

equipment requirement for sand quarry

Gold Wash Plant Dewatering

gold mining rocker box

vibrating sieve of a drilling

Used Grinder Mill Suppliers And Used Grinder Mill

brick grinding production line

Lime Stone Crusher Specifiions

mineral grinding circuit

procedure to start robo sand plant

Quarry Plant Information In Nigeria

in canada 2c mining crushing mills

Mesin Ball Mill Grinding

draw draw and explain jaw crusher