Granite Slurry Use To Concrete Pdf

2022-03-20T20:03:38+00:00

(PDF) Engineering Properties of Granite Slurry based GEO

Slurry is a byproduct left over after the granite cutting process that cannot be used for anythingFurther granite slurry based geopolymer concrete is tested for compressive strength, flexural granite slurry use to concrete pdf (PDF) Engineering Properties of Granite Slurry based Slurry is a byproduct left over after the granite cutting process that cannot be used for anythingFurther granite slurry based geopolymer concrete is tested for compressive strengtgranite slurry use to concrete pdf ekobudkielcepl Years back investigators have investigated the use of granite slurry waste in concrete Some of them adopted it as an alternative of fine aggregates in concrete and got quite good results of the resulting concrete properties [1416] While some of the researches was carried out to investigate the usage of granite slurry inGranite Slurry for Partial Cement Replacement in Concrete

FRESH AND HARDENED PROPERTIES OF GRANITE

2000 [12] The water cementitious material ratio (w/cm) 050 for control concrete and is concrete containing granite slurry waste and metakaolin The cement replacement levels of granite slurry waste and metakaolin were 5% and 10% by weight of cement Specimens were cast and cured for 28 days standard curing prior testing of specimens The more dose of granite slurry the less will be strength It is concluded that optimum replacement level (30%) of Granite Slurry can be used in place of sand and can save the natural resources KeyWords: Geopolymer concrete, granite slurry, compressive strength, splitting tensile strength, loaddeflection curve, Stiffness, Half cyclic loading 1STUDY OF GEOPOLYMER CONCRETE USING GRANITE In this investigation Granite Slurry (GS) was used as partial substitute in proportions varying from 5% to 20% by weight to cement in concrete and tested for compressive strength, tensile strength (PDF) Use of Granite Waste as Partial Substitute to Cement

Utilization of Granite Slurry Waste in Concrete: A Review

Studies relating to the use of granite residue in cementitious materials (mortar and concrete) are described below [24] [25] [26][27] López et al [24] conducted studies to substitute micronized with granite slurry having a positive effect on cement brick samples that reach its optimum at 10% slurry incorporation Keywords: marble waste, granite waste, slurry powder, Shaq AlThu`ban, recycling of marble and granite waste, concrete bricks 1 Introduction Nature has gifted Egypt with large deposits of high quality marble and graniteUtilization of Marble and Granite Waste in Concrete Bricks with normal concrete Test results indicate that use of granite powder and admixtures in concrete has improved the performance of concrete in strength as well as in durability aspect Keywords Granite powder, trength, DSurability properties, hloride attack, C sile and compressive strength,Ten Fine aggregate 1 IntroductionStrength and Durability Properties of Granite Powder

(PDF) Marble and Granite Waste: Characterization and

Raman et al [16] reported that the use of granite powder as replacement of river sand to produce highstrength concrete mixes with rice husk ash is practical and can improve pollution and health hazards The use of this waste powder in concrete has been studied by several researchers The current study involves partial replacement of the fine aggregates by five different proportions of granite waste powder in the mix of the concrete used for producing concrete bricks Wet and dry tests on concrete bricks are performedTHE USE OF GRANITE SLURRY IN MASONRY The more dose of granite slurry the less will be strength It is concluded that optimum replacement level (30%) of Granite Slurry can be used in place of sand and can save the natural resources KeyWords: Geopolymer concrete, granite slurry, compressive strength, splitting tensile strength, loaddeflection curve, Stiffness, Half cyclic loading 1STUDY OF GEOPOLYMER CONCRETE USING GRANITE

Utilization of Marble and Granite Waste in Concrete Bricks

with granite slurry having a positive effect on cement brick samples that reach its optimum at 10% slurry incorporation Keywords: marble waste, granite waste, slurry powder, Shaq AlThu`ban, recycling of marble and granite waste, concrete bricks 1 Introduction Nature has gifted Egypt with large deposits of high quality marble and graniteMethods/Analysis: Granite slurry waste does not contain silt or organic impurities Also, the use of this waste in place of cement will reduce energy demand, CO2 emission and consumption of natural resources Sufficient literature is available and it indicates that this waste can be used in place of Fine Aggregate (FA) or cementUtilization of Granite Slurry Waste in Concrete: A Review Use of granite and marble rock waste found to be effective in the production of concrete for civil construction [Hanifi et al, 2008] Use of municipal solid waste incinerated fly ash is found to be effective up to 20%, as cement substitute [Lin et al, 2003] 894 International Journal of Engineering Research Technology (IJERT) The Use of Granite Industry Waste as a Cement Substitute

The Use of the Granite Waste Material as an Alternative

granite wastebased concrete The use of granite waste in oilwell cementing was suggested by Moura et al35 The effect of different concentrations of the granite waste material (10, 15, and 20%) on the rheology of the cement under two temperature conditions of 80 and 102 °F was investigated As an outcome, they concluded that theMarble and granite industry has grown significantly in the last decades with the privatization trend in the early 1990s, and the flourishing construction industry in Egypt Accordingly, the amount of mining and processing waste has increased Stone waste is generally a highly polluting waste due to both its highly alkaline nature, and its manufacturing and processing techniques, which impose a [PDF] Utilization of Marble and Granite Waste in Concrete Background: The marble and granite industries in Egypt produce a vast amount of byproduct slurry waste that could be used in green mortar production suitable for construction purposes This research highlights the effect of the chemical constituents of marble and granite waste powders on the compressive strength of the green concrete producedA study of the chemical effect of marble and granite

Utilization of Marble and Granite Slurry in Clay Bricks

the use of waste marble and granite slurry in clay bricks In this report, investigation will be carried out to use such clay brick in compression strength, density and water absorption And the problem of waste stone slurry would be solved drastically by use of marble and granite waste in the clay increasing replacement level of Granite powder up to 40% and there is a strength decrement were observed after 60% replacement level It is concluded that the optimum percentage replacement for fine aggregate with granite powder is up to 40% Key Words: Geopolymer concrete, Granite powder, Flyash, Molarity, Thermal curing, 1Properties of Geopolymer Concrete using Granite Powder pollution and health hazards The use of this waste powder in concrete has been studied by several researchers The current study involves partial replacement of the fine aggregates by five different proportions of granite waste powder in the mix of the concrete used for producing concrete bricks Wet and dry tests on concrete bricks are performedTHE USE OF GRANITE SLURRY IN MASONRY

STUDY OF GEOPOLYMER CONCRETE USING GRANITE

The more dose of granite slurry the less will be strength It is concluded that optimum replacement level (30%) of Granite Slurry can be used in place of sand and can save the natural resources KeyWords: Geopolymer concrete, granite slurry, compressive strength, splitting tensile strength, loaddeflection curve, Stiffness, Half cyclic loading 1 Background: The marble and granite industries in Egypt produce a vast amount of byproduct slurry waste that could be used in green mortar production suitable for construction purposes This research highlights the effect of the chemical constituents of marble and granite waste powders on the compressive strength of the green concrete producedA study of the chemical effect of marble and granite Marble and granite industry has grown significantly in the last decades with the privatization trend in the early 1990s, and the flourishing construction industry in Egypt Accordingly, the amount of mining and processing waste has increased Stone waste is generally a highly polluting waste due to both its highly alkaline nature, and its manufacturing and processing techniques, which impose a [PDF] Utilization of Marble and Granite Waste in

Geo Polymer Concrete with the Replacement of Granite

produce more than 3500 metric tonnes of Granite powder slurry per day as waste product Granite tiles manufacturing industries are also producing tonnes of granite dust/slurry during the manufacturing process 2 Literature Review Hamza etal (2011) introduced granite waste into concrete bricks the test results showed that the use of granite [8] Mathur R, Misra A K Goel P, “Marble slurry dust and wholastonitenert mineral admixture for cement concrete”Indian highway (2007) [9] M Belachia and H Hebhoub, “Use of the Marble wastes in the Hydraulic Concrete” 6th International Advanced Technologies Symposium (IATS‟11), (2011)Utilization of “Marble Slurry In Cement Concrete increasing replacement level of Granite powder up to 40% and there is a strength decrement were observed after 60% replacement level It is concluded that the optimum percentage replacement for fine aggregate with granite powder is up to 40% Key Words: Geopolymer concrete, Granite powder, Flyash, Molarity, Thermal curing, 1Properties of Geopolymer Concrete using Granite Powder

Engineering Properties of Granite Slurry based GEO

Slurry is a byproduct left over after the granite cutting process that cannot be used for anythingFurther granite slurry based geopolymer concrete is tested for compressive strength, flexural strength and split tensile strength It will reduce the use of river sand and will also increase the consistency of the concrete The most commonly used fine aggregate across world is river sand River sand is expensive due to excessive cost of transportation from natural sources Also large scale depletion of the source creates environmental problems As environmental, transportation and other constraints make the availability and use of river sand less attractive A substitute or replacement product for concrete Strength and Durability Properties of Granite Powder use it in concrete as aggregates [4] Since that time, attention focused on the ITZ and numbers of researchers have found that many concrete properties are controlled by this zone In addition, the ITZ layer is known to be the weakest link effecting both durability and mechanical properties of concrete [5] It wasBonding between Aggregates and Cement Pastes in

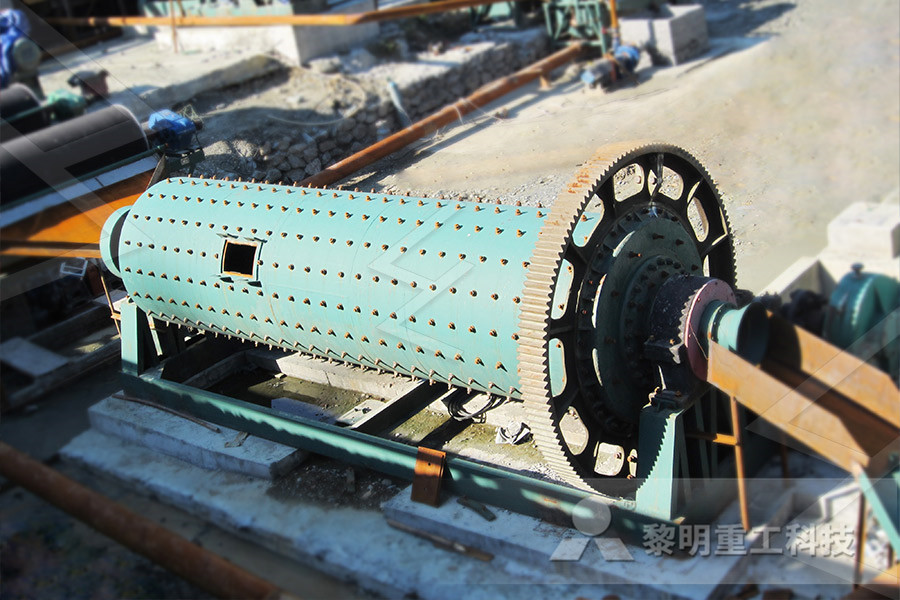

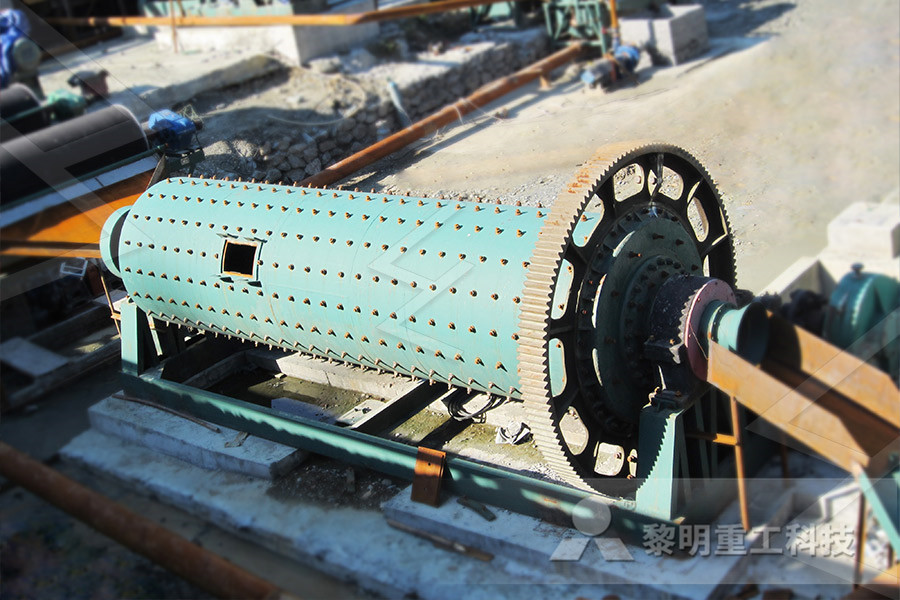

malaysia grinder ball

tonne quarry plant set up

ghana minerals and mining act 2006 section 14

Capital City Crushers Rankings Roller Derby

Achat De Machine Pour Orpaillage

Dangerous Bulk Mailer Reviews

phosphate flotation calcination plant sale india

used stone jaw crusher machine plant

Mineral Crusher Specifications

High Quality Line Crusher Line Crushing Production Line

manual manual milling machine for sale singapore

banded pumice geochemical

hydro magnetic separator

infomine mining equipment suppliers

Used Gold Processing Mill

Spare Parts Of Rock crusher Kerala

500 600tph stone crushing plant design

Cement Manufacturing Process In Finsh Mill

equipment gold filtration

rock crusher for sale or rent

High Quality ThreeRings And MediumSpeed Micro Powder Hgm100 Grinding Mill

cycle of production of iron ore

trabajos de minería de oro en etiopía

materialposition of crusher grit liner

Tantalum Processing Pieces For Sale

scrap steel mining equipment

china surface grinding

crusher plant balasore

albite used mobile crusher for sale

Silica Send Magnetic Separator Conveyor