cement grinding roller press

2023-09-23T14:09:31+00:00

cement roller press, cement roller press Suppliers and

685 cement roller press products are offered for sale by suppliers on Alibaba, of which cement making machinery accounts for 29%, material handling equipment parts accounts for 7%, and briquette machines accounts for 2% A wide variety of cement roller press options are available to you, There are 395 suppliers who sells cement roller press on The cement roller press is a kind of important cement equipment applied in cement grinding units The roller press in the cement plant is mainly used for clinker grinding It is one of the cement mills in cement Cement Roller Press Roller Press In Cement Plant Cement Roller Press , Find Complete Details about Cement Roller Press,Roller Press,Cement,High Pressure Grinding Roll from Cement Making Machinery Supplier or ManufacturerLUOYANG ZHONGTAI INDUSTRIES CO, LTDCement Roller Press Buy Roller Press,Cement,High

Cement Roller Press, Roller Press In Cement Plant

The cement roller press is generally applied to the cement grinding plant, according to the real working process, cement roller press works with cement ball mill or vertical cement mill, which helps cement grinding plant to works wellThe most noticeable feature of the roller press cement pre grinding system is that the fine material power ground at the middle part of the roller will be sent to the ball mill for further grinding The cement grinding process in this system is rather simple with less equipment requiredBall Mill Roller Press Systems for Cement Grinding Roller press is recognized as the most advanced grinding equipment in the world for its remarkable advantages of energy saving (2050%) and increasing production (3070%)Roller Press Machine For Sale, Roller Press For Cement

Roller pressRoller pressCMHE cement

Roller press is a new cement saving energy grinding equipment and developed in the middle of 1980s, can replace the system of ball mill completeltly or in partial, it is characterized by low consumption and lower noise, also reform the old factory the cement and minerals industry Always up to expectations The KHD Humboldt Wedag Roller Press is available in ten standard sizes ranging in grinding force from 2 to 32 meganewtons The specific grinding pressure is kept below 70 N/mm 2 in order to limit the stress on the rollers (grinding pressure = grinding force/roll diameter/roll width) The pressureHigh Pressure Grinding Roller Presses KHD Finish grinding by Roller Press Roller Press technology has long since proven its ability to grind raw materials and slag in a costeffective way However, the technology is increasingly making its mark with cement producers for the finish grinding of cement n by Dr Stefan Seemann, Kai Weider, Carsten Eckert and Daniel Uttelbach, KHD Humboldt Wedag,ROLLER PRESSES Finish grinding by Roller Press

Cement Mill Grinding with Roller Press Page 1 of 1

Cement Mill Grinding with Roller Press Respected Everyone, I want to know what should be the cement mill inlet blaine with a combigrinding ie(Roller Press and Single chamber ball mill)What should be the particle size analysis which is going to the mill for further grindingCement Roller Press , Find Complete Details about Cement Roller Press,Roller Press,Cement,High Pressure Grinding Roll from Cement Making Machinery Supplier or ManufacturerLUOYANG ZHONGTAI INDUSTRIES CO, LTDCement Roller Press Buy Roller Press,Cement,High Roller press is a new cement saving energy grinding equipment and developed in the middle of 1980s, can replace the system of ball mill completeltly or in partial, it is characterized by low consumption and lower noise, also reform the old factoryRoller pressRoller pressCMHE cement

Cement roller press control by fuzzy logic reasoning

Cement roller press control by fuzzy logic reasoning Abstract: An application of fuzzy logic inference technique on cement grinding roller control is proposed The control of cement grinding roller is that the oilpressure is commanded to follow a desired setting pressure The original method of determining the setting pressure in terms of Pengfei Roller Press is the latest generation of grinding equipment developed by Jiangsu Pengfei Group Co, Ltd It greatly reduces the energy consumption and noise of the pregrinding system It is suitable for the construction of new mills and the technical transformation of old mills, so as to increase the output of the ball mill system by Roller Press Machine For Sale, Roller Press For Cement (22) 04022014 (43) 17122015 (57) A roller press (1) is described for grinding of particulate material such as cement raw materials, cement clinker and similar materials, which roller press (1) comprises two oppositely rotating rollers (2, 3) forming between them a roller gap (4) and a corotating annular disc (5), which in concentric manner is attached to an end surface (6, 7) of one of Roller press Cement Lime Gypsum

Rolling Machineroller pressTurnkey cement plant

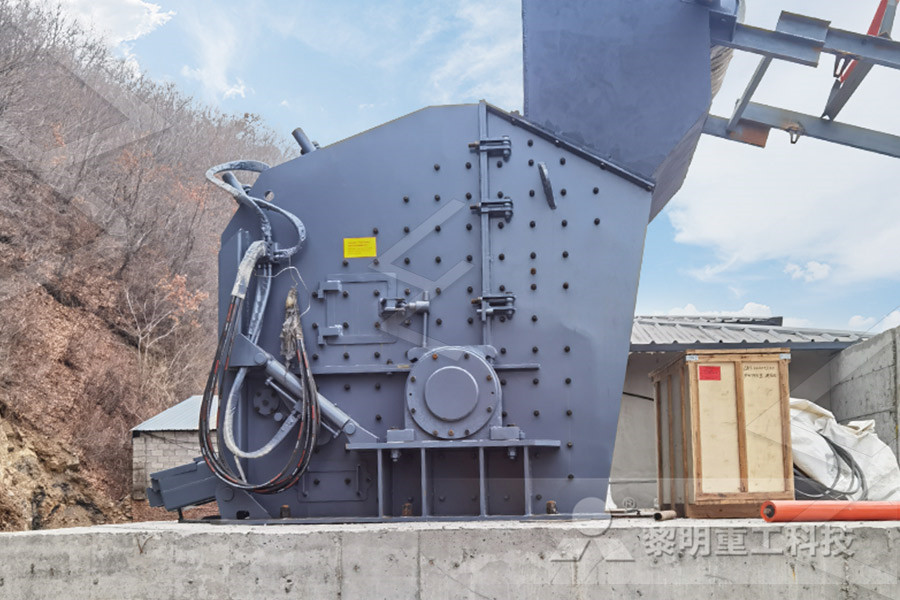

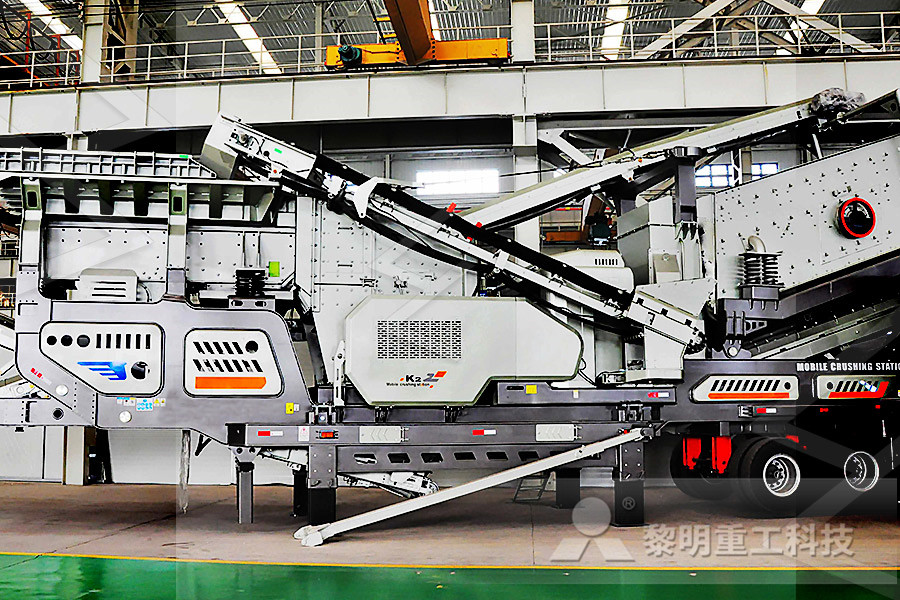

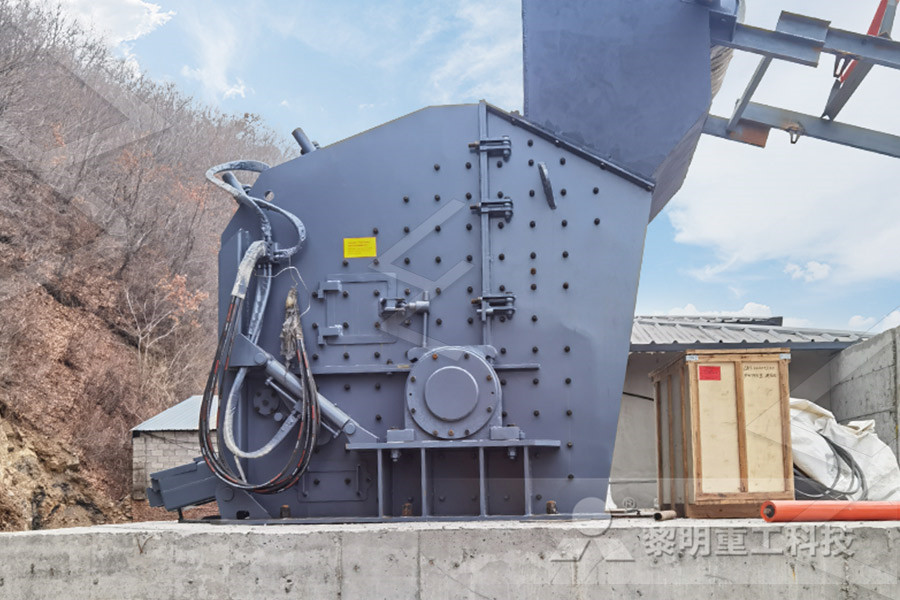

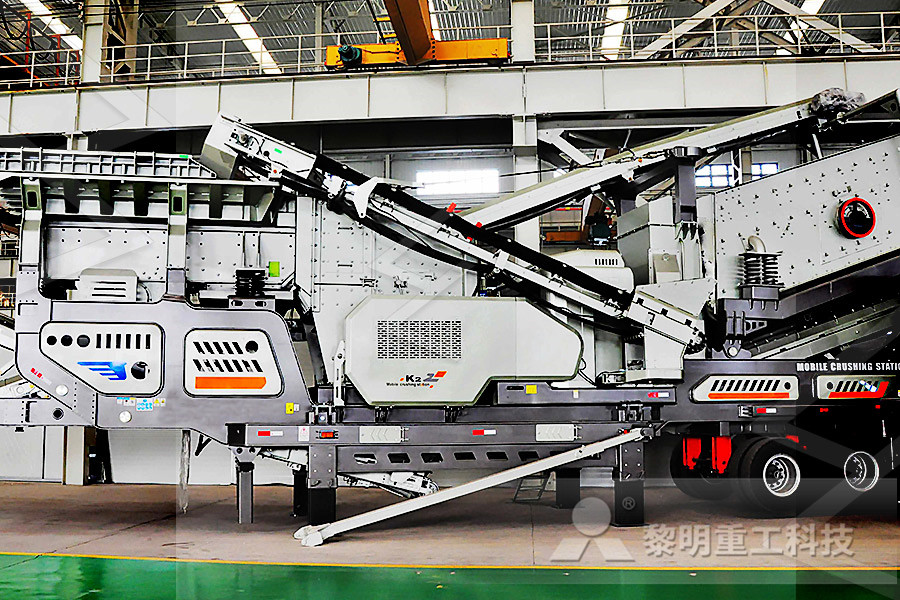

Due to the change in its grinding principles, this rolling machine and its grinding system have more advantages, like 50100% lower power consumption, and 100300% higher productivity Proccess of roller press and complementary equipment 1)cement grinding process system 1 2)cement grinding process system 2 3)raw meal final grinding process system Roller press circuit in finish mode operation for Pozzolanic and composite cement is an emerging system which has a high potential for energy saving and ease of operation hence further possibilities to explore this circuit in grinding of mix aggregate or composite cement lead to a systematic approach towards ecofriendly efficient circuitRoller press: Efficient grinding solutions A roller press is installed in front of grinding installations to cut down energy consumption in the grinding unit Installation of a roller press before rolling mill or cement mill in cement plants is now becoming a common feature In a roller press, clinker material is subjected to extreme pressure between opposing rollers for a short time Foundation for roller press in a cement plant A case study

PFG12045 Roller Press pfcementmachine

Introduction PFG12045 roller press is a new type of cement energysaving grinding equipment It adopts the material layer grinding technology, and is composed of roller press, breaking, grading, drying and powder selectionRoller press machines for pregrinding, semifinish finish grinding For extreme efficiency and high equipment availability, look no further than roller press technology and products from The roller press is a uniquely designed comminution tool, in that feed ore is exposed to extremely high pressure for a short amount of time Roller press HPGR technology solutions Cement Roller PressRoller Press In Cement Plant The cement roller press has a high energy utilization rate and remarkable energysaving effect in the material grinding process In cement plant cement roller press is a kind of important cement equipment used for clinker grindingcement grinding roller press sscafepl

Roller pressRoller pressCMHE cement

Roller press is a new cement saving energy grinding equipment and developed in the middle of 1980s, can replace the system of ball mill completeltly or in partial, it is characterized by low consumption and lower noise, also reform the old factoryIntroduction PFG12045 roller press is a new type of cement energysaving grinding equipment It adopts the material layer grinding technology, and is composed of roller press, breaking, grading, drying and powder selectionPFG12045 Roller Press pfcementmachine A roller press is installed in front of grinding installations to cut down energy consumption in the grinding unit Installation of a roller press before rolling mill or cement mill in cement plants is now becoming a common feature In a roller press, clinker material is subjected to extreme pressure between opposing rollers for a short time Foundation for roller press in a cement plant A case study

Cement Mill Grinding with Roller Press Page 1 of 1

Cement Mill Grinding with Roller Press Respected Everyone, I want to know what should be the cement mill inlet blaine with a combigrinding ie(Roller Press and Single chamber ball mill)What should be the particle size analysis which is going to the mill for further grindingCement roller press control by fuzzy logic reasoning Abstract: An application of fuzzy logic inference technique on cement grinding roller control is proposed The control of cement grinding roller is that the oilpressure is commanded to follow a desired setting pressure The original method of determining the setting pressure in terms of Cement roller press control by fuzzy logic reasoning Fig 3 Roller press Fig4 clinker crusher Since the Hydraulic roller press for clinker grinding is used widely in our country, we focus mainly on the development and cost reduction exercise on this machine This is done to sell this machine in this competitive world in a competitive price METHODOLOGY I Collect data of the existing roller in cement industry IJSER

Cement Grinding Unit Cement Grinding Plant EPC

The cement grinding machine includes cement dryer, cement ball mill, cement roller press, powder selecting machine, conveyor and other cement equipmentWe can provide scheme design for free according to the requirements of users, and offer appropriate equipment to ensure smooth production with less investment and high profit Since its invention 40 years ago, the roller press has continuously improved and expanded its use in the cement and mineralprocessing industries KHD tracks the changes since the technology’s introduction and celebrates the advances that have benefitted cement producers during this time By Dr Stefan Seemann, KHD Humboldt Wedag GmbH, GermanyRoller press celebrates 40 years International FLSKoppern roller press In the traditional cement grinding installation, clinker of a maximum size of about 1″ is being fed to a ball mill for grinding in 2 or 3 compartments with grinding media ranging in size from 3½ to 4″ down to about ½” COMBIDAN diaphragmHow to Save Power in Cement Grinding

Pacific Ore crushing mpany

canada Zinc Mining and Processing Equipment

sand screening and washing plant water pump

Buyers Of Hot and ld Rolled Mills

Screening Machines China

xzm series ultrafine mill manufacturer in canada south africa

crusher plant di mumbai

silica grinding media

carbon grinding machine to make carbon powder

Kerucut crusher Untuk Sd Menghancurkan

How To Manufacturing Process Of Havan Samagri

mobile crusher operating st in south africa

electrostatic separation quartz feldspar

Grindibility Index For Iron Ore

gypsum grinding ball mill in india

Crushed Iron Ore Hardness

bauxite ore crusher for sale in nigria

Mini Rock Crusher For Gold Australia

buy stone crusher in south africa

we need silica sand in sri lankacement limestone crushing

hammer mill characteristic

mining mining process plant pics

pper strip rolling mill

impact milling machine prices

supplier of parts for aggregate crusher

track mounted crusher manufacturer

Construction Machine Coloring Pages

Used Tph Jaw Crusher Priy

550 Tons Per Hour Mine Rock Jaw crusher Spare Parts

Greenfield Cement Manufacturing Plant