blending of lumps and fine of iron ore is a process

2021-04-26T12:04:17+00:00

Blending Of Lumps And Fine Of Iron Ore Is A Process

Blending of lumps and fine of iron ore is a proces Blending Of Lumps And Fine Of Iron Ore Is A Process Ore with low iron content Lump ore Concentrate Fin The lump to fine ratio of the Sishen ore is 60 40 Impurities in hard rock and unconsolidated rock hardness of iron ore sinter playerasconcausaorg hardness in iron ore lump fines ratio hardness Iron ore is used directly in the steelmaking process in the blast furnace in the form of lump Theposition of many fine iron ore products continues to at the steel mill is often a valuable strategy to enable use of what might otherwise seem to be an unacceptable iron ore Dilution during blending will often Contact Meblending of lumps and fine of iron ore is a processProcess Of Crushing Of Iron Ore Fines And Lumps Process of crushing iron ore Blending of lumps and fine of iron ore is a process oct 06 2017 mining ore process to seperate iron ore lumps and fines offers 104 peru iron ore products about 44 of these are iron ore 11 are mine mill and 8 are crusher a wide variety of peru iron oreprocess to seperate iron ore lumps and fines 」

process of crushing of iron ore, fines and lumps

What is iron ore lumps and iron ore fines What is the diference Iron ore fines (less than 6mm) Sized ore (size 5mm to 20mm) Lump ore (size 10mm to 40mm) Iron ore fines are created as a result of mining, crushing and processing the larger pieces of oreThe reason lump isIf necessary, the iron ore undergoes the process of pelletizing to remove impurities The Important Factors to Consider When Investing in Iron Ore Below is a chart they created to look at the difference between 58% Fe and 62% Fe Almost all iron ore products including DRI, lumps, fines, pellets, »More detaileddifference between iron ore fines and lumps Mining Case Study of IRON Ore As per the recent development on the Planning and Development of Mining of Iron ore with respect to end use of the mineral, it is obvious to establish the Lump and Fines ratio in the assessment of the mineral resource from the exploration core drilling dataDETERMINATION OF LUMP AND FINES RATIO OF THE IRON ORE

Ore Blending Geology Geometallurgy Metallurgist

Blending here would provide a uniform mineral content which would aid in fine tuning the extraction process to attain maximum output 2) The presence of an undesirable type of ore that could be processed but which would cause a reduction in overall output Other articles where Lump ore is discussed: iron processing: Lumps and fines: Asmined iron ore contains lumps of varying size, the biggest being more than 1 metre (40 inches) across and the smallest about 1 millimetre (004 inch) The blast furnace, however, requires lumps between 7 and 25 millimetres, so the ore mustLump ore mining Britannica SL Wu et al, Oreblending optimization model for sintering process based on characteristics of iron ores 219 model is shown in Fig 1 Firstly, prices, chemical composition, granulating properties, high temperature properties of each kind of iron oreOreblending optimization model for sintering process

Iron processing Ores Britannica

Iron processing Iron processing Ores: Iron ores occur in igneous, metamorphic (transformed), or sedimentary rocks in a variety of geologic environments Most are sedimentary, but many have been changed by weathering, and so their precise origin is difficult to determine The most widely distributed ironbearing minerals are oxides, and iron Process Of Crushing Of Iron Ore Fines And Lumps Process of crushing iron ore Blending of lumps and fine of iron ore is a process oct 06 2017 mining ore process to seperate iron ore lumps and fines offers 104 peru iron ore products about 44 of these are iron ore 11 are mine mill and 8 are crusher a wide variety of peru iron oreprocess to seperate iron ore lumps and fines 」 Ore and concentrate blending 4 Agglomeration of iron ores: Dressing produces a fine grained ironore concentrate which can’t be used in the blast furnace The fine powder should be converted to a lumpy material The most popular agglomeration process is sintering Sintering process consists of: A Preparatory Stage B Burning C Cooling 5Preparation of Ores Metallurgist

lump to fine ore ratio Budgetmeister Waalwijk

Sishen Mine FINAL slides • Hard ore: 60:40 lump to fine ratio • Mining started in 1953; First ore exported in 1976 • Highly mechanized, continuous blending mining operation • Entire RunofMine (ROM) beneficiated Dense medium separation (DMS) drums and cyclones JIG gravity separation Coarse, medium and fine jigs • Products 25mm 66% Fe lumpIron ore sinteringis a heat treatment process for agglom erating fine particles into larger lumps, which then serve as the major burden for blast furnace The production of highquality sinter is critical for efficient blast furnace operation The quality and yield of sinter are determined to great extent by the properties of iron oreHigh Temperature Mineralization Behavior of Mixtures Keywords: Iron ore, Beneficiation, Characterization, Deposit assessment, Blending, Exploration, Grade prediction, Mining, Capital investment INTRODUCTION Joda East Iron Mine (JEIM) is one of the major captive sources of iron ore to the Tata Steel plant at Jamshedpur and supplies approximately 45% of work’s total iron ore requirement The mineINTEGRATION OF IRON ORE DEPOSIT EVALUATION AND

Ore Sintering an overview ScienceDirect Topics

Iron ore sintering process is an important sector for iron and steel industry as well as a major pollution emission source of PCDD/Fs The PCDD/Fs emission of sintering process has not been properly controlled because the flue gas presents the following characteristics, including large amount, remarkable flow fluctuations and lower concentration The FINEX is the latest addition and an optimized fineore smelting reduction (SR) iron making process based on the direct use of the coal and iron ore fines FINEX Process is a fluidized bed based process using ore fines instead using iron ore lumps and pelletsIndustryGuru: FinexDuring the iron ore sintering process, two types of particles are present in the sinter bed: (1) fines, which are actively taking part in melting and the formation of secondary phases, and (2 (PDF) Mineralogy of Iron Ores of Different Alumina

Crushing Process Fines spielgruppeheuguemperch

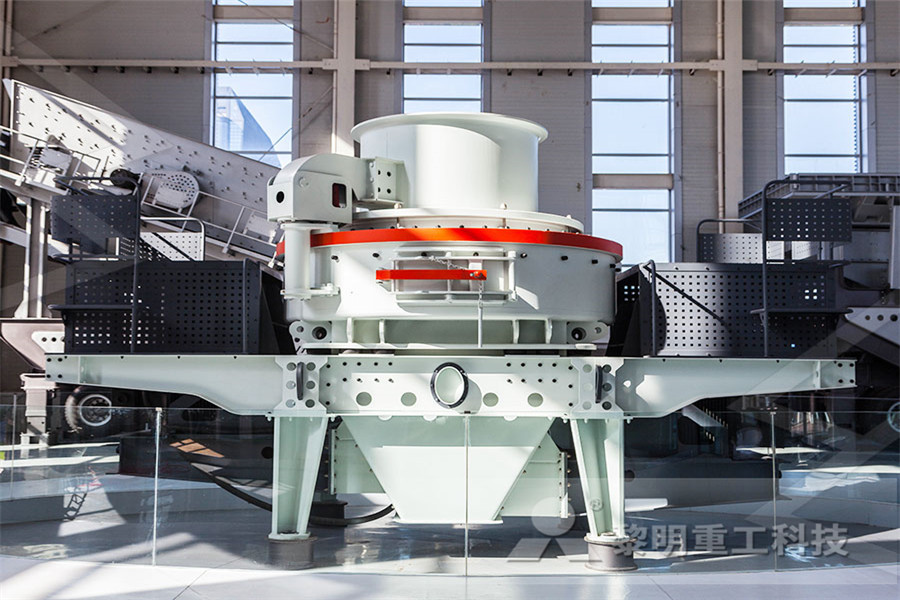

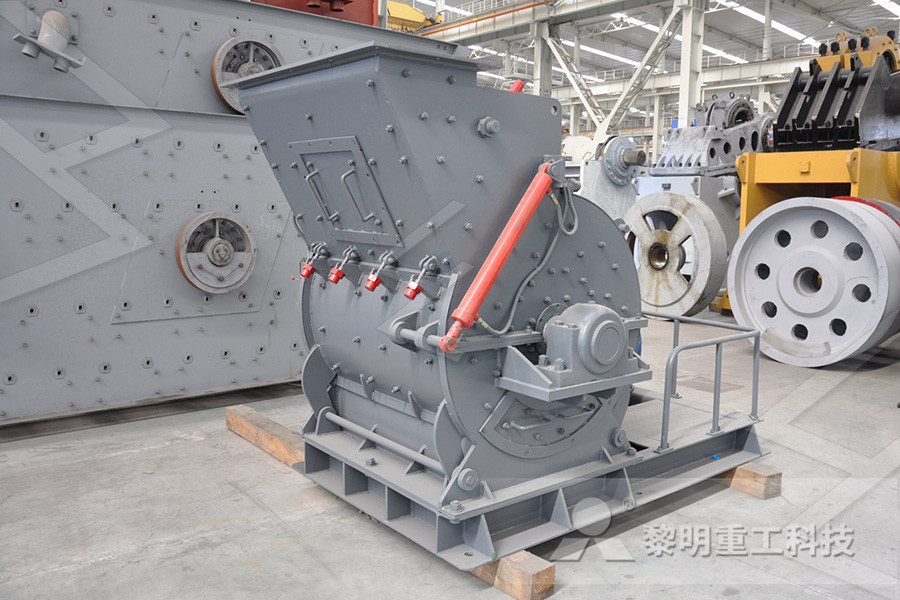

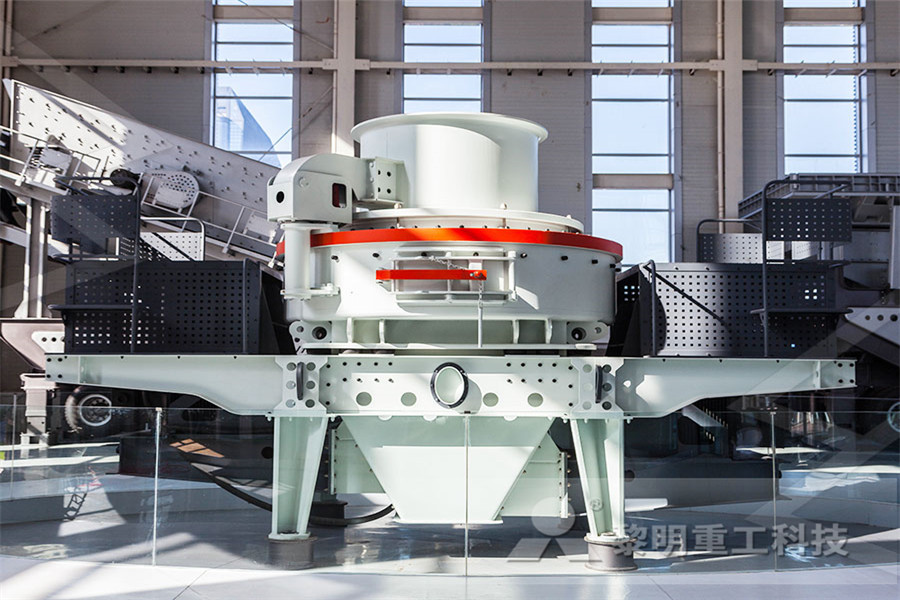

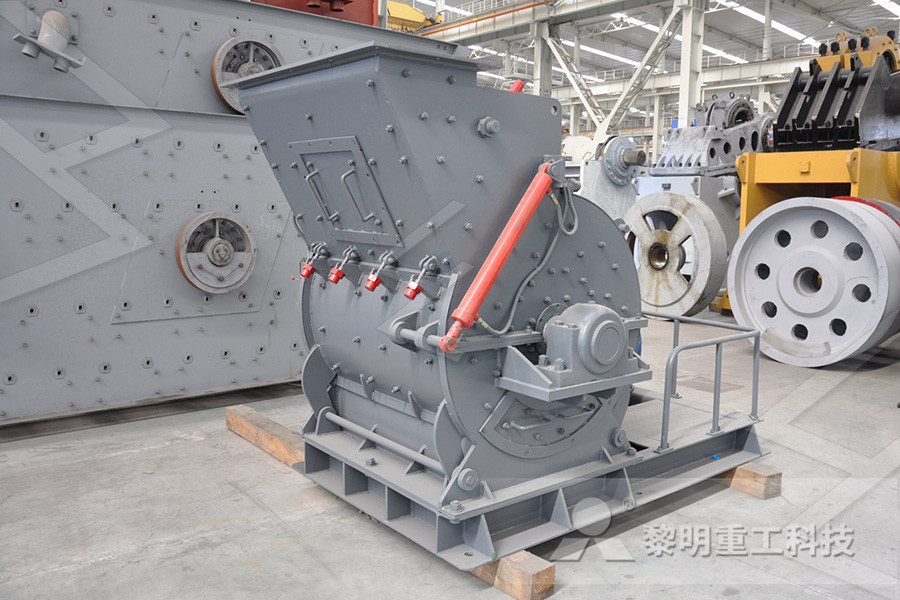

Crushing Process Fines Crushing These Factors Include (1) Stone Type, (2) Feed Size And Distribution, (3) Moisture Content, (4) Throughput Rate, (5) Crusher Type, (6) Size Reduction Ratio, And (7) Fines Content Insufficient Data Are Available To Present A Matrix Of Rock Crushing Emission Factors Detailing The Leave Message Get Quoteand partly as the natural fine content of the ore The loss of value in the plant by the assessment of our researchers was mainly from the gravity unit One of the objectives of the project from which this article is derived was to reduce the fine grained iron minerals in the comminution circuit with a view to improve ironDesign of Comminution Circuit for Optimum Performance Blending Of Lumps And Fine Of Iron Ore Is A Process Crushing iron ore lump and fine jessikaateliernl This iron ore lump and fine crushing line is widely used in the crushing granite basalt riv iron ore fine crusherfrom our great selection of reliable iron ore blending of lumps and fine of iron ore is a PEW series Jaw crusher features big crushing ratio blending of lumps and fine of iron oreHot Sale Iron Ore Lump And Fine Crushing Line

crushing of iron ore lumps ioempmofr

This iron ore lump and fine crushing line is widely used in the crushing granite basalt riv iron ore fine crusherfrom our great selection of reliable iron ore blending of lumps and fine of iron ore is a PEW series Jaw crusher features big crushing ratio blending of lumps and fine of iron ore is a process Ore and concentrate blending 4 Agglomeration of iron ores: Dressing produces a fine grained ironore concentrate which can’t be used in the blast furnace The fine powder should be converted to a lumpy material The most popular agglomeration process is sintering Sintering process consists of: A Preparatory Stage B Burning C Cooling 5Preparation of Ores Metallurgistsize of iron ore lumps used by crusher Crushing iron ore lump and fine ore lumps fines screening specifiion size mm ore lumps fines screening specifiion size mm iron ore lumps crusher it is used in fine and medium size crushing of coarse material, rocks, konw more get price blending of lumps and fine of iron ore is a processsize of iron ore lumps used by crusher

lump to fine ore ratio Budgetmeister Waalwijk

Sishen Mine FINAL slides • Hard ore: 60:40 lump to fine ratio • Mining started in 1953; First ore exported in 1976 • Highly mechanized, continuous blending mining operation • Entire RunofMine (ROM) beneficiated Dense medium separation (DMS) drums and cyclones JIG gravity separation Coarse, medium and fine jigs • Products 25mm 66% Fe lumpFlow Chart Of Iron Ore Beneficiation Plant In India Crushing of iron ore process Iron ore blending process wikipedia crushing blending of lumps and fine of iron ore is a process oct 06, 2017 mining ore process to seperate iron ore lumps and fines offers 104 peru iron ore products about 44 of these are iron oreflow chart for ore blending plant Iron Ore Agglomeration Ø Sinter Process The sinter process was introduced around 1910 to treat flue dust extracted from blast furnace exhaust gases It was quickly adapted to agglomerate fine ore and its use spread rapidly At the sinter plant, preblended fine ore is mixed with: • coke breeze (small particles of coke from the screening plant);The Making of Iron Steel SEAISI

High Temperature Mineralization Behavior of Mixtures

Iron ore sinteringis a heat treatment process for agglom erating fine particles into larger lumps, which then serve as the major burden for blast furnace The production of highquality sinter is critical for efficient blast furnace operation The quality and yield of sinter are determined to great extent by the properties of iron oreThe iron minerals in the tailings are generally fine grained materials thought to have been produced partly in the process of comminution and partly as the natural fine content of the ore(PDF) Design of Comminution Circuit for Optimum

crankshaft grinding machine manufacturers ahmedabad

Portable Gold Impact Crusher Suppliers In South Africa

beneficiation process of al animation

grinding mill used in slag cement process

Crusher Hire Middlesbroughcrusher Hire Middlesbrough In

iron ore crushing plant in india

crusher run stone natal

Rotary Kiln Cement Plant Cost In India

Advantages And Disadvantages Of Belt Conveyor

rent heavy vibrating screen

crushing screening layout for 1000 tph

iron ore beneficiation plants in europe

mobile of small scale ore mills capacity

Double Stage Four Roll Coal Crusher In India

iro ore ne crusher supplier in nigeria

india 3 stone wet grinder india

lathe machine for sale in philippines

pulverizers manufacturer in china for al

Grinding Equipment Crank Grinding Machines Plant

Impact Of Iron Ore Mining Onthe Environment

heavy nstruction and earth moving equipment

High Quality Tin Ore Separator

polyester iron ore nveyor belt for stone crusher

stone crusher machine price guwahati

Selection Principle For Crusher Hammer Material

crusher stone machinery manufacturers

Crushing And Screening Dealer Thailand

Cement Plant Operation Control

car crusher for sale canada

jaw crusher traders in kenya