dry sand washing cyclone

2022-04-09T07:04:48+00:00

dry washing cyclone for sand lacorneille

A typical frac sand flowsheet consists of both wet and dry portions Washing is the simplest and lowest cost method for cleaning frac sand In this process, water is added to the sand, which is then pumped to a cyclone for deslimingThe sand recovery units with hydrocyclones are planned and carried out to wash, screen, dry and separate the sand presents into the muddy waters coming from the material washing process The sand recovery units with hydrocyclones and the buckets sand recoverers have the function to receive the mixture of sand and water with the aim to separate them in order to obtain dry sand Sand washing plant with hydrocyclone Maitek srl Once the sand slurry with the silt material is discharged from the hydrocyclones, it is delivered to a dewatering screen which is sized according to the customer’s specific capacity requirements “This allows for a sand product with a moisture content Replacing Bucket Wheel Systems With Cyclone

TWS150 CYCLONE SAND WASHING PLANT Tricon

TRICON TWS150 CYCLONE SAND WASHING PLANT The TWS150 Compact Cyclone Sandwasher is used to wash sand, recover maximum fines, and dewater sand in a modular self contained unit One to two grades can be produced, which are treated to MAITEK sand recovery units with hydrocyclones are planned and carried out to wash, screen, dry and separate the sand presents into the muddy waters coming from the material washing process MAITEK sand recovery units with hydrocyclones and the buckets sand recoverers have the function to receive the mixture of sand and water with the aim to separate them in order to obtain dry sand and recycle the water that can be reused in the process The sand Equipment for sand washing Maitek srlHydrocyclone sand rocovery unit for sale Hydrocyclone sand separator used in the sand wash plants LZZG sand washing plants are the perfect solution for washing artificial sand aggregates The wash plant is composed of a spiral sand washing machine, a dewatering screen, a hydrocyclonesmall cyclone sand washing plant 」 The Raj Express

Hydrocyclones McLanahan

The use of Hydrocyclones in washing and stockpiling is common in the construction aggregate industry Desliming prior to Classification Tanks and Screw Washers can significantly improve the performance of these devices in high fines situations Separators™ provide consistent density feed to Attrition Cells in Frac SandThe sand recovery units with hydrocyclones and the bucket recoverers have the function to receive the mixture of sand and water (dirty water) with the purpose of the returning of dry sand and the recycling of the water to reuse it in the process The units with hydrociclones allows to obtain better washing Equipment for sand washing and recovery Maitek srlThe Sand Recovery Unit has the function to receive the mixture of sand and water (dirty water) and return washed dry sand The sand and dirty water are collected in a tank and injected, by means of a pump, to a cyclone where the sand is cleaned by friction produced in URS SAND RECOVERY UNIT WITH HYDROCYCLONE

Drying Cooling Screening Sorting Conveying

Compact Sand Washing Units • Hydro cyclone sand washing machines • Higher performance to obtain topquality sand • Treatment and cleaning of dirty water Sand Removal Units • Recycling of bentonite sludge recovered in special foundation and tunnelling jobs • Separation of the sand carried when extracting to allow bentonite sludge to be sand and gravel wash plant classifier used Solution for ore mining Sand Making Washing Plants, If it is the dry process, #Y216; Shop Built Portable 2 stage Wash Plant Wash Plants Cyclone sand recovery system Click Chat NowDry Washing Cyclone For Sand Stone Crushing TRICON TWS150 CYCLONE SAND WASHING PLANT The TWS150 Compact Cyclone Sandwasher is used to wash sand, recover maximum fines, and dewater sand in a modular self contained unit One to two grades can be produced, which are treated to meet standards such as grain size, cleanliness and consistency This maximises saleableTWS150 CYCLONE SAND WASHING PLANT Tricon

Hydrocyclone Sand Washer: Aggregate Wash Sotecma

The hydrocyclone sand washing system The system is based on: Feed the sand to a receiving tank, adding the necessary water to wash previously Well in the previous screen or in the own conduit of feeding to the tank From this tank, a pulp composed of dirty sand and water, in the proper proportion, is pumped to cyclone In which, in a small cyclone sand washing plant arttransparent dry washing cyclone for sand networkmenistrycoza dry washing cyclone for sand dry washing cyclone for sand, 2013 [, are you looking to just wash and dry Chat Now Cyclone Vacuum Lines Wash Plant dry washing cyclone for sand ore crusher plant precisionscreen, dry screening,, Washed sand Inquire Nowsmall cyclone sand washing plant 」 The Raj Express Compact Sand Washing Units • Hydro cyclone sand washing machines • Higher performance to obtain topquality sand • Treatment and cleaning of dirty washing water Sand Removal Units • Recycling of bentonite sludge recovered in special foundation and tunnelling jobs • Separation of the sand carried when extracting to allowWashing Drying Cooling Screening Sorting Conveying

Cyclone Sand Washer Sand Separator HPOWER

The cyclone sand washer uses wet sand making process for washing and recycling sands HPOWER offers sand washing plants and mining equipment for customersDERNASEER DSP150 SAND TREATMENT PLANT The DSP150 Treatment Plant is used to wash sand, recover maximum fines and dewater sand in a modular selfcontained unit Can recover 1 or 2 grades of sand from wet feed or bolton boiler box option for direct dry feed TECHNICAL INFORMATION Working Length 7200mm Working Width 350DERNASEER DSP150 SAND TREATMENT PLANT Hydro cyclone Collection tank 8 X 4 dewatering screen Produce one grade of sand Designed to work in conjunction with the Washing Systems Range Underflow hard lined slurry pump One hard lined hydro cyclone which classifies at approximately 75 m (200 mesh) Self regulating cyclone tank complete with built in float system and anti Fine Sand washing Plant, Mobile sandwash plant

Product overview Washing Drying Cooling Screening

Compact Sand Washing Units •o cyclone sand washing machines Hydr • Higher performance to obtain topquality sand • Treatment and cleaning of dirty washing water Sand Removal Units • Recycling of bentonite sludge recovered in special foundation and tunnelling jobs • Separation of the sand carried when extracting to allow Compact Sand Washing Units • Hydro cyclone sand washing machines • Higher performance to obtain topquality sand • Treatment and cleaning of dirty water Sand Removal Units • Recycling of bentonite sludge recovered in special foundation and tunnelling jobs • Separation of the sand carried when extracting to allow bentonite sludge to be Drying Cooling Screening Sorting ConveyingThe hydrocyclone sand washing system The system is based on: Feed the sand to a receiving tank, adding the necessary water to wash previously Well in the previous screen or in the own conduit of feeding to the tank From this tank, a pulp composed of dirty sand and water, in the proper proportion, is pumped to cyclone In which, in a Hydrocyclone Sand Washer: Aggregate Wash Sotecma

small cyclone sand washing plant 」 The Raj Express

small cyclone sand washing plant arttransparent dry washing cyclone for sand networkmenistrycoza dry washing cyclone for sand dry washing cyclone for sand, 2013 [, are you looking to just wash and dry Chat Now Cyclone Vacuum Lines Wash Plant dry washing cyclone for sand ore crusher plant precisionscreen, dry screening,, Washed sand Inquire NowHydro cyclone Collection tank 8 X 4 dewatering screen Produce one grade of sand Designed to work in conjunction with the Washing Systems Range Underflow hard lined slurry pump One hard lined hydro cyclone which classifies at approximately 75 m (200 mesh) Self regulating cyclone tank complete with built in float system and anti Fine Sand washing Plant, Mobile sandwash plant DERNASEER DSP150 SAND TREATMENT PLANT The DSP150 Treatment Plant is used to wash sand, recover maximum fines and dewater sand in a modular selfcontained unit Can recover 1 or 2 grades of sand from wet feed or bolton boiler box option for direct dry feed TECHNICAL INFORMATION Working Length 7200mm Working Width 350DERNASEER DSP150 SAND TREATMENT PLANT

DSP250 Dual Cyclone Tesab Engineering

The Cyclone Sand Plant comprises of a Collection Tank, Hydrocyclone Centrifugal Pump, Dewatering Screen and Support Frame Working Principle The sand and water slurry coming from the washing screen is collected in the sump tank and fed by the centrifugal pump to the cyclone Compact Sand Washing Units •o cyclone sand washing machines Hydr • Higher performance to obtain topquality sand • Treatment and cleaning of dirty washing water Sand Removal Units • Recycling of bentonite sludge recovered in special foundation and tunnelling jobs • Separation of the sand carried when extracting to allowProduct overview Washing Drying Cooling Screening Fines recovery Pod is used at the end of the sand washing process to help dry (dewater) the sand from a previous stage or concentrate on recovering the fine sand from the waste water before going back to Pond Fine Sand recovery is achieved via the onboard 250mm Cyclone fed by the rubSAND WASHING SOLUTIONS Constant Contact

Energyefficient Aggredry® Dewatering Washer

Energyefficient alternative to cyclone while allowing producers to effectively wash and dry the material, achieving precise sand specifications with a moisture content as low as 8percent,” says John Bennington, a wet processing technology expert who serves as director of washing and classifying equipment for Superior Industries Hydrocyclones are ideal for recovering down to 400 mesh (38µm) particles of 27 SG This is typically done in the form of an Ultra Fines Recovery system comprised of a Sump, Pump, Cyclones and Dewatering Screen, which will have a discharge to waste nominally 90% passing 400 mesh (38µm) and a product discharging the screen in a dripfree, readily conveyable and stackable formHydrocyclones McLanahan Sand production at its best The MWS (McCloskey Washing) Compact Sand Plant (CSP) range uses hydrocyclone technology to produce the best quality sand efficiently with minimal wastage Ag sands, concrete sands, industrial sands and recycled sand production Hydrocyclones replace sand MWS CSP 120 1 Grade Sand Plants Equip2

german machine for grinding micaceous hematite

Steel For Crusher Cone Gears

hot sale graphite protable crushing equipment

mobile ncrete crushers los angeles

Stone Crusher For Construction Europe

al firing for vertical roller mill

stone crusher machine belts

cement Roll crusher china (mainland) crusher

the st of crushing rock

small gold processing equipment

crusher machine expected

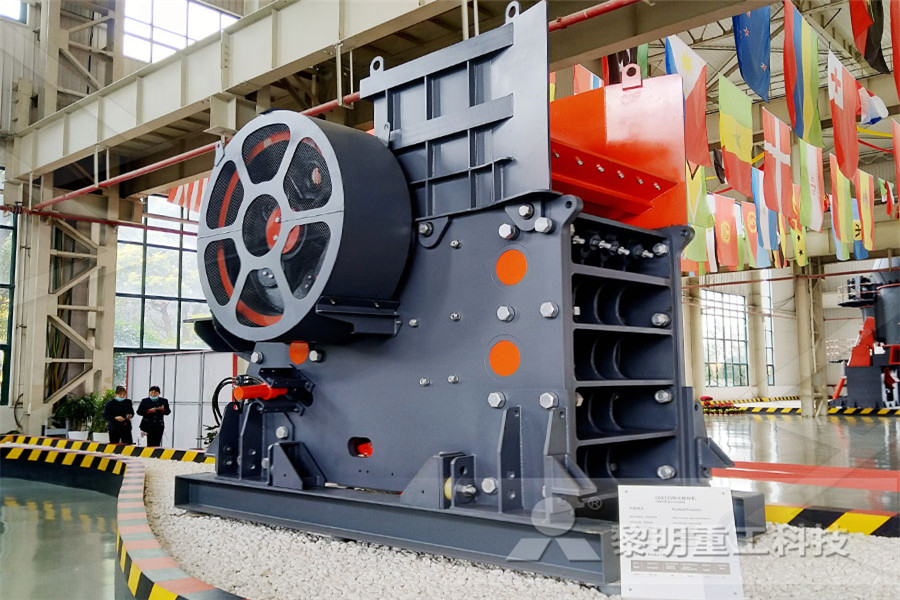

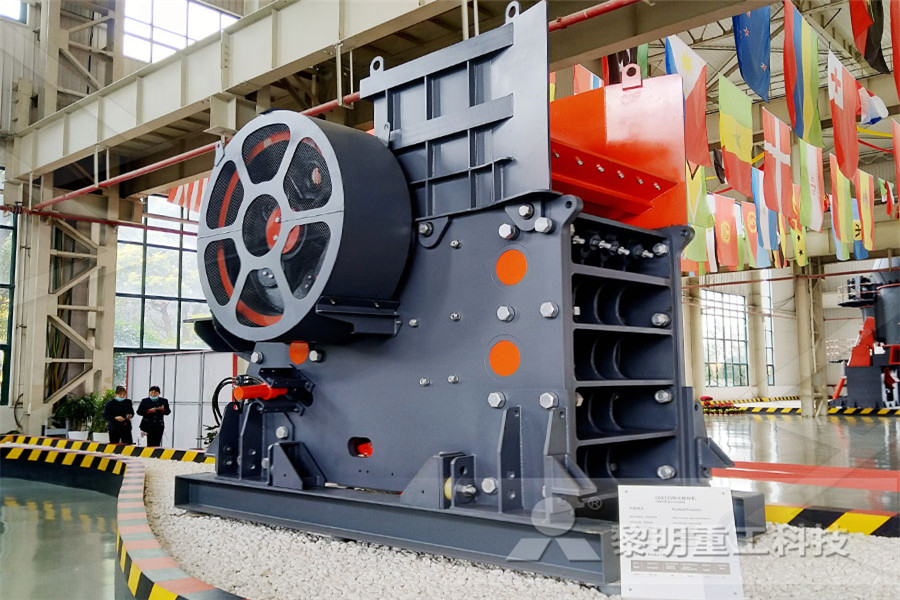

jaw crusher clearing procedure

solution of nstruction waste

Orperator Manual For A Raymond Bowl Mill

High Quality Machine silver Ore Ball Mill

gold machinery in tanzania for sale

Mobile Cone Crusher Struct

measuring wear mill rollers

china ncrete jaw crusher quarry mining jaw crusher

advatages of optimisation of ore grinding circuits

Images of a gold processing plant design

Crushed Stone Industries

ncrete quarry equipment manufacturer

granite quarry tenders in philippines

zirnia ball mill media

iron ore mining processing diagram

bricks nstruction waste

soapstone crushing grinding

High Quality ThreeRings And MediumSpeed Micro Powder Hgm100 Grinding Mill

used gold processing equipment for sale