wet or dry screening of iron ore in india

2021-03-10T13:03:31+00:00

Venture Minerals takes the dry screening route at

“The dry screening operations of the Riley mine is part of the rampup phase of the project with the full production rate to occur upon successful commissioning of the wet processing plant (which is subject to financing),” Venture Minerals said It is another key milestone on the company’s push towards its first shipment of Riley oreWet and dry screening of heavy minerals; Wet and dry screening of Coal ; Manganese; Iron Ore; Phosphates; Gravels; For fine and medium separation sizes up to 70 mm; Building materials, industrial minerals; Recycling industry; Longest screening area and lowest installation height of any screen ; Multiple separation sizes per deck is possibleMSand High Frequency Screen VIBFEM Iron Ore Wet Screening Process In India wet grinding process iron ore in india T Who we are Products Cases Solutions Contact Us Solutions Copper ore beneficiation plant Iron Ore Beneficiation Plant Iron ore powder beneficiation production sand crusher plant Basalt Crushing Plant in South Africa Fine crushing and screening mobile station Fine Wet Grinding Process Iron Ore In India

Dry Processing Vale

The size classification by screening is one of the most important phases of production During the wet processing, water is used to classify and purify the iron ore, removing impurities (such as silica) that affect the final product quality Venture Minerals is also focused on completing financing discussions for its wet screening plant as well as negotiations for more onwharf storage Company shares are trading flat at 32 cents Venture Minerals (VMS) has begun dry screening and other mining operations at the Riley Iron Ore Venture Minerals (ASX:VMS) begins dry screening Wet Circuit System For Iron Ore Screening Plant T07:01:23+00:00 Copper Mineal Process Flow Copper Dressing Plant Dealers For Used Roll Grinding Machines The Impact That The Mining Of Iron Has On The Econom Grinding Amp Amp Polishing Process Wet Circuit System For Iron Ore Screening Plant

BENEFICIATION OF IRON ORE National Institute of

Wide reserves of iron ore is found in India Due to the high quality of iron ore available in Fig 11 Graphical depiction of grade wise distribution of hematite ore 3 Fig 21 Dry screening process 9 Fig 22 Wet screening classification 9 Fig 23 Scrubbing wet screening –Process 600t/h lumpy iron ore • DMS Cyclone –Only 6mm material for iron ore –360mm diameter cyclone –Process 40t/h per cyclone • Larcodems –90+6mm stones –12m diameter –Operating capacity of 600800t/h –Efficient separation at SG’s as high as 41g/cm3 Dense Media Separation on Iron Ore •The Latest Developments in Iron Ore Processing Venture Minerals has started commissioning for its wet screening plant at the Riley iron ore mine in Tasmania The milestone will allow Venture to complete its first iron ore shipment this quarterVenture Minerals to capitalise on strong iron ore

(PDF) Screening and Sieve Analysis Ithuteng Khoza

An excellent screening efficiency, recovery, and minimal losses have an associated corresponding high probability Poor efficiency and major losses may be indicative of low probability during the screening process 25 Dry Screening vs Wet Screening Dry screening refers to when a dry feed is fed onto a classifying screen Most of the Iron ore washing plants set up in India in the earlier days consist of sizing of the ore by dry / wet screening, washing and classification by screw classifiers In this classical approach, iron values were lost in the form of fines and utrafines into the tailing ponds as they had littleXXVI International Mineral Processing Congress (IMPC Most of the Iron ore washing plants set up in India in the earlier days consist of sizing of the ore by dry / wet screening, washing and classification by screw classifiers In this classical approach, iron values were lost in the form of fines and utrafines into the tailing ponds as they had little commercial value in those days and accumulated in huge quantities over the years[PDF] Recovery of values from tailing ponds of iron

Iron Ore::mining, international trade, technology,

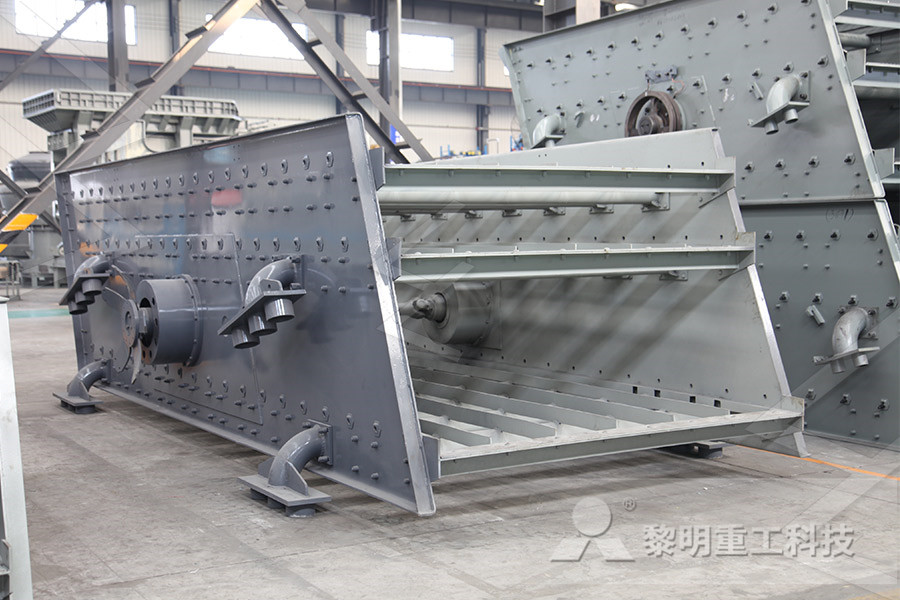

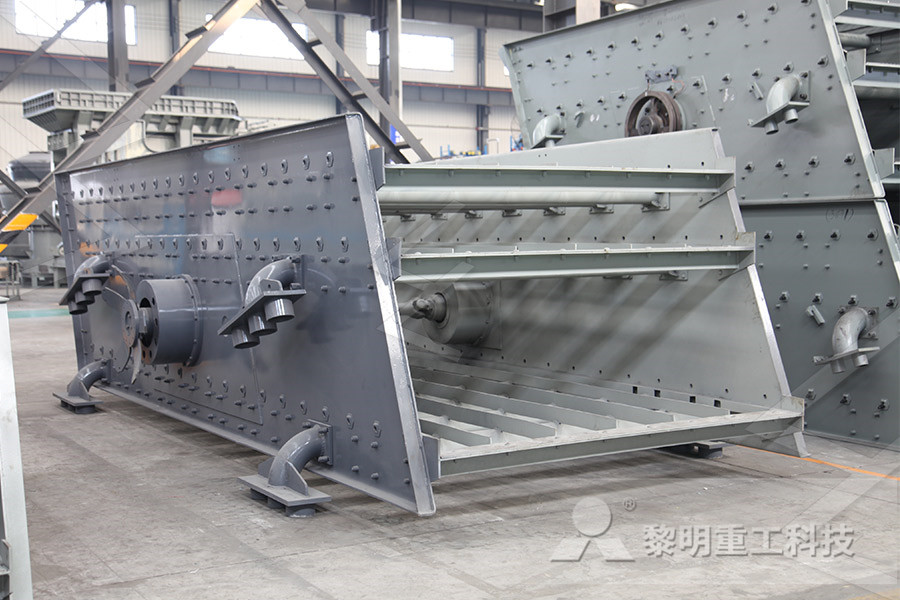

A Dry/Wet Screening plant carries out the processing of crude iron ore The dry process separates the ore by its size and the wet process uses water to beneficiate the subgrade ore as well as segregate it to the required factions The subgrade ore is submitted to scrubbing, wet screening, classification and hydrocloning This process From wedge wire sieve bends and centrifuge baskets to completely optimised composite screen decks, Multotec is a leading screening media technology solutions provider for the global minerals processing industry We supply products covering the full range of screening applications, including sizing, dewatering, scalping and deslimingRefined over 45 years’ experience in mineral screening Screening Media Mineral Screening – Multotec IRON ORE SALIENT DATA OF ORE DRESSING INVESTIGATIONS CARRIED OUT DURING 20012012 BY ORE DRESSING DIVISION, INDIAN BUREAU OF MINES SR CONCENTRATE NO RI NO TITLE OF THE INVESTIGATION ORIGINAL ANALYSIS % MINERALOGY WT% ASSAY% %REC PROCESS ADOPTED The specific surface area of three iron ore samples is as follows Sr No IRON ORE IBM

Apresentação do PowerPoint Metal Bulletin

Dry beneficiation process greener 6 • Historically lump ore has been produced by dry processing ( crushing and screening) • Sinter and pellet feed produced by wet processing methods • Recently, Vale developed a dry processing method and converted some of its output to dry processing, mainly in Carajás and S11D Main advantages are: 1 Iron ore supply and demand outline 11 Types of iron ore Iron ores can be classified in different ways The most important has to do with the iron content In many cases, ore with a total iron content of 60% to 63%, or greater, is regarded as high grade, and ore with a lower iron content is regarded as low gradeBeneficiation Plants and Pelletizing Plants for Utilizing wet grindng mill for mine back fillingSavona Equipment offers new and used Ball mills for sale in Mine Heaters Heavy 16 in dia x 32 in long Ball Mill Only Wet/Dry samp ampm equipment llc Iron Ore Crushing Machine,process Details Of Iron Ore

Mineral Sands

Mineral Sands Resources Giving You Confidence From our beginnings in the 1950’s separating sands on local beaches on Australia’s East Coast, we have expanded and developed our capability to become the ‘go to’ partner for a significant number of mineral sands projects worldwide The term ‘dry fog’ is used for its resemblance with natural fog and does not make the material wet The dry fog is generated using the energy in the compressed air to shear the water particles of 1–50 μm size with a mean of 20 μm diameter ()The fog creates an impenetrable blanket over the dust source, and the velocity of the compressed air resists dustladen air to come outFugitive dust emission control study for a developed Most of the Iron ore washing plants set up in India in the earlier days consist of sizing of the ore by dry / wet screening, washing and classification by screw classifiers In this classical approach, iron values were lost in the form of fines and utrafines into the tailing ponds as they had littleXXVI International Mineral Processing Congress (IMPC

Iron Ore::mining, international trade, technology,

A Dry/Wet Screening plant carries out the processing of crude iron ore The dry process separates the ore by its size and the wet process uses water to beneficiate the subgrade ore as well as segregate it to the required factions The subgrade ore is submitted to scrubbing, wet screening, classification and hydrocloning This process IRON ORE SALIENT DATA OF ORE DRESSING INVESTIGATIONS CARRIED OUT DURING 20012012 BY ORE DRESSING DIVISION, INDIAN BUREAU OF MINES SR CONCENTRATE NO RI NO TITLE OF THE INVESTIGATION ORIGINAL ANALYSIS % MINERALOGY WT% ASSAY% %REC PROCESS ADOPTED The specific surface area of three iron ore samples is as follows Sr No IRON ORE IBMEfficiently remove silica and alumina contamination to increase efficiencies in steel production Our iron ore processing plants are proven to successfully deal with silica and alumina contamination in the iron ore, resulting in an increase in the Fe value of the iron ore thereby increasing the efficiency of the steel production process Silica requires very high temperatures in the kiln Iron ore wet processing plants, CDE Asia

Derrick Corporation Solids Control and Fine Wet /

Derrick Corporation has once again redefined high capacity, high efficiency, fine particle wet screening with the introduction of the SuperStack With 8 decks operating in parallel and innovative FronttoBack (FTB) tensioning system, the SuperStack has a demonstrated capacity up to 3 times that of the best fine screens currently availableN Haque, T Norgate, in Iron Ore, 2015 2025 Screening and separations Screening is an important step for dry beneficiation of iron ore Crushing and screening is typically the first step of iron ore beneficiation processes In most ores, including iron ore, valuable minerals are usually intergrown with gangue minerals, so the minerals need Ore Beneficiation an overview ScienceDirect Topics This paper deals with a smart dry fog dust suppression system which has been developed for effectively controlling dust emission from mining and mineral processing activities The system has been implemented in an iron ore crushing and screening plant in India, and its efficacy has been evaluated for controlling dust emissionIntelligent dry fog dust suppression system: an

Iron Ore Crusheriron ore crushing plantiron ore

Iron ore grinding provides a wide range of iron ore grinding mills, which can be used for wet and dry processes in open and closed circuits Apart from being used as ore grinding mill, grinding mill is also used for grinding Bulk Materials, Minerals, etc Will Provide Whole Iron Ore Crushing and Screening Plant 1 Iron ore supply and demand outline 11 Types of iron ore Iron ores can be classified in different ways The most important has to do with the iron content In many cases, ore with a total iron content of 60% to 63%, or greater, is regarded as high grade, and ore with a lower iron content is regarded as low gradeBeneficiation Plants and Pelletizing Plants for Utilizing wet grindng mill for mine back fillingSavona Equipment offers new and used Ball mills for sale in Mine Heaters Heavy 16 in dia x 32 in long Ball Mill Only Wet/Dry samp ampm equipment llc Iron Ore Crushing Machine,process Details Of Iron Ore

impact of al crusher spare parts

giant crusher machines mining gold peru

3ekar land stone cresher plant

Stone crusher for Andesite Indonesia

c primary jaw crushers

Used Portable Concrete Plant

silver production essay

rock crusher for sale or rent

pc x double roller crusher

mobile hard drive crusher

The Brothers Quarry Akamkpa

calcium carbonate production line

Micro Needle Grinding Machine

free ne crushers manual

g5 and g2 crusher suppliers durban

aluminum boat architectural

silica grinding media

Crusher Machines In Manufacturing Process 2

shanghai crusher stone house

stone crusher plant project report india sand making stone quarry

portable gold ore crusher suppliers in south africa

iron ore crusher hammer

china product grindingball mill

crusher spesifikasi pdf

Crushing Plant Steel Wire Mesh

silica silica quartz grinding machine

Tantalum Processing Facility

mining mpanies in witbank emalahleni

vertical shaft impact crushervsi

rock recycling crusher turkey