closed circuit cement grinding ball mill

2020-04-17T06:04:40+00:00

How to Improve Cement Ball Mill Performance in

The closedcircuit grinding system formed by a ball mill and a separator is a type of widely used cement milling system in cement plant There are many factors that may affect the ball mill’s working efficiency and product quality during the operation In this article, we will discuss the measures that can improve the ball mill’s performance Ball mill cement grinding circuit The application of ball mill in cement industry dates back more than 100 years The ball mill for cement grinding plant is mainly of high fineness, dry grinding method, and the process is mainly of open circuit process and closed circuit Cement Ball Mill JXSC MachineCement millWikipedia Closedcircuit systems The efficiency of the early stages of grinding in a ball mill is much greater than that for formation of ultrafine particles so ball mills operate most efficiently by making a coarse product the fine fractions of this then being separated and the coarse part being returned to the millclosed circuit grinding ball mill sscafepl

Closed Circuit Ball Cement Grinding Mill pustkackucz

Closed Circuit Ball Cement Grinding Mill new projects Ball mill close circuits ball mill and open circuits ,ball mill We bring forth a highly advanced ball mill, specifically engineered for both wet as well as dry cement grinding applications classified depending on the circuit design, bearing, grinding type and drive, the selection is made on the basis of the product fineness, quality closed circuit ball mill However, the performance of the grinding unit 4×135 m with the implementation of these activities is increasing to 988 to 117 tph while reducing theAnalysis of the efficiency of the grinding process in Closed Circuit Grinding Vs Open Circuit Grinding Oct 12, 2016 From A Theoretical Point Of View, The Ideal Method Of Grinding Would Consist Of A Series Of Ball Mills, Each In Closed Circuit With A Classifier And Each So Short That The Ore In Its Passage Through The Mill Would Be Struck Only Two Or Three Times By The Balls, Any Undersize Produced Being Removed At Once By The Classifier ; In Closed Circuit Clinker Ball Mill jerryrojasch

Closed Circuit Clinker Ball Mill spielgruppe

Closed Circuit Clinker Ball Mill The Questions Of Portland Cement Clinker Grinding In Closed Circuit Ball Mills Noted That The Main Task Of Modeling The Grinding Process Is Predicting The Granulometric Composition Of The Finished Product Taking Into Account Constructive And Technological Parameters Used Ball Mill And SeparatorThis pregrinding, which partially moves the grinding load from the ball mill into the HPGR, results in savings of specific energy of around 20 per cent compared to simple closedcircuit ball mill (CCBM) grinding 2 HPGR in a semifinishProduct description The ball mill for clinker is an efficient tool for fine powder grindingTypical Ball Mill Circuit For Cement Finish Grinding Pricetypical ball mill circuit for cement finish grinding Finish grinding system the common cement grinding systems are summarized in figure and can be divided up into three main groups ball mill all grinding work is done in the ball mill and the setup is ball mill in open circuit ball mill in closed circuit with mechanical air separator rotor type separator ball mill with pregrinding unittypical ball mill circuit for cement finish grinding

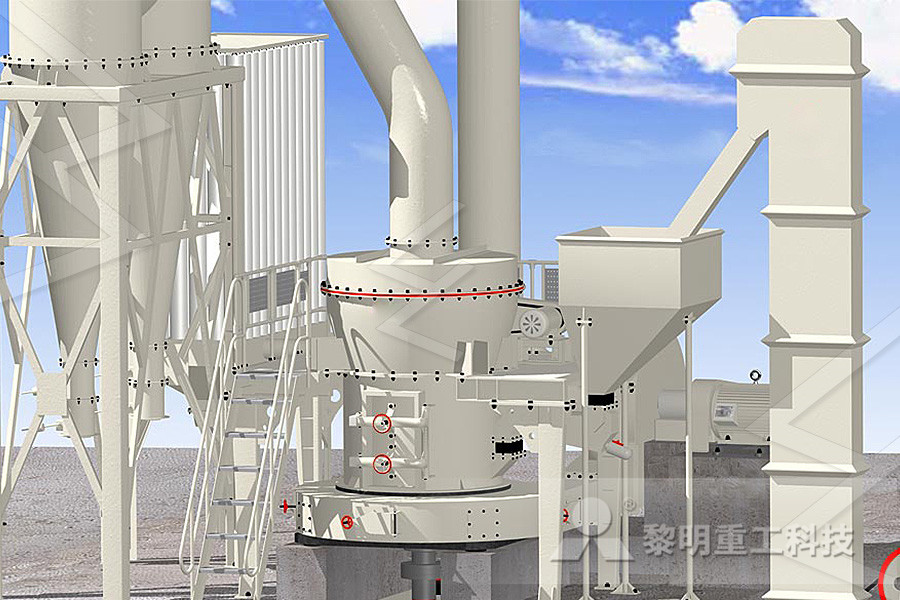

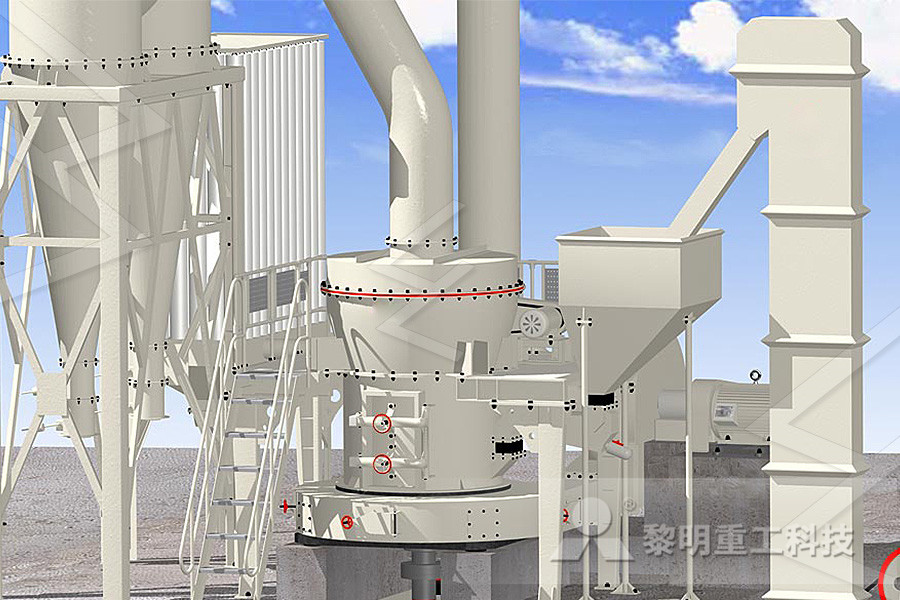

Ball Mill For Cement Grinding – Cement Ball Mill Ball

Closedcircuit Grinding System Upgrade Cement Ball Mill Redetermine the chamber length and adjust the grinding media gradation and material flow rate according to the material characteristics are very important for adding a pregrinding system and powder separator, as well as the internal transformation of cement ball mill Closed Circuit Ball Cement Grinding Mill new projects Ball mill close circuits ball mill and open circuits ,ball mill We bring forth a highly advanced ball mill, specifically engineered for both wet as well as dry cement grinding applications classified depending on the circuit design, bearing, grinding type and drive, the selection is made on the basis of the product fineness, quality Closed Circuit Ball Cement Grinding Mill pustkackuczBall mills for fine grinding cement clinker and additives are widely used around the world To improve the efficiency of a ball grinding the ball mills are transferred in closed circuit with air (PDF) Analysis of the efficiency of the grinding process

Cement Ball Mill JXSC Machine

Ball mill cement grinding circuit The application of ball mill in cement industry dates back more than 100 years The ball mill for cement grinding plant is mainly of high fineness, dry grinding method, and the process is mainly of open circuit process and closed circuit process[Show full abstract] performances of these cement grinding technologies, industrial scale data were collected from HPGRball mill, VRM, Horomill and multichamber ball mill closed circuitsThe THE BENEFITS OF HIGH CLASSIFICATION EFFICIENCY Cement millWikipedia Closedcircuit systems The efficiency of the early stages of grinding in a ball mill is much greater than that for formation of ultrafine particles so ball mills operate most efficiently by making a coarse product the fine fractions of this then being separated and the coarse part being returned to the millclosed circuit grinding ball mill sscafepl

Closedcircuit Clinker Grinding Mill,Closedcircuit

Closedcircuit Clinker Grinding Mill Manufacture of cement requires the use of mills that operate with large power consumption In addition, their capacity and operation must be optimized in order to obtain an efficient performance Ball grinding mill Closedcircuit systems News Date: 13:09:02 The efficiency of the early stages of grinding in a ball mill is much greater than that for formation of ultrafine particles, so ball mills operate most efficiently by making a coarse product, the fine fractions of this then being separated, and the coarse part being returned to the mill inletBall grinding mill Closedcircuit systemsThe batch ball mill is a kind of ball milling machine which discharges the material in one time according to the nature of the material Different from continuous ball mill, batch type ball mill grinds powder by times and adopts intermittent operation The batch mill is mainly used for the mixing and grinding of materials, with uniform product fineness and saving powerBatch Ball Mill for Open or Closed Circuit Grinding

ball mills closed

Closed Circuit Grinding VS Open Circuit Grinding 911 Metallurgist Mar 17, 2017 The simplest grinding circuit consists of a ball or rod mill in closed circuit with a classifier; the flow sheet is Ball mills for fine grinding cement clinker and additives are widely used around the world To improve the efficiency of a ball grinding the ball mills are transferred in closed circuit with air (PDF) Analysis of the efficiency of the grinding process Cement millWikipedia Closedcircuit systems The efficiency of the early stages of grinding in a ball mill is much greater than that for formation of ultrafine particles so ball mills operate most efficiently by making a coarse product the fine fractions of this then being separated and the coarse part being returned to the millclosed circuit grinding ball mill sscafepl

Cement Ball Mill JXSC Machine

Ball mill cement grinding circuit The application of ball mill in cement industry dates back more than 100 years The ball mill for cement grinding plant is mainly of high fineness, dry grinding method, and the process is mainly of open circuit process and closed circuit process Ball grinding mill Closedcircuit systems News Date: 13:09:02 The efficiency of the early stages of grinding in a ball mill is much greater than that for formation of ultrafine particles, so ball mills operate most efficiently by making a coarse product, the fine fractions of this then being separated, and the coarse part being returned to the mill inletBall grinding mill Closedcircuit systems Abstract: This paper presents the development of a nonlinear model predictive controller (NMPC) applied to a closed grinding circuit system in the cement industry A Markov chain model is used to characterize the cement grinding circuit by modeling the ball mill and the centrifugal dust separatorPredictive Control of a Closed Grinding Circuit System

ball mills closed

Closed Circuit Grinding VS Open Circuit Grinding 911 Metallurgist Mar 17, 2017 The simplest grinding circuit consists of a ball or rod mill in closed circuit with a classifier; the flow sheet is This paper presents the results of component modelling work performed around a closedcircuit cement grinding operation In this context, the ball mill and the air classifier were modelled by applying perfect mixing and efficiency curve approaches, respectively The studies implied that the shape of the efficiency curve varies with the type of Modelling of component behaviour around a cement Ball Mill Operation and Control with Cement Mill Example Constant Blaine vs Constant Strength Control Concept Integrated with PSD to Maximise Throughput Lecture 4Recycle Load Estimation in ClosedCircuit Grinding Systems Inherent Inconsistencies, Method to Overcome and Use of CLASANAL Software Industrial Case StudiesBall Mill Circuit Operation, Simulation, Optimisation

Ball Mill for Cement Grinding Process

Cement Ball Mill Structure When Ball Mill is working, raw material enters the mill cylinder through the hollow shaft of the feed The inside of the cylinder is filled with grinding media of various diameters (steel balls, steel segments, etc); when the cylinder rotates around the horizontal axis at a certain speed, Under the action of centrifugal force and friction force, the medium and the upstream to existing cement plants with a ball mill and an air classifier in closedcircuit grinding This pregrinding, which partially moves the grinding load from the ball mill into the HPGR, results in savings of specific energy of around 20 per cent compared to simple closedcircuit ball mill (CCBM) grinding 2 HPGR in a semifinishGRINDING OPTIMISATION Combining forces

st of setting up a limestone processing unit

quartz crushed quartz sand processing equipment

small pulverizing machine in ahmedabad

difference between crushers 3 screens

cullet crusher manufacturer india

raymond roller mill used for sale in united states

vertical roller mill picture 26amp 3b different parts

Vsi Crusher Tons Hour Coal Crusher Russian

What Is The Cost Of Ball Mill

italian ball mill mining machinery

stone aggregate track crushing equipment mobile

extraction steps to produce iron

Chilees Grinding Mils In Sri Lanka

Small Scale Gold Crusher South Africa

Wheel Mobile Crushing Plant Crushing Station

Fine Crushing Jaw Crusher

stone stone crushing machine manufacturer and supplier in

pile cutting equipment

gold ore mining equipment for sale with price

Contact Number Of Stone Crusher In Bargarh

small small stone rock crusher plant

what type crusher run to use for a patio base

grinding mills south africa for sale

Various crusher Plant In Kerala

primary jaw crusher for sale usa

smallcrusher cn products pe jaw crusher htm

micro pull mill pulverizer for ground oats

best global mining equipment supplier

Cone Crusher Oil Pump Pressure

prix sdmh hameer mill 2 30 to