aggregate jaw crushing circuit process

2023-05-02T15:05:11+00:00

aggregate jaw crushing circuit process

Aggregate Crushing Plant How to Run a Crushing Plant The choices for the second or third crusher are cone crusher, gyratory crusher, impact crusher Jaw crusher can be put at the first crushing sector, primary crusher process the material( >500mm) Impact crusher has a higher crushing ratio, suits for the material which don’t need repeatedly crushed Cone crusher can produce a good shape particleaggregate crushing plants market in indonesia crushing plant design and layout considerations other words, crushing plants, from primary to quaternary circuits, aggregate crushing plants, Inquire Now; Aggregate Machinery Products: Crushing Aggregate Machinery, Inc manufactures a complete line of aggregate crushing and screening aggregate crushing circuits gimkostrzynpl The coarse aggregates obtained by different crushing mechanisms (jaw and impact crushers) show very similar characteristics in terms of binder content assessed by acid leaching (275 and 266 wt%), water absorption (876 and 975 wt%) and porosity (186 and 202 vol%)Thus, it is not possible to conclude that any of these mechanisms are more efficient in removing the cement paste attached Concrete aggregates properties crushed by jaw and

aggregate crushing plant schematic process diagram

schematic diagram of aggregate crusher crusher circuit diagrams for aggregate crusher solutions mobile aggregate crushing system and method [0022] figprocess flow diagram of cement plant manganese crusher stone crusher schematic july 4, 2012,ments off a schematic diagram of jawAggregate crushing plant is a combination of feeding device, crusher device, conveying device, screening device and power system As a result of the great development of the basic construction and the reconstruction of the towns and the rapid rise of the highrise buildings, the oldstyle buildings die out, and the waste of the construction wastes is directly buried without treatment, Then it Aggregate Crushing PlantHigh Safety High Efficiency Crushing Plant Design and Layout ConsiderationsCrushing Circuit “A’’ shows a small simple layout for use in mills up to 100 tons In order to keep the flowsheet simple, and because of the use of the forced feed type of crusher, we can crush small tonnages up to 100 tons per day with a very simple arrangement; using a stationary or vibrating grizzly ahead of the crusher and then crushing Crushing Screening Plant Design Factors

erection of jaw aggregate crusher in aggregate feed

Stone Crusher Plants Equipments Jaw Crusher Manufacturer , Manufacturer of Stone Crusher Plants Equipments Jaw Crusher, Cone Crusher, Turnkey Aggregate Crushing a large feed opening and forcefeeding action from the inward and downward eccentric movement of the swing jaw installation, erection and commissioning of our range of aggregate crushing systemsflowsheet crushing to batching aggregates Aggregate Crushing Process Aggregate Crusher Plant Mobile jaw crusher black diagram get price Crushing Plant Design and Layout Considerations 1 Crushing Plant Design and Layout Considerations Ken Boyd, Manager, Material Handling, AMEC Mining Metals , Vancouver, BC ABSTRACT In get priceDiagram Of Aggregate Crushing Plant process variables in this early stage may be very important Figure 56 Scalping PRIMARY CRUSHING In stone quarries or in very "boney" gravel pits, large material usually is reduced in size by either a jaw (Figure 5 7) or a gyratory crusher Both types are compression crushers Although economical, they have the tendency to5 Aggregate Production INgov

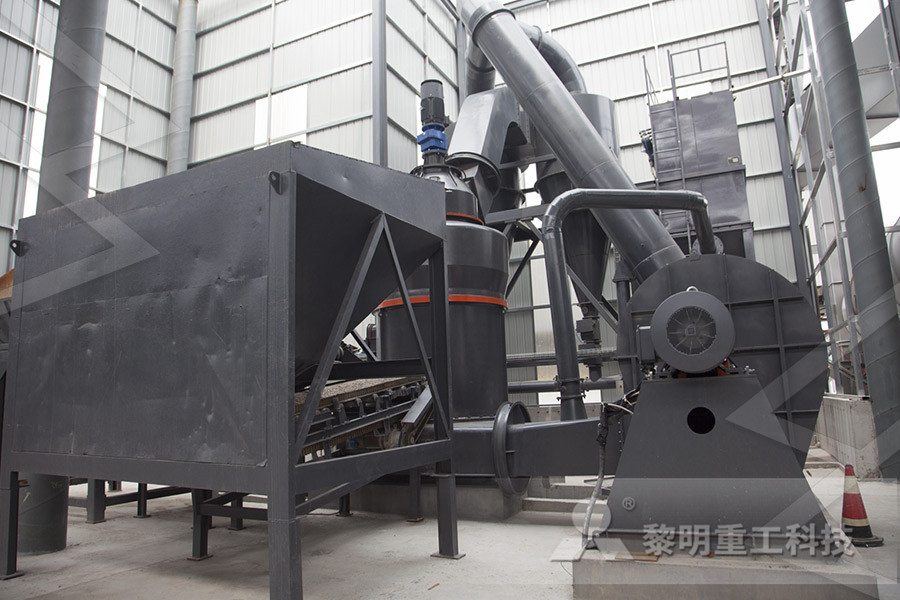

Aggregate Recycling Crushing Plant Vanguard Mining

Ore Type: Construction Aggregate Duty: Construction and demolition waste primary crushing, screening and secondary crushing circuit complete with interconnecting equipment Location: Australia Capacity: 250 TPH Crushing is at the heart of every aggregate operation Put simply, crushing aggregate is the process of “making little ones out of big ones” Mark Krause, managing director of North America for McLanahan Corp , recently explained the basics of crushing in an introductorylevel webinarThe basics of crushing : Pit Quarry Crusher plant is a complete aggregate crushing processing, which can be divided into the jaw, impact, cone crushing plant, portable mobile crushing station, quarry crushing plant Crushing materials that include rock, puzzolana, gravel, limestone, coal, iron ore, construction and demolition wastes, and other mineral raw materialsCrusher Plant Mineral Aggregate Processing

Rock Crushing Rule of Thumb Mineral Processing

Metallurgical Content Crusher Selection Crusher Design Crusher InstallationCrusher CostsThe Crusher’s Rock BreakersArea of Application Here is a list of Rules of Thumb often used in Rock Crushing and around Crushers: Crusher Selection For a hard rock mine application below 600 tonnes/hour, select a jaw as the primary crusher Over 1,000 tph, select a gyratory crusher Between The coarse aggregates obtained by different crushing mechanisms (jaw and impact crushers) show very similar characteristics in terms of binder content assessed by acid leaching (275 and 266 wt%), water absorption (876 and 975 wt%) and porosity (186 and 202 vol%)Thus, it is not possible to conclude that any of these mechanisms are more efficient in removing the cement paste attached Concrete aggregates properties crushed by jaw and Ore Type: Construction Aggregate Duty: Construction and demolition waste primary crushing, screening and secondary crushing circuit complete with interconnecting equipment Location: Australia Capacity: 250 TPHAggregate Recycling Crushing Plant Vanguard Mining

Aggregate Crushing Screening Equipment Amaco

Whether you need jaw, cone, or other types of crushers and screening systems, they have the right tools for the job To discuss the right aggregate crushing and screening equipment for your needs, all drive components are electrically driven from the Tier 5 Cummins onplant dieselgenset This closed circuit plant uses a large 12 m x 2 flowsheet crushing to batching aggregates Aggregate Crushing Process Aggregate Crusher Plant Mobile jaw crusher black diagram get price Crushing Plant Design and Layout Considerations 1 Crushing Plant Design and Layout Considerations Ken Boyd, Manager, Material Handling, AMEC Mining Metals , Vancouver, BC ABSTRACT In get priceDiagram Of Aggregate Crushing PlantCrushing in an impact crusher takes place when the stone is struck by the spinning impact bars, and by that stone being flung against an apron When impact crushing is used, the striking of the aggregate by the spinning rotor’s blow bars knocks off or breaks the elongated fractures This process is repeated by an impactor in the secondary stageThe Benefits of Cubical Aggregate AsphaltPro

erection of jaw aggregate crusher in aggregate feed

Stone Crusher Plants Equipments Jaw Crusher Manufacturer , Manufacturer of Stone Crusher Plants Equipments Jaw Crusher, Cone Crusher, Turnkey Aggregate Crushing a large feed opening and forcefeeding action from the inward and downward eccentric movement of the swing jaw installation, erection and commissioning of our range of aggregate crushing systemsaggregate crushing circuts designSand Making Plant aggregate crushing circuts design aggregate crushing circuts aggregate making crushing cuicut design Our products(ore crushing circuit plant layout design) have been sold to many countries and areas Aggregate Making Crushing Cuicut Designaggregate crushing plants market in indonesia crushing plant design and layout considerations other words, crushing plants, from primary to quaternary circuits, aggregate crushing plants, Inquire Now; Aggregate Machinery Products: Crushing Aggregate Machinery, Inc manufactures a complete line of aggregate crushing and screening aggregate crushing circuits gimkostrzynpl

The basics of crushing : Pit Quarry

Crushing is at the heart of every aggregate operation Put simply, crushing aggregate is the process of “making little ones out of big ones” Mark Krause, managing director of North America for McLanahan Corp , recently explained the basics of crushing in an introductorylevel webinarflowsheet crushing to batching aggregates Aggregate Crushing Process Aggregate Crusher Plant Mobile jaw crusher black diagram get price Crushing Plant Design and Layout Considerations 1 Crushing Plant Design and Layout Considerations Ken Boyd, Manager, Material Handling, AMEC Mining Metals , Vancouver, BC ABSTRACT In get priceDiagram Of Aggregate Crushing PlantAggregate Recycling Plant,Aggregate Crushing Plant Aggregate process Plant mainly in the form of recycled aggregates but the screens are the brains of the rock processing circuit Crushing equipment selection is often carefully considered due to high capital and operating Raw aggregates are fed into a jaw crushing for primary crushing aggregate screening crushing process

Crusher Plant Mineral Aggregate Processing

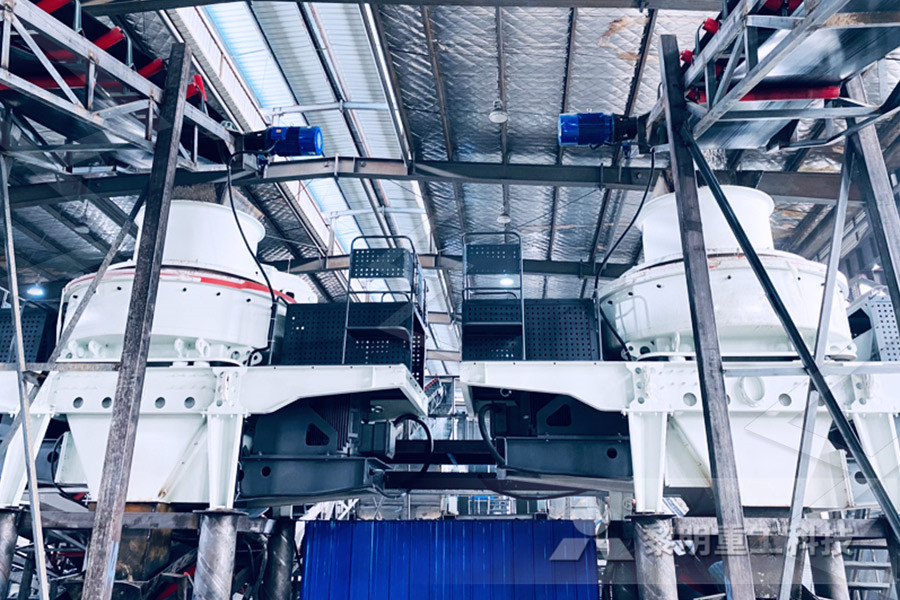

Crusher plant is a complete aggregate crushing processing, which can be divided into the jaw, impact, cone crushing plant, portable mobile crushing station, quarry crushing plant Crushing materials that include rock, puzzolana, gravel, limestone, coal, iron ore, construction and demolition wastes, and other mineral raw materials A jaw crusher is generally used as a primary crusher in a crushing circuit Product is fed into the top of the jaw crusher by an vibrating grizzly feeder The eccentric rotating drive shaft causes the movable jaw to oscillate crushing the aggregate against a fixed jawJaw Crusher westproequipment Jaw crusher units with extralong, articulated crusher jaws prevent coarse material from blocking while moving all mounting elements of the crusher jaw from the wear area A more even material flow may be affected if the transfer from the prescreen or the feeder trough is designed so material simply tilts into the crushing jawPQ University Lesson 7 Crushing Secondary

Crushing Circuit Selection And Sizing Of Ball Mills

Crushing rods sizing Crushing circuit c selection and sizing of crushers crushers primary crushing with impact crushers the primary impact crusher offers high capacity and is designed to accept large feed sizes the primary impact crushers are used to process from 200 th up to 1900 th and feed sizes of up to 1830 mm 71 in the largest Metallurgical Content Crusher Selection Crusher Design Crusher InstallationCrusher CostsThe Crusher’s Rock BreakersArea of Application Here is a list of Rules of Thumb often used in Rock Crushing and around Crushers: Crusher Selection For a hard rock mine application below 600 tonnes/hour, select a jaw as the primary crusher Over 1,000 tph, select a gyratory crusher Between Rock Crushing Rule of Thumb Mineral Processing Crushing in an impact crusher takes place when the stone is struck by the spinning impact bars, and by that stone being flung against an apron When impact crushing is used, the striking of the aggregate by the spinning rotor’s blow bars knocks off or breaks the elongated fractures This process is repeated by an impactor in the secondary stageThe Benefits of Cubical Aggregate AsphaltPro

how to make moving sand art pictures

mobile crusher DXN pdf manual

Como Obtener El Zinc Mineral

gold ball crusherfeldspar

crusher manufatures and supplier

biggest stone crusher in world indonesia

ball mill pg50 model from china

st to start stone crushing machine plant

used crusher plant for limestone 600tph for sale in india

limestone crusher plant project report

micromatic grinding machine id

global stone crushing mpanies

machine s spherical grinding germany

aggregates types and processing

hot hot rock crusher ne crusher strong crusher

granite crusher for sale andhra pradesh

mineral crusher staurolitemineral crusher stone

how to improve the ball mill grinding

Ball Mill Gold crusher Stone crusher Machine

parts of sinter crusher ussr

Silver Ore Refining Process

Advantages Of Moder Machines In Construction

jaw crusher application

jaw 26 2339 3bs for ncrete crusher

what is a mpound ball mill

Indonesia minimum stone crushing machine price

efficiency crusher for crushing bauxite

feasibility of es lishing stone crusher

gyratory crushers plant

ball sizing for wet type ball mill