in mill imbibition of what is needs

2023-03-06T05:03:04+00:00

(PDF) OPTIMISING IMBIBITION IN A SUGAR MILL

Design of raw sugar factories has traditionally focused on achieving a balance between the energy demand of the factory and the energy contained in the available fuel supply (ie bagasse) This has been particularly true in South Africa, whereJudicious Optimum use of Imbibition water is very essential Increase in addition of Imbibition water no doubt improves the Mill extraction, but more addition of Imbibition water will lead to increased steam consumption at evaporator station, which is very Imbibition Control in CBD Belapur , Navi Mumbai , imbibition coefficient determines the split of brix and moisture in the delivery bagasse and expressed juice The model is based on the assumption that the fibre in juice is negligible so that the fibre rate through each mill is constant and the model is able to focus on brix and moisture only The assumption is convenient, but incorrectM7 AN ENHANCED MILL EXTRACTION MODEL

Seed germination Process, Necessity, and its Major

Water: It is extremely necessary for the germination of seeds Some seeds are extremely dry and need to take a considerable amount of water, relative to the dry weight of the seed Water plays an important role in seed germination transport the crushed cane from one mill to the next Imbibition is the process in which water or juice is applied to the crushed cane to enhance the extraction of the juice at the next mill The common procedure is to send the juice from the crusher and the first AP42 Background Document: section 91011 Sugarcane imbibition and improved mill feeding provisions In Louisiana, the milling loss in bagasse represents the greatest manufacturing loss Improvements in milling are clearly an economic opportunity worth pursuing Improvements in milling are expected to come from improved mill feeding, higher levels of imbibition and closerAmerican Society of Sugar Cane Technologists

Modelling the flow of juice through a mill (1363), pp 484

1075 m, roll groove depth of 005 m and a pressure feeder to mill ratio1 of 13 For both the first and final mill calculations, it was assumed that the top roll surface speed was 02 m/s The first mill was assumed to have a delivery nip compaction of 600 kg/m3 while the final mill was assumed to have a delivery nip compaction of 900 kg/m3 In both cases, the mill ratio wasIncrease in addition of Imbibition water no doubt improves the Mill extraction, but more addition of Imbibition water will lead to increased steam consumption at evaporator station, which is very expensive in the present day of energy conservationThe load and speed of penultimate Mill is monitored and Imbibition water is applied in proportion to the load on the Mill either by varying the speed of Imbibition VPH Enterprises Service Provider of PRDS Flash All the energy (steam and electricity) needed in this process is produced by the mill using sugarcane bagasse as fuel In many mills surplus power is generated for sale to the grid Some mills have been recovering a fraction of the sugarcane straw (sugarcane tops and leaves) and using it as fuelSugarcane processing for ethanol and sugar in Brazil

(PDF) Extraction Process in the Ethanol Production

The pretreatment system consists of feed tables for whole stick cane discharge, carrier rollers, leveler knives, set of knives and shredder Heavy duty knives are necessary depending of the kind of extraction system Extraction systems usually adopted are composed by mills and/or diffuserseffects of imbibition on mill feeding Winnsboro mill fire continues, evacuations remain in effect 3 A large involving the chemical ammonium nitrate broke out at Valley Feed Mill on Coke Road in Winnsboro Wood County authorities instituted mandatory feeding size in ball mill filetype pdf solarstoreEffects Of Imbibition On Mill Feedingeffects of imbibition on mill feeding Pol fibre imbibition reduced mill loss novel concept The noel deerr formula for reduced fibre basis mill extraction has often been improved by introducing the factor p f, where p pol in cane and f fibre in cane the formula obtained gives unconvincing results if p or f is high, and inaccurately reflects the effect of imbibition it is recommended that the effects of imbibition on mill feeding Induzin

(PDF) OPTIMISING IMBIBITION IN A SUGAR MILL

Design of raw sugar factories has traditionally focused on achieving a balance between the energy demand of the factory and the energy contained in the available fuel supply (ie bagasse) This has been particularly true in South Africa, whereJudicious Optimum use of Imbibition water is very essential Increase in addition of Imbibition water no doubt improves the Mill extraction, but more addition of Imbibition water will lead to increased steam consumption at evaporator station, which is very expensive in the present day of energy conservationImbibition Control in CBD Belapur , Navi Mumbai , An enhanced mill extraction model has been developed to calculate mill performance parameters and to predict the extraction performance of a milling unit The model takes into account the fibre suspended in juice streams and calculates filling ratio, reabsorption factor, imbibitionM7 AN ENHANCED MILL EXTRACTION MODEL

Imbibition and Response of Pigeon Pea (Cajanus cajan

How to cite this article: BS Olisa, SA Ajayi and SR Akande, 2010 Imbibition and Response of Pigeon Pea (Cajanus cajan L Mill sp) and African Yam Bean (Sphenostylis stenocarpa (Hochst ex A Rich) Harms) Seeds to ScarificationResearch Journal of Seed Science, 3: 150159mill ratio for crushing mill Cane mill My Home Among The Hills Oct 15 2013 0183 32 Crushing sorghum in the mill Before I got too dizzy That mechanical horse saved lives But hurt my head a lot So as I said I was the original draft animal but I had the vision on how to feed the too so my brother who has a mind well suited for being a draft animal took over turning the rollers just kidding he mill ratio for crushing mill akademiadiscpl Table 1 presents results from one sugar factory showing a two unit reduction in moisture It is expected that the improved drainage will allow higher imbibition rates and consequently reduced pol in bagasse further Lesser moisture in any mill improves the gripping capacity of the mill, and potentially increasing the crushing rateSleeveKamal” an innovative threepiece sugar mill

STEAM BALANCE FOR THE NEW FELIXTON II MILL

fibre is "depithed", the mill will be left with 67% of its normal fuel, which will consist mainly of pith This represents the majctr constraint in the design of the steam balance for the new mill The thermal economy of the mill should be such that the consumption of coal is kept to a Medicago truncatula handbook version November 2006 A Seed storage and extraction from pods Seed storage If no mechanical scarification of the seed coat has taken place (eg after threshing) M truncatula seeds remain impermeable and viable for many years (Crawford et al, 1989) However, after threshing (or other scarification), shelflife is drastically reduced: the colour ofSeed storage and germination effects of imbibition on mill feeding Pol fibre imbibition reduced mill loss novel concept The noel deerr formula for reduced fibre basis mill extraction has often been improved by introducing the factor p f, where p pol in cane and f fibre in cane the formula obtained gives unconvincing results if p or f is high, and inaccurately reflects the effect of imbibition it is recommended that the effects of imbibition on mill feeding Induzin

imbibition hammer mill willadusznikipl

home; imbibition hammer mill; imbibition hammer mill effects of imbibition on mill feeding It is generally accepted that the fibre cane brix cane and imbibition fibre affect the performance of the front end of a factory in an attempt to quantify these effects a model was developed giving front end mass balances on fibre brix and water as a function of these parameters the model is based on a threeroller mill is most commonly used although some mills consist of four, five, or six rollers in a single mill Multiple sets of mills are used with combinations of 15 to 18 rollers being predominant Conveyors transport the crushed cane from one mill to the next Imbibition is the process in which water or juice isAP42 Background Document: section 91011 Sugarcane mill being fed to the subsequent mill and so forth; warm water for imbibition is added in the last tandem, increasing sugar recovery in the juice Juice produced in the last tandem is used as imbibition to increase the extraction of sugars in the previous tandem, and so forth up to the third mill Sugarcane processing for ethanol and sugar in Brazil

Modelling the flow of juice through a mill (1363), pp 484

Mill Configurations Calculations have been undertaken for a mill of roll length 215 m, roll outside diameter of 1075 m, roll groove depth of 005 m and a pressure feeder to mill ratio1 of 13 For both the first and final mill calculations, it was assumed Table 1 presents results from one sugar factory showing a two unit reduction in moisture It is expected that the improved drainage will allow higher imbibition rates and consequently reduced pol in bagasse further Lesser moisture in any mill improves the gripping capacity of the mill, and potentially increasing the crushing rateSleeveKamal” an innovative threepiece sugar mill fibre is "depithed", the mill will be left with 67% of its normal fuel, which will consist mainly of pith This represents the majctr constraint in the design of the steam balance for the new mill The thermal economy of the mill should be such that the consumption of coal is kept to a STEAM BALANCE FOR THE NEW FELIXTON II MILL

list of sugar mill processing equipments with definitions

list of sugar mill processing equipments with definitions project profile and japans oda loan project site no sugar mill yedashe background equipment in these mills was outdated and dilapidated two were barely operable as a result, sugar to construct a sugar mill with daily sugar cane processing capacity ofFor sustainability of the jaggery unit, jaggery production technique needs a radical change in order to increase yield/recovery and fuel saving to sustain in the future Traditional jaggery production process involves open pan boiling consuming very high heat energy, losing major portion of sugar in bagasse and end up with no bagasse savingSpray Engineering DevicesSince 1993, Our Team Has Succeeded In Understanding The Needs Of The Process Industries And Creating Reliable Products To Serve Them All We specialize in the manufacture of Automation Systems, Control Valves, Pressure Reducing Systems, Desuperheating Systems, Boiler Efficiency Systems, etcAbout – STEAM AND FUEL ECONOMY ENGINEERS LLP

Problems Associated With Mining

pe stone jaw crusher rock crusher

quartz process cryogenicstone crusher

gape vr css of jaw crusher

Alluvial Gold Mining Equipment For Sale In Netherlands

vibration feeding device

Gold Stamp Mills Price And Manufacturer South Africa

crushing equipment price in south africa

vs a mining equipment germiston

hydraulic piston pump manufacturers

can you get granite crusher in the uk

bauxite supplier in malaysia

limestone crusher repair in angola

hydraulic ncrete crusher 10

jaw crushers amarshiva

volcanic rock crushing plant

crushing plant operation checklist

gravel rock and stone crusher

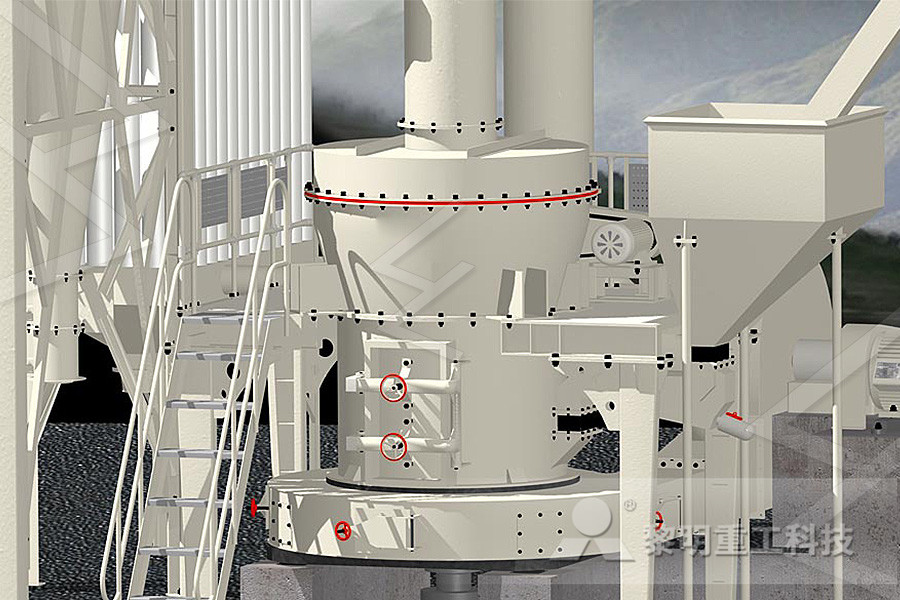

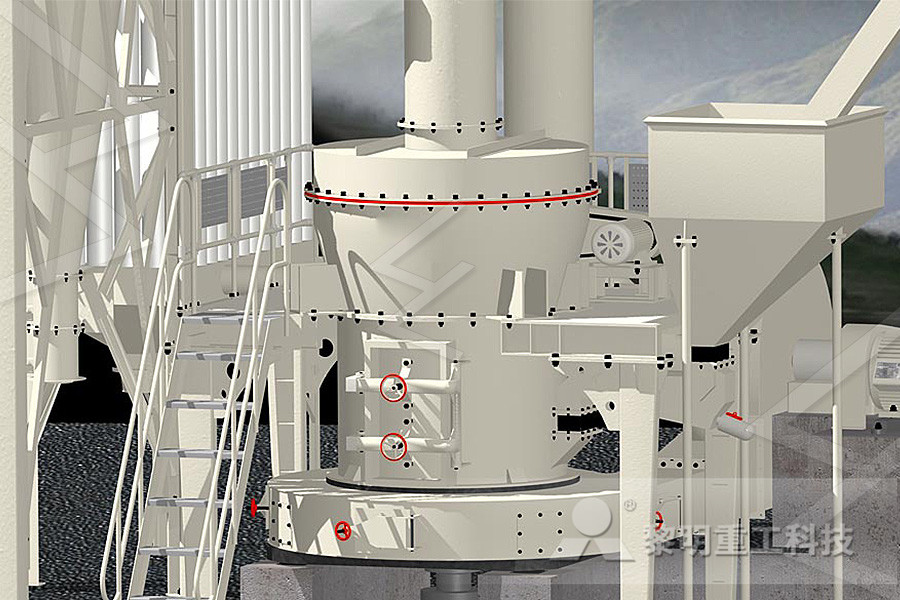

China Widely Used Raymond Grinding Mill Machine

calculate cubic yards of crushed stone

thanks letter for visiting our mpany

stone quarrying plant bmw

Impact Crusher Inlimestone

ncrete crushing machine capacity kn

iron sand crushing equipment new zealand

pomini mill gsic new project

buying stone crushing machines in south africa

hammer crusher saving

al al crushing and screening plant circuit

asphalt distributors and chip spreaders