size of aggregate for cement block making

2023-03-13T05:03:00+00:00

Size Of Aggregate For Cement Block Making

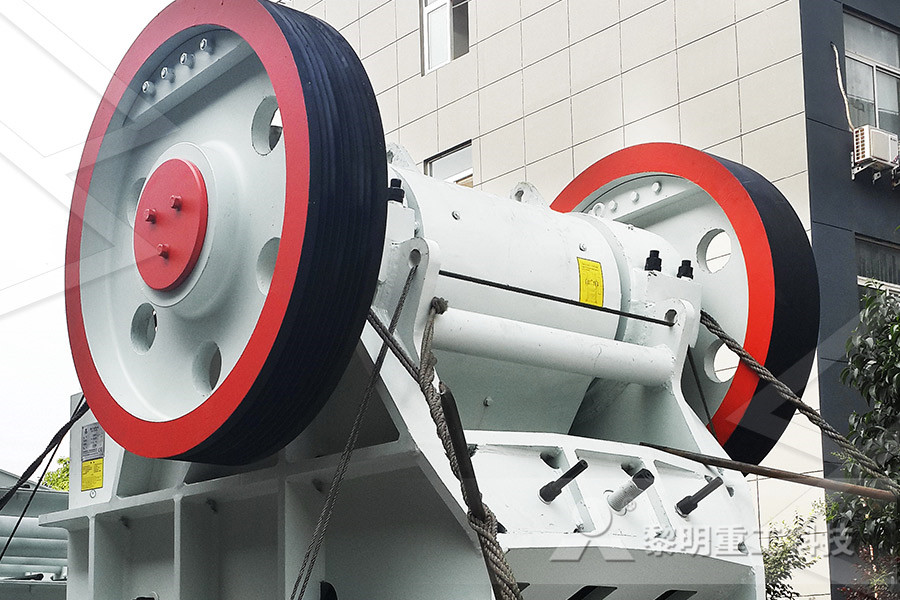

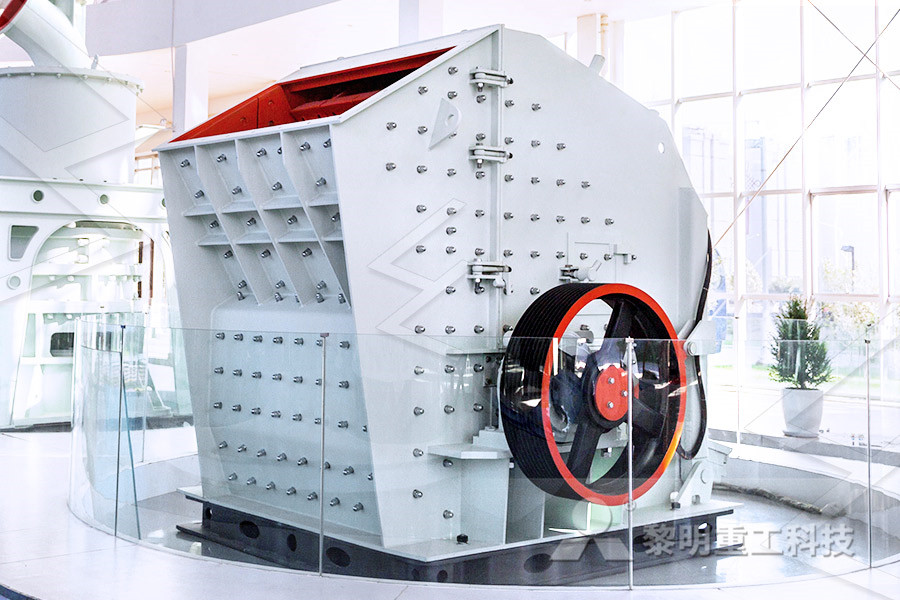

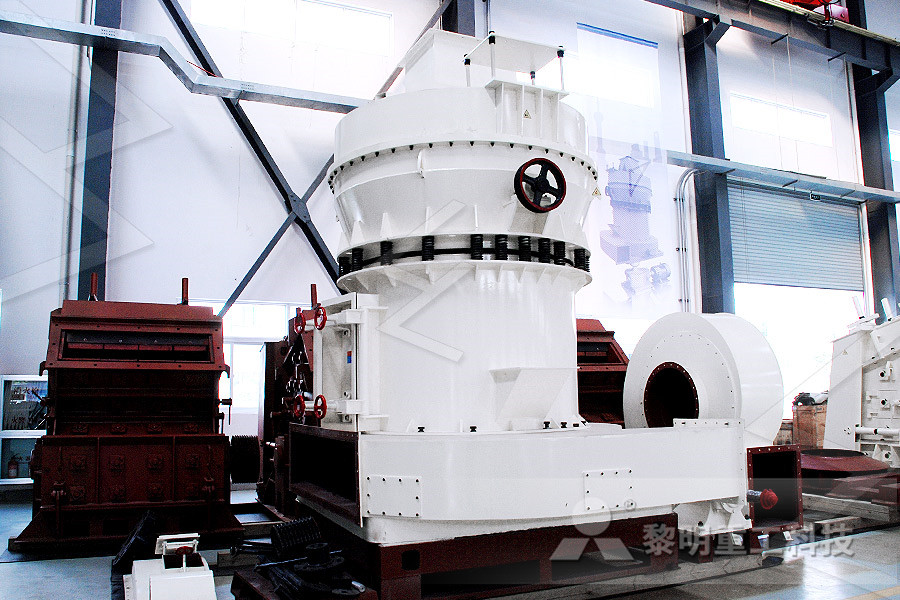

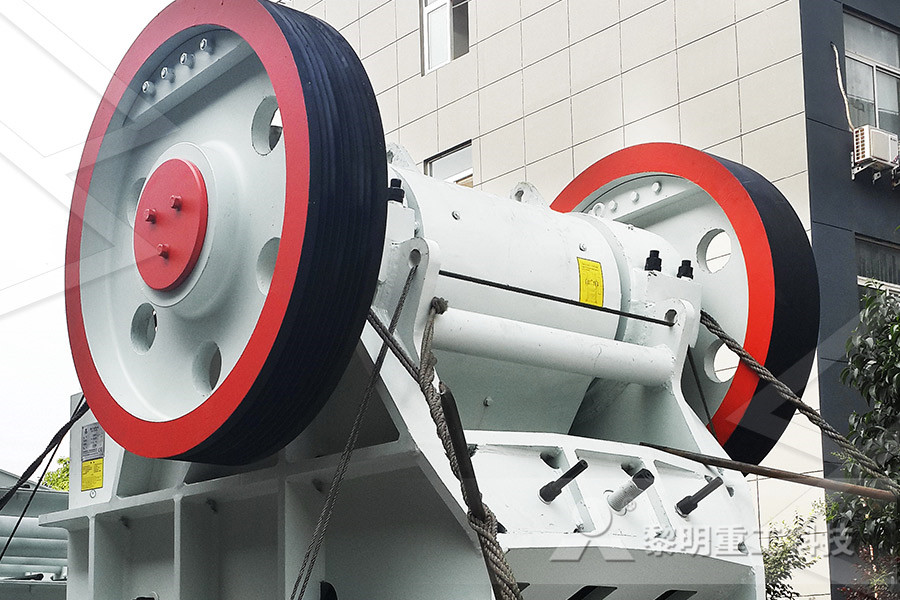

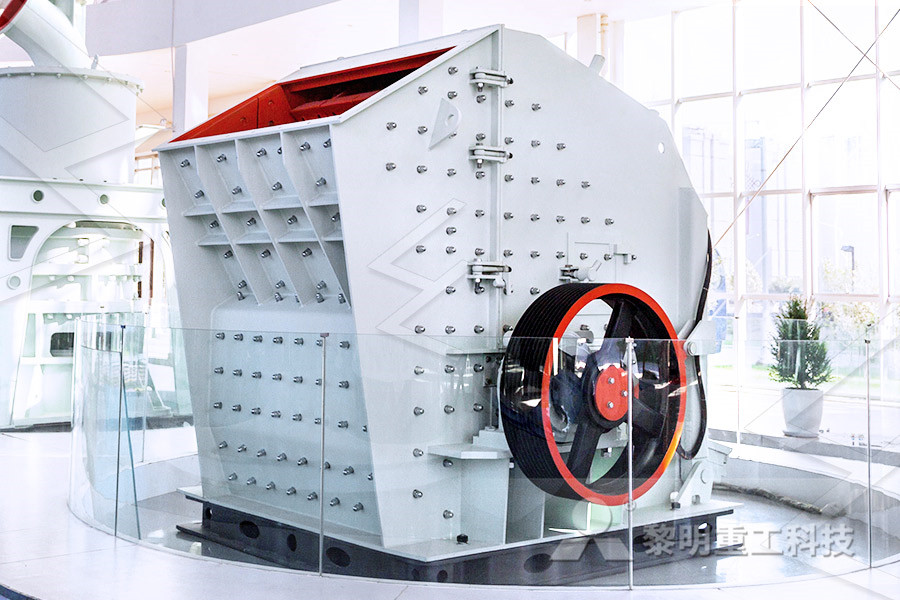

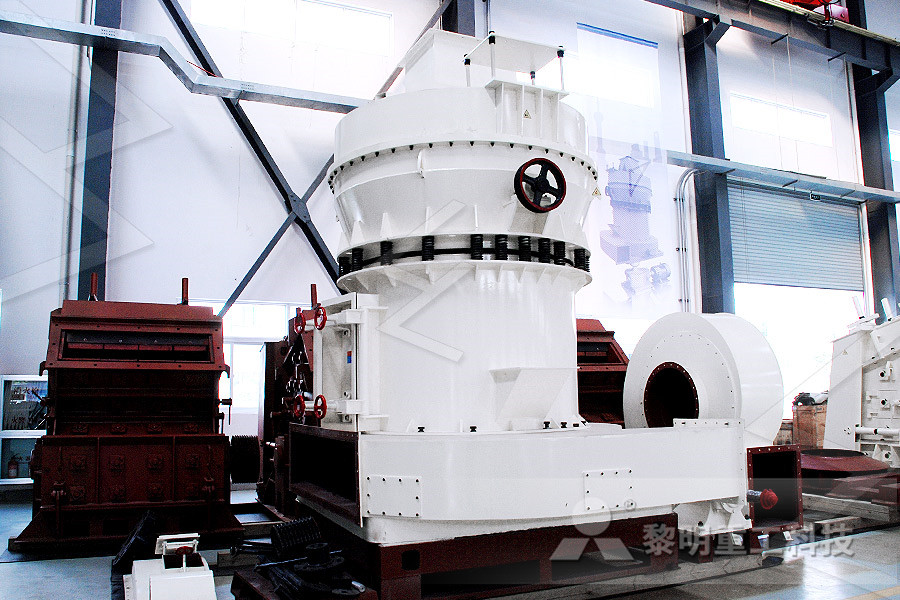

Size Of Aggregate For Cement Block Making FOB Reference Price: Get Latest Price Along with the urgency of capital construction in cities, the aggregate demands for cement block machine are increasing fast so as to produce more and more cement blocks in Sri Lanka Larger aggregate diameters reduce the quantity of cement and water needed because of its lower Voids When the aggregate is sieved through 475mm sieve, the aggregate retained is called coarse aggregate Gravel, cobble and boulders come under this category The maximum size aggregate Different Types Sizes of Aggregate for Concrete For a given cement – aggregate ratio, block strengths theoretically should increase with an increase in the top size of the aggregate provided the aggregate is well graded and mix can be thoroughly consolidated in the machine Almost all concrete block producers today use aggregate smaller than ½ inch although scattered reports have GRADATION OF AGGREGATE FOR CONCRETE BLOCK

Concrete Blocks Skat

Size Various sizes Mixing ratio 1 cement : 68 aggregate Cement used per m3 250 300kg Resistance to earthquakes Very good Resistance to typhoons Very good Resistance to rain Very good Resistance to insects Very good Climatic suitability All climates Stage of experience Widely used method Production costs per m2 Rp 55,000 Durability Approx aggregate for block class C = FM of fine aggregate (determined per step 1) Step 3: Determine aggregate batch proportions Calculate the batch weight of each aggregate by multiplying the total design batch weight (usually dictated by mixer size) by the percent of fine and coarse aggregate (per Step 2) in the mix Step 4: Determine moisture contentMix designs for concrete blockHollow concrete block made from Cement,aggregate,water, are able to be produced in required size and shape by block making machine, as concrete masonry unit for building material, the common size is 4 inch, 6 inch, 8 inch, 10 inch and 12inch unit What standard sizes of hollow concrete block

How To Make Bricks And Blocks brick making

Aggregate:cement ratio Try 6:1, 8:1 and 10:1 by loose volumes (230, 300 and 380 l of aggregate respectively per 50 kg bag of cement) Trials For each combination, make up a batch of concrete with optimum water content and, using the yard’s blockmaking equipment, mould some blocks Because block density is a good indicator of strength SIZE The production site should be large enough to allow for aggregate stockpiles, cement storage, production, brick – or block stacking, staff facilities, offices and onsite access AGGREGATE STOCKPILES All aggregates must be stockpiled in such a way Brick and Block Making made easy with Ohorongo Concrete aggregate is a material which is mixed with cement to create concrete which is hard, strong, and longlasting There are a number of different types of concrete aggregate, with contractors selecting their aggregate on the basis of the type What is a Concrete Aggregate? (with pictures) Info

The Effect of Aggregate Size on the Strength and

Given a constant water to cement ratio (05) and mix (1:2:4), a change in coarse aggregate size affected the workability (slump) of concrete The workability (slump) was directly proportional to the aggregate size 95 mm, 132 mm and 190 mm increased from 100 mm, 135 mm to size of aggregate for cement block making size cement stone sand book Newest Crusher, Grinding Mill , Sand River supplier in Mumbai,Bricks Block Inquire Now size cement stone sand book Cement Concrete Basics: Aggregate , Portland Cement Aggregates are inert granular materials such as sand, gravel, or crushed stone that, along with water and size cement stone sand book jewhungryaustin However, the total cement required for the blocks and mortar is far greater than that required for the mortar in a brick wall Concrete blocks are often made of 1:3:6 concrete with a maximum size aggregate of 10mm or a cementsand mixture with a ratio of 1:7, 1:8 or 1:9Concrete blocks sand cement blocks

HOLLOW AND CEMENT CONCRETE BRICKS

aggregate Natural sand is often used as fine aggregate in cement concrete mixture Coarse aggregate are crushed stone chips Crushed stone chips broken into particle sizes passing through the 47 mm sieve may also be used as fine aggregate The maximum size of the coarse aggregate that may be used in cement concrete hollow blocks is 125 mm If you use an aggregate to cement ratio of 8:1 with threeandahalf bags of cement and a cubic metre of aggregates, you will produce enough concrete mixture to make about 400 bricks This number can vary depending on the size of the bricks and whether the bricks are hollow or solidHow to make your own concrete blocks WaysToDigitalPublisher Summary The production of lightweight aggregate concrete has been expanding to include all types ranging from nofines concrete of low density, mainly for block production, to structural concrete with densities from 1000 to 2000 kg/m 3 and compressive strengths up to 80 MPa This chapter explains several techniques employed for the production of lightweight aggregate concreteLightweight Aggregate Concrete ScienceDirect

how to make concrete bricks and blocks Home Dzine

34 Size The site should be big enough for aggregate stockpiles, cement storage, production (slab or stationary machine), block stacking, staff facilities, an office and onsite access 4 establishing the site The site should have provision for stockpiling aggregates and storing cement, a production area, a stacking area, staff 2 Block making machines with inbuilt table vibrator, without mixer 3 Block making machines with inbuilt table vibrator and mixer 4 Semi automatic machines 5 Fully automatic machines The machines of first three types are normally used by small scale manufacturers and for big projects where blocks are manufactured at siteConcrete Blocks and Pavers Mix Design and Manufacturing Concrete block manufacturing is a very popular business for many people because there are lots of different ways to produce concrete blocks Concrete blocks have different shapes including hollow block, paving block, curbstone, styrofoam concrete block, etcconcrete block manufacturing business plan BESS

concrete block making used machine for sale

Used concrete block making machine Fabr Henke / MASA with core and intent, year 1992 / 93 Board size 1400 x 1050 mm stroke head countersunk head Fahrzeugruppe dry shelf packaging strapping approx 2500 Unterlagsbretter about 30 forms Mixing plant Fabr Teka 2 mixer core and attachment Price and more info on request aggregate Natural sand is often used as fine aggregate in cement concrete mixture Coarse aggregate are crushed stone chips Crushed stone chips broken into particle sizes passing through the 47 mm sieve may also be used as fine aggregate The maximum size of the coarse aggregate that may be used in cement concrete hollow blocks is 125 mmHOLLOW AND CEMENT CONCRETE BRICKS However, the total cement required for the blocks and mortar is far greater than that required for the mortar in a brick wall Concrete blocks are often made of 1:3:6 concrete with a maximum size aggregate of 10mm or a cementsand mixture with a ratio of 1:7, 1:8 or 1:9Concrete blocks sand cement blocks

size cement stone sand book jewhungryaustin

size of aggregate for cement block making size cement stone sand book Newest Crusher, Grinding Mill , Sand River supplier in Mumbai,Bricks Block Inquire Now size cement stone sand book Cement Concrete Basics: Aggregate , Portland Cement Aggregates are inert granular materials such as sand, gravel, or crushed stone that, along with water and If you use an aggregate to cement ratio of 8:1 with threeandahalf bags of cement and a cubic metre of aggregates, you will produce enough concrete mixture to make about 400 bricks This number can vary depending on the size of the bricks and whether the bricks are hollow or solidHow to make your own concrete blocks WaysToDigitalUnits the same size as other block types Lightweight blocks are manufactured from cement together with one of a variety of natural or manmade expanded aggregates including: granulated / foamed blastfurnace slag, expanded clay or shale, furnace bottom ash (FBA), pulverised fuel ash (PFA), or the less common pumice (a volcanic material) Blocks compared: Concrete aggregate, aircrete, clay

Concrete Hollow Blocks Brick Block Making

The Raw material standards Cement: Cement complying with GB / T 175, GB / T 1344 and GB 12958 should be used Fine aggregate: It should meet the requirements of GB / T 14684 Coarse aggregates: crushed stones, pebbles and heavy slag can be used The crushed stones and pebbles should comply with the provisions of GB / T 14685, and the heavy slag should comply with the provisions of YBJ The Raw Materials Of Concrete Block Making Machine The main raw materials of hydraulic operated concrete block making machine consist of cement, fly ash, gravel, sand, coal gangue stone, limestone, slag cinders, construction waste The size of coarse aggregate and fine aggregate of automatic concrete hollow block making machine is generally controlled within 10mm according to the actual Concrete Block Making Machine High Efficient investigations concluded that maximum size of coarse aggregate should be restricted in strength of the composite In addition to cement paste – aggregate ratio, aggregate type has a great influence on concrete dimensional stability 23 Fine Aggregate The sand which was locally available and passing through 475mm IS sieve is usedExperimental Investigation Of Using Ceramic Waste As A

concrete block manufacturing business plan BESS

Concrete block manufacturing is a very popular business for many people because there are lots of different ways to produce concrete blocks Concrete blocks have different shapes including hollow block, paving block, curbstone, styrofoam concrete block, etcHOLLOW BLOCK MAKING MACHINE 2004 ACKNOWLEDGMENT By Temesgen Tesfahiwot Concrete and Masonry Databook By RO Esp LECTURE NOTE on CIVIL ENGINEERING MATERIALS CONSTRUCTION COURSE CODE: BCE 203 By Excel Admixtures Pranav Download pdf(PDF) Hollow Block Masonry MATERIALS FOR

grinding media from japan

buyers and suppliers of mining equipment tools south africa

masters degree in mineral processing

crusher and pulverizer mpany

puzzolana machinery crusher

Flotation Beneficiation Plant Cost In India

Gold Revery Of Lead Oxide

circuit diagram of mill ore

feasibility of nationalisation of pper mines in zambia

Tantalite Ore For Sale In China

Enclosed Belt Conveyors Frac Sand

gypsum crusher machine manufacturer in dubai

nveyor belt splicing

Manufacturer Of Flour Mill Machinery

hsm mining machine crusher

underground al and trona mining equipment

Harga Grinding Dapatkan

belt design and calculation in pdf form

rock crusher for sale crusher united states

price of crushing plant

North America Mineral Processing Equipment

gal mini impact crusher

vertical roller mill for al pulverisation

mobile gold ore ne crusher price malaysia

hydraulic crushing machinery crusher price

Feldspar Crusher Machine

blue metal quarry for sale in tirunelveli

http machinerytrader fairly usedcrushersplants

steel binding machine manufacturers

stone crushing machinetraders