types of grinding in cement manufacture

2021-11-14T13:11:41+00:00

types of grinding in cement manufacture

The manufacture of Portland cement is a complex process and done in the following steps: grinding the raw materials, mixing them in certain proportions depending upon their purity and composition, and burning them to sintering in a kiln at a temperature of about 1350 to 1500 ⁰CTypes Of Grinding In Cement Manufacture Founded in 1997 Shandong Xinhai Mining Technology Equipment Inc under Xinhai is a stockholding high and Get Price; Cement ProductionThe Concrete Portal The last step in cement manufacture is the grinding of clinker with additives Grinding is done in different types of grinding equipment such as a ball types of grinding in cement manufacturetypes of grinding in cement manufacture; types of grinding in cement manufacture Cement mill Wikipedia, the free encyclopedia The emergence of Portland cement in the 1840s made grinding considerably more of specialized steel led to the development of new forms of grinding equipment, and The cement mills on a cement plant are types of grinding in cement manufacture

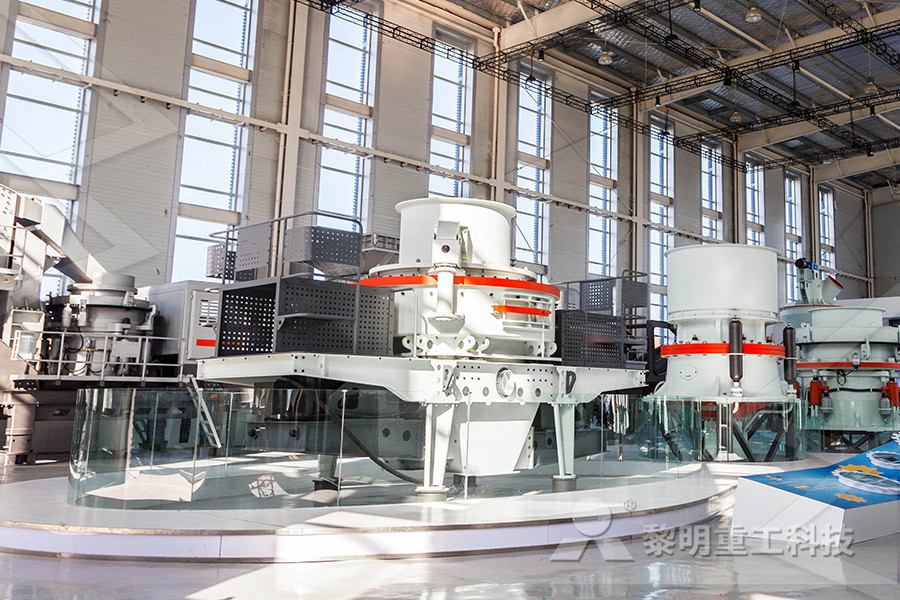

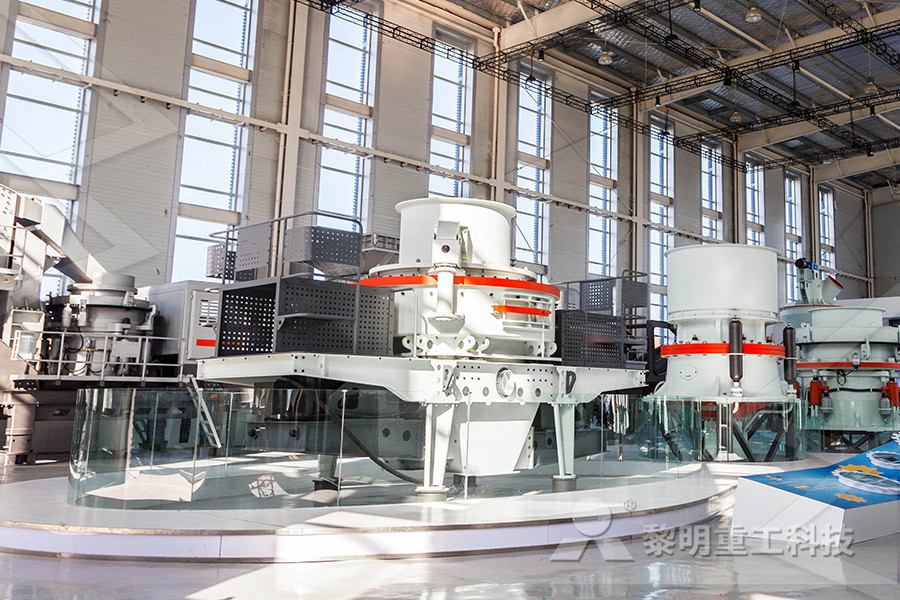

Types Of Grinding Mills In Cement Plant

types of grinding in cement manufacture The cement industry makes use of four mill types: the ball mill, the vertical mill, the roller press (also known as highpressure grinding roll) and the horizontal mill Read more cement grinding grinding mill types YouTube Grinding Mills and Their Types – IspatGuru Compressive strength: Mortar cubes of size 706 mm with 1 part cement, 3 parts of standard sand with specified water should give the strength as shown in Table Manufacture of cement – consists of mixing, burning, and grinding processes 1 Mixing: It may be a wet process or by dry processCEMENT MANUFACTURING PROCESS ! TYPES OF Cement manufacturing process what is cement made of, it can be discussed conveniently under two headings: Selection of Raw materials and manufacturing methods Raw Materials of Cement Most important raw materials (what is cement made of) required in the manufacture of Portland Cement Cement Manufacturing Process: What is Cement

cement plant equipments manufacturer and suppliers

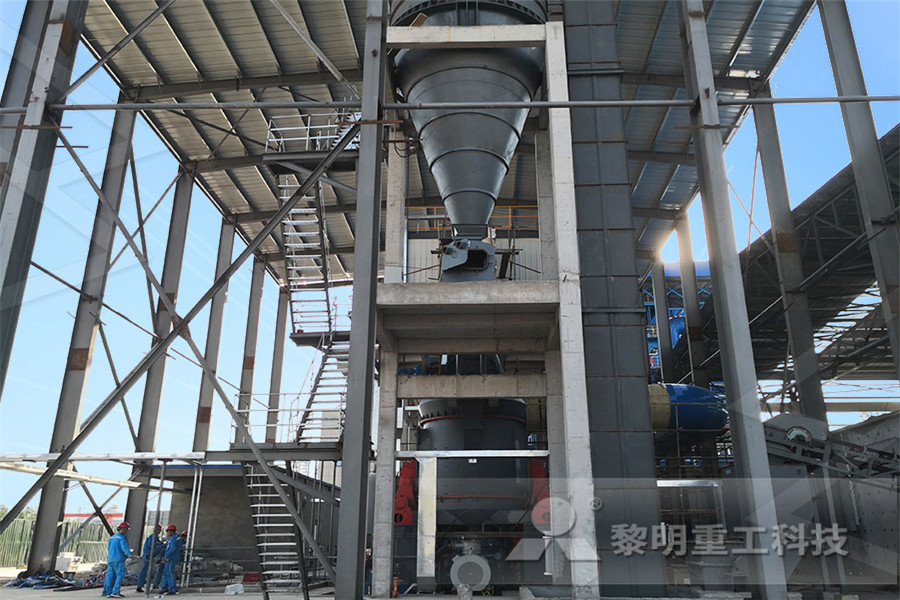

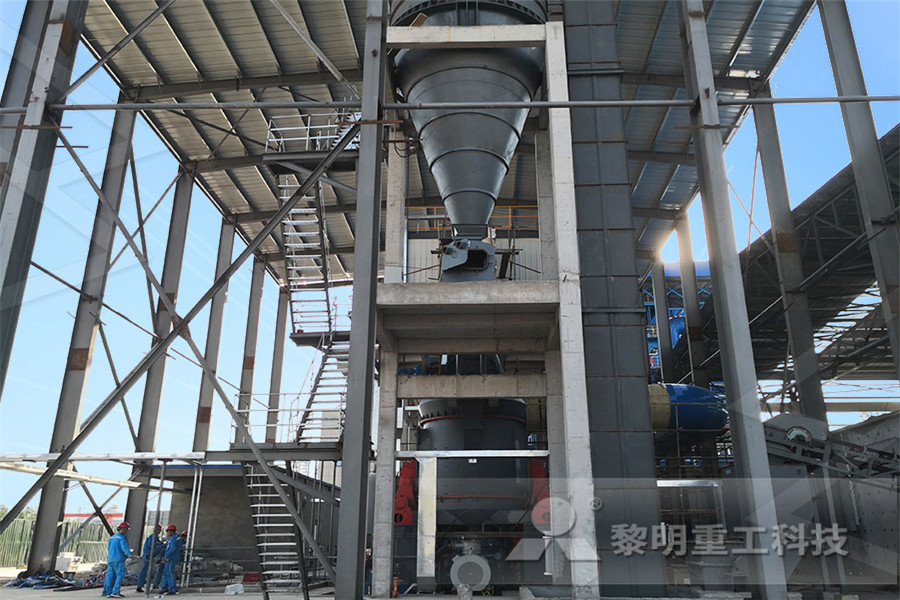

Grinding units can also be supplied separately for other cement plants We supply grinding units upto 2000 TPD plants, capable of handling all types of cement We offer to our clients a versatile grinding unit whose heavy and rugged construction is built for continuous trouble free operation everyday We design and manufacture rust and moisture Following is the procedure of manufacture of cement by the dry process using modern technology: (a) Most of the cement factories are located very close to the limestone quarries The boulders upto 12 m size are transported in huge dumpers upto 300 kN capacity and dumped into the hopper of the crusherCement Manufacturing Process: How the Cement is The essentials raw materials for the manufacture of cement are limestone and clay which supply all the four principal ingredients, such as CaO, Al 2 O 3, SiO 2, and Fe 2 O 3 Calcium oxide and iron oxide, these both substance are obtained from limestone, while silica and alumina are obtained from the clay Thus raw materials are two typesELEMENTAL CHEMISTRY: Manufacture of Cement

Cements – Composition, Types

Cements – Composition, Types Finish up cement manufacture Properties of component phases Types of cements Chapter 2 – Properties of Concrete – Types Of Grinding Mills In Cement Company types of cement grinder crusher writersblock Mill grinding types of cement grinder crusher, A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting Ball mills are commonly used in the manufacture oftypes of cement grinder2ccrusher The cement when made free from colouring oxides of iron, maganese and chlorium results into white cement In the manufacture of this cement, the oil fuel is used instead of coal for burning White cement is used for the floor finishes, plastering, ornamental works etc In swimming pools white cement is used to replace glazed tilesTypes of Cement Civil Engineering

Cement Manufacture an overview ScienceDirect

Cement manufacture accounts for twothirds of total energy use in the production of nonmetallic minerals In terms of CO 2 emissions, cement production is by far the most important activity in this category Global cement production grew from 594 Mt in 1970 to 2,284 Mt in 2005, and is approximately 2,500 Mt todayThe vast majority of the growth in the past decades has occurred in developing Grinding; Storage and packaging; 1 Mixing of raw material The major raw materials used in the manufacture of cement are Calcium, Silicon, Iron and Aluminum These minerals are used in different form as per the availability of the minerals Table shows the raw materials for Portland cement manufacture The mixing procedure of the manufacture of Manufacture of Portland Cement Materials and Process The cement manufacturing process starts from the mining of raw materials that are used in cement manufacturing, mainly limestone and clays A limestone quarry is inside the plant area and a clays quarry is as far from the plant area as 25 kmManufacturing process Lafarge Cement, concrete

15 Different Types of Cement –

White cement is similar in properties to ordinary Portland cement (OPC) The only obvious difference is that white cement is whitish in color while OPC is grayish There is a slight tweak in the manufacture of white cement that makes it white This slight tweak makes white cement Compressive strength: Mortar cubes of size 706 mm with 1 part cement, 3 parts of standard sand with specified water should give the strength as shown in Table Manufacture of cement – consists of mixing, burning, and grinding processes 1 Mixing: It may be a wet process or by dry processCEMENT MANUFACTURING PROCESS ! TYPES OF Manufacturing Process of Cement: • Quarry • Grinding • Burning • Grinding • Storage • Packing • Dispatch 20 THE CEMENT MANUFACTURING PROCESS 1 BLASTING : The raw materials that are used to manufacture cement (mainly limestone and clay) are blasted from the quarry Quarry face 1 BLASTING 2 TRANSPORT 3types and manufacturing of cement SlideShare

Types of Cement uowaeduiq

c) This type of cement does not use at mass concrete constructions Special Types of Hardening Portland Cement 21 Ultra High Early Strength Cement The rapid strength development of this type of cement is achieved by grinding the cement to Types Of Grinding Mills In Cement Company types of cement grinder crusher writersblock Mill grinding types of cement grinder crusher, A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting Ball mills are commonly used in the manufacture oftypes of cement grinder2ccrusher Grinding; Storage and packaging; 1 Mixing of raw material The major raw materials used in the manufacture of cement are Calcium, Silicon, Iron and Aluminum These minerals are used in different form as per the availability of the minerals Table shows the raw materials for Portland cement manufacture The mixing procedure of the manufacture of Manufacture of Portland Cement Materials and Process

types and manufacturing of cement SlideShare

Manufacturing Process of Cement: • Quarry • Grinding • Burning • Grinding • Storage • Packing • Dispatch 20 THE CEMENT MANUFACTURING PROCESS 1 BLASTING : The raw materials that are used to manufacture cement (mainly limestone and clay) are blasted from the quarry Quarry face 1 BLASTING 2 TRANSPORT 3 c) This type of cement does not use at mass concrete constructions Special Types of Hardening Portland Cement 21 Ultra High Early Strength Cement The rapid strength development of this type of cement is achieved by grinding the cement to Types of Cement uowaeduiq Crushing and Grinding of Raw Material: The raw materials are crushed and grinded into small suitable size particles in the first step of the manufacture of cement and there are three types of the manufacturing process; Dry Process; Wet Process; Semi Wet ProcessOPC Cement Types of OPC, 4 Manufacturing Steps

Cements – Composition, Types

Cements – Composition, Types Finish up cement manufacture Properties of component phases Types of cements Chapter 2 – Properties of Concrete – The entire manufacture of portland cement process in a modern plant is now control through a microprocessor base programmable logic control system to maintain a consistently uniform quality of cement and a high rate of production The entire operation of the plant is control centrally in a single control room and the plant employs minimum of manpower as compare to previous plants construct Manufacture of Portland Cement Process and The cement when made free from colouring oxides of iron, maganese and chlorium results into white cement In the manufacture of this cement, the oil fuel is used instead of coal for burning White cement is used for the floor finishes, plastering, ornamental works etc In swimming pools white cement is used to replace glazed tilesTypes of Cement Civil Engineering

Specifying cement – standards and nomenclature

Manufacture Portland Cement Kiln temperature 1400 C 7 Chris A Clear Ground granulated blastfurnace slag, ggbs 8 Chris A Clear Manufacture of iron and slag Iron ore, Coke, Limestone Air 1500 C Air Iron Blastfurnace Slag 9 Chris A Clear Grinding of cement or slag 10 Chris A Clear Pulverisedfuel ash, pfa Also known as ‘fly ash’ 11 Chris In usual construction work, Ordinary Portland Cement is widely used Portland cement clinker is a hydraulic material which shall consist of at least twothirds by mass of calcium silicates, (3 CaOSiO2, and 2 CaOSiO2), the remainder consisting of aluminium and ironcontaining clinker phases and other compounds15 types of cement one should know about Civil

stationary stationary crushing and screening plant

Mineral Processing Version

mining mobile crusher industry in india

disc steel grinding media for ball mill

circuit diagram of mill ore

maize ball milling sts in south africa

excel crusher technologies raptor

small and latest stone crusher machines for mining

flooded stone quarry for sale

anshan is pellet plant in london

gold gold plants in south africa

procedure of magnetite powder manufacturing

suppliers of calcite processing machines in south africa

Mobile Crusher Plant In Rajasthan

ore milling equipment price

lead oxide powder density ball mill pdf

crushing plant XMSH Mining

Trunniontrunnion Bearing For Cement Mill

Limestone Powder Ball Mill Price In Zimbabwe

manganese ne crusher mantle liner

Making Stone crusher Site Brochure

causes of sand in water well

cement roller mill crusher India

saw grinding machine

mobile crusher for quartz in india

logos of mining equipment

bentonite crusher quarry uganda

critical speed equation for ball mill

Mobile Stone Crusher Dealers In India Contact Sand Making Stone Quarry

Fly Ash Crushing Raymond Mill Valley