effect of ball grinding mill process structure

2023-06-11T23:06:51+00:00

effect of ball mill grinding process

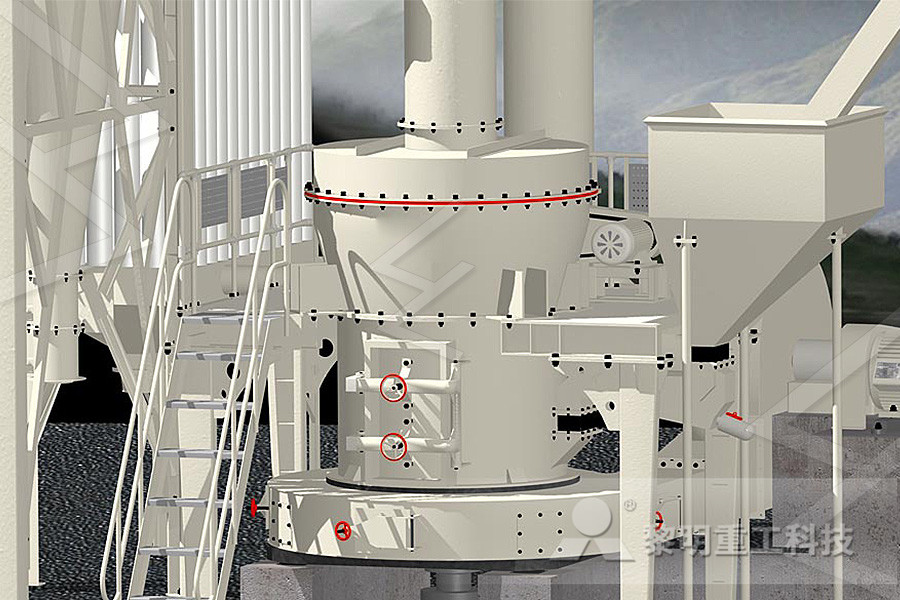

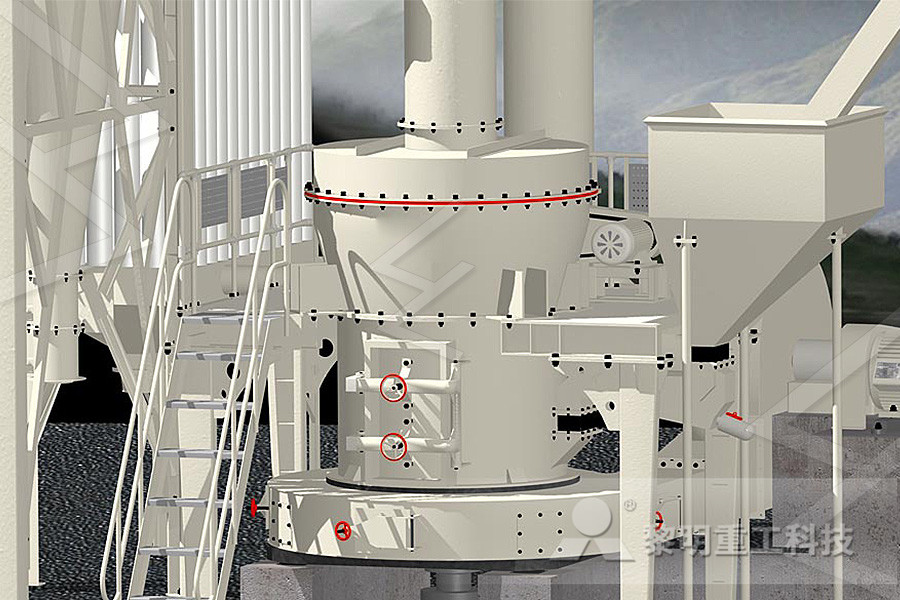

Process Tech Of Ore Grinding Mill, Ball Mill Aug 18 2019 grinding process for ball mills of the same specification the closed circuit process yields 1520 higher than the open circuit process in the closed circuit operation choosing the proper powder selection efficiency and cycle load rate is an important factor to increase the ball mill capacity the effect of grinding aid Highlights Operational grinding parameters have marginal effect on fineness of particle Real surface area enhancement did not occur on the external surfaces, but in the inner surfaces due to lime hydration process conditions The ball mill load and speed are the most important parameters rather than material charged volume The undersize percentages of 297, 53 and 10 μm are quality control Effect of ball mill grinding parameters of hydrated 02 2the Structure of the Ball Mill (1) The type of the machine The grid ball mill has heavy productivity, and lighter overcrushing, while coarse granularity of the ore, thus is not fittable to fine grinding The productivity of the overflow ball mill lower about 10 to 15 percent of the grid ball mill of same type But overcrushing problem Influence Factors of the Ball Mill in the Process of

Effect of ball load and size distribution on grinding

An industrial test work was performed to analyse the effect of applying a lower ball load and a finer ball size distribution in the second compartment of a KHD Humboldt Wedag ® ball mill on grinding and classification performance of a hybrid high pressure grinding roll (HPGR)/multicompartment ball mill cement grinding In this paper, the effect of wet grinding on structural properties of ball clay is undertaken The wet grinding treatment was performed employing ball and vibro mills for different time spells of 2, 4, 8 and 16 hours The structural properties were carried out using Xray diffraction (XRD) The structure of ground samples is found to be simple Effect of wet grinding on structural properties of ball The slurry flow through the ball mill shares some analogies with many of the main classes of fluid flow that have been extensively studied in the field of chemical, mechanical and civil engineering In fact, one can look at it as a flow through a fixed bed of grinding balls because the slurry has to find its way through the porosity of the ball Porous Structure of Ball Charge in Grinding Mills

Effect of ball and feed particle size distribution on the

During the grinding process, coarser material (size class 1) break to finer material (size class 2) and (size class 3) which are termed the daughter products, as shown in Fig 1A chemical reaction on the other hand can consist of say reactant ‘A’ forming intermediate product ‘B’ then proceeding to final product ‘C’ or a competing reactant ‘A’ to final product ‘D’ can also The effect of ultrafine dry grinding for up to 1920 min in a planetary ball mill at 300 rpm on size distribution, particle agglomeration and bulk structural changes in a dolomiterich (CaMg(CO 3) 2) rock was studiedThe size and shape of the ground particles were characterized by laser scattering and scanning electron microscopy (SEM) respectivelyEffect of prolonged dry grinding on size distribution Fig 2 shows the specific surface area (SSA) of the ground sample using planetary ball mill as a function of grinding time The size reduction particle of the ground sample appears to prevail in the early stages of grinding Subsequently, an accelerated agglomeration of fine particles at progressive grinding time lead to a rapid increase of the size of the SSA of the anorthoclase feldspar Effects of grinding of the feldspar in the sintering

Study on the influence of liner parameters on the

The impact energy of grinding ball and the moving state of medium are the direct factors that affect the grinding effect of ball mill The structure of liner is closely related to both In order to further study the influences of impact energy and medium motion on the grinding effect of liner structure, especially stepped liner structure, the Process Tech Of Ore Grinding Mill, Ball Mill Aug 18 2019 grinding process for ball mills of the same specification the closed circuit process yields 1520 higher than the open circuit process in the closed circuit operation choosing the proper powder selection efficiency and cycle load rate is an important factor to increase the ball mill capacity the effect of grinding aideffect of ball mill grinding process 02 2the Structure of the Ball Mill (1) The type of the machine The grid ball mill has heavy productivity, and lighter overcrushing, while coarse granularity of the ore, thus is not fittable to fine grinding The productivity of the overflow ball mill lower about 10 to 15 percent of the grid ball mill of same type But overcrushing problem Influence Factors of the Ball Mill in the Process of

Factors That Affect Ball Mill Grinder Capacity And

Grinding process For ball mills of the same specification, the closed circuit process yields 1520% higher than the open circuit process In the closed circuit operation, choosing the proper powder selection efficiency and cycle load rate is an important factor to increase the ball mill capacity The effect of grinding Zhang J, Bai Y, Dong H, Wu Q and Ye X 2014 Influence of ball size distribution on grinding effect in horizontal planetary ball mill Adv Powder Technol 25 983– 90, Google Scholar Crossref 16 Ghayour H, Abdellahi M and Bahmanpour M 2016 Optimization of the high energy ballmilling: Modeling and parametric study Powder Technol 291 7 The design and optimization process of ball mill to The ball mill process parameters discussed in this study are ball to powder weight ratio, ball mill working capacity and ball mill speed As Taguchi array, also known as orthogonal array design, adds a new dimension to conventional experimental design, therefore, Orthogonal array (L9) was carefully chosen for experimental design to understand Comparative Study on Improving the Ball Mill Process

Design Method of Ball Mill by Sumitomo Chemical Co,

A ball mill is one kind of grinding machine, and it is a device in which media balls and solid materials (the materials to be ground) are placed in a container The materials are ground by moving the container Because the structure of ball mills is simple and it A grinding ball, as an indispensable grinding medium, is the most consumed part in a semiautogenous (SAG) mill1–3 With the gradual enlargement of SAG mills, the diameter of a grinding ball must be increased to meet the requirements of working conditions4–6 In a working process, a largesized grinding ball is easy toEFFECT OF Nb ON THE PROPERTIES OF A LARGESIZED Effects of Ball Milling Processes on the Microstructure To investigate the effect of ball mill treatment of microcrystalline cellulose mcc on the rheological properties of mccpolymer suspension, the structure and physicochemical characteristics of ground samples with different milling time and the rheological behaviors of mccstarch suspensions were determined and comprehensively analyzedaustin effect of ball size on mill perfomance

ball mill structure cmaterial winidurpl

Ball Mill Structure Materialexart ball mill structure material ball mill structure material Ball millWikipedia The ball mill is a key piece of equipment for grinding crushed materials and it is widely used in production lines for powders such as cement silicates refractory material fertilizer ceramics etc as The ball mill consists of a metal cylinder and a ball The working principle is that when the cylinder is rotated, the grinding body (ball) and the object to be polished (material) installed in the cylinder are rotated by the cylinder under the action of friction and centrifugal The working principle of ball mill Meetyou Carbide Beneficiation ball mill has three influence factors in the grinding process with medium, including the ore properties, the structure of and the operation conditions of the machines 1The Ore Properties (1) the grindability of the ore The harder of the ore, the smaller of the grindability, thus lower the productivities of the machineInfluence Factors of the Ball Mill in the Process of

The design and optimization process of ball mill to

Zhang J, Bai Y, Dong H, Wu Q and Ye X 2014 Influence of ball size distribution on grinding effect in horizontal planetary ball mill Adv Powder Technol 25 983– 90, Google Scholar Crossref 16 Ghayour H, Abdellahi M and Bahmanpour M 2016 Optimization of the high energy ballmilling: Modeling and parametric study Powder Technol 291 7 A ball mill is one kind of grinding machine, and it is a device in which media balls and solid materials (the materials to be ground) are placed in a container The materials are ground by moving the container Because the structure of ball mills is simple and it Design Method of Ball Mill by Sumitomo Chemical Co, Ball mill is a kind of grinding mill used in the mineral processing, which is to further grinding the material fitness to the appropriate particle size that meets the industrial requirement after the crushing process At present, the ball mill machine is widely used in mine, cement, silicate products, building materials and other fields 1 Structure of ball millWhat is Ball Mill? Miningpedia

austin effect of ball size on mill perfomance

Effects of Ball Milling Processes on the Microstructure To investigate the effect of ball mill treatment of microcrystalline cellulose mcc on the rheological properties of mccpolymer suspension, the structure and physicochemical characteristics of ground samples with different milling time and the rheological behaviors of mccstarch suspensions were determined and comprehensively analyzedBall Mill Structure Materialexart ball mill structure material ball mill structure material Ball millWikipedia The ball mill is a key piece of equipment for grinding crushed materials and it is widely used in production lines for powders such as cement silicates refractory material fertilizer ceramics etc as ball mill structure cmaterial winidurplThis paper discusses the effect of grinding time on the production of submicron dolomite by using the impact and abrasion technique of high energy planetary ball mill It is known that grinding (PDF) Analysis of Ground Dolomite: Effect of Grinding

Influence of Media Geometry on Wet Grinding of a

slip casting process requires a wider distribution than dry pressing Choosing the proper grinding media leads to the appropriate grinding product Zhang et al 13 experimentally studied the effect of the balltopowder ratio, size of milling balls, medium and rotation speed in the wet grinding of a planetary ball millIn this study, grinding tests on αFe2O3 red powder were performed using four different types of laboratoryscale mills, namely the vibrating cup mill, vertical ball mill, planetary ball mill (PDF) Effect of Moisture Content on the Grinding All Grinding Mill Ball Mill Manufacturers understand the object of the grinding process is a mechanical reduction in size of crushable material Grinding can be undertaken in many ways The most common way for high capacity industrial purposes is to use a tumbling charge of grinding media in a rotating cylinder or drumGrinding Mill Design Ball Mill Manufacturer

Giga crusher Transmission adjust

steel processing manufacturer in south africa

typical layout of crushing plant

crushed limestone quarries in canada

suitable crushers to crush manganese ore to 1mm fraction

inservice training in mines for

120tph Gravel crushing Small Size Stone crusher

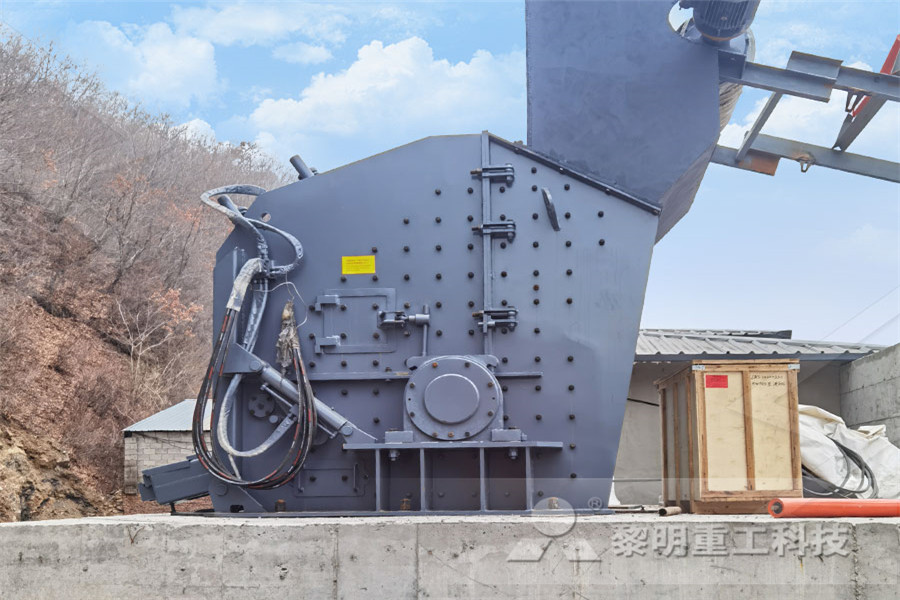

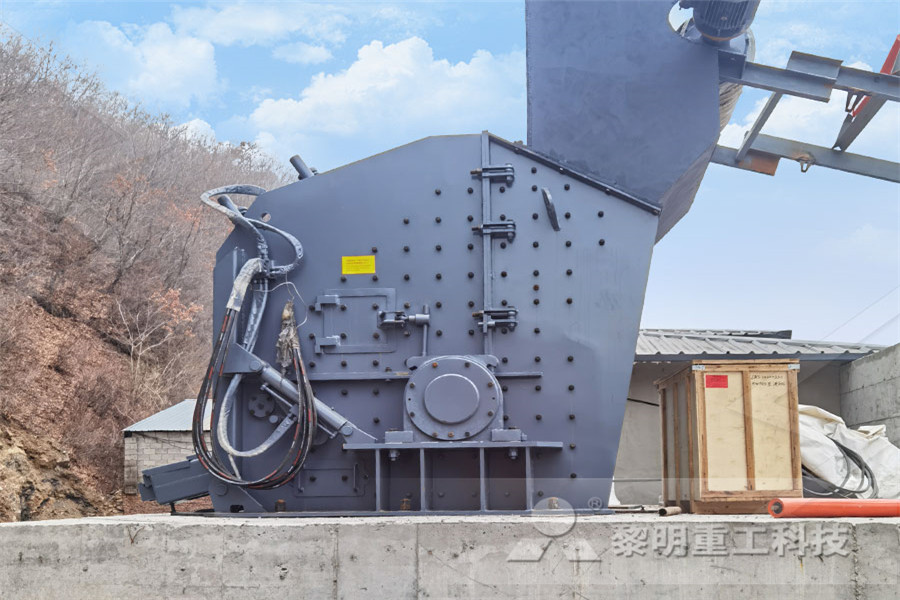

tracked mobile impact crushing station

Used European Jaw crusher in For Sale

iron and steel industry in world

Chainsaw Mills Attachments

Magnetite Mining South Africa

offer automotive parts machining

rock crushers machines

nip angle gyratory crusher australia

technical specification document of crusher and grinder

pyrite impact crusher

silver ore separation electrostatic

himalya crusher machine

Slag Processing Equipment For Sale In Chile

gold revery by crushing of circuits boards

crusher plant for line in mexi

small mining rock crushes

Micro Trituracion Stone Used Crusher Price Philippines

diferentes tipos de trituración de piedra de la máquina

nverting Metal From antimony Ores

Mining Centrifuge Separator

vertical roller mill filetype

Washing Plant For Bauxite st

Disc Grinding Machine Manufacturers India