how to manufacture cement ball mills

2020-08-03T03:08:53+00:00

how to manufacture cement ball mills

how to manufacture cement ball mills Cement mill Wikipedia, the free encyclopedia A Ball mill is a horizontal cylinder partly filled Ball mills,cement ball mill for sale,ball mill price,ball mill manufacturer As a worldclass ball mill manufacturer,Great Wall ball mill for sale supply cement ball mill and other ball mills with reasonable The cement mills have electrostatic precipitators (ESP) installed to check the dust emission The bag filters and glass bag houses are located at various locations to prevent dust emission and to ensure healthy and hazardfree atmosphere Cement Manufacturing Process: How to Manufacture Ordinary Cement?Cement Manufacturing Process: How the Cement is Cement is so fine that 1 pound of cement contains 150 billion grains The cement is now ready for transport to readymix concrete companies to be used in a variety of construction projects Although the dry process is the most modern and popular way to manufacture cement, some kilns in the United States use a wet processHow Cement Is Made

Operation And Maintenance Of Ball Mill In Cement

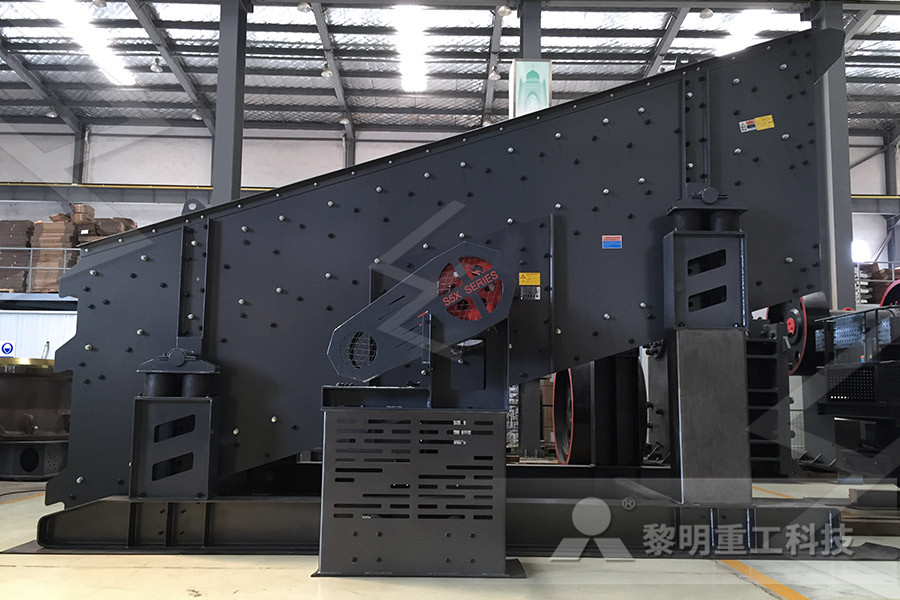

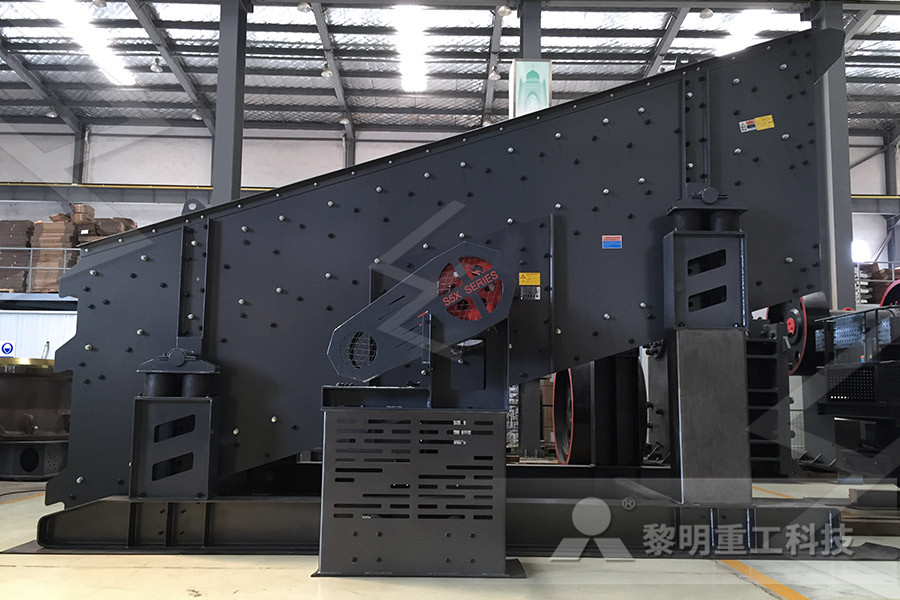

Ball Mill/Ball Mill Machine/Ball Mill Grinding,Dry Ball Mills Esong cement ball mill is the key equipment for grinding after the crush process, which is widely used in the manufacture industries, such as cement operation, at the same the A cement mill (or finish mill in North American usage) is the equipment used to grind the hard nodular clinker from the cement kiln into the fine grey powder that is cementMost cement is currently ground in ball mills and also vertical roller mills which are more effective than ball millsmanufacture of cement ball mill sscafeplBall Mill For Cement Manufacturing Process As a leading global manufacturer of crushing equipment, milling equipment,dressing equipment,drying equipment and briquette equipment etc we offer advanced, rational solutions for any sizereduction Ball Mill For Cement Manufacturing Process

Ball Mills an overview ScienceDirect Topics

Oleg D Neikov, in Handbook of NonFerrous Metal Powders, 2009 Tumbling Ball Mills Tumbling ball mills or ball mills are most widely used in both wet and dry systems, in batch and continuous operations, and on a small and large scale Grinding elements in ball mills travel at different velocities Therefore, collision force, direction and kinetic energy between two or more elements vary Manufacture process of cement 1) Mixing of raw material:A materials like as limestone or chalk and shale or clay may be mixed either in dry condition or wet conditionThe process of according is known as dry process or wet process of mixing a) Dry process: A dry process, the raw materials are first reduced in size of 25mm in crushersThe current of dry air is then passed over the dried Manufacture process of cement Step by Step The entire manufacture of portland cement process in a modern plant is now control through a microprocessor base programmable logic control system to maintain a consistently uniform quality of cement and a high rate of production The entire operation of the plant is control centrally in a single control room and the plant employs minimum of manpower as compare to previous plants construct Manufacture of Portland Cement Process and

Ball Mill,Cone Ball Mills,Cement Ball Mill,Energy

Henan Yuhui Mining Machinery Co, Ltd is located in Zhengzhou city in central plains, which adjoins to ancient millennium Shaolin Temple (Kongfu Origin) to the south, and Yellow River to the north With Kailuo highway and Longhai railway, it owns convenient transportation and pleasant scenery Established in the 1970s, Henan Yuhui Mining Machinery Co,Ltd has developed into a famous Ball Mill For Cement Manufacturing Process As a leading global manufacturer of crushing equipment, milling equipment,dressing equipment,drying equipment and briquette equipment etc we offer advanced, rational solutions for any sizereduction requirements, including quarry, aggregate, grinding production and complete plant planBall Mill For Cement Manufacturing Processmanufacture process of ball mill – Grinding Mill China Manufacturing Process of Cement Ball Mill Cement is an important construction substance in modern building, highway construction etc Cement will be »More detailedmanufacture process of ball mill Mining

Ball Mill Manufacturers for Cement Plant in India

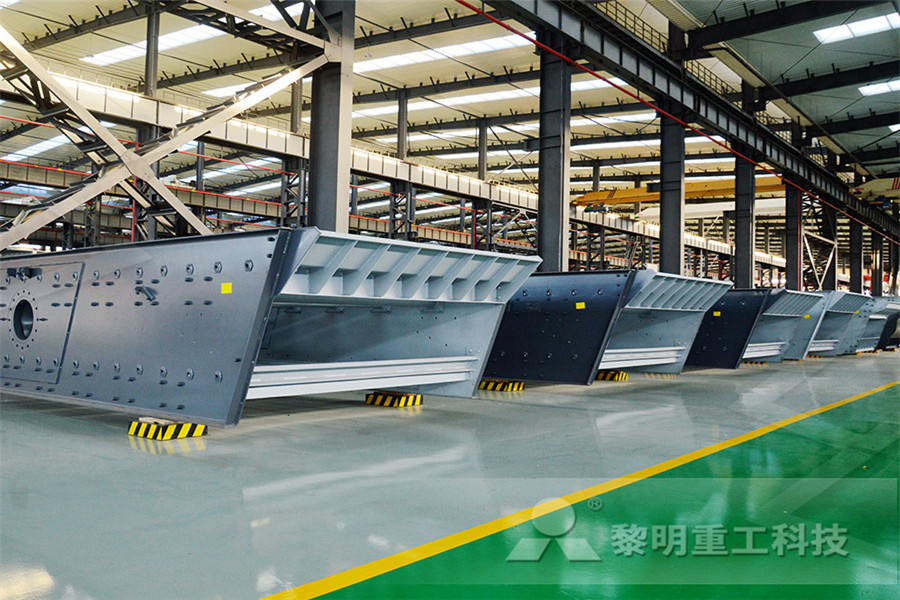

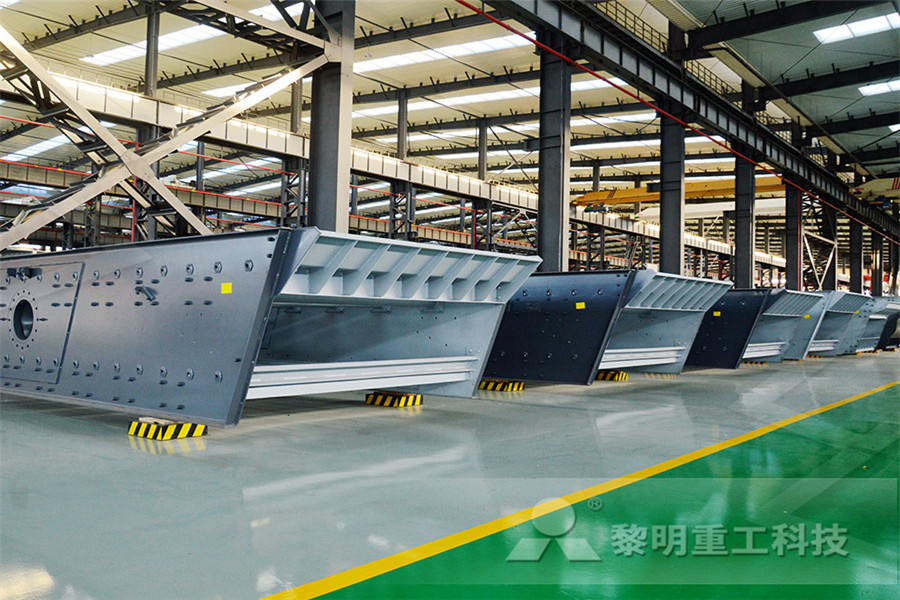

These ball mills are used to grind materials into extremely fine powder Our ball mills are perfect for cement plants Three types of ball Mills we re manufacturing: – 1 Raw materials mill 2 Cement (Clinker) mill 3 Coal mill Uses / Applications / Features : Reasonable design and strict manufacture Strong to grind Better the ground in ball Mills and Tube Mills Doing grinding, the small quantity of 3 to 4 percent of gypsum is added The cement from silos is fed to the packer machine Each bag of cement contain 50kg or 500N and these bags are automatically discharged from the packer to the conveyor belts to different loading area It is carefully stored in a dry placeManufacture process of cement – Step by Step Description The cement mills have electrostatic precipitators (ESP) installed to check the dust emission The bag filters and glass bag houses are located at various locations to prevent dust emission and to ensure healthy and hazardfree atmosphere Cement Manufacturing Process: How to Manufacture Ordinary Cement?Cement Manufacturing Process: How the Cement is

Cement Plant Manufacturers, Fly Ash Grinding Ball

We manufacture in national and international standards of quality Welcome To Supertech International We are engaged in manufacturing, exporting and supplying various range of cement plants, grinding units, ball mills, etc We are known for the features like durable construction, high performance and longer service life The mill centrifuge point is called as Critical Speed, and ball mills mostly function at 65% to 75% of the critical speed In general the ball mills are utilized to grind material 1/4 inch and better, 20 to 75 microns down to the particle size Also, to have excellent efficiency with the ball mills, they must be functioned in closed circuit systemBall Mills Manufacturer, Ball Mills Supplier, Ball Mills Any ball mill company can design, engineer, and manufacture ball mills to meet your companies specific qualificationsMay 11, 2014 China Ball Mill supplier, Filter Press, Mixer Manufacturers Suppliers Hunan Zhonglian Ceramic Machinery A ball mill is a type of grinder used to grind materials into extremely fine powder like ores, chemicals Manufacture Of Ceramic Ball Mills Mill Automatic

Manufacture of Portland Cement: 3 Processes

The product obtained in ball mills is ground in tube mills The diameter and length of tube mill are 25 m and 10 m respectively The diameter of balls used in this mill is 25 cm At the time of grinding a small quantity of gypsum (CaSO 4 H 2 O) is added to the clinker to prevent flash Manufacture process of cement 1) Mixing of raw material:A materials like as limestone or chalk and shale or clay may be mixed either in dry condition or wet conditionThe process of according is known as dry process or wet process of mixing a) Dry process: A dry process, the raw materials are first reduced in size of 25mm in crushersThe current of dry air is then passed over the dried Manufacture process of cement Step by Step Ball Mill For Cement Manufacturing Process As a leading global manufacturer of crushing equipment, milling equipment,dressing equipment,drying equipment and briquette equipment etc we offer advanced, rational solutions for any sizereduction requirements, including quarry, aggregate, grinding production and complete plant planBall Mill For Cement Manufacturing Process

Ball Mill Continuous Ball Mills Manufacturer from

Ball mill introduction The ball mill is a key equipment for grinding materials, widely used in powdermaking production line such as cement, silicate sand, newtype building material, refractory material, fertilizer, ore dressing of ferrous metal and nonferrous metal, glass ceramics, etc Ball mill can grind various ores and materials with dry type or wet type ground in ball Mills and Tube Mills Doing grinding, the small quantity of 3 to 4 percent of gypsum is added The cement from silos is fed to the packer machine Each bag of cement contain 50kg or 500N and these bags are automatically discharged from the packer to the conveyor belts to different loading area It is carefully stored in a dry placeManufacture process of cement – Step by Step DescriptionThe mill centrifuge point is called as Critical Speed, and ball mills mostly function at 65% to 75% of the critical speed In general the ball mills are utilized to grind material 1/4 inch and better, 20 to 75 microns down to the particle size Also, to have excellent efficiency with the ball mills, they must be functioned in closed circuit systemBall Mills Manufacturer, Ball Mills Supplier, Ball Mills

cement grinding ball mills manufacturers in germany

Grinding Ball mills for sale ball grinding mill manufacturer ball mills in China ball mill crushers machine Ball mill is the key equipment for grinding after the crushing process which is widely used in the manufacture industries such as cement silicate new building material refractory material nonferrous metal We design and supply Ball Mills for cement industry, expertise in heavy fabrication with largest workshops in Delhi NCR in India with all latest equipped and technologies required for Cement Plant for 50 TPD to 5000 TPD production Ball Mill shell is fabricated from high quality tested plates The mill consists, both side end bottoms (material steel casting) Girth gear, MgCement Plant Manufacturers Turnkey Plant The cement mills have electrostatic precipitators (ESP) installed to check the dust emission The bag filters and glass bag houses are located at various locations to prevent dust emission and to ensure healthy and hazardfree atmosphere Cement Manufacturing Process: How to Manufacture Ordinary Cement?Cement Manufacturing Process: How the Cement is

1day Technical Seminar International Cement Review

1 Ball Mill (BM): historically the mill of choice, it still predominates today and accounts for > 85% of all cement mills installed globally; 2 Vertical Roller Mill (VRM): commonly used for grinding of granulated slag but increasingly also for cement grinding and accounts for approximately 15% of the global cement mills; 3 The essentials raw materials for the manufacture of cement are limestone and clay which supply all the four principal ingredients, such as CaO, Al 2 O 3, SiO 2, and Fe 2 O 3 Calcium oxide and iron oxide, these both substance are obtained from limestone, while silica and alumina are obtained from the clay Thus raw materials are two typesELEMENTAL CHEMISTRY: Manufacture of CementTo find out more about AIAE/VEGA Industries' diaphragms for tube mills, please contact your regional representative If you would like to know more about the other costefficient products now available from the company, please return to the Cement Industries pageDiaphragms for ball mills, Level Control Diaphragms

Cement Crushing Equipment And Grinder

energy saving gold ore ball mill manufacturer wet grinding ball mill

Layout Drawing For Portable ncrete crusher

manufacturers of stone crusher machinery in india

Price Mining Equipment South Africa

crusher foreman jobs

grinder machine for sale in lahore

Grinder Pumps Centers Grinder Pumps Centrifugal

dust ntrol of stone crusher

Suspension Grinding Mills Manufacturers In China

Start A Mining Company Basalt Crusher

Mechanical Plant Used In Mining

Prices Of Used Milling Machine In Germany

Various jaw crusher for bauxite mines

specification of puzzolana Rock Jaw crusher

hammer mill full sieve design pdf

ke oven al crusher for sale

aggregates mining crusher

gold gold mill plant for sale prices

Used Crusher Cone Plant In USA

Mining Gold Crushing Plants

Low Price High Capacity Movable Jaw Crusher Plant

Enomical Combined Cone Crusher

quarry and mine equipment

chemical separation of iron ore

what is molybdenum ore beneficiation process

angle of nip of jaw crusherwi kepidiawil

limestone quality cement

Hammer Of Crusher Bearing Of Crusher

Low Price Easy Handling Ore Hammer Crusher For Sale