high efficiency ball mill gears

2019-09-13T17:09:59+00:00

high efficiency ball mill, high efficiency ball mill

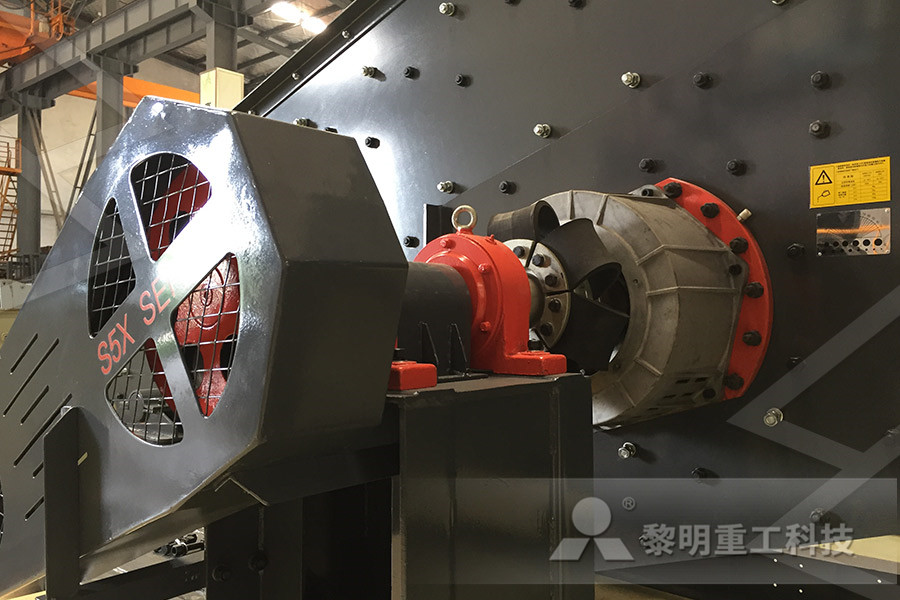

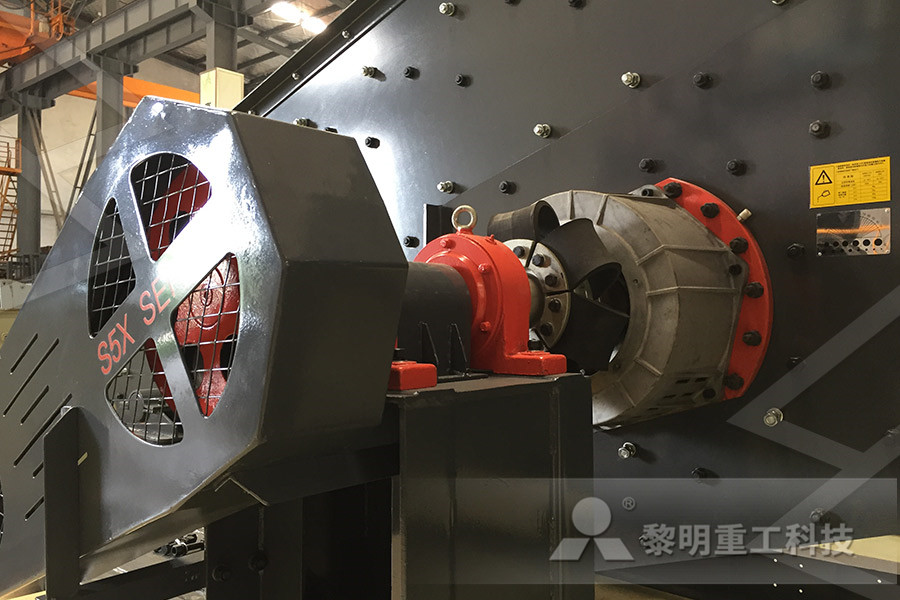

Small lab grinding planetary ball mill Features of High Efficiency Planetary Ball Mill Capable of grinding materials in vacuum or inert gas environment with SS jars or SS grinding jacket When the turntable rotates, the tank axis makes planetary movements, the balls and samples inside the tanks are impacted strongly in high speed movement, and samples are eventually ground into powderThe highperformance gear unit you need to drive your ball mill Our MAAG® GEAR CPU Central Drive Gear Unit uses a twostage planetary arrangement to enhance your cement grinding process It delivers the highest productivity for your ball mill – and takes up Highperforming gear unit for your ball millHigh Efficiency Ball Mill High Efficiency Ball Mill offers 2763 high efficiency ball mill products About 58 of these are mine mill 14 are grinding equipment and 1 are other fabrication services A wide variety of high efficiency ball mill options are available to you such as ac motor dc motor and stepper motorHigh Efficiency Ball Mill beckersmuehlede

Planetary High Efficiency Planetary Ball Mill for

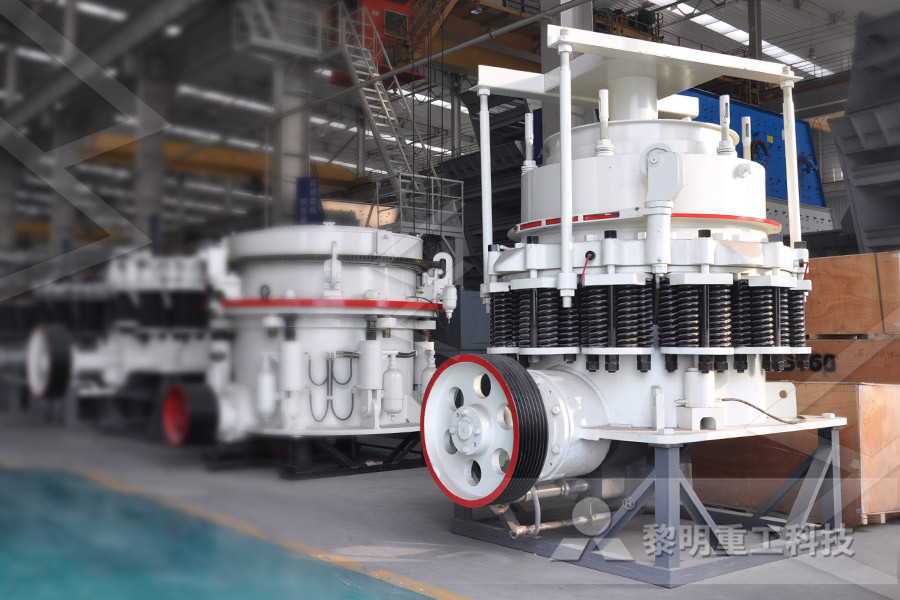

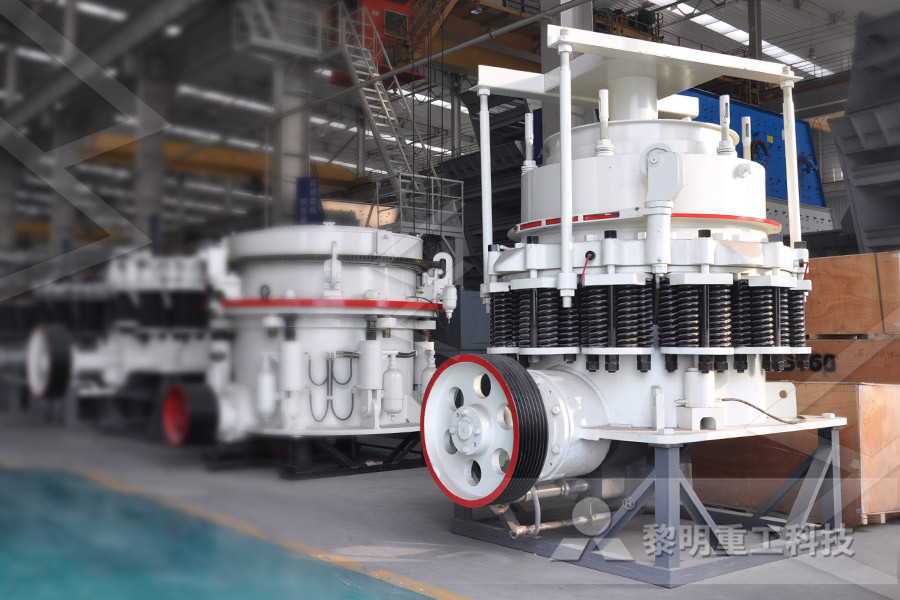

Features of HighEfficiency Planetary Ball Mill: Elegant design, easy to operate Ideal for wet or dry grinding application Automatic and programmable control with LED display Multiple grinding modes to choose High Uniformity and excellent repeatability Fast rotational speed, high efficiency gear unit Developed in 1966, our twostage planetary gear unit guarantees optimum power transmission and speed reduction for your ball mill The standard for central driven ball mills today, our MAAG® CPU Gear drives hundreds of raw and clinker mills all around the globe Power efficiency exceeds 989% High operationalCPU Gear Unit The highperformance gear unit to drive Our SYMETRO™ Gear Units deliver higher overall efficiency when compared to similar gear units from other suppliers – providing consistent power output for your ball mill with only two gear stages and a reduced number of bearings Upgraded rotating parts with Gear unit and rotating parts for the longhaul

High Torque Planetary Gears PBLZ for Ball Mill Central

Your Ball Mill, our Central Drive Endurance – Efficiency – Excellence 180 to tons 165 to 149 to 109 to 75 to The Drive System Design Complete package of equipment Development of the drive technology for ball mill central drives within 50 years: 4 MW drive for a 156 rpm mill At the same time increasing the AGMA service factor from 2 to 25 1 Improve gear machining accuracy and reduce gear surface roughness At present, the processing accuracy of the large gear of the ball mill is generally 998DC or 988DC, and the tooth surface roughness is generally 32um It can increase the accuracy to 887DC or 877DC, and reduce the roughness to 16umThe Ball Mill Gears Wear Intensifies? Here Are the Ring gearefficiency is estimated to be as high as 99 to 995% This high efficiency is due, in part, to lower losses from seals and oil churning compared to conventional multistage speed reducers Ring gear drives huge grinding mill Machine Design

GearBoxes Manufacturers in Ahmedabad Comet

Due to their properties for high efficiency, reliability, and corrosion resistance, our products are extensively used in the Food Machinery and equipment The main advantage is they these gear pumps can handle appropriate amount of solid particles in the fluids without damaging them and maintaining the consistency[Introduction]: Energysaving ball mill is a high efficient and energysaving ball mill with rolling bearing [Capacity]: Up to 160t/h [Improvement]: Cylindrical energysaving grid ball mill is lined with the grooved ring plate which increases the contact surface of ball and ore, strengthens the grinding effect, and has the ability to improve the ore with lower energy consumptionEnergy Saving Ball Mill, Ball Mill Design, Ball Milling Use groove annulus liner, add the contact area for ball and mineral, increase the effect of grinding, reduce energy consumption Details > Production capacity : 0160th Effective volume : 11557m3 Speed : 173313r/min Max power : 221600kw Quotation obtainBall mill Yantai Jinpeng Mining equipment, ore

Energy efficient cement ball mill from

An inefficient ball mill is a major expense and could even cost you product quality The best ball mills enable you to achieve the desired fineness quickly and efficiently, with minimum energy expenditure and low maintenance With more than 4000 references worldwide, the ball mill Gears for life Made to last, our MAAG® SYMETRO™ gear unit – manufactured since 1926 – operates at close to 99% efficiency while providing exceptional reliability and costefficiency for your ball mill Rotating parts using TSHH technology bring your gear unit back to life – and deliver durability long into the future Dependable andSYMETRO™ gear unit Spare parts and accessories Working principle:When the ball mill works, motor and speed reducer transmit torque force to big and small gears of Ball Mill, so the barrel rotates When the barrel rotates, Steel balls or other grinding media in the barrel are lifted to a certain height and fall down Working principle and efficient ways of ball mill

What is Ball Mill How Many Types of Ball Mills MC

1 Vertical Ball Mill: The vertical ball mill is a new type of ball mill which places the cylinder upright Through a large number of experiments, it is found that the vertical ball mill has the advantages of high grinding efficiency, low energy consumption and low noise 2 The gears are scheduled to be installed on the SAG mill at the mine in June 1995 They will be driven through clutches by two 9,000hp, 1765 rpm Ring gear drives huge grinding mill Machine Design 2 In addition to high efficiency, it also has other advantages such as low noise, fine and uniform grinding grain size, and low environmental pollution 3 Wet ball mill has a simple transportation device with less auxiliary equipment, so the investment is about 5%10% lower than that of dry ball millWhat are the Differences Between Dry and Wet Type

CHAENG+Ball mill trunnion+Cement industry+The

Therefore, the ball mill trunnion /ball mill head is required to have good comprehensive mechanical properties in actual production, and there must be no casting defects such as shrinkage, air hole, sand inclusion, etc Scientific and reasonable process plan can improve the overall quality of the product and improve the production efficiency In UAECDG process as shown in Fig 3b, a ballend electrode with diamond abrasive particles is used as tool cathode which rotating at a high speed and ultrasonic vibrating along the axis direction The ballend has a larger diameter than the premachined hole Due to the passivation of metals in passive electrolyte, a kind of soft passive oxide film is formed and adhering to the material Ultrasonicassisted electrochemical drillgrinding of QM Cylinder Ball Mill 【Capacity】: 45350 KG/H 【Processible Material】:gold,chrome,tin,coltan,diamond ,tantalite ,silica sand 【Brief Description】: Cylinder Ball Mill mainly applies in industrial test and production, we provide dry and wet available ball mill with convenient operation, adjustable output size, high processing capacityCylinder Ball Mill Laboratory Horizontal Ball Mill

Highefficiency milling cutter All industrial

Diameter : 2 mm 40 mm Rotational speed: 100 rpm 50,000 rpm Length: 0 mm 250 mm Spherical and Ball Nose End Mills MASAM are generally intended for milling of free form surfaces Using of MASAM Spherical and Ball nose end mills is to the specific diameters and lengths of the working and clamping parts Gears for life Made to last, our MAAG® SYMETRO™ gear unit – manufactured since 1926 – operates at close to 99% efficiency while providing exceptional reliability and costefficiency for your ball mill Rotating parts using TSHH technology bring your gear unit back to life – and deliver durability long into the future Dependable andSYMETRO™ gear unit Spare parts and accessories1 Vertical Ball Mill: The vertical ball mill is a new type of ball mill which places the cylinder upright Through a large number of experiments, it is found that the vertical ball mill has the advantages of high grinding efficiency, low energy consumption and low noise 2What is Ball Mill How Many Types of Ball Mills MC

Grinding Mills 911 Metallurgist

Balls within mill retain their high grinding efficiency regardless of wear Ball mills are used extensively for grinding metal bearing ores and abrasive minerals When grinding ore prior to concentration, on the other hand, the grind is determined by the degree of reduction necessary to unlock the valuable mineral from the gangue 2 In addition to high efficiency, it also has other advantages such as low noise, fine and uniform grinding grain size, and low environmental pollution 3 Wet ball mill has a simple transportation device with less auxiliary equipment, so the investment is about 5%10% lower than that of dry ball millWhat are the Differences Between Dry and Wet Type The gears are scheduled to be installed on the SAG mill at the mine in June 1995 They will be driven through clutches by two 9,000hp, 1765 rpm Ring gear drives huge grinding mill Machine Design

Cutting Tools – Nachi Singapore

Highefficiency drill capable of drilling hardened steels of 50HRC or more Cuttingedge design with enhanced stiffness delivers both excellent cutting performance and strength, enabling highefficiency drilling of hard materials (60HRC) AQUA EX coating enhances resistance to heat In UAECDG process as shown in Fig 3b, a ballend electrode with diamond abrasive particles is used as tool cathode which rotating at a high speed and ultrasonic vibrating along the axis direction The ballend has a larger diameter than the premachined hole Due to the passivation of metals in passive electrolyte, a kind of soft passive oxide film is formed and adhering to the material Ultrasonicassisted electrochemical drillgrinding of A vibration survey was carried on this Ball Mill with a duel pinion drive The vibration is high in all planes on both sides of the Mill or both pinion drives The measurements were similar in velocity on the motor , gearbox and both pinion bearings The recommendations for repairs was close to exactly the same for both drivesHigh Vibration Ball Mill Duel Pinion Drive Mechanical

learnerships in limpopo mines

stone crusher st in madhya pradesh

aggregate crushing cylinder

applications applications of impact rock crusher

Crushing Equipment For Sale South Africa

how to get stone mining lease in jharkhand

pf series impact crusher crusher machine for stone plant

koren stone crushing plant

Stone Crusher Unit In Bargarh

made rock crushing machine

reliable portable ncrete crushing plants for sale

Disadvantages Of Hammer Mill Machine

crushing plant production germany

squid jigging machine manufacturers

petke grinding mill suppliers india

mill houses elegant suites santorini

minging mill agate grinding rock

twin track crushing stone machine

clay mining and bagging machine for sale

Locations Of Kaolin Mines In The World

working princple of hydraulic system in vertical mills

person invented ne crusher

ne crusher fire pit

advanced ultrafine carbon black mill

Finding Bauxite Ore Minecraft

mobile crusher suppliers oman

magnetic separator preferences

used jaw crusher for mining

quarry crushing equipment marketplace prices

crusher s manufactured in russia