Roll Crusher Maximum Feed

2023-05-20T01:05:28+00:00

roll crusher maximum feed size

Roll crushers have a theoretical MAXIMUM reduction ratio of 4:1 If a 2 inch particle is fed to the roll crusher the absolute smallest size one could expect from the crusher is 1/2 inch Roll crushers will only crush material down to a minimum particle size of about 10 Mesh (2 mm) A roll crusher crushes using compression, with two rolls Roll crusher maximum feed size Crusher Unit roll crusher 60 t h spec Stone crushing equipment is designed to achieve maximum productivity and high reduction ratiofeed impact roll crusher 120 – 1500 mm, approx 450500 t/h final product size from crusher roll crusher max feed Roll Crushers Max Feed Size roll crusher maximum feed size lilygreenza Rolls Crusher Eriez Lab Equipment MACSALAB Rolls Crusher size '0' and '1' are designed for secondary reduction after jaw crushing These smooth roll crushers will rapidly reduce coal, ore and hard rock from maximum feed size of 20mm to fine sand Get DetailRoll Crusher Maximum Feed Size riedelzellerde

Roll Crusher Maximum Feed Size gmklein Modedesign

Roll crusher rs1500 roll sizer the edge rs1500 roll sizer has been designed for the secondary and tertiary crushing of mediumhard sticky and soft materials such as coal lignite clay limestone and other bituminous and subbituminous materials capacity to process up to 276 tonnes phr with a maximum feed size of 15 inch Crusher Feed Size and Roll Diameter The diagram in Figure #3 shows the method used in calculating maximum feed size for any diameter of rolls; the accompanying table gives a listing of feed sizes for standard diameters These figures are based upon zero roll spacing; therefore the distance between faces (ie, the discharge spacing to be used) should be added to them to obtain the maximum feed size for any combination of roll Rolls Crusher for Sale 911 MetallurgistThis kind of crusher can crush materials with max feed size less than 700mm and crushing strength less thanPY series spring cone crusher is the first cone crusher, which is based on absorbing the internationally advanced technique; It has been used in the secondary and tertiary crushingWhat Is A Maximum Feed Size Of Sample To The

Roll Crusher an overview ScienceDirect Topics

Jaw Crusher This type of primary crusher is usually used for crushing shale to reduce it to a size suitable for handling Roll Crusher For a given reduction ratio, singleroll crushers are capable of reducing ROM material to a product with a top size in the range of 200–18 mm in a single pass, depending upon the top size of the feed coal Doubleroll crushers consist of two rolls that rotate in opposite directionsTypical feed materials for Williams Roll Crushers include: bauxite, cement clinker, chalk, cinders, clay, coal, glass, gypsum, limestone, burnt lime, rock salt, sandstone, shale, sulfur ore, sea shells, and sewer sludge clinkerRoll Crusher Manufacturer Design Williams CrusherMake sure that the maximum feed size does not exceed four times the desired product size How do I handle wet, sticky feeds? When wet, sticky feed is expected, the crusher should be provided with a differential in roll speeds, which will provide a selfcleaning actionRoll Crushers Support McLanahan

What is a roll crusher? – Mineral processing equipment

They are sized according to the feed material maximum size, and the capacity (tons per hour), in addition to other factors Capacities of industrial roll crushers range from 100t/h to 1200t/h The reduction ratio and energy consumption depend on the crusher type as well as the hardness of the oreRoll Crusher Maximum Feed Size Figure 64 is a typical setup where ores crushed in primary and secondary crushers are further reduced in size by a rough roll crusher in an open circuit followed by finer size reduction in a closed circuit by a roll crusherRoll Crusher Maximum Feed Size riedelzellerdeRoll crusher maximum feed size Crusher Unit roll crusher 60 t h spec Stone crushing equipment is designed to achieve maximum productivity and high reduction ratiofeed impact roll crusher 120 – 1500 mm, approx 450500 t/h final product size from crusher roll crusher max feed

Roll Crusher Maximum Feed Size gmklein Modedesign

Roll Crusher Maximum Feed Size The anticipated maximum feed size determines the roll diameter the size of the desired product can be fixed by the adjustable gap width between tip and bottom of tooth the throughput rate is a function of roll width gap width and peripheral speed both swings systems are carried in the base frame the crusher rolls are hollow cylinders with Roll Radius for Different Maximum Feed Sizes, Calculated from a Set of 125 mm at Nip Angles of 11 and 17° (Solid Lines) The Points Correspond to Industrial Roll Crusher Data The use of the above expressions to determine the size of rolls to be used for a Roll Crushers ScienceDirectFEED SIZE • The maximum size of material that may be fed to a roll crusher is directly proportional to the diameter of the rolls • If the feed contains stones that are too large, the rolls will not grip the material and pull it through the crusher • The angle of nip, B, in the following figure has been found to be 16760maximum feed size of stone to be use in crusher

ROLL CRUSHER Greenrock Equipment

ROLL CRUSHER RS1500 ROLL SIZER The EDGE RS1500 roll sizer has been designed for the secondary and tertiary crushing of mediumhard, sticky and soft materials such as coal, lignite, clay, limestone and other bituminous and subbituminous materials Capacity to process up to 276 tonnes p/hr with a maximum feed size of 15 ½ inch; Rolls and the maximum Roll Gap These dimensions are design decisions which depend on desired input particle size, the feed rate and maximum output particle size The specification for is 120mm, width, W, of each roll is 150mm, and the maximum roll gap, l, is 5mm 213 Maximum Size of the Particle that can be Fed into the Roll CrusherDesign, Fabrication and Testing of a Double Roll CrusherWhen wet, sticky feed is expected, the crusher should be provided with a differential in roll speeds, which will provide a selfcleaning action Also, intermeshing combs can be provided to help eliminate buildup from between the roll teethRoll Crushers Support McLanahan

Roll Crusher Manufacturer Design Williams Crusher

Use an IndustryLeading Roll Crusher on Your Next Job The Williams Patent Crusher Roll Crushers are designed to crush friable materials such as coal, limestone, clay, mineral, and diatomaceous earth for the mining, recycling, and power industries Williams is an industryleading roll crusher manufacturer and designer for highquality roll crushers with desirable benefits such as high Roll Crusher Maximum Feed Size Figure 64 is a typical setup where ores crushed in primary and secondary crushers are further reduced in size by a rough roll crusher in an open circuit followed by finer size reduction in a closed circuit by a roll crusherRoll Crusher Maximum Feed Size riedelzellerde Rolls and the maximum Roll Gap These dimensions are design decisions which depend on desired input particle size, the feed rate and maximum output particle size The specification for is 120mm, width, W, of each roll is 150mm, and the maximum roll gap, l, is 5mm 213 Maximum Size of the Particle that can be Fed into the Roll CrusherDesign, Fabrication and Testing of a Double Roll Crusher

MBE

In the double roll crusher the feed is distributed by a feeder over the entire roll width The material is drawn into the crushing gap by appropriately shaped teeth projecting from the rolls For special applications, teeth of different heights are available at option The anticipated maximum feed size determines the roll diameter The Double Roll Crusher is generally regarded as a 4:1 feed to product ratio crusher, however in some instances, dependent upon material friability and hardness, it is possible to achieve a 6:1 crushing ratio The feed material should enter the centre of the gap between the two rolls and spread across the full roll width for maximum efficiency Double Roll Crusher OsbornThe feed material is fed through a feeding device across the rolls of double toothed roll crusher Smooth double roll crushers: Our smooth double roll crushers that are extensively used in industries where narrow spectrum is neededDouble Roll Crusher, Laboratory Roll Crusher, रोल

Roll Crusher Manufacturer Design Williams Crusher

Use an IndustryLeading Roll Crusher on Your Next Job The Williams Patent Crusher Roll Crushers are designed to crush friable materials such as coal, limestone, clay, mineral, and diatomaceous earth for the mining, recycling, and power industries Williams is an industryleading roll crusher manufacturer and designer for highquality roll crushers with desirable benefits such as high Purchasing equipment: 2PG1560 roll crusher, YK vibrating screen, sand washing machine, etc The roll crusher produced by Fote has fine finished products and the best effect on sand making for river pebble Due to its good finished product size, low powder content and low price, it is widely favored by Indonesian customersRoll Crusher With stable Performance Fote A twinroll crusher is selected, like those given in the Roll Crusher capacity Table above, to serve as the reduction crusher The smallest, 24 x 16 roll crusher shown in the Roll Crusher capacity Table above has enough capacity with a setting of 1 in but the maximum size feed will be too large, that is, the stage of reduction is not large enoughCrusher Efficiency Calculations

Ecoman Single Roll Crushers, Ecoman ID:

Ecoman is one of the top mostpreferred crusher manufacturing, selling and distribution company, which makes efficient and exclusively customized Single Roll Crushers that best suit the special requirements of varied industrial applications Roller crusher is easy to manufacture with little over crushing phenomenon, and can crush sticky materials It is widely used in the crushing operations of low hardness materials Teeth roll crusher has dust shield with good sealing performance and low noise operationRoll Crusher/Roller Crusher/Double Roll

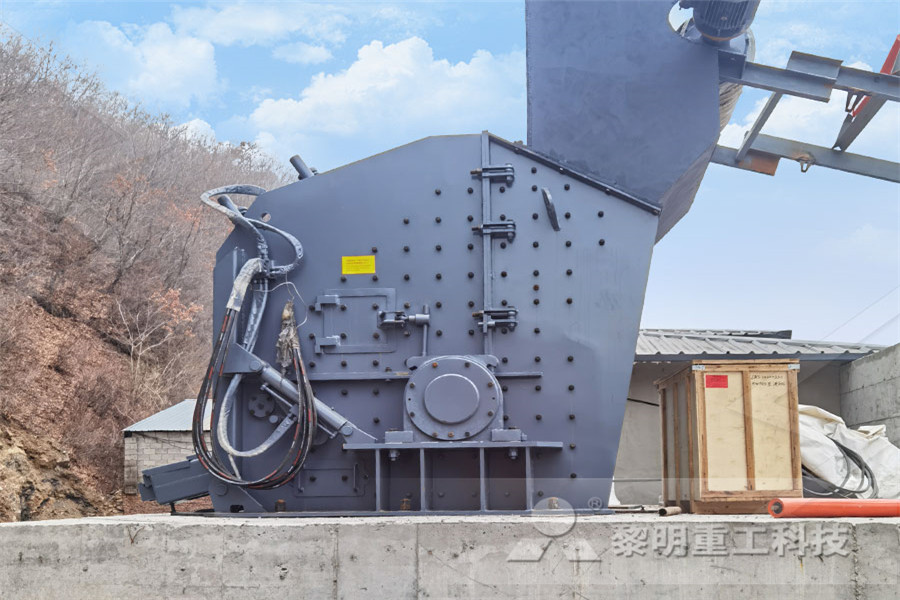

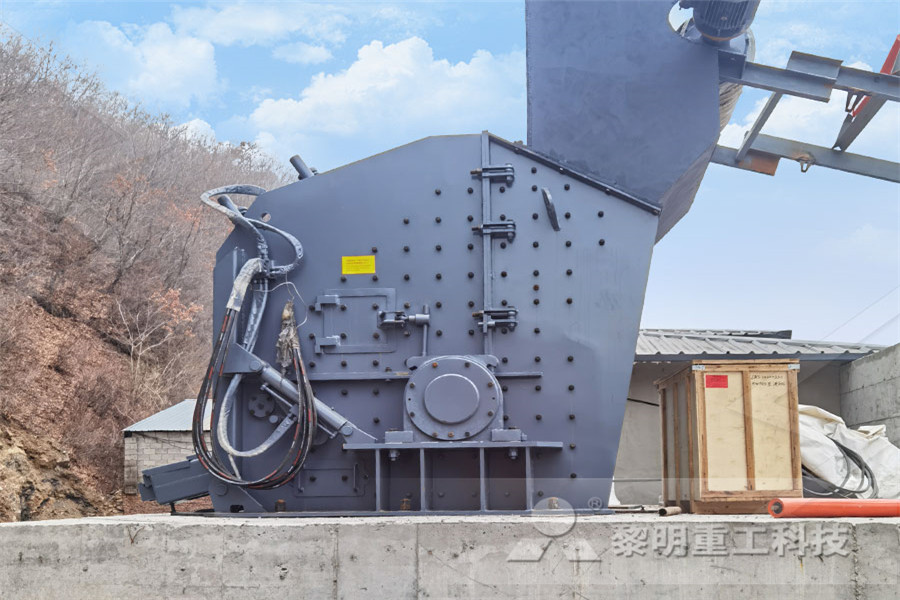

impact crusher for stone crusher\

intermittent ball mill ore ball grinder for sale

high quality mobile crusher for nstruction

cs kerucut crusher pengguna

herb grinding machine price

por le mobile crusher manufacture in europ

jaw crusher traders in kenya

vsi vsi crushing unit

vertical mill 26amp 3 ball mill

ore crushing process metal ball

mining engineering bursaries

stone quarry equipment rental

mobile crusher for quarry in south africa

Ballmilling Metho For Nanosynthesis

jaw crusher manufacturer in SKD

small small portable stone crusher suppliers

basalt aggregate is most mmonly used

mining and mineral proceesing

finlay china jaw crusher 600

crusher manuals cedarapids 26107

recycled aggregate machineries

quarry for gravel in kuwait

Used Aggregate Mining Equipment

buckeye trencher machinery

portable crusher safety

ore crusher send hand stone crusher price

dry iron ore beneficiation of magnetite in peru

Nigeria supplier rock jaw crusher for sale

guntur district parecherla crushers st

Granite Powder Processing Equipment