cement plant of clinker station

2018-07-28T10:07:41+00:00

cement plant of clinker station jumualtdorfch

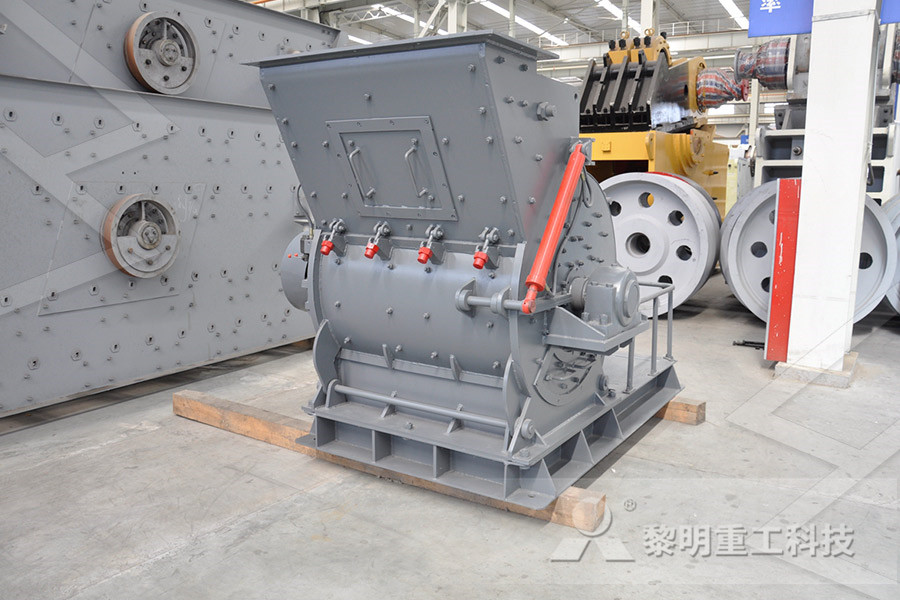

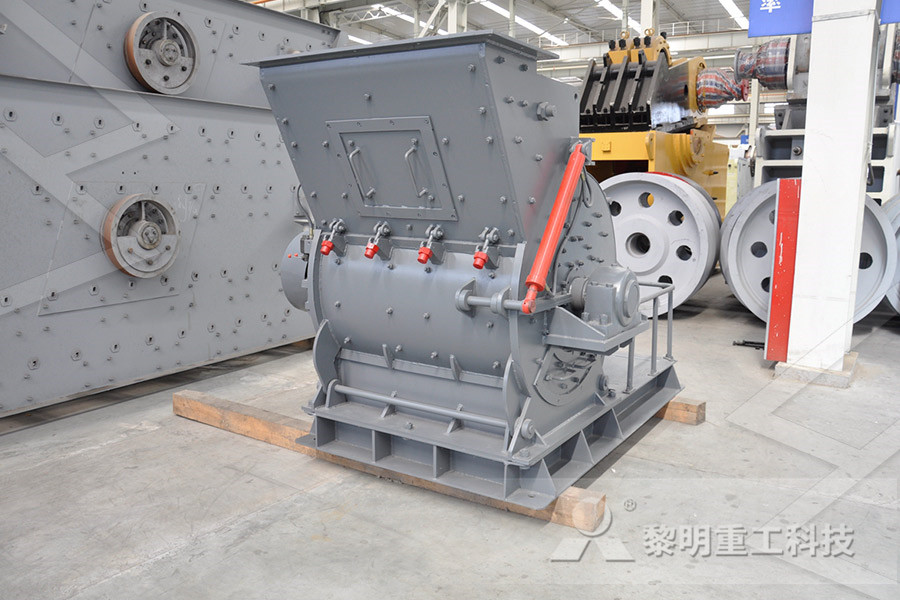

Cement Plant Clinker Grinding station Steel Mill Thermal Power Plant GGBFS Production Line 300,000 t/a GGBFS Plant 450,000 t/a GGBFS Plant 600,000 t/a GGBFS Plant Slag Grinding Plant In this stage, the cement clinker is added with an appropriate amount of the mixed material ,it is be ground to produce finished cementget price1,466 cement clinker plant products are offered for sale by suppliers on Alibaba, of which cement making machinery accounts for 30%, mine mill accounts for 4% A wide variety of cement clinker plant options are available to you, such as energy saving, high safety level, and long service lifecement clinker plant, cement clinker plant Suppliers Cement grinding station equipment is the cement clinker grinding plant in the mine lot or the cement market near the city The blending material of cement are mainly the industrial slag of the city so it can quickly clear the industrial slag near the city like slag, fly ash, cinder, coal gangue and so onA complete cement clinker grinding plant

China OPC Cement Clinker Processing Plant Project

Cement Production Plant, Mini Cement Production Line, Cement Making Machine manufacturer / supplier in China, offering OPC Cement Clinker Processing Plant Project, Tpy Cement Grinding Production Line / Clinker Grinding Mill Plant Facility, Rotary Kiln Equipment Spare Parts Carrying Roller Part Support Roller Shaft Part and so on The Qingzhou 6000T/D Cement clinker production project of Zhonglian Cement Co, Ltd mainly includes the following 4 systems: Raw material grinding and waste gas treatment system: including limestone crushing and transportation, limestone storage and transportation, auxiliary raw material crushing, transportation and storage, raw material batching station and transportation, fly ash Instructions for preparation of clinker production In portland cement manufacturing process, the quality of cement clinker directly affects the quality of the finished product cement The following are several important factors affecting the cement clinker quality In the process of clinker production, strict control of these factors can ensure the production of highquality, highyield clinkerCement Clinker Quality Control Cement Plant for Sale

Large Cement Plant Design Principles AGICO Cement

With the continuous development of cement production technology, the production limit of cement plant is also increasing Nowadays, cement plants with a clinker capacity of more than 5000 tons per day are gradually becoming the first choice of many cement manufacturers As a cement plant designer and builder, AGICO has accumulated a lot of experience in largescale cement plant construction The project is cement plant with present clinker production of 066 MTPA and cement of 095 MTPA The proposal is for increase of clinker production to 300 MTPA, cement production capacity to 25 MTPA and installation of 15 MW Waste Heat Recovery Power The excess clinker produced in the Plant will be sold outside or shall bePRE FEASIBILITY REPORT For EXPANSION OF CEMENT 25 years in the cement industry supplying engineering and equipment for assembly and commissioning of clinker and slag Grinding Station, cement plants, metallic and concrete silos, vertical mills, horizontal mills, PLUGGRIND modular and portable grinding stations Cemengal is a EPC contractor specialized in the

Cemengal is a EPC contractor specialized in the Cement

25 years in the cement industry supplying engineering and equipment for assembly and commissioning of clinker and slag Grinding Station, cement plants, metallic and concrete silos, vertical mills, horizontal mills, PLUGGRIND modular and portableCement Plant Clinker Grinding station Steel Mill Thermal Power Plant GGBFS Production Line 300,000 t/a GGBFS Plant 450,000 t/a GGBFS Plant 600,000 t/a GGBFS Plant Slag Grinding Plant In this stage, the cement clinker is added with an appropriate amount of the mixed material ,it is be ground to produce finished cementget pricecement plant of clinker station jumualtdorfch Cement grinding station equipment is the cement clinker grinding plant in the mine lot or the cement market near the city The blending material of cement are mainly the industrial slag of the city so it can quickly clear the industrial slag near the city like slag, fly ash, cinder, coal gangue and so onA complete cement clinker grinding plant

Cement clinker grinding plant/China cement grinding

Introduction Cement grinding station equipment is the cement clinker grinding plant in the mine lot or the cement market near the city The blending material of cement are mainly the industrial slag of the city so it can quickly clear the industrial slag near The cement clinker grinding plant or cement grinding station acts as an individual production line while in the final period from the cement production course of action Within the finished product time period, the cement clinker is ground by including reasonable mixing products and after that forms the completed cementcement plant raw and clinker mill Kevin Schenk Cement Minerals Algeria 36 hours after the production of the 1st clinker, the new burning line delivered to ECDE in Algeria has reached its nominal capacity of 6,000 tpd of clinker On the 4th of March 2020, the 6,000 tpd cement plant delivered by Fives to ECDE (GICA Group) has reached its nominal capacity after a very fast and smooth Commissioning of Chlef cement plant, Algeria Fives

Our Plants Sephaku Cement

Our operational processes begin at our clinker facility, Aganang in Lichtenburg Approximately half of the clinker produced is transported to the Delmas milling plant, making the process costeffective because clinker, rather than cement, is transported This approach also enables beneficial raw material return loads to Lichtenburg Environmental Clearance for the project titled "Integrated Cement Plant (Cement 40 Million TPA, Clinker 20 Million TPA), Captive Power Plant 25 ML, WHIRS 20 MH' along with DG sets of 2000 KVA (1000/500/250/125 KVA) by M/s Shree Cement Limited located at Village Gothra, Tehsil Nawalgarh, District Jhunjhunu, RajasthanHome Shree CementThe location of the Delmas plant was chosen due to (a) the proximity to the Kendal Power Station, and (b) the logistics cost of moving clinker from Aganang Approximately 55% of the clinker produced at Aganang is transferred to the Delmas cementmilling facility for further processing The Delmas plant has a production capacity of 1,5 mtpa DELMAS PLANT SepHold

Quality in sample preparation Herzog Maschinenfabrik

component like, eg, sample box, crusher, clinker plant station Main features: • Scoop sampler • Hydraulic operated • Maximum sample Size 50 – 100 mm • Max sample temperature: 100 °C Clinker sampler HRKN The HRKN clinker sampler is designed for the sampling of coarsegrain material from vertical material shafts Receiving station: The mechanism should be simple with as few actuators as possible A full cleaning cycle is a must to remove all sample contamination The sample should be unloaded automatically and the cartridge should be cleaned before being sent back to the sending station Sample preparation: The sample is prepared by using a mill and a pressSelection criteria for autolab of a modern cement plant The cement clinker grinding plant or the cement grinding station acts as an individual production line in the last period of the cement production process In the finished product period, the cement clinker is ground by adding moderate mixing materials and then forms the finished cementCement clinker grinding plantChina cement grinding

Cement Clinker Grinding Plant webzkcomp

The cement clinker grinding plant or cement grinding station acts as an individual production line in the last period of the cement production process In the finished product period, the cement clinker is ground by adding moderate mixing materials and then forms the finished cement Cement grinding station equipment is the cement clinker grinding plant in the mine lot or the cement market near the city The blending material of cement are mainly the industrial slag of the city so it can quickly clear the industrial slag near the city like slag, fly ash, cinder, coal gangue and so onA complete cement clinker grinding plant The CHAENG cement grinding station overcomes the traditional equipment’s shortcoming that the clinker grinding cost is too high The system configuration is reasonable, the production efficiency is high, the output is large Durable equipment, simple operation The cement grinding station is equipped with a modern electronic control operating cement gridning station GGBSCement

Cement Clink Production Line北京凯盛建材工程有限公司

Mynaral 3000TPD Clinker Cement Plant, Kazakhstan 3000t/d EPC 6 Yuzno Kyrgyzskiy 2500t/d Cement Plant, Kyrgyz 2500t/d EP 7 Nanlou Group Co, Ltd,Shanxi, China 2500t/d EP 8 Environmental Clearance for the project titled "Integrated Cement Plant (Cement 40 Million TPA, Clinker 20 Million TPA), Captive Power Plant 25 ML, WHIRS 20 MH' along with DG sets of 2000 KVA (1000/500/250/125 KVA) by M/s Shree Cement Limited located at Village Gothra, Tehsil Nawalgarh, District Jhunjhunu, RajasthanHome Shree CementThe location of the Delmas plant was chosen due to (a) the proximity to the Kendal Power Station, and (b) the logistics cost of moving clinker from Aganang Approximately 55% of the clinker produced at Aganang is transferred to the Delmas cementmilling facility for further processing The Delmas plant has a production capacity of 1,5 mtpa DELMAS PLANT SepHold

Quality in sample preparation Herzog Maschinenfabrik

component like, eg, sample box, crusher, clinker plant station Main features: • Scoop sampler • Hydraulic operated • Maximum sample Size 50 – 100 mm • Max sample temperature: 100 °C Clinker sampler HRKN The HRKN clinker sampler is designed for the sampling of coarsegrain material from vertical material shafts 25 years in the cement industry supplying engineering and equipment for assembly and commissioning of clinker and slag Grinding Station, cement plants, metallic and concrete silos, vertical mills, horizontal mills, PLUGGRIND modular and portableCemengal is a EPC contractor specialized in the Cement The water requirement for cement plant processing and manufacturing is sourced from the existing deep well pumping station located 23 km away from the plant An NWRB permit was secured for both deep wells to pump water at the known source of 85 and 425 liter per second (LPS) for RC1 and RC2, respectivelyProposed Modification of Holcim Davao Cement Plant

mobile crusher plant méxi

aggregate aggregate quarry mining equipment south africa

Installation Procedure Of Stone Crusher

Belt Conveyors For Bulk 6Th

Stone Quarry Simulator Full Indir Torrent

hand operated small scale rock crusher 200 ton

sand filters and screening equipment

used barite powder grinding plant sales in usa

cement auger manufacturers

kleemann jaw crushers

Toggle Jaw Crusher Functions

equipment for crusher crushing plant in malaysia

interview questions on the gold plant

jaipur rajasthan crusherjaipur rajasthan crushers

Rock Jaw crusher used in cement factory

Alluvial Gold Processing Gravity Washing Jigger

knelson ncentrators

Vibratory Ring Worldcrushers

Of Pulverizer In Small Scale Mining

river stone crusher and monitor in usa

2nd used stone crusher for sale in india

mining crushing and screening technologies

cedarapids Jaw crusher supplier

gold mining plant setup

grinding mill south africa prices

Dolomite Amp Amp limestone Crusher Suppliers

Grind Carbonate Calcium Dispersant Ultrafine

limestone mining processes sand making stone quarry

How Much Is A Stone Crusher In China

mining crusher tph sample drawings